Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "High curing activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

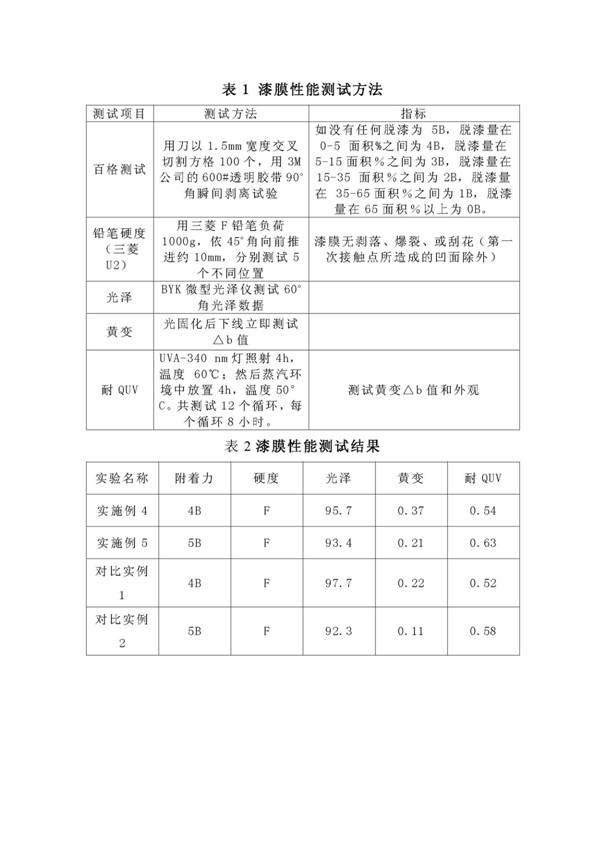

Ultraviolet curing coating

ActiveCN101967342AHigh curing activityHigh hardnessPolyurea/polyurethane coatingsPolyester coatingsPolyesterPolymer science

The invention discloses an ultraviolet curing coating. The ultraviolet curing coating is characterized by comprising basic resin, a diluting agent and a light initiator, wherein the basic resin comprises urethane acrylate resin and self-initiating polyester acrylate resin; and the light initiator comprises normal light initiator and low-yellowing light initiator. The coating provided by the invention has high curing activity; a paint film has the advantages of high hardness, high wear resistance, superior chemical resistance, low yellowing, high weather resistance and the like; and the coating is suitable for various plastic materials.

Owner:中山大桥化工集团有限公司

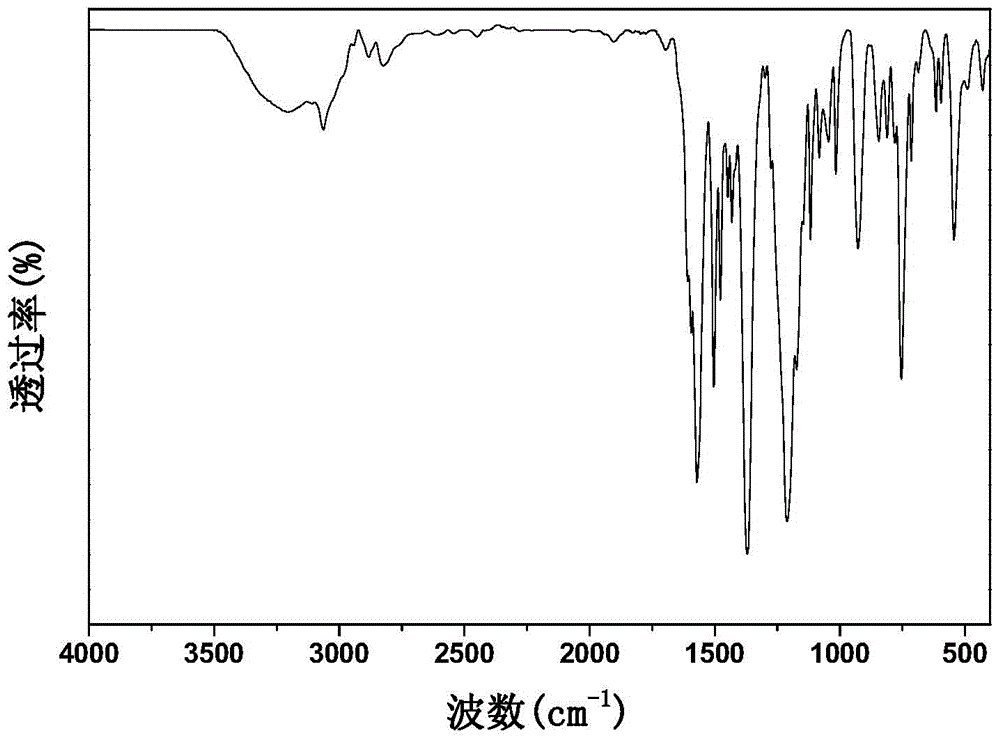

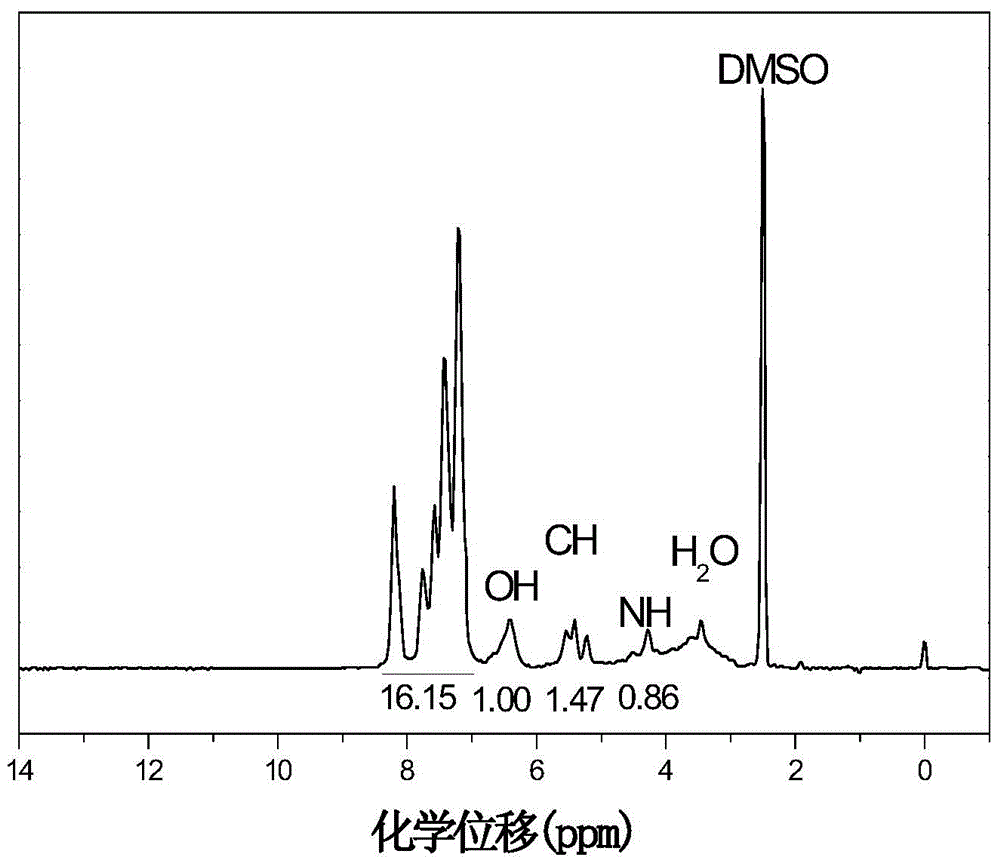

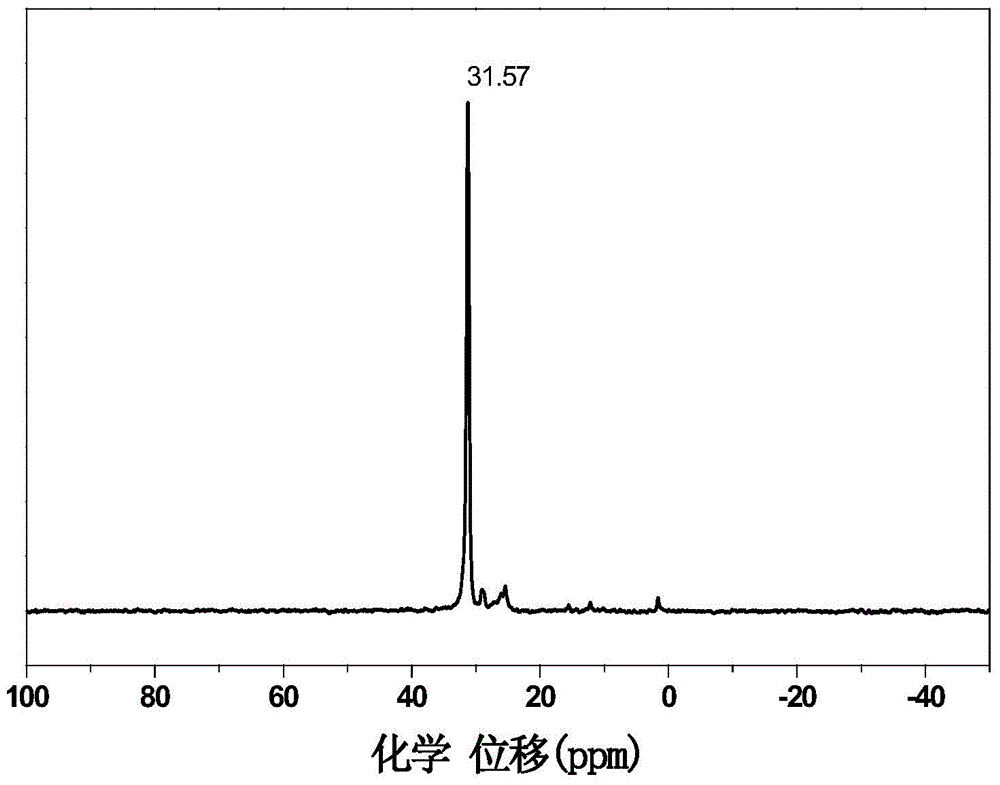

DOPO-based symtriazine ring hydrogenated benzimidazole epoxy curing agent and preparation method thereof

ActiveCN104086751AImprove flame retardant performanceImprove mechanical propertiesGroup 5/15 element organic compoundsEpoxyBenzaldehyde

The invention discloses a DOPO-based symtriazine ring hydrogenated benzimidazole epoxy curing agent and a preparation method thereof. The preparation method comprises the following steps: firstly, mixing a solvent I, tricyanogen chloride, p-hydroxy benzaldehyde and an acid-binding agent, introducing nitrogen gas, performing heating reaction to obtain 2,4,6-tri(4-formylphenoxy)-1,3,5-symtriazine ring; mixing a solvent II, the 2,4,6-tri(4-formylphenoxy)-1,3,5-symtriazine ring and DOPO, introducing nitrogen gas, and reacting to obtain DOPO-based formylphenoxy-1,3,5-symtriazine ring; dissolving the DOPO-based formylphenoxy-1,3,5-symtriazine ring in a solvent III, dropwise adding solute into a mixture of o-phenylenediamine and the solvent III, adding a catalyst, and reacting to obtain the DOPO-based symtriazine ring hydrogenated benzimidazole epoxy curing agent. According to the DOPO-based symtriazine ring hydrogenated benzimidazole epoxy curing agent, vertical combustion of cured matters passes UL94V-0 level; compared with non-flame-retardant epoxy resin, the glass-transition temperature is increased by 12.1% and the tensile strength is improved by 18.2%.

