Self-emulsifying waterborne epoxy resin curing agent and preparation method thereof

A technology of water-based epoxy resin and epoxy resin, which is applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of unstable curing performance, and achieve high curing activity, good heat resistance, and high boiling point. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

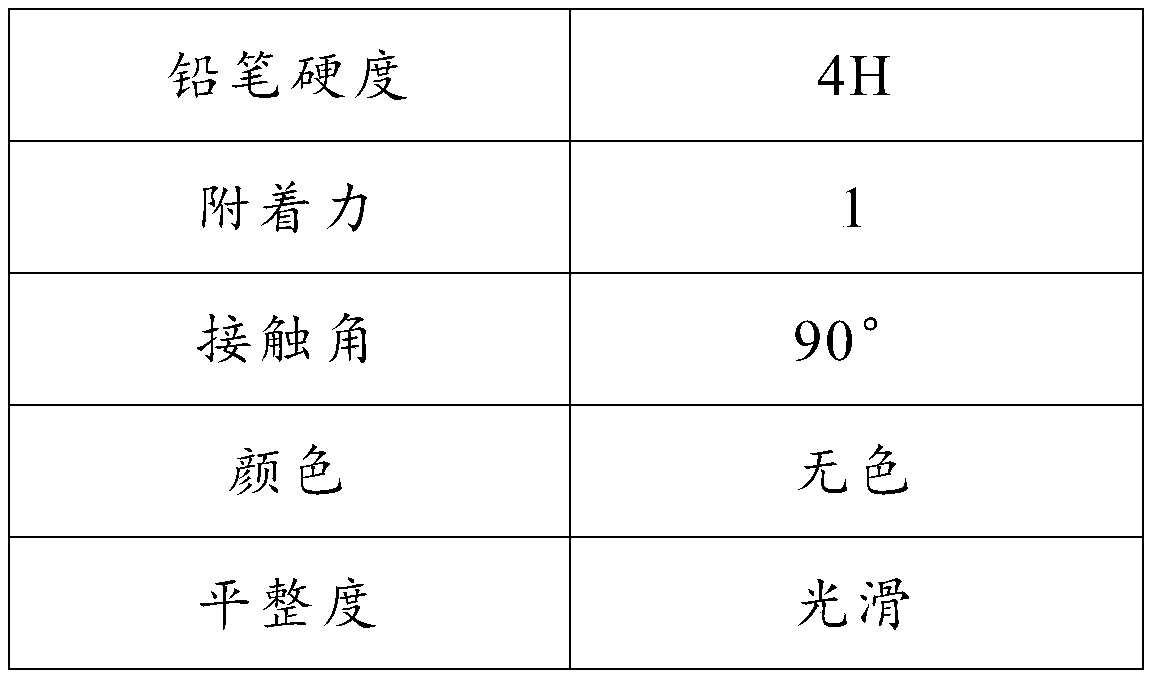

Embodiment 1

[0034] The preparation method of self-emulsifying waterborne epoxy resin curing agent comprises the following steps:

[0035] Step 1: Dissolve 1 part of aminomethylsiloxane in 50 parts of propylene glycol ether, then add 0.15 parts of reaction auxiliary ethylenediamine, stir evenly, and add 20 parts of A mixed solution composed of E-51 epoxy resin and 50 parts of propylene glycol ethyl ether, after the dropwise addition is completed, continue to react at 70°C for 3h;

[0036] Step 2: Continue to add a mixed solution consisting of 1 part of end-capping agent glycidyl methacrylate and 20 parts of propylene glycol ethyl ether dropwise at a constant speed under the condition of 75 ° C and an inert gas atmosphere. The reaction is carried out for 0.5 hours, and the reaction is continued for 2 hours. Cool down to 60°C;

[0037] Step 3, adding 0.1 parts of citric acid to adjust the stability of the emulsion, and distilling under reduced pressure at a vacuum degree of 2kPa and a tempe...

