High-performance epoxy resin curing agent and preparation method thereof

An epoxy resin curing, high-performance technology, applied in the field of curing agent preparation, can solve the problems of low temperature resistance, poor mechanical properties, low curing activity of curing agent, single performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

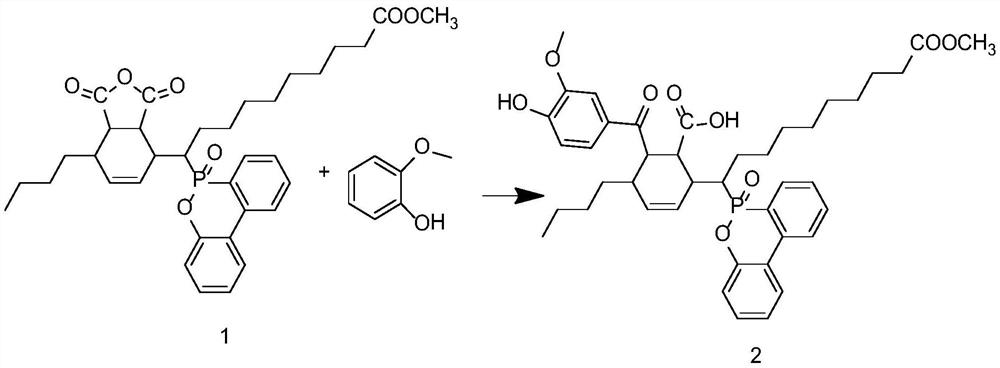

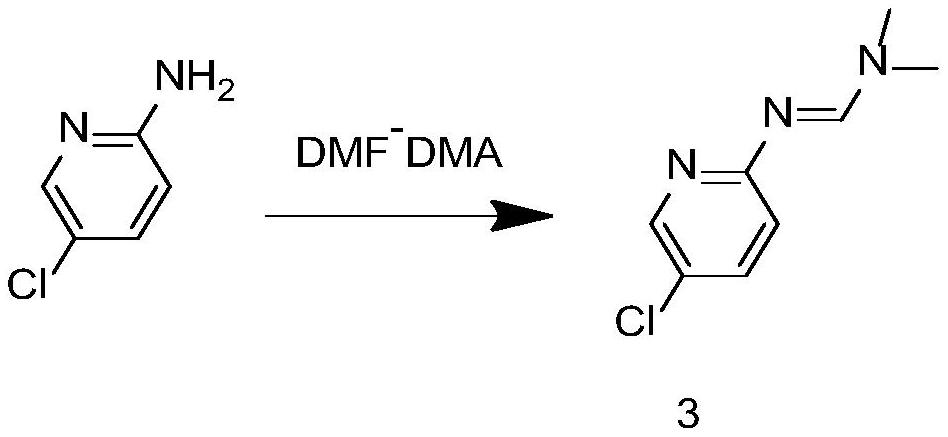

Method used

Image

Examples

Embodiment 1

[0046] A high-performance epoxy resin curing agent, comprising the following raw materials in parts by weight: 10 parts of cardanol, 5 parts of diethylenetriamine, 5 parts of paraformaldehyde, 30 parts of ethylene glycol, 5 parts of trimellitic anhydride, 1 part of accelerator, 2 parts of agent, 0.1 part of catalyst;

[0047] This high-performance epoxy resin curing agent is made by the following steps:

[0048] The first step is to add cardanol, diethylenetriamine and catalyst into the reaction kettle, stir for 10 minutes at a rotation speed of 60r / min, then raise the temperature to 90°C, add paraformaldehyde to the reaction kettle, and increase the rotation speed to 100r / min. Keeping the temperature constant, after stirring and reacting for 1 hour, the first composition is obtained;

[0049] The second step, add ethylene glycol to the first composition, stir at constant speed for 10 minutes, add trimellitic anhydride, accelerator and auxiliary agent to the reaction kettle, ...

Embodiment 2

[0065] A high-performance epoxy resin curing agent, comprising the following raw materials in parts by weight: 15 parts of cardanol, 8 parts of diethylenetriamine, 7 parts of paraformaldehyde, 35 parts of ethylene glycol, 8 parts of trimellitic anhydride, 1 part of accelerator, 2 parts of agent, 0.1 part of catalyst;

[0066] This high-performance epoxy resin curing agent is made by the following steps:

[0067] The first step is to add cardanol, diethylenetriamine and catalyst into the reaction kettle, stir for 10 minutes at a rotation speed of 80r / min, then raise the temperature to 95°C, add paraformaldehyde to the reaction kettle, increase the rotation speed to 150r / min, Keeping the temperature constant, after stirring and reacting for 1 hour, the first composition is obtained;

[0068] The second step is to add ethylene glycol to the first composition, stir at constant speed for 10 minutes, add trimellitic anhydride, accelerator and auxiliary agent to the reaction kettle,...

Embodiment 3

[0084] A high-performance epoxy resin curing agent, comprising the following raw materials in parts by weight: 20 parts of cardanol, 10 parts of diethylenetriamine, 8 parts of paraformaldehyde, 40 parts of ethylene glycol, 10 parts of trimellitic anhydride, 1 part of accelerator, 2 parts of agent, 0.1 part of catalyst;

[0085] This high-performance epoxy resin curing agent is made by the following steps:

[0086] The first step is to add cardanol, diethylenetriamine and catalyst into the reaction kettle, stir for 10 minutes at a rotation speed of 100r / min, then raise the temperature to 100°C, add paraformaldehyde to the reaction kettle, increase the rotation speed to 200r / min, Keeping the temperature constant, after stirring and reacting for 1 hour, the first composition is obtained;

[0087] The second step, add ethylene glycol to the first composition, stir at constant speed for 10 minutes, add trimellitic anhydride, accelerator and auxiliary agent to the reaction kettle, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com