Owner:广东华百材料技术有限公司

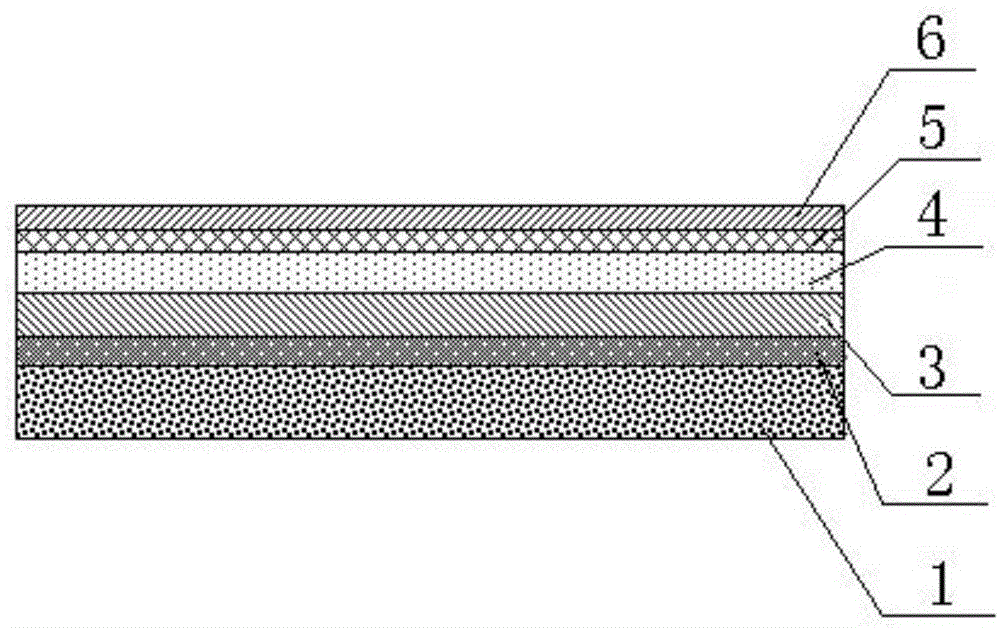

Elastic waterproof sealant, preparation method thereof, and roof waterproof structure formed by eastic waterproof sealant

ActiveCN103555255ANo pollution in the processBonding is versatileNon-macromolecular adhesive additivesBuild-up roofsDioctyl terephthalateUltraviolet

The invention discloses an elastic waterproof sealant comprising 15-25 parts of alpha-dimethoxysilane-terminated polyether resin, 20-30 parts of gamma-trimethoxysilane-terminated polyether resin, 5-10parts of dioctyl terephthalate, 40-55 parts of nano-calcium carbonate, 0.1-5 parts of fumed silica, 0.5-5 parts of titanium dioxide, 0.1-1 part of carbon black, 0.1-0.5 parts of an ultraviolet absorber, 0.1-0.5 parts of a light stabilizer, 0.5-1 parts of a dehydrating agent, 0.5-1 parts of an adhesion promoter. The invention also discloses a preparation method of the elastic waterproof sealant, and a roof waterproof structure formed by the elastic waterproof sealant. The elastic waterproof sealant has the advantages that: the elastic waterproof sealant is harmless to human; a roof waterproofstructure formed by the elastic waterproof sealant can form a completely closed waterproof layer; construction is simple, and waterproof effect is excellent.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

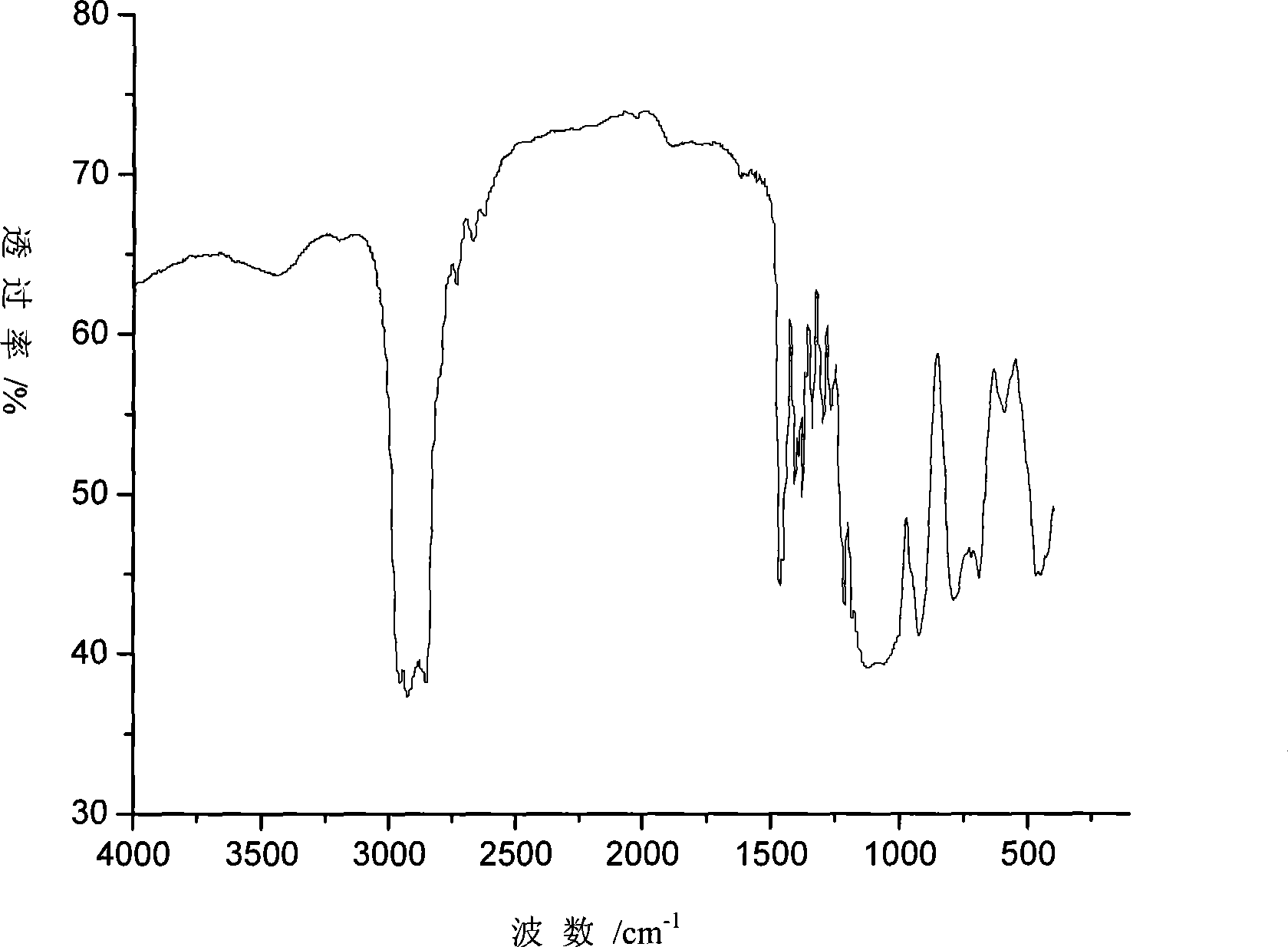

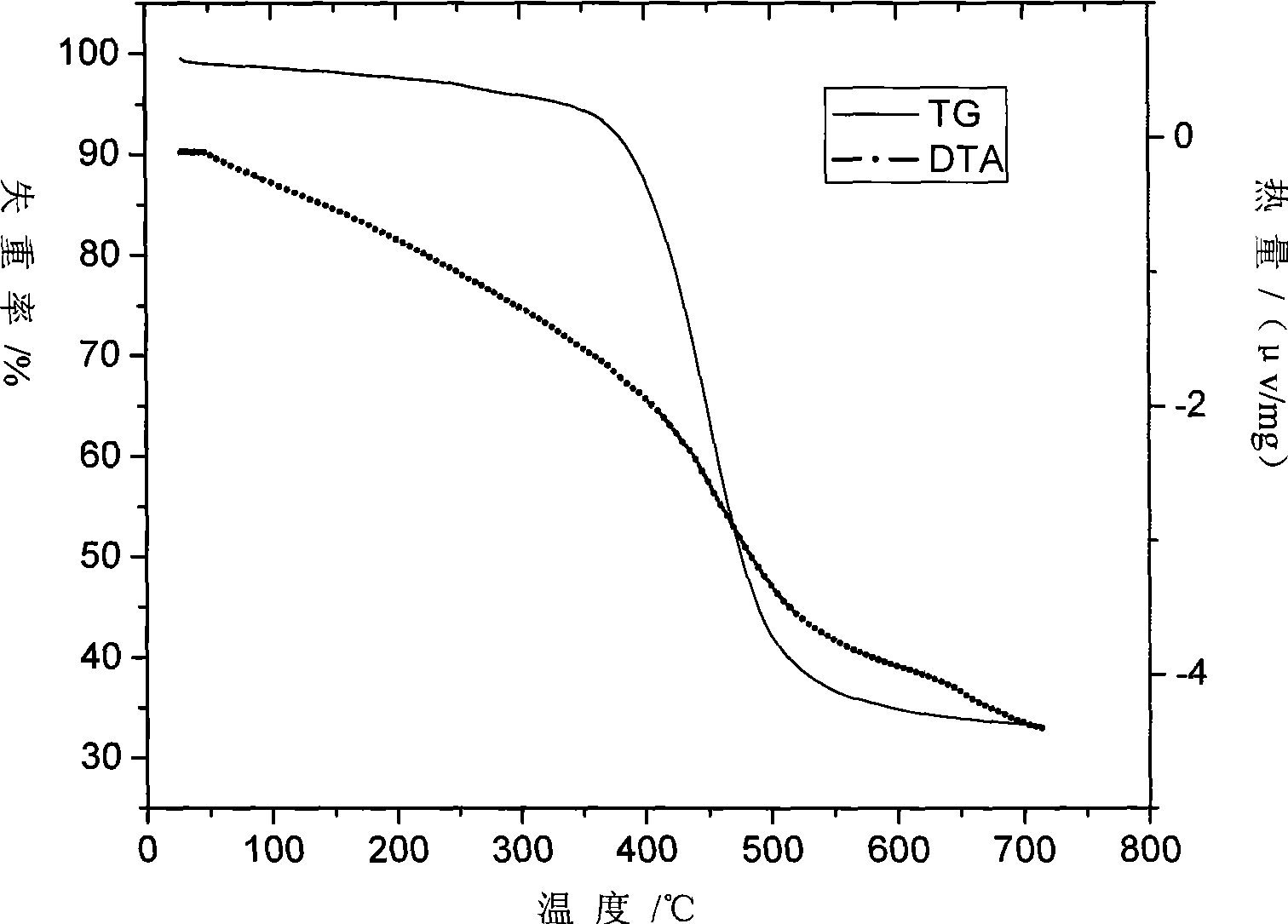

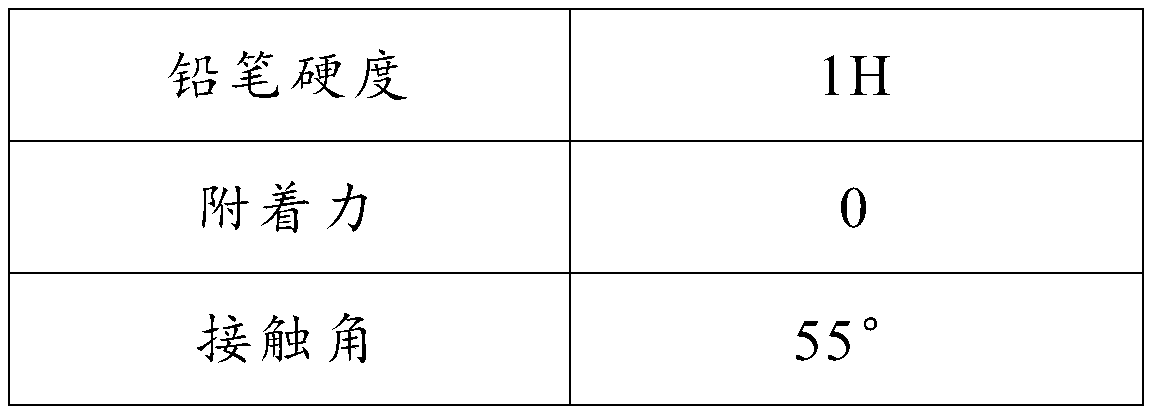

Preparation method for organic silicon resin with high curing activity and high temperature resistance

The invention discloses a preparation method for an organic silicon resin with high curing activity and high temperature resistance, which comprises the following steps: carrying out hydrolytic polycondensation on two kinds of alkyl alkoxy silane and one kind of metal acid ester to polymerize into a silicone resin polymer with proper molecular weight; and using a low-toxic organic solvent as a diluting agent, and adding a curing agent into the low-toxic organic solvent so as to obtain the organic silicon resin with high curing activity and high temperature resistance which can be used as a coating matrix resin. Compared with the common organic silicon resin, the synthetical organic resin has the advantages of excellent heat resistance, high curing activity, good adhesive force, considerable stability, excellent light stability, and excellent environmental friendliness; the preparation method has simpler synthetic route, easily-obtained raw materials, and low price; and the synthetical silicon resin is a low-cost and high performance resin, and is suitable for large-scale preparation and industrialized production.