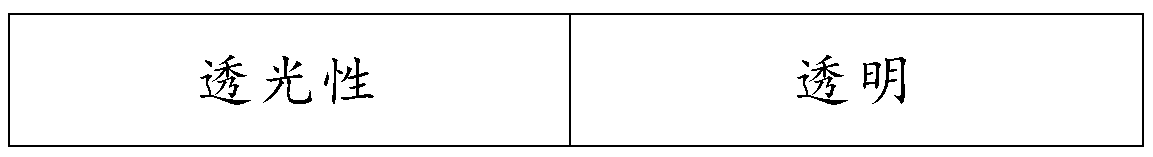

Embodiment 2

[0040] The preparation method of self-emulsifying waterborne epoxy resin curing agent comprises the following steps:

[0041] Step 1: Dissolve 5 parts of aminopolydimethylsiloxane in 80 parts of propylene glycol ether, then add 0.15 parts of reaction auxiliary triethylamine, stir evenly, and dropwise add the A mixed solution composed of 10 parts of E-44 epoxy resin, 10 parts of E-51 epoxy resin and 50 parts of propylene glycol ethyl ether, after the dropwise addition is completed, continue to react at 70 ° C for 3 hours;

[0042] Step 2, continue to add a mixed solution consisting of 2 parts of capping agent butyl glycidyl ether and 20 parts of propylene glycol ether at a constant speed under the condition of 75 ° C and an inert gas atmosphere, capping reaction for 1 hour, continue the reaction for 2 hours, and then lower the temperature to 65°C;

[0043] Step 3, adding 1 part of citric acid to adjust the stability of the emulsion, and distilling under reduced pressure at a v...

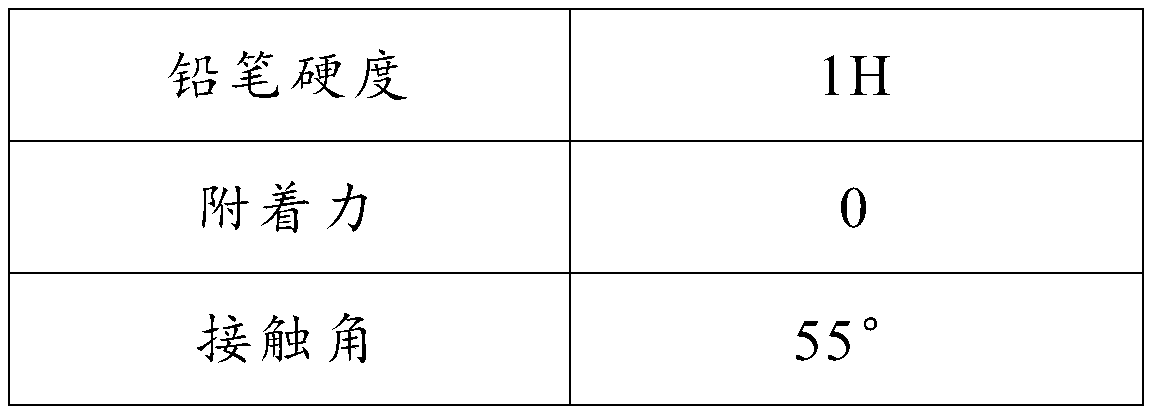

Embodiment 3

[0046] The preparation method of self-emulsifying waterborne epoxy resin curing agent comprises the following steps:

[0047] Step 1, dissolve 5 parts of aminopolydimethylsiloxane and 5 parts of diaminopolydimethylsiloxane in 100 parts of dipropylene glycol methyl ether, then add 0.1 part of triethylamine and 0.2 part of ethylenediamine, Stir evenly, and add 20 parts of E-51 epoxy resin, 10 parts of E-20 epoxy resin, 50 parts of propylene glycol ethyl ether, and 50 parts of propylene glycol butyl ether dropwise at a constant speed under the condition of 80 ° C and an inert gas atmosphere. After the addition is complete, continue to react at 85°C for 2h;

[0048] Step 2: Continue to add a mixed solution consisting of 3 parts of capping agent butyl glycidyl ether and 20 parts of propylene glycol ethyl ether dropwise at a constant speed under the condition of 85 °C and an inert gas atmosphere. 65°C;

[0049] Step 3, adding 1 part of citric acid to adjust the stability of the em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com