High sensitivity mobile phone protection screen full lamination adhesive and preparation method thereof

A mobile phone protection and high-sensitivity technology, applied in the direction of modified epoxy resin adhesives, adhesives, adhesive types, etc., can solve the problem of 100% bonding of curved screens, high difficulty of bonding protective films, and constraints on development And other problems, to achieve the effect of shortening the sizing time, good peeling characteristics, and convenient transmission of ultrasound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

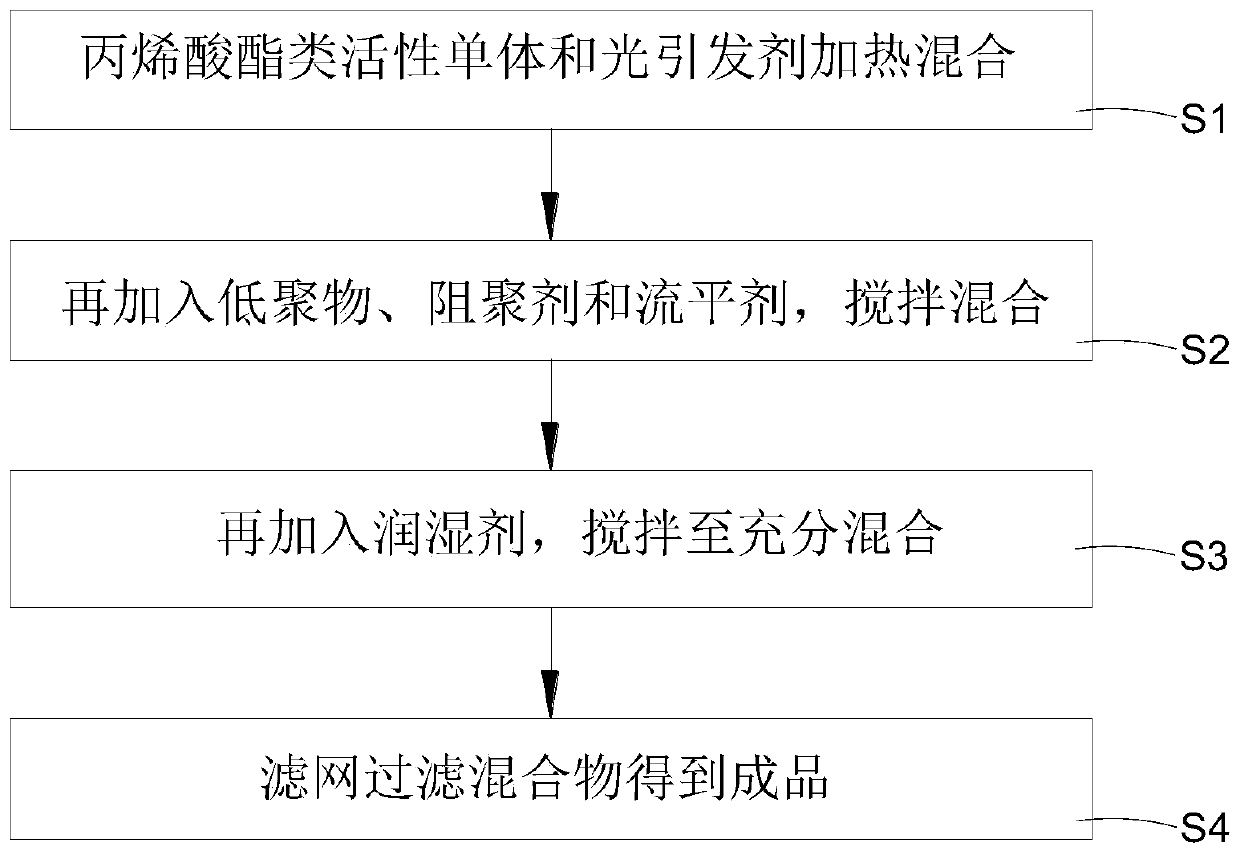

[0023] like figure 1 As shown, the preparation method of the high-sensitivity mobile phone protective screen full-fit adhesive of the present invention comprises the following steps:

[0024] S1, acrylate active monomer and photoinitiator are heated and mixed;

[0025] S2, add oligomer, polymerization inhibitor and leveling agent again, stir and mix;

[0026] S3, add wetting agent again;

[0027] S4, filter the mixture to obtain the finished product.