Owner:GUANGDONG UNIV OF TECH

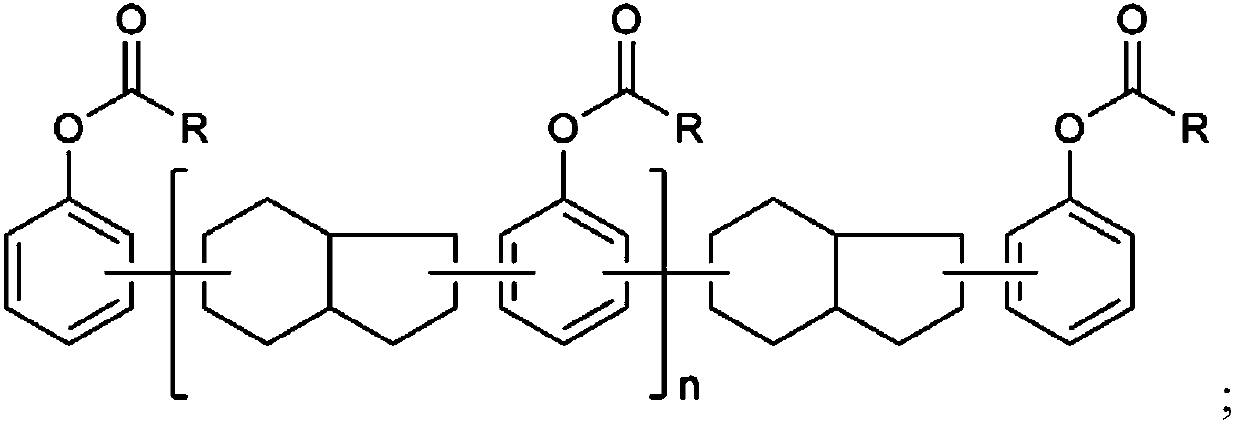

Active ester curing agent and epoxy resin composition

InactiveCN107915830ALow hygroscopicityLow dielectric constantPreparation from carboxylic acid halidesOrganic compound preparationEpoxyDielectric loss

The invention provides an active ester curing agent and relates to the field of copper-cladding plates. The active ester curing agent has a dicyclopentadiene-phenyl ester alternate structure. On one hand, a dicyclopentadiene structure of the active ester curing agent is capable of well preserving excellent properties such as low hygroscopicity, dielectric constant and dielectric loss angle tangentcaused after the reaction between the curing agent and epoxy resin. On the other hand, the content of an active ester structure in the structure is relatively high, so that the curing agent has veryhigh reaction activity in the reaction with the epoxy resin. The preparation method of the active ester curing agent is easy in operation, the raw materials are easily available, and the large-scale industrial production can be realized. The invention further provides an epoxy resin composition. By virtue of reasonable matching of the active ester curing agent, the epoxy resin and an imidazole compound in a specific proportion, the epoxy resin composition is high in curing activity and has a good curing effect, and a cured condensate has excellent dielectricity and water absorption property and can be used for preparing prepregs, laminated boards and copper-cladding plates.

Owner:SHAANXI SHENGYI TECH

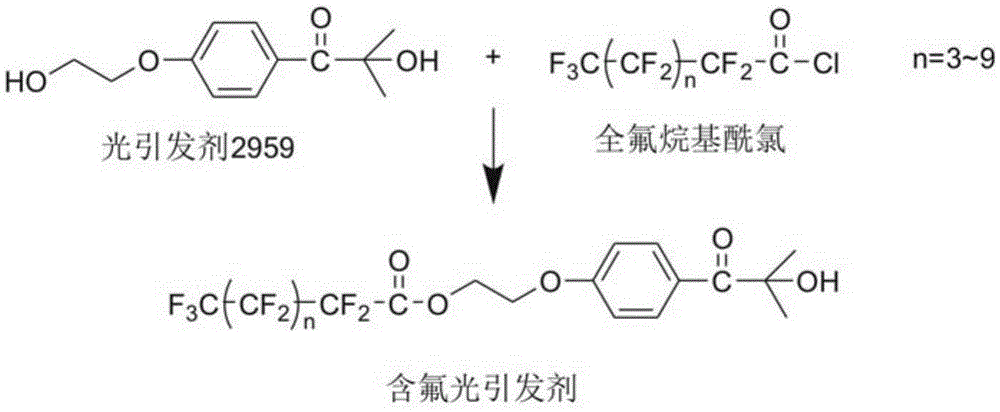

Colored UV-light-curable paint

ActiveCN102816513AImprove performanceHigh curing activityPolyurea/polyurethane coatingsPolymer scienceAcrylate ester

The invention discloses a colored UV-light-curable paint comprising the components of, by weight: 40-80 parts of main resin, 2-8 parts of an active diluent, 0.1-5.0 parts of a transparent colorant, 2-4 parts of a photo-initiator, and 20-30 parts of a solvent. The main resin is composed of 40-80wt% of polyurethane acrylic ester and 20-60wt% of self-triggered UV-light-curable resin. The photo-initiator is at least one selected from an alpha-hydroxyketone photo-initiator, a phosphine oxide photo-initiator, and a titanocene photo-initiator. The transparent colorant is prepared from mixed and grinded materials of the self-triggered UV-light-curable resin as a carrier and a transparent toner. The colored UV-light-curable paint provided by the invention has advantages of excellent performance, high curing activity, high adhesion strength, good decorative effect, wide toning range, wide application range, and the like. The paint can cooperate with traditional primer paint, and electronic product film coating can be completed with a double-layer coating technology. Therefore, production cost of coating technologies can be reduced, environment pollution can be reduced, and product defective rate can be reduced.

Owner:中山大桥化工企业集团中山智亨实业发展有限公司

Low-refractive optical fiber coating resin

ActiveCN105273613AAvoid breakingLow refractive indexPolyurea/polyurethane coatingsRefractive indexPhotoinitiator

The invention relates to low-refractive optical fiber coating resin. The low-refractive optical fiber coating resin is prepared from, by weight, 30-65% of prepolymer A, 0-40% of prepolymer B, 2-8% of a photoinitiator, 20-40% of an active diluent and 0.5-2% of a silane coupling agent, and the sum of the weight percentages of all the components is 100%. The low-refractive optical fiber coating resin is high in adhesive power, optical fiber is not likely to be broken when bent, and the low-refractive optical fiber coating resin is low in refractive rate and can enlarge the digital transmission aperture of the optical fiber.

