A kind of piperazine epoxy resin curing agent and its prepared epoxy resin composition and application

A technology of epoxy resin curing and epoxy resin, which is applied in the direction of epoxy resin glue, adhesives, organic chemistry, etc., can solve the problems of film forming difficulties, economic losses, and reduce curing temperature, so as to facilitate construction by workers and reduce environmental pollution. Hazardous, low volatility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) Mix 100g of anhydrous piperazine with 50g of methanol (mass ratio 1:0.5), then mix 150g of the above mixture with 70g of pentaerythritol tetraglycidyl ether (molar ratio 3:0.7), and heat up to 40°C for 1 hour. Distill at 60°C after the reaction to obtain a piperazine epoxy resin curing agent.

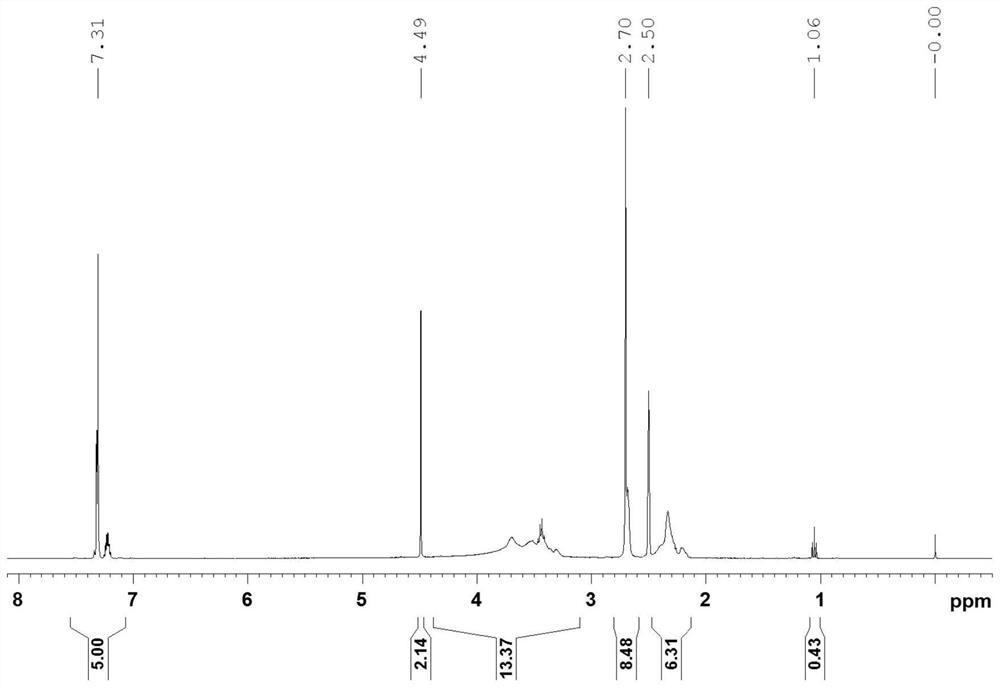

[0056] (2) Characterize the obtained curing agent product by proton nuclear magnetic resonance spectrum, the result is as follows figure 1 Shown, CH in the epoxy group 2 The chemical shifts of -OH are at 2.73 and 3.09, and the chemical shifts of -OH are at 3.45 and 3.7. From the figure, it can be seen that the resonance peaks at 2.73 and 3.09 disappear, and the resonance peaks at 3.45 and 3.7 appear, indicating that the epoxy group Disappeared, a new hydroxyl group was generated, indicating that the product was a piperazine curing agent.

[0057] (3) prepare epoxy resin composition:

[0058] Component A: Add 100g of DER331 into the reactor, raise the temperature to 60°C an...

Embodiment 2

[0062] (1) Mix 100g of anhydrous piperazine with 100g of ethanol (mass ratio 1:0.5), then mix 200g of the above mixture with 131g of glycerol triglycidyl ether (molar ratio 3:1.3), and heat up to 50°C for reaction After 3 hours, after the reaction, distill at 70° C. to obtain a piperazine epoxy resin curing agent.

