Preparation method of waterborne epoxy curing agent

A water-based epoxy and curing agent technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of single molecular structure, emulsification performance and curing performance to be improved, so as to enhance curing activity, emulsification effect and curing effect , to compensate for the effect of steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

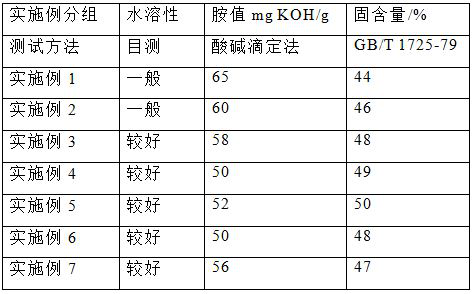

Examples

Embodiment 1

[0044] The present embodiment provides a preparation method of a water-based epoxy curing agent, and the specific preparation process includes the following steps:

[0045] (1) Take 30 parts of polyetheramine M600 into a four-neck reaction flask, slowly add 12 parts of bisphenol A glycidyl ether dropwise in a nitrogen atmosphere, and then heat up to 110 °C for 4 hours to obtain polyetheramine-epoxy Additives;

[0046] (2) Take 30 parts of benzyl polyamine and 10 parts of ethylene glycol propyl ether into a four-neck reaction flask, under nitrogen atmosphere, slowly add polyetheramine-epoxy adduct, heat up to 65 ℃ and react for 4 hours, then Cool to 50°C, slowly add 18 parts of the second epoxy compound (butyl glycidyl ether) dropwise, heat up to 65°C and react for 4h, then slowly add 45 parts of water, disperse for 22min, and filter to obtain a water-based epoxy curing agent.

Embodiment 2

[0048] On the basis of embodiment 1, this embodiment also provides another second epoxy compound, and its preparation method is:

[0049] S1. After mixing oleyl alcohol polyoxyethylene ether with 14 times the amount of water, add 7 times the amount of peach wood powder to soak for 1.5h, and then evaporate the water to obtain surface-treated peach wood powder;

[0050] S2. According to the mass ratio of 0.3:1:7.5, the surface-treated peach wood powder, exo-3,6-epoxy-1,2,3,6-tetrahydrophthalic acid and toluene are placed in the reaction flask and mixed evenly , after the C12-C14 glycidyl ether and the catalyst 2-ethylhexanoate chromium were mixed uniformly, slowly dropped into the reaction flask, and stirred and refluxed for 6h in an oil bath at 105 °C, wherein the exo-3,6-epoxy The molar ratio of -1,2,3,6-tetrahydrophthalic acid, C12-C14 glycidyl ether and catalyst is 1:1.15:0.015;

[0051] S3, after the reaction finishes, filter out the peach wood powder, and the filtrate eva...

Embodiment 3

[0054] On the basis of embodiment 1, this embodiment also provides a kind of preparation method of above-mentioned benzyl polyamine:

[0055] A. Take 2,4-diaminobutyric acid, water, potassium hydroxide, and methanol into a four-necked reaction flask. Under a nitrogen atmosphere, slowly add toluene-chloride dropwise, then heat up to 60°C and react for 5h. After the reaction is completed , filtration, oil-water separation, take the organic phase, vacuum distillation;

[0056] B, the product obtained in step A is mixed with 3.5 times the amount of thionyl chloride, and the reaction is refluxed at normal temperature for 3h, while the tail gas is treated, and the obtained product is dewatered;

[0057] C, according to mass ratio 1:0.08:3, polyethylene glycol, pyridine and dichloromethane are mixed uniformly, under ice bath, stirring condition, drip the mixed solution of the product that step B obtains and dichloromethane (mass ratio is 1:3), then react for 6h, after the reaction, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com