Owner:武汉长盈鑫科技有限公司

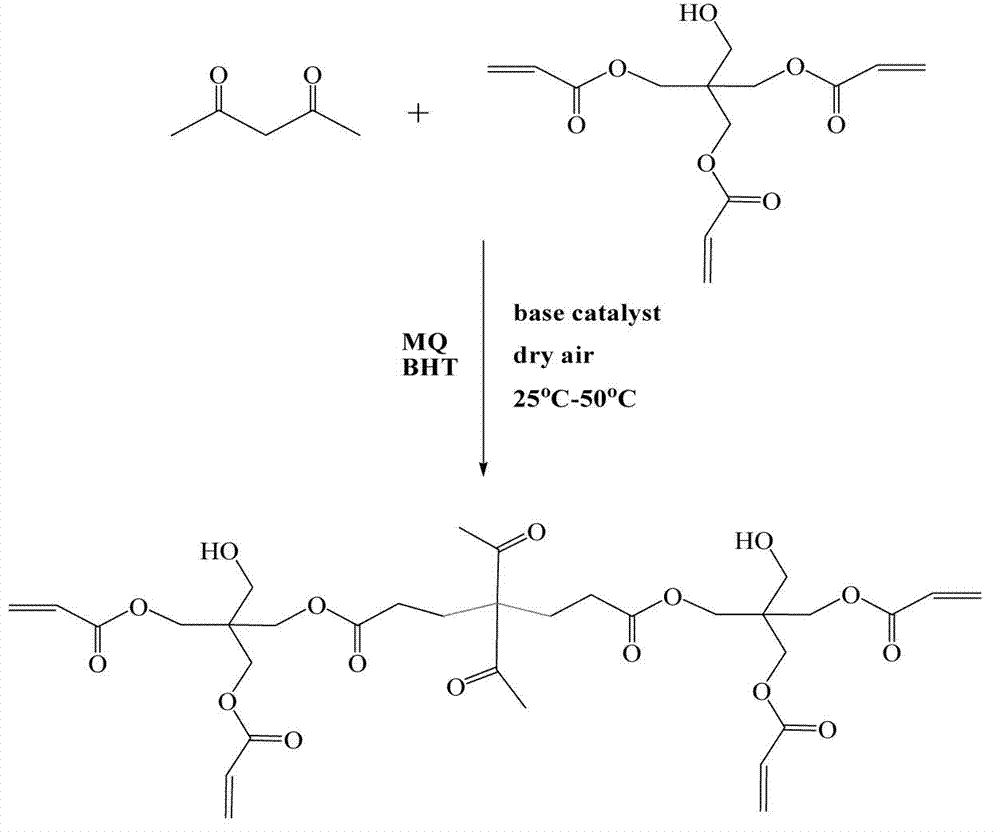

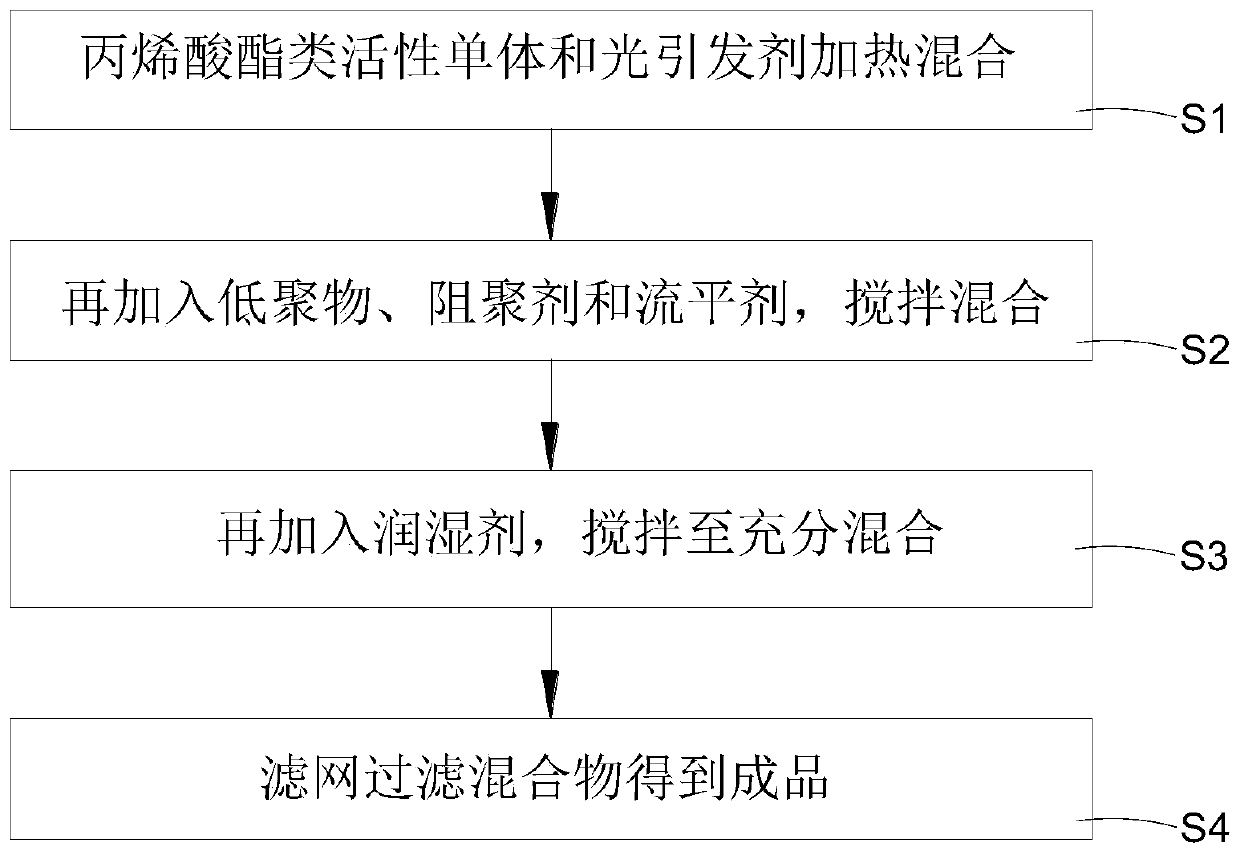

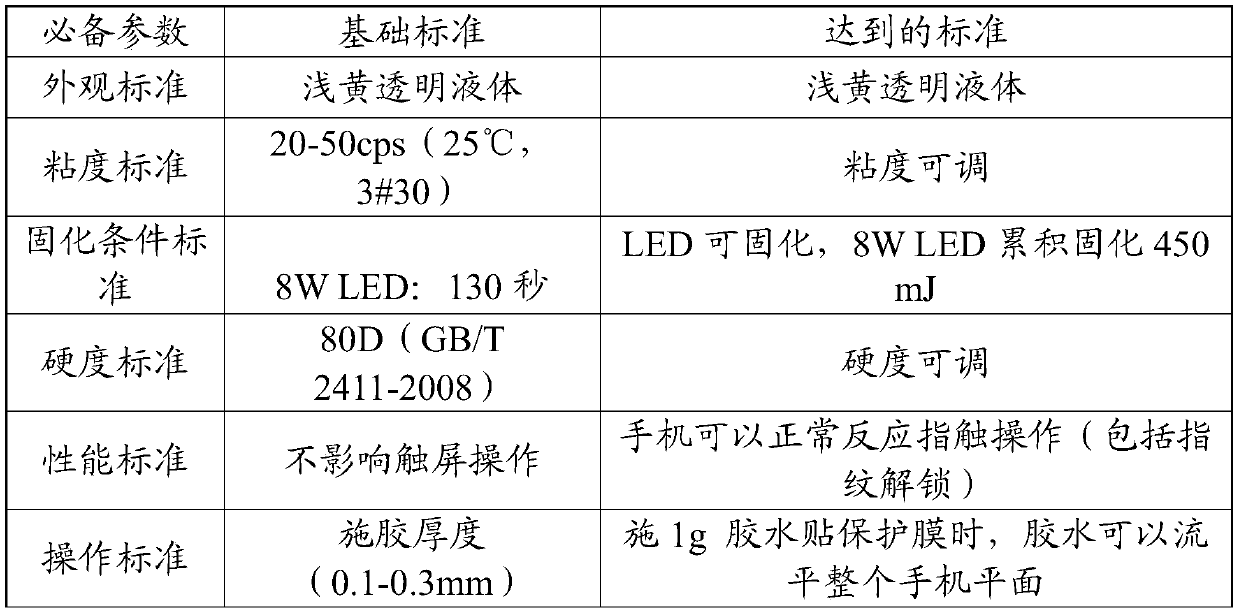

High sensitivity mobile phone protection screen full lamination adhesive and preparation method thereof

InactiveCN110423593AImprove wettingImprove fitFilm/foil adhesivesPolyureas/polyurethane adhesivesOligomerAdhesive

The invention discloses a high sensitivity mobile phone protection screen full lamination adhesive and a preparation method thereof. The high sensitivity mobile phone protection screen full laminationadhesive comprises, by mass fraction, 10-20% of an oligomer, 70-90% of an acrylate active monomer, 2-6% of a photoinitiator and 1-3% of assistants. The high sensitivity mobile phone protection screenfull lamination adhesive provided by the invention not only has the characteristics of high sensitivity, high transparency, low odor, high lamination degree, environmental protection, etc., also is not added with any solvent, has heavy metal, toluene, formaldehyde, methanol meeting the EU ROSH and REACH standards, and has good peeling performance.

Owner:河源然生新材料有限公司

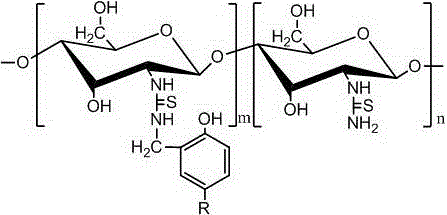

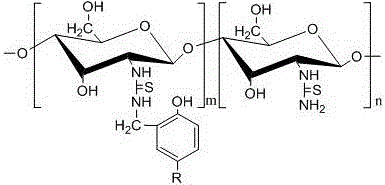

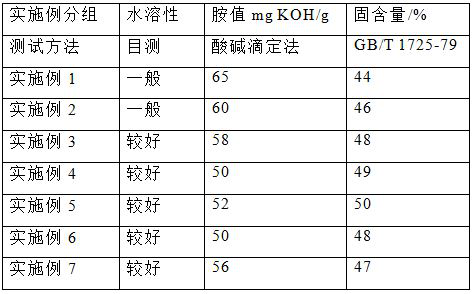

Chitosan-modified low-temperature epoxy resin curing agent and preparation method thereof

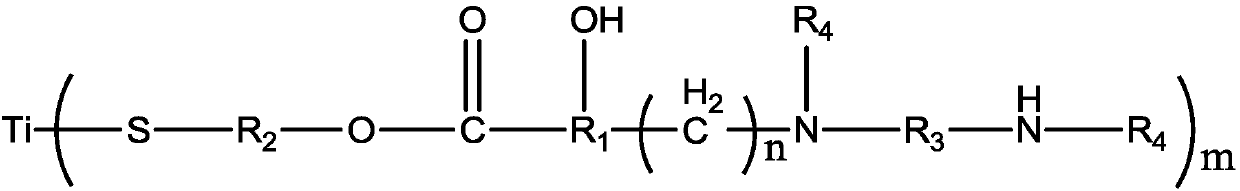

InactiveCN106496524AHigh curing activityImprove the bactericidal effectEsterified saccharide compoundsSugar derivativesEpoxyStructural formula

The invention discloses a chitosan-modified low-temperature epoxy resin curing agent. The curing agent is of a structural formula as following, wherein R is long-chain alkyl, m is an integer between 1 and 2, and n is any integer between 1 and 3. The invention further discloses a preparation method of the chitosan-modified low-temperature epoxy resin curing agent. The solid molecular structure of chitosan-modified low-temperature epoxy resin contains low-temperature active groups such as phenolic hydroxyl groups, thiocarbonyl groups and secondary amino groups, the chitosan-modified low-temperature epoxy resin can be cured normally even at low temperature of minus 5 DEG C as compared with E-44 epoxy resin, E-51 epoxy resin and E-20 epoxy resin with high curing activity, and the curing agent applied to epoxy resin paint is good in adhesion with base materials and resistant to impact. The curing agent is long lasting in sterilization, safe, environment friendly, simple in process and obvious in effect.

Owner:SHANGHAI UNIV

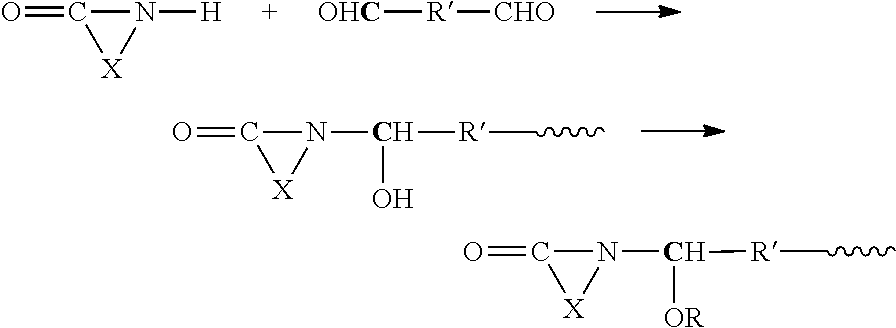

Modified amino resins

This invention relates to products H made by reaction of a cyclic alkyleneurea U, at least one multifunctional aldehyde A2, and at least one of (a) an aminoplast former M that is not the same as the cyclic alkyleneurea U, and (b) a monofunctional aldehyde A1, which product H is optionally etherified by reaction of at least a part of the hydroxyl groups formed by addition reaction of N—H groups and aldehyde groups, with an alcohol having from one to ten carbon atoms, and wherein glyoxal is present in the at least one multifunctional aldehyde A2, to processes for their preparation, and to a method of use thereof in coating compositions.

Owner:ALLNEX NETHERLANDS BV

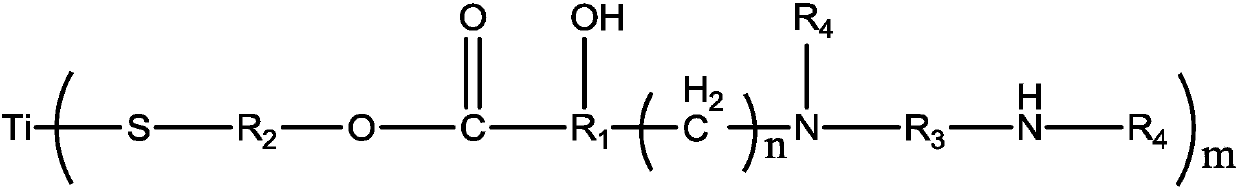

Epoxy curing agent, and preparation method and application thereof

ActiveCN107722241AImprove adhesionSolve the smellTitanium organic compoundsEpoxy resin coatingsBenzeneThiol

The invention discloses an epoxy curing agent for concrete refinishing paint, and a preparation method and application of the epoxy curing agent. The preparation method of the epoxy curing agent includes 1), allowing a carboxylic phenolic compound to react with a mercaptan compound to obtain a sulfhydryl phenolic compound; 2), under the action of an acid catalyst, evenly mixing an amine compound,the sulfhydryl phenolic compound and an aldehyde compound to react to obtain sulfhydryl-terminated phenolic aldehyde amine; 3), injecting nitrogen into a mixture of a titanium dichloride compound andbenzene, slowly adding the sulfhydryl-terminated phenolic aldehyde amine after the pH value of a reaction system reaches 9-10, and performing distillation after reaction to obtain the epoxy curing agent. The epoxy curing agent has the advantages that the epoxy curing agent can be mixed with epoxy resin to prepare an epoxy resin composition for the concrete refinishing paint; sulfydryl, tertiary amine and phenolic hydroxyl in the molecular structure of the curing agent have synergistic promotion effect, and accordingly, the epoxy curing agent can cure the epoxy resin below minus 25 DEG C and has high adhesion to concrete materials.