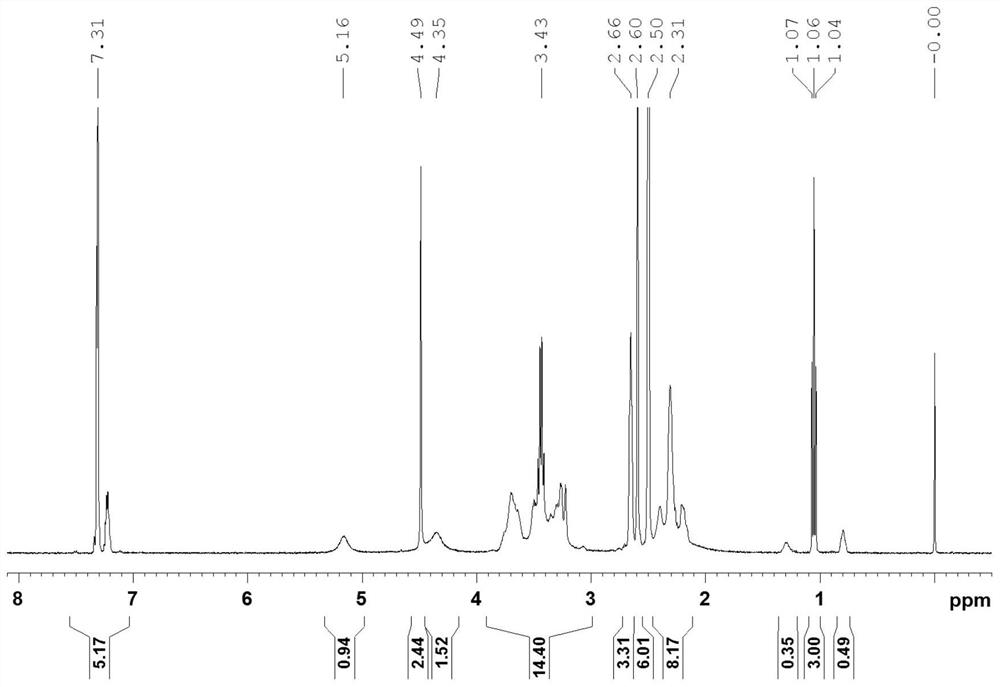

[0063] (2) Characterize the obtained modified curing agent product by proton nuclear magnetic resonance spectrum, the result is as follows figure 2 Shown, CH in the epoxy group 2 The chemical shifts of -OH are at 2.73 and 3.09, and the chemical shifts of -OH are at 3.45 and 3.7. From the figure, it can be seen that the resonance peaks at 2.73 and 3.09 disappear, and the resonance peaks at 3.45 and 3.7 appear, indicating that the epoxy group disappeared, and a new hydroxyl group was generated, indicating that a multifunctional piperazine curing agent was obtained.

[0064] (3) prepare epoxy resin composition:

[0065] Component A: Add 108g of NPEL-127E into the ...

Embodiment 3

[0069] (1) Mix 100g anhydrous piperazine with 125g n-butanol (mass ratio 1:1.25), then mix 225g of the above mixture with 129g trimethylol triglycidyl ether (molar ratio 3:1.1), and heat up to React at 70°C for 5h, and distill at 75°C after the reaction to obtain a piperazine epoxy resin curing agent.

[0070] (2) Characterize the obtained modified curing agent product by proton nuclear magnetic resonance spectrum, the result is as follows image 3 Shown, CH in the epoxy group 2 The chemical shifts of -OH are at 2.73 and 3.09, and the chemical shifts of -OH are at 3.45 and 3.7. From the figure, it can be seen that the resonance peaks at 2.73 and 3.09 disappear, and the resonance peaks at 3.45 and 3.7 appear, indicating that the epoxy group disappeared, and a new hydroxyl group was generated, indicating that a multifunctional piperazine curing agent was obtained.

[0071] (3) prepare epoxy resin composition:

[0072] Component A: Add 102g of DER331 into the reaction kettle, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com