[0028] In step S1, the heating and mixing temperature is 40-50°C, and stirring is carried out at 1200-2000r / min for 40-45min; the stirring time in step S2 is 30-45min, and the stirring time in step S3 is 10-15min; In step S4, a 300-mesh filter is used to filter the mixture, and the filtrate is packaged to obtain the full bonding adhesive for the mobile phone screen protective film.

[0029] In addition, in the preparation method of the high-sensitivity mobile phone protective screen full-fit adhesive of the present invention...

Embodiment 1

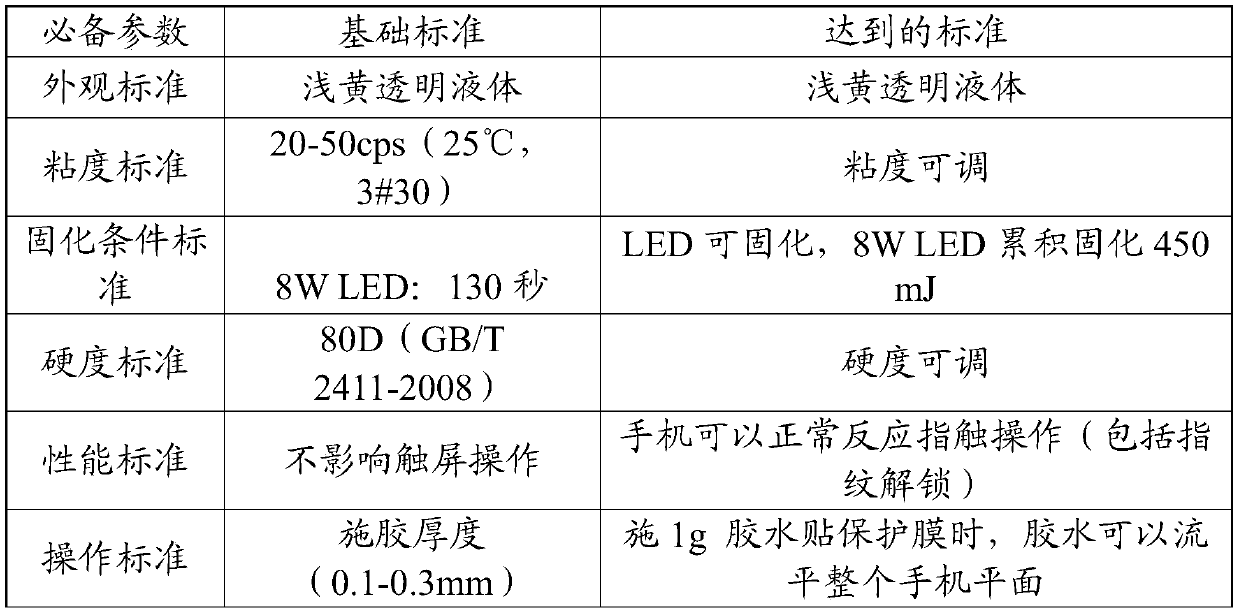

[0040] A method for preparing a high-sensitivity mobile phone protective screen full-fit adhesive. Calculated by mass fraction, first weigh 8% acryloylmorpholine, 8% isobornyl acrylate, 32% ethoxyethoxyethyl acrylate, Mix 32% 2-phenoxyethyl acrylate, 2% acyl phosphine oxide and 2% benzoin, heat to 40-50°C, and stir at 1200-2000r / min for 40-45min. Then add 7% urethane acrylate oligomer, 3% polyether acrylate oligomer, 4% epoxy acrylate oligomer and 0.8% polymerization inhibitor in turn, after stirring for 20-30min, add 0.1% moistening The aerosol and 0.1% leveling agent are stirred for 10-15 minutes, filtered through a 300-mesh filter, and the filtrate is packaged to obtain a full-fit adhesive for the mobile phone protective screen. The properties of the obtained mobile phone protective screen full-fit glue are as follows:

[0041]

[0042] Compared with the prior art, the present invention has the following beneficial effects: the proportion of oligomer is low, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com