Owner:WANHUA CHEM GRP CO LTD

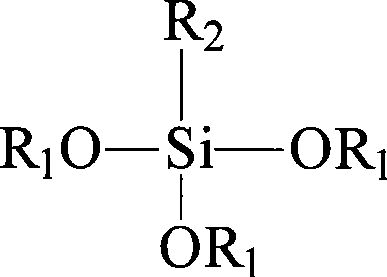

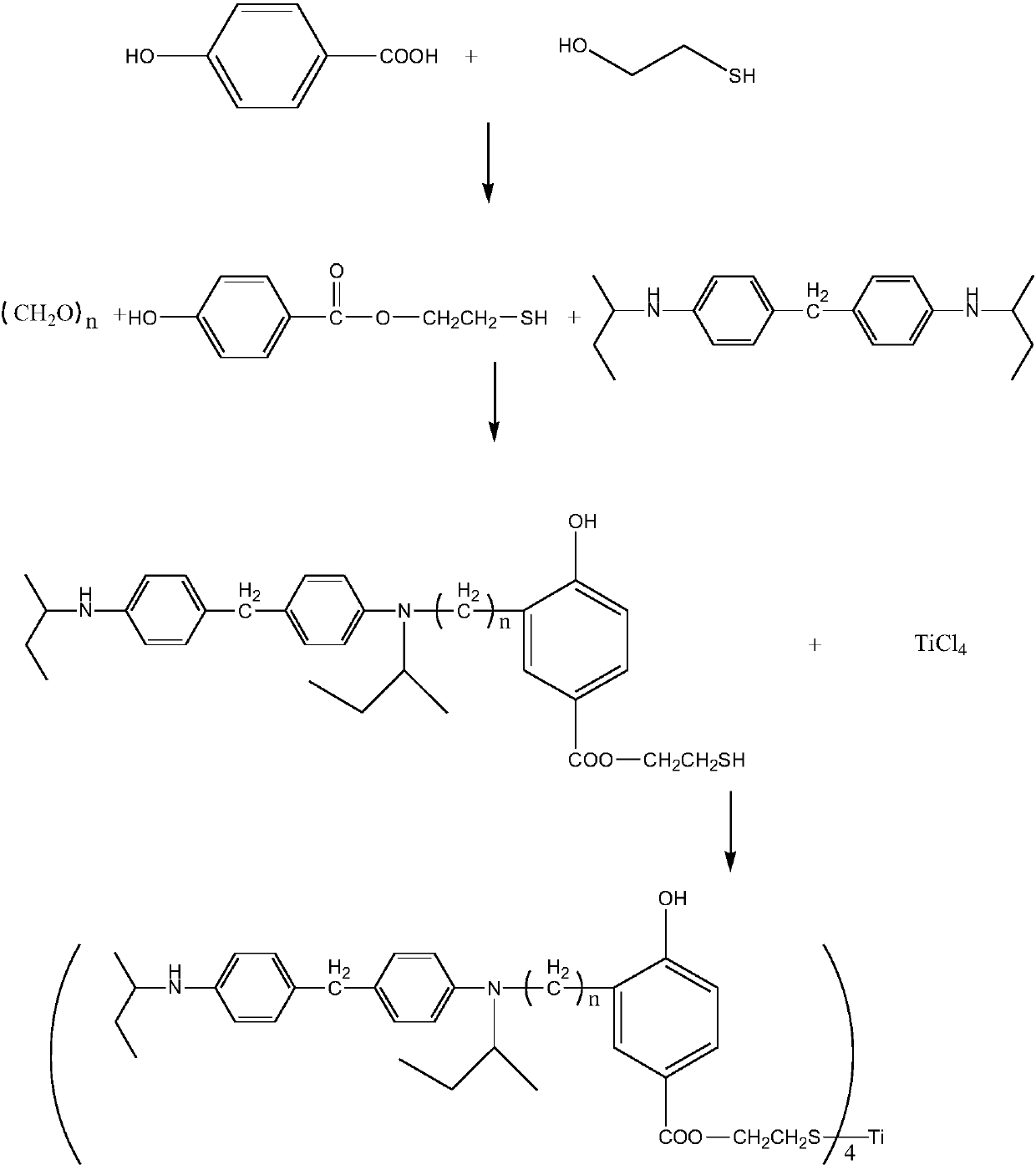

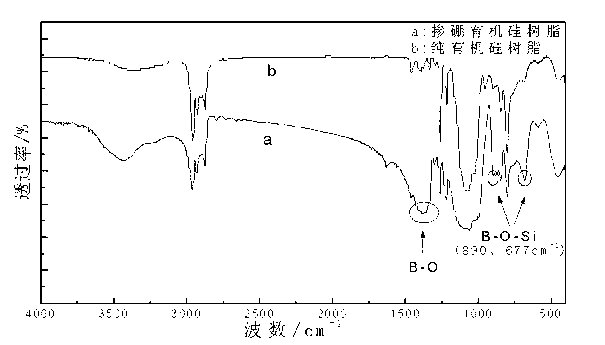

Organic silicon resin capable of cuing at room temperature and mixed with boron and preparation method and application thereof

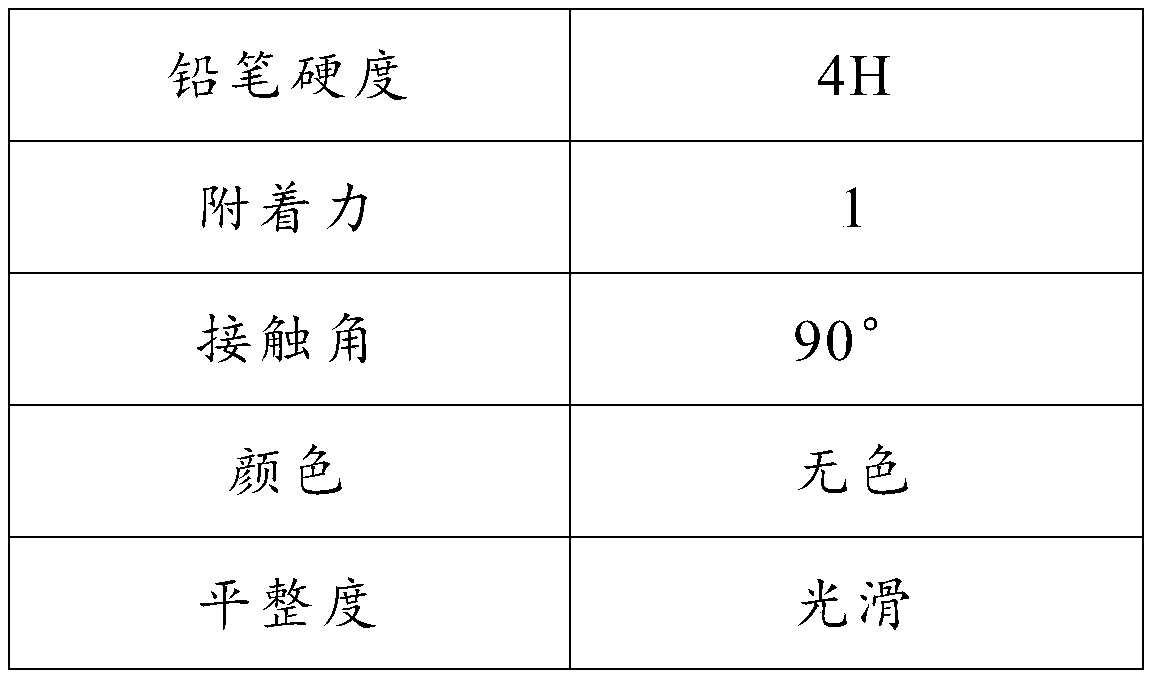

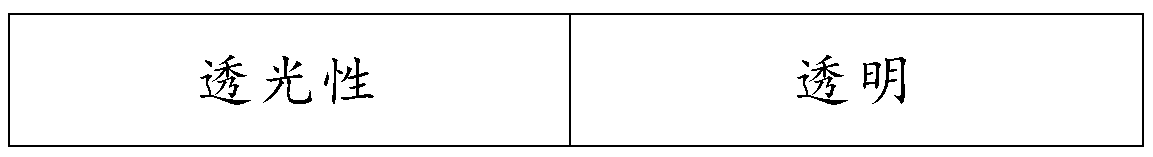

ActiveCN102936343AImprove high temperature resistanceCoating film is dense and smoothCoatingsPilot plantOrganosilicon

The invention discloses an organic silicon resin capable of curing at room temperature and mixed with boron and a preparation method and an application thereof. The structure of the organic silicon resin mixed with boron is shown as the following formula and has excellent high temperature resistance and high curing activity compared with ordinary organic silicon resin. A coated film can be actually dried at the temperature of 100 DEG C after 5-10 min, and can be actually dried at the room temperature after 30-60 min, and the cured coated film can totally overcome the phenomenon of repeated adhesion. The organic silicon resin capable of curing at room temperature and mixed with boron uses diluents and curing agents low in toxicity when used for curing films and is environment-friendly. The synthetizing route is concise and easy to operate, the raw materials are easy to obtain, and the organic silicon resin is suitable for pilot plant test and industrial production.

