Anti-thick coating pinhole, excellent acid and alkali resistance powder coating and preparation method thereof

A technology of acid and alkali resistance and powder coating, which is applied in the direction of powder coating, polyether coating, anti-corrosion coating, etc. It can solve the problems of unsatisfactory acid and alkali resistance and high cost of polyester resin, and overcome the poor acid and alkali resistance , reduce consumption and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

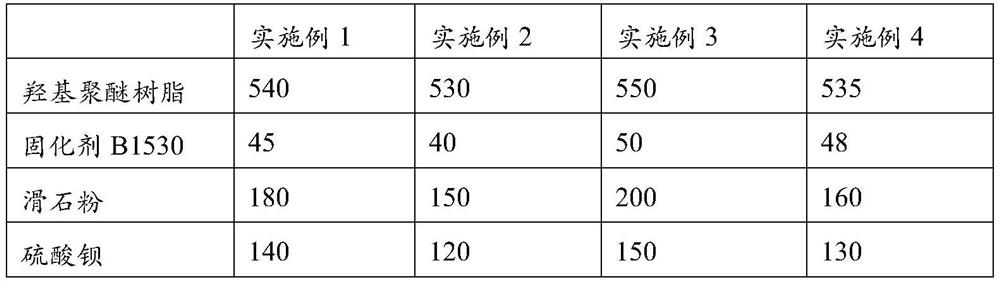

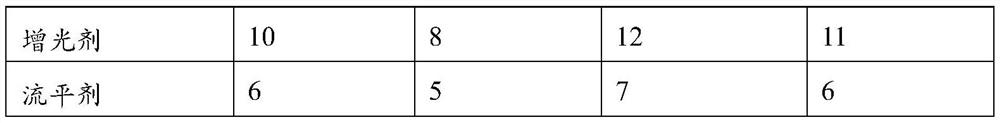

Embodiment 1

[0056] The preparation method of the powder coating with anti-thick coating pinhole and excellent acid and alkali resistance comprises the following steps:

[0057] S1: Weigh the material into the high-speed mixer according to the following formula, start the mixing device, and mix at high speed for 10-25 minutes;

[0058] S2: After the materials in S1 are mixed evenly, put them into a twin-screw extruder for melt extrusion, the temperature of the extrusion section is 130-140°C, and the screw speed is 360-380rpm;

[0059] S3: Use a twin-screw extruder to melt the material extruded in S2, and then use a tablet press with a tap water cooling system to tablet the melted material and roughly break it into granules;

[0060] S4: The coarse particles are further ground through the mill, and the particles with a particle size of 160-180 mesh are screened and collected through the air induction system of the mill to obtain the finished powder coating.

[0061] Wherein, the hydroxyl p...

Embodiment 5

[0079] Coating coating preparation: Spray the prepared powder coating on the surface-treated tinplate substrate with an electrostatic spray gun, with a film thickness of about 150 μm, and fully cure at 175°C / 15min to obtain the coating coating.

[0080] Coating index detection is based on GB / T 21776-2008 "Guidelines for Testing Standards of Powder Coatings and Coatings"; coating film leveling level testing is based on JB / T 3998-1999 "Determination of Coating Leveling and Scratching"; attached The level of stress is based on GB / T9286-1998 "Cross-cut test of paint and varnish film"; the acid and alkali corrosion resistance is in accordance with the standard of GB / T 9274-1988 "Determination of resistance to liquid media of paint and varnish" Soaking method) is carried out, test according to the acid-base concentration of commonly used industrial cleaning, adopt respectively the hydrochloric acid solution of 5% mass concentration, the phosphoric acid solution of 10% mass concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com