Owner:GUANGDONG UNIV OF TECH

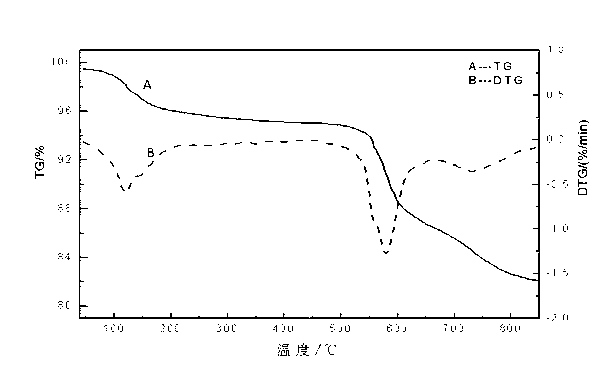

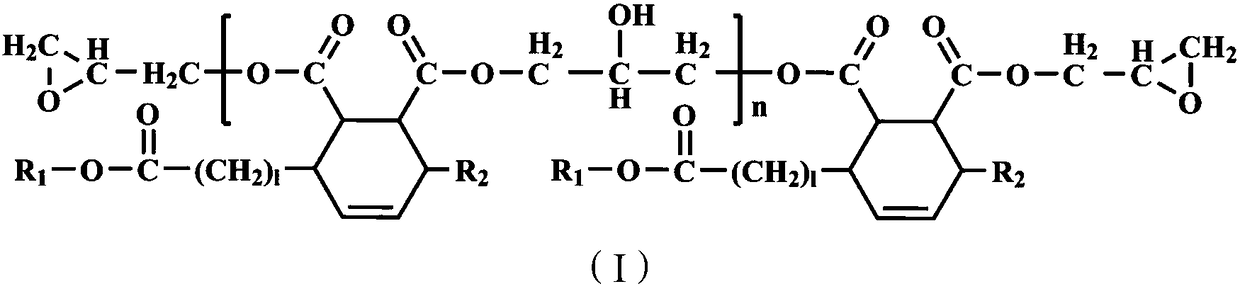

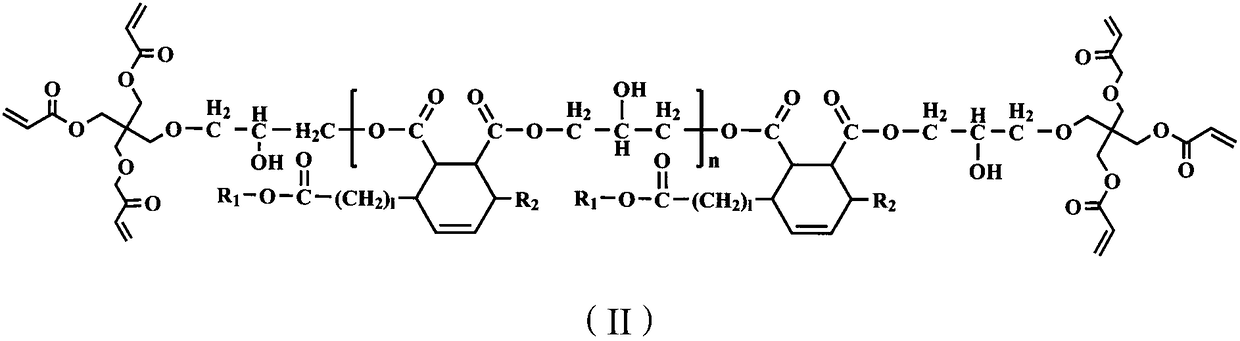

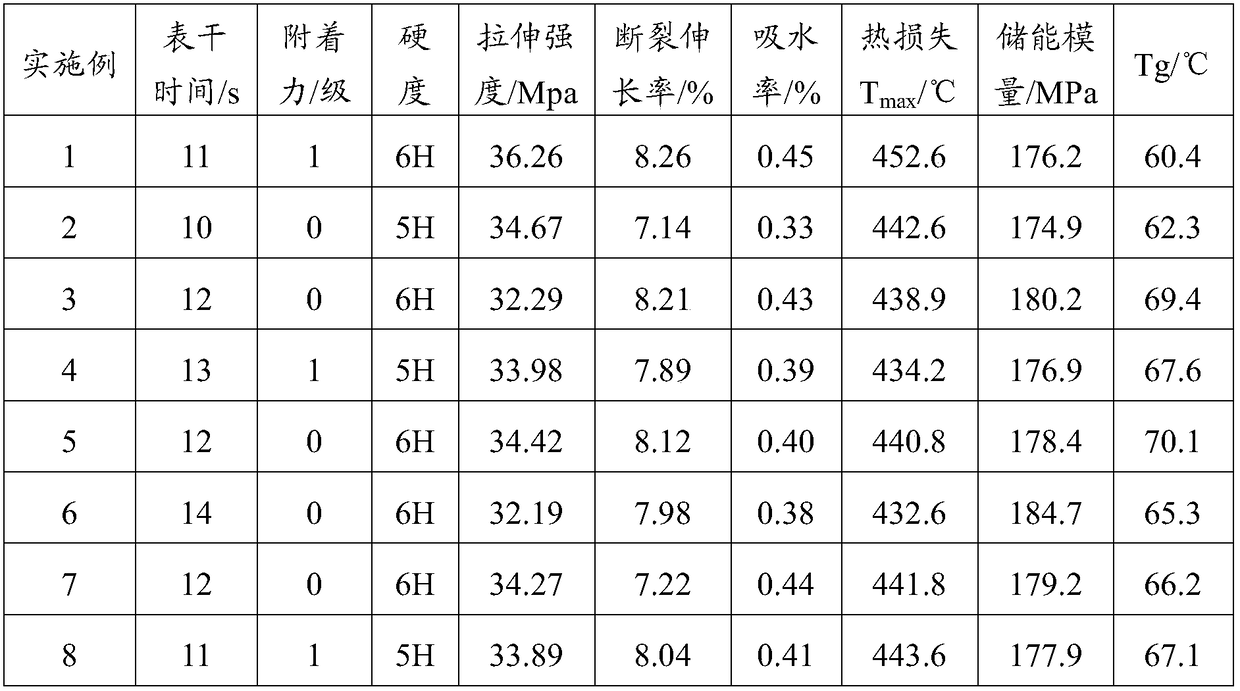

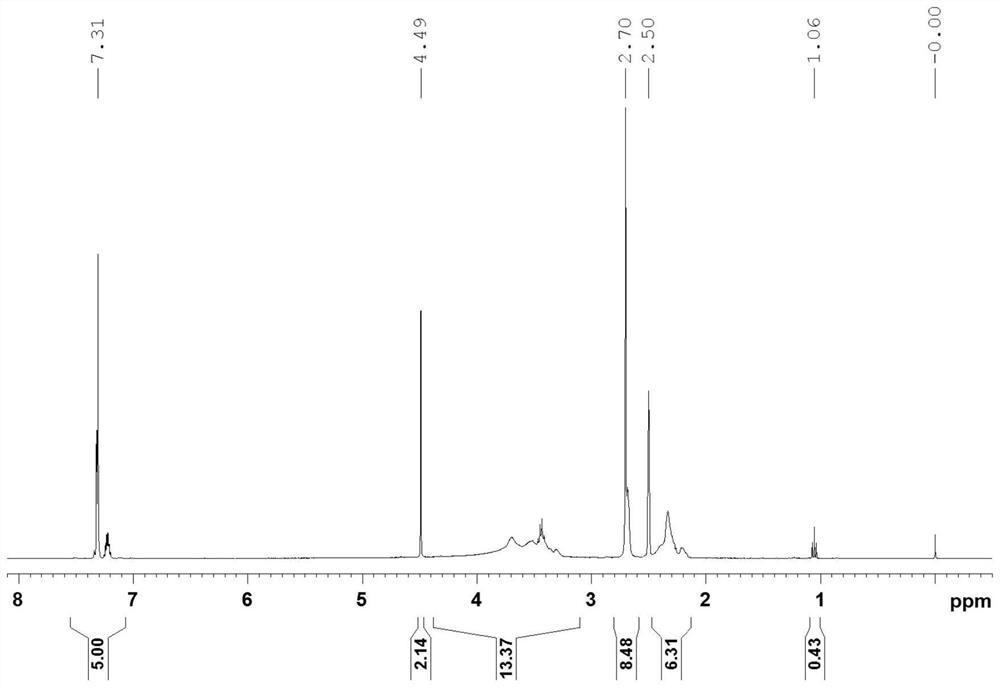

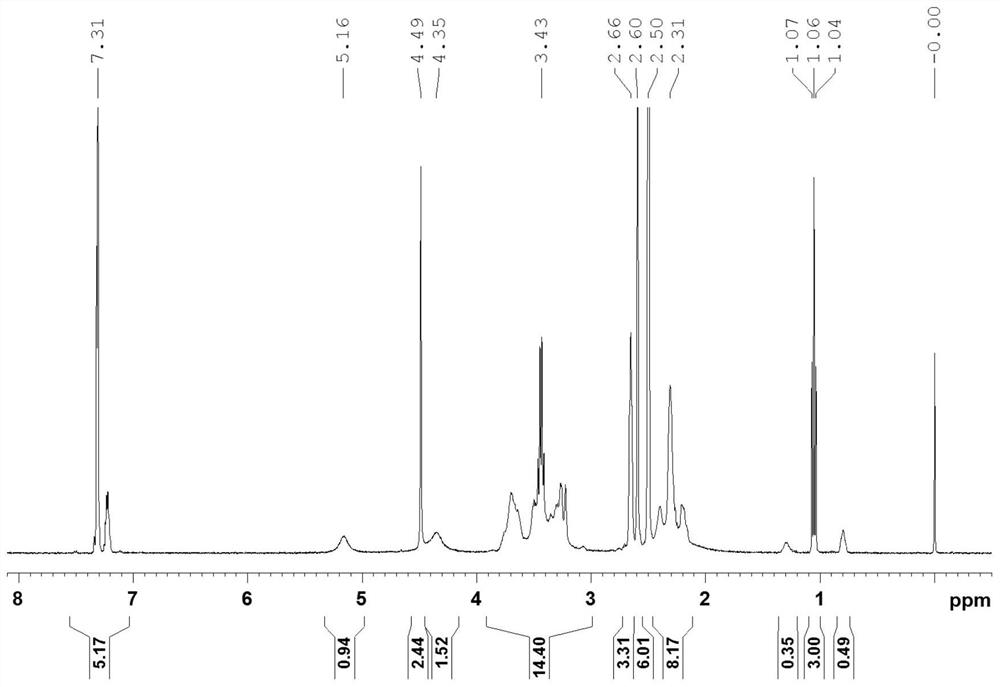

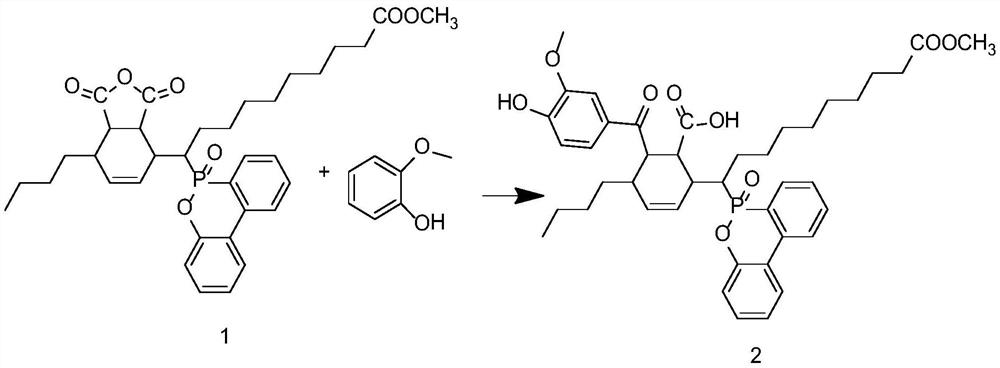

Vegetable oil-based epoxy prepolymer and preparation method thereof, vegetable oil-based UV curing prepolymer as well as preparation method and application thereof

The invention discloses a vegetable oil-based epoxy prepolymer and a preparation method thereof. The vegetable oil-based epoxy prepolymer has a structure shown by a general formula (I) shown in the specification. The invention further discloses a vegetable oil-based UV curing prepolymer as well as a preparation method and application thereof. According to the method, the vegetable oil-based epoxyprepolymer is firstly prepared by prepolymerizing a vegetable oil D-A reaction product with water and epichlorohydrin, and then the vegetable oil-based epoxy prepolymer reacts with pentaerythritol triacrylate to obtain the vegetable oil-based UV curing prepolymer; vegetable oil is introduced into the UV curing prepolymer, thereby greatly reducing the use amount of conventional petrochemical-derived raw materials. The vegetable oil-based UV curing prepolymer provided by the invention has very high UV curing activity and can be rapidly cured into a film in 10 to 60 s, and the cured film is goodin adhesion and excellent in physical properties, mechanical properties and thermal properties, and can be widely applied to the fields of UV curing coatings, inks, adhesives, 3D printing and other UVcuring materials.

Owner:SOUTH CHINA AGRI UNIV +1

Self-emulsifying waterborne epoxy resin curing agent and preparation method thereof

PendingCN111234178AHigh curing activityHigh molecular weightFireproof paintsAnti-corrosive paintsEndcappingPolymer science

The invention discloses a self-emulsifying waterborne epoxy resin curing agent, which is prepared from 1 to 10 parts of amino silicon oil, 20 to 30 parts of epoxy resin, 0.01 to 5 parts of a reactionauxiliary agent, 120 to 250 parts of a solventand 1 to 10 parts of an end-capping agent. The preparation method comprises the following steps: firstly, dissolving amino silicone oil in thesolvent, then adding the reaction aid, uniformly stirring, dropwise adding a mixed solution of epoxy resin and the solvent at a constant speed under the condition of 60-80 DEG C and in an inert gas atmosphere, and continuously reacting after dropwise adding is finished; continuously dropwise adding a mixed solution of the end-capping reagent and the solvent at a constant speed, and carrying out an end-cappingreaction; and finally adding a regulator, and carrying out reduced pressure distillation. The self-emulsifying waterborne epoxy resin curing agent disclosed by the invention has self-emulsifying anddefoaming properties, and can have excellent curing properties for different waterborne epoxy resins, so that a cured epoxy resin film has good properties such as heat resistance, weather resistance,electric insulativity, chemical resistance and hydrophobicity.

Owner:陕西立高涂料有限公司

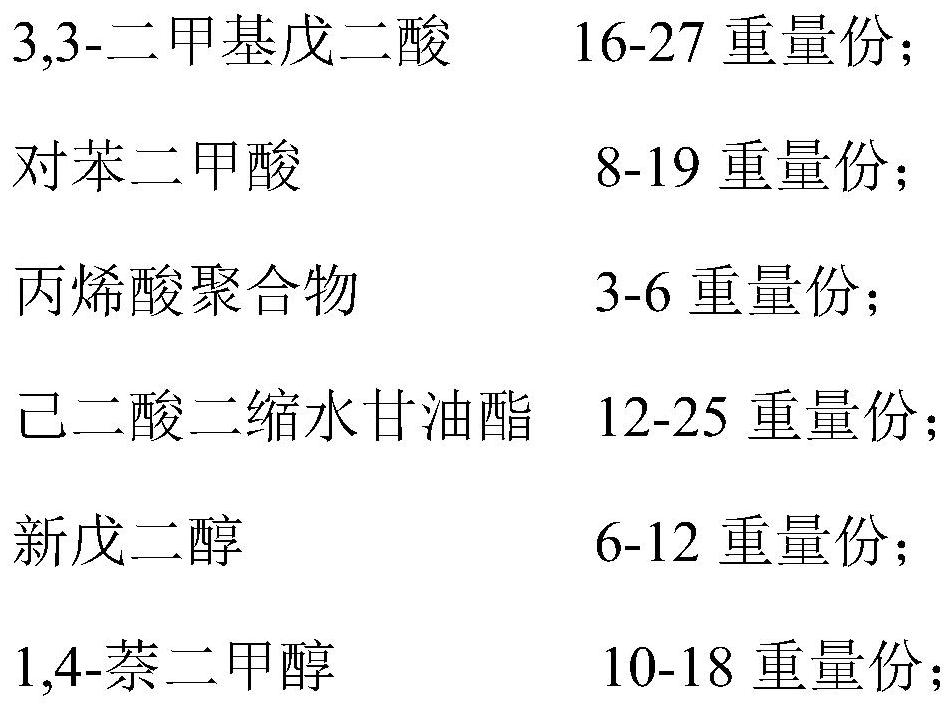

Low-temperature quick-curing polyester resin and powder coating for coiled materials prepared from same

The invention belongs to the technical field of powder coatings, particularly relates to a low-temperature quick-curing polyester resin, and further discloses an extinction type powder coating for coiled materials, which is prepared from the low-temperature quick-curing polyester resin. The low-temperature quick-curing polyester resin is prepared by polymerizing the following raw materials: 3, 3-dimethyl glutaric acid, terephthalic acid, an acrylic polymer, diglycidyl adipate, neopentyl glycol, 1, 4-naphthalene dimethanol, 1, 10-decylenediamine and ethylenediamine-N, N '-diacetic acid. The low-temperature quick-curing polyester resin product contains active amino, amide groups with different structures and a small amount of carboxyl, the final acid value is relatively low (less than 12mgKOH / g), the total amine value is relatively high (35-45mgKOH / g), low-temperature quick curing can be conveniently realized completely, and a self-extinction effect is achieved.

Owner:HUANGSHAN ZHENGJIE NEW MATERIALS

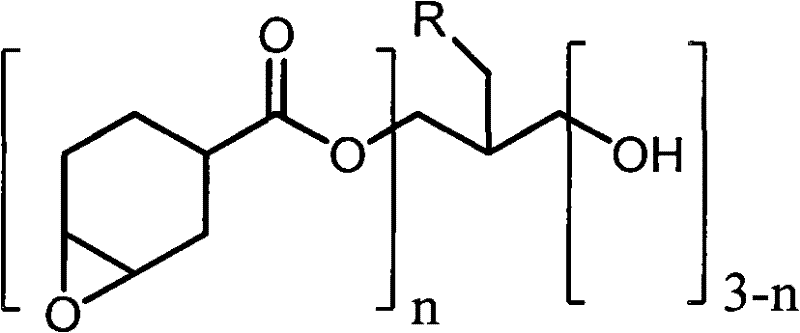

Hydroxyl-contained alicyclic epoxy resin and preparation method thereof

The invention discloses a hydroxyl-contained alicyclic epoxy resin and a preparation method thereof. The preparation method comprises the following steps of: mixing a hydroxyl compound with 3,4-epoxycyclohexane carboxylic acid methyl ester; then adding a catalyst and evenly mixing; and heating at 80-150 DEG C for reaction for 3-8 hours in the presence of inert gas shield to obtain the hydroxyl-contained alicyclic epoxy resin. According to the invention, an accelerator is not needed to be added in the solidifying process of the hydroxyl-contained alicyclic epoxy resin, and moreover, the chemical modification performance is good. Solidified products have good heat resistance and mechanical property.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Epoxy resin for high-hardness and low-temperature curing type powder coating and preparation method

ActiveCN112321799AImprove rigidityHigh functionalityFireproof paintsPowdery paintsGlutaric anhydridePtru catalyst

The invention discloses a preparation method of epoxy resin for a high-hardness and low-temperature curing type powder coating. The epoxy resin is prepared from the following raw materials in parts bymole: 3-5 parts of melamine, 30-40 parts of formaldehyde, 3-6 parts of hexafluorobutanol, 15-25 parts of cyclohexane, 2-4 parts of phosphorus pentoxide, 6-11 parts of glutaric anhydride, 2-4 parts ofpyromellitic dianhydride, 5-10 parts of pentaerythritol tetraglycidyl ether, a catalyst and a pH regulator. The obtained epoxy resin does not contain halogen elements, contains nitrogen, phosphine and other environment-friendly flame-retardant elements, has good flame retardancy, has high cross-linking density with a film obtained after low-temperature curing of a dicyandiamide curing agent, haspencil hardness of 3H or above, and has excellent water boiling resistance, neutral salt mist resistance and flame retardancy.

Owner:黄山新佳精细材料有限公司

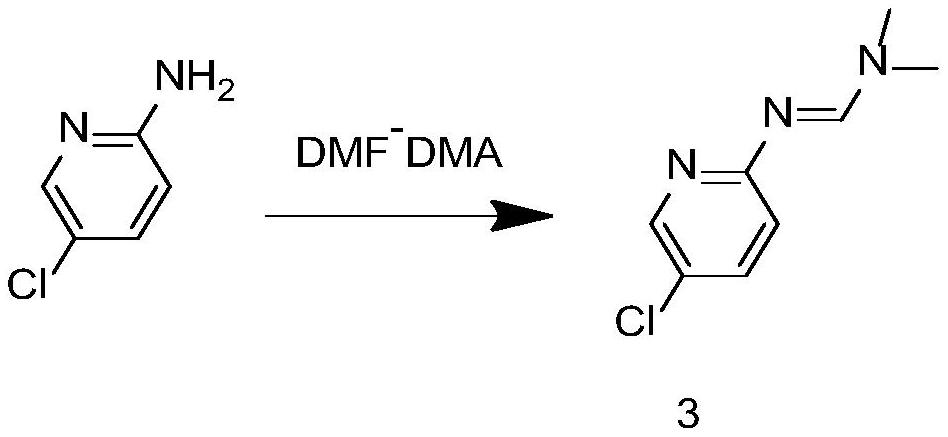

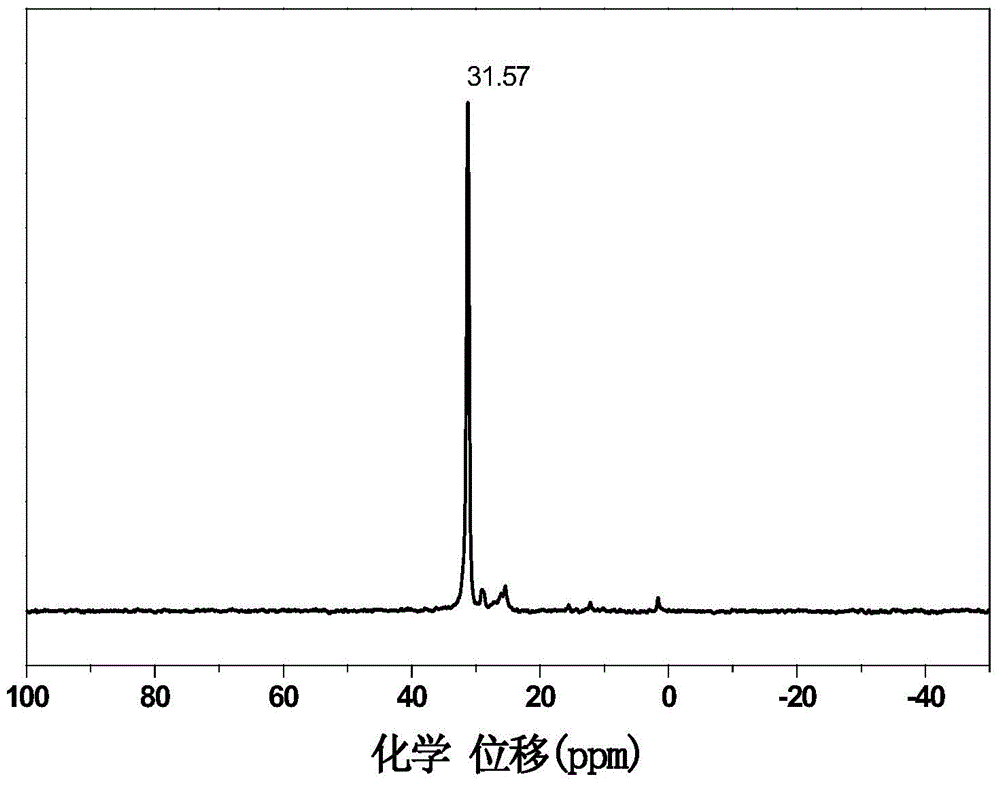

Phosphorus-nitrogen flame-retardant imidazole latent curing agent and preparation method thereof

ActiveCN107814913AHigh curing activityImprove flame retardant performanceGroup 5/15 element organic compoundsEpoxyNitrogen

The invention discloses a phosphorus-nitrogen flame-retardant imidazole latent curing agent, and the molecular structural formula of the curing agent is described shown in the description. A preparation method of the phosphorus-nitrogen flame-retardant imidazole latent curing agent comprises the step of enabling an active N-H bond in an imidazole compound, a P-H bond in 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and triglycidyl isocyanurate (TGIC), which are taken as raw materials, to be subjected to an addition reaction so as to obtain the phosphorus-nitrogen flame-retardant imidazole latent curing agent containing phosphaphenanthrene and a triazinetrione ring. The phosphorus-nitrogen flame-retardant imidazole latent curing agent has the characteristics of being good in flame-retardant effect, excellent in latent property and high in curing activity for epoxy resin.

Owner:WUHAN UNIV OF TECH

Preparation method of boronized furan resin

InactiveCN111718458AImprove the degree of graphitizationImprove morphology and electrochemical performanceCoatingsFuranComposite material

The invention discloses a preparation method of boronized furan resin, belonging to the technical field of furan resin production. The preparation method comprises the following steps that: furan resin is used as a carbon source, and boronic acid is added for boronation so as to obtain boronized furan resin. According to the invention, the doped boric acid can effectively improve the graphitization degree of the furan resin, so the wear resistance, thermal shock resistance and shock absorption of the furan resin are improved, the fatigue resistance, creep resistance, corrosion resistance and wear resistance of the furan resin are better, a thermal expansion coefficient of the furan resin is smaller, and the furan resin has more excellent high-temperature resistance and very high curing activity; and by improving raw materials and the preparation method, the process of production is mild and easy to control, gel curing is not easily to occur, a synthesis route is simple, operation is easy, dehydration is not required, and wastewater is not generated.

Owner:山东永创材料科技有限公司

A Low Refractive Index Optical Fiber Coating Resin

ActiveCN105273613BAvoid breakingLow refractive indexPolyurea/polyurethane coatingsFiberRefractive index

The invention relates to low-refractive optical fiber coating resin. The low-refractive optical fiber coating resin is prepared from, by weight, 30-65% of prepolymer A, 0-40% of prepolymer B, 2-8% of a photoinitiator, 20-40% of an active diluent and 0.5-2% of a silane coupling agent, and the sum of the weight percentages of all the components is 100%. The low-refractive optical fiber coating resin is high in adhesive power, optical fiber is not likely to be broken when bent, and the low-refractive optical fiber coating resin is low in refractive rate and can enlarge the digital transmission aperture of the optical fiber.

Owner:武汉长盈鑫科技有限公司

Curing agent and urea resin composition containing same

ActiveCN111440563AFast curing cross-linking reactionImprove latencyNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPolymer sciencePolymer chemistry

The invention relates to the technical field of curing agents, particularly provides a curing agent and a urea-formaldehyde resin composition containing the same. The curing agent is prepared from atleast a nitrogen-containing compound and a solvent, wherein the mass ratio of the nitrogen-containing compound to the solvent is (1.5-2.5):3.

Owner:HANGZHOU LINAN DIEN CHEM CO LTD

A kind of piperazine epoxy resin curing agent and its prepared epoxy resin composition and application

ActiveCN109400849BFast curingShorten the construction periodOrganic chemistryEpoxy resin adhesivesPolymer scienceAdhesive

The invention provides a piperazine epoxy resin curing agent and the prepared epoxy resin composition and application. The raw materials for the preparation of the curing agent are polyfunctional glycidyl ether, alcohol solvent and anhydrous piperazine. The curing agent has high reactivity at low temperature and normal temperature, and has good strength and weather resistance after reacting with the composition composed of epoxy resin. The curing agent provided by the invention can be widely used in the fields of construction emergency repair in winter, fast electronic packaging materials and adhesives.

Owner:WANHUA CHEM GRP CO LTD

High-temperature-resistant and high-strength epoxy adhesive capable of being cured at medium and low temperatures and preparation method thereof

PendingCN114605948AImprove thermal stabilityHigh curing activityNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesive cementPolymer science

The invention relates to the field of high polymer materials and preparation, and particularly discloses a high-temperature-resistant and high-strength epoxy adhesive capable of being cured at medium and low temperatures and a preparation method of the high-temperature-resistant and high-strength epoxy adhesive capable of being cured at medium and low temperatures. The curing temperature of the adhesive is effectively reduced, and meanwhile, the high-temperature adhesive property of the adhesive is remarkably improved. And the viscosity of the adhesive is adjusted through the filler. The epoxy adhesive can be cured at medium and low temperature (not more than 110 DEG C), and the tensile-shear strength at 250 DEG C is not less than 6.5 MPa. The epoxy adhesive provided by the invention is simple in preparation method, mild in curing condition and suitable for construction operation in various occasions.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

High-performance epoxy resin curing agent and preparation method thereof

The invention discloses a high-performance epoxy resin curing agent, which is prepared from the following raw materials in parts by weight: 10 to 20 parts of cardanol, 5 to 10 parts of diethylene triamine, 5 to 8 parts of para-formaldehyde, 30 to 40 parts of ethylene glycol, 5 to 10 parts of trimellitic anhydride, 1 part of an accelerant, 2 parts of an auxiliary agent and 0.1 part of a catalyst. The invention also discloses a preparation method of the high-performance epoxy resin curing agent, which comprises the following steps: 1, adding cardanol, diethylene triamine and a catalyst into a reaction kettle, heating to 90-100 DEG C, adding para-formaldehyde, and reacting for 1 hour under stirring to obtain a first composition; and 2, adding ethylene glycol into the first composition, stirring for 10 minutes, adding trimellitic anhydride, an accelerant and an auxiliary into the reaction kettle, and keeping on stirring for 30-60 minutes. The epoxy resin curing agent provided by the invention not only can improve the toughness and curing rate of cured epoxy resin, but also endows the epoxy resin with flame retardant property and antibacterial property.

Owner:杨向娟

Long-acting weather-resistant, chlorine-salt corrosion-resistant polyester powder coating and preparation method thereof

ActiveCN112048235BGood linear structureLow softening pointAnti-corrosive paintsPowdery paintsWeather resistanceLow temperature curing

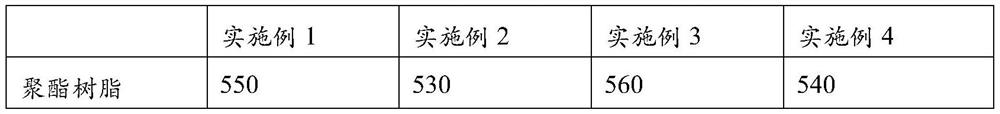

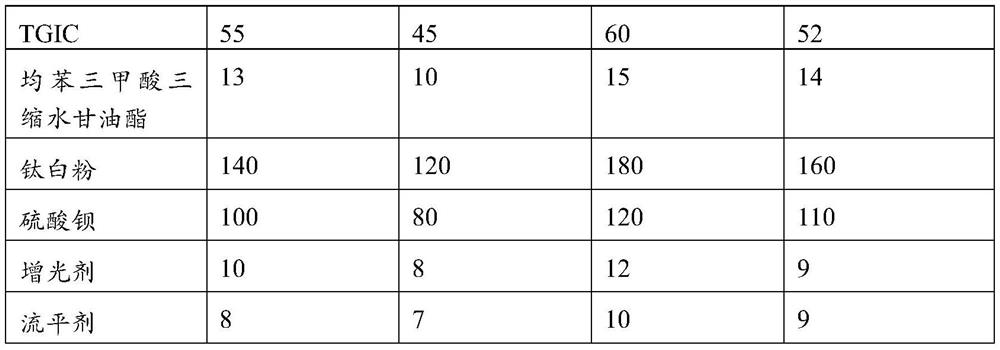

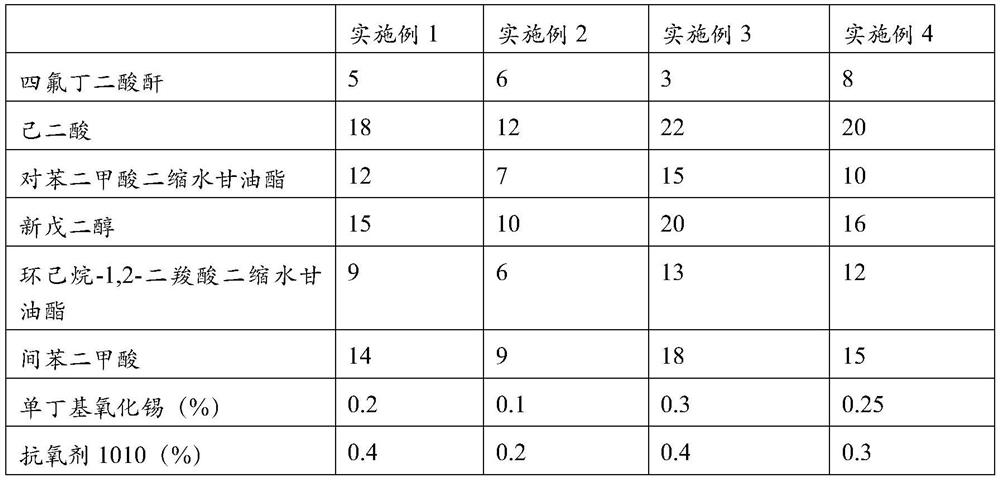

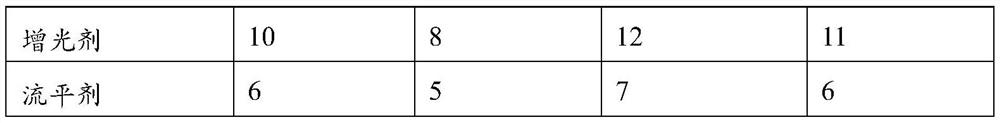

The invention belongs to the technical field of polyester powder coating preparation, and in particular relates to a long-acting weather-resistant, chlorine-salt corrosion-resistant polyester powder coating and a preparation method. The main raw materials of the powder coating of the present invention are: 530-560 parts of polyester resin, 45-60 parts of TGIC, 10-15 parts of trimesic acid triglycidyl ester, 120-180 parts of titanium dioxide, and 80-120 parts of barium sulfate , 8‑12 parts of brightening agent, 7‑10 parts of leveling agent. The polyester resin used in the powder coating of the present invention has a good linear structure, which ensures excellent fluidity; the powder coating uses a larger amount of trifunctional curing agent TGIC, and is matched with triglycidyl trimesic acid with a low melting point and excellent water resistance Esters are used as low-temperature curing agents to further improve the crosslinking density and water resistance of the coating film, and finally ensure long-term weather resistance and chloride salt corrosion resistance. The final powder coating product can be used for low-temperature curing at 160°C. The coating film prepared by it has good long-term weather resistance and chlorine salt corrosion resistance, and is especially suitable for infrastructure spraying on highways such as guardrails and bridges.

Owner:安徽鑫友高分子新材料科技有限公司

Bicomponent condensed type room temperature sulfidization silicon rubber high-efficiency curing agent

The invention discloses a double-component condensed type RTV silicone rubber curing accelerator which is obtained by mixing cross-linking agent, catalyst and catalyst promoter by a certain ratio; the invention also discloses curing agent which contains the curing accelerator and the application of the curing agent in silicon rubber preparation. The curing accelerator of the invention can effectively improve the curing speed and the silicon rubber performance after curing.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Anti-thick coating pinhole, excellent acid and alkali resistance powder coating and preparation method thereof

ActiveCN112011260BGood acid and alkali resistanceOvercome the shortcomings of poor acid and alkali resistanceAnti-corrosive paintsPolyether coatingsPolymer scienceLow temperature curing

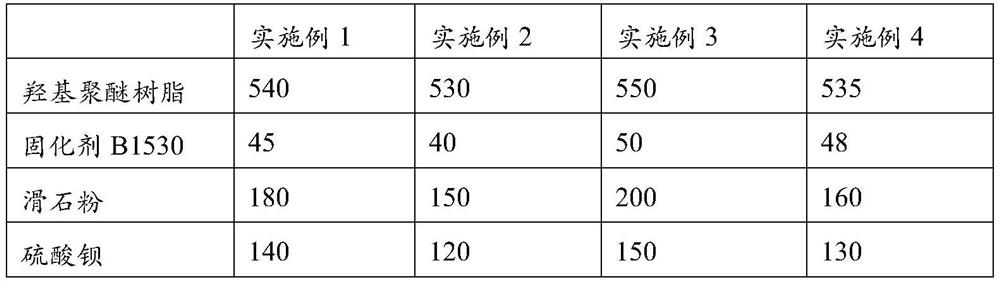

The invention belongs to the technical field of powder coatings, and in particular relates to a powder coating with excellent pinhole resistance and acid and alkali resistance and a preparation method thereof. The parts by weight of the main raw materials of the powder coating of the present invention are: 530-550 parts of hydroxyl polyether resin, 40-50 parts of B1530 curing agent, 150-200 parts of talcum powder, 120-150 parts of barium sulfate, 8-12 parts of brightening agent Parts, 7-10 parts of leveling agent; Hydroxy polyether resin is prepared by polycondensation of materials with the following molar fractions: the molar fractions of each component are: 1,4-cyclohexanedimethanol 4-8 , 1,6-hexanediol 3-6, resorcinol diglycidyl ether 5-10, propylene oxide 30-45, triglycidyl isocyanurate 4-8, octyl glycidyl ether 6-13 . The present invention uses high-functionality hydroxyl polyether resin as the raw material, the hydroxyl value is 15-20mgKOH / g, the amount of B1530 curing agent required for curing is small, the cost of powder coating is low, and it can be cured at 175°C / 15min at low temperature, and The prepared coating film has good resistance to pinholes in thick coating, and the high-functionality polyether has excellent acid and alkali resistance, and can be used for coating metal facilities in industrial cleaning places.

Owner:安徽鑫友高分子新材料科技有限公司

Preparation method of waterborne epoxy curing agent

PendingCN114835881AImprove temperature resistanceGood chemical resistanceEpoxy resin coatingsEpoxyPolymer science

The invention discloses a preparation method of a water-based epoxy curing agent, which comprises the following specific preparation processes: (1) taking polyether amine, putting the polyether amine into a four-mouth reaction bottle, slowly dropwise adding a first epoxy compound in a nitrogen atmosphere, then heating to 80-150 DEG C, and reacting to obtain a polyether amine-epoxy adduct; and (2) putting benzyl polyamine and alcohol ether into a four-mouth reaction bottle, slowly adding the polyether amine-epoxy adduct in a nitrogen atmosphere, heating to 50-80 DEG C, reacting, cooling to 40-60 DEG C, slowly dropwise adding a second epoxy compound, heating to 50-80 DEG C, reacting, slowly adding water, and dispersing for 15-30 minutes to obtain the waterborne epoxy curing agent. According to the preparation method of the waterborne epoxy curing agent provided by the invention, the emulsifying property and the curing property are improved by improving the molecular structure of the curing agent.

Owner:江西百盛精细化学品有限公司

Dopo-based s-triazine ring hydrogenated benzimidazole epoxy curing agent and preparation method thereof

ActiveCN104086751BImprove flame retardant performanceImprove mechanical propertiesGroup 5/15 element organic compoundsEpoxyTriazine

The invention discloses a DOPO-based s-triazine ring hydrogenated benzimidazole epoxy curing agent and a preparation method thereof. Its preparation method first mixes solvent I, cyanuric chloride, p-hydroxybenzaldehyde and an acid-binding agent, feeds nitrogen, and heats the reaction to obtain 2,4,6-tris(4-formylphenoxy)-1, 3,5‐s-triazine ring; mix solvent Ⅱ, 2,4,6-tris-formylphenoxy-1,3,5-s-triazine ring and DOPO, blow nitrogen into it, and react to obtain DOPO-based aldehyde phenoxy-1,3,5-s-triazine ring; DOPO aldehyde-phenoxy-1,3,5-s-triazine ring was dissolved in solvent Ⅲ and added dropwise to o-phenylenediamine and solvent Ⅲ A catalyst is added into the mixture to react to obtain a DOPO-based s-triazine ring hydrogenated benzimidazole epoxy curing agent. The cured product of the present invention passes the UL94V-0 level in vertical combustion, and the glass transition temperature and tensile strength are respectively increased by 12.1% and 18.2% compared with non-flame retardant epoxy resin.

Owner:广东华百材料技术有限公司

Hydroxyl-contained alicyclic epoxy resin and preparation method thereof

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com