Vegetable oil-based epoxy prepolymer and preparation method thereof, vegetable oil-based UV curing prepolymer as well as preparation method and application thereof

An epoxy prepolymer, vegetable oil-based technology, applied in the application, epoxy resin glue, epoxy resin coating, etc., can solve the problem that the performance of the cured film of UV curing adhesive needs to be improved, and achieve good adhesion of the cured film , good promotion significance, and the effect of relieving stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

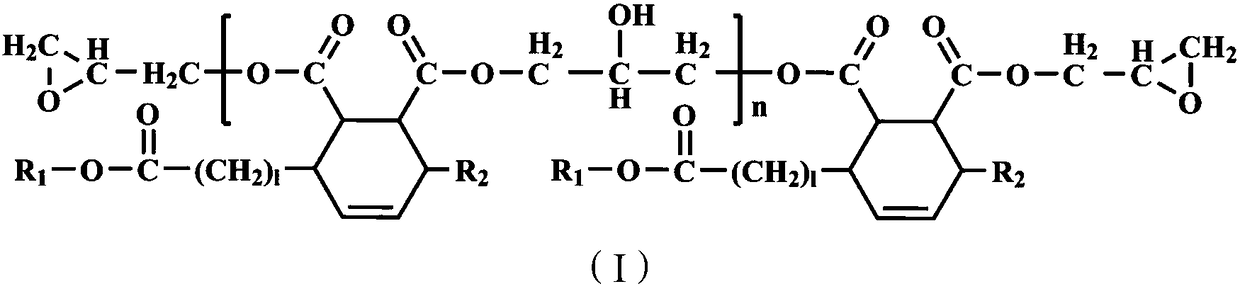

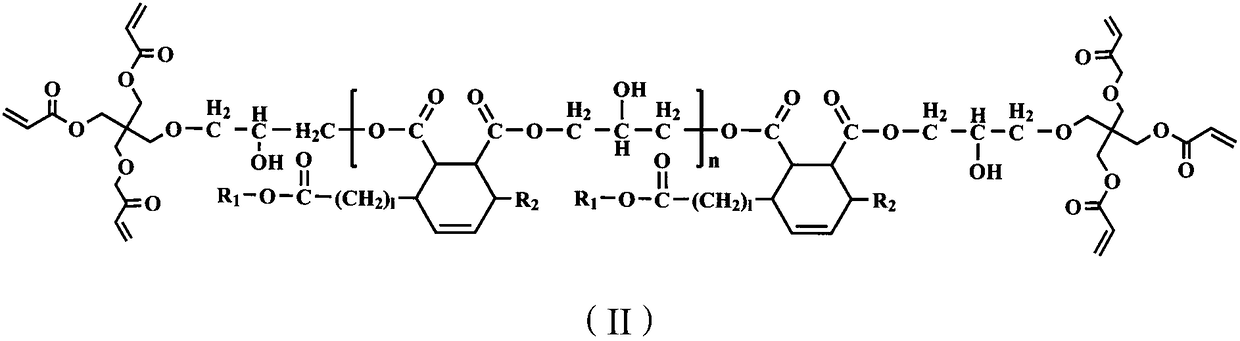

Method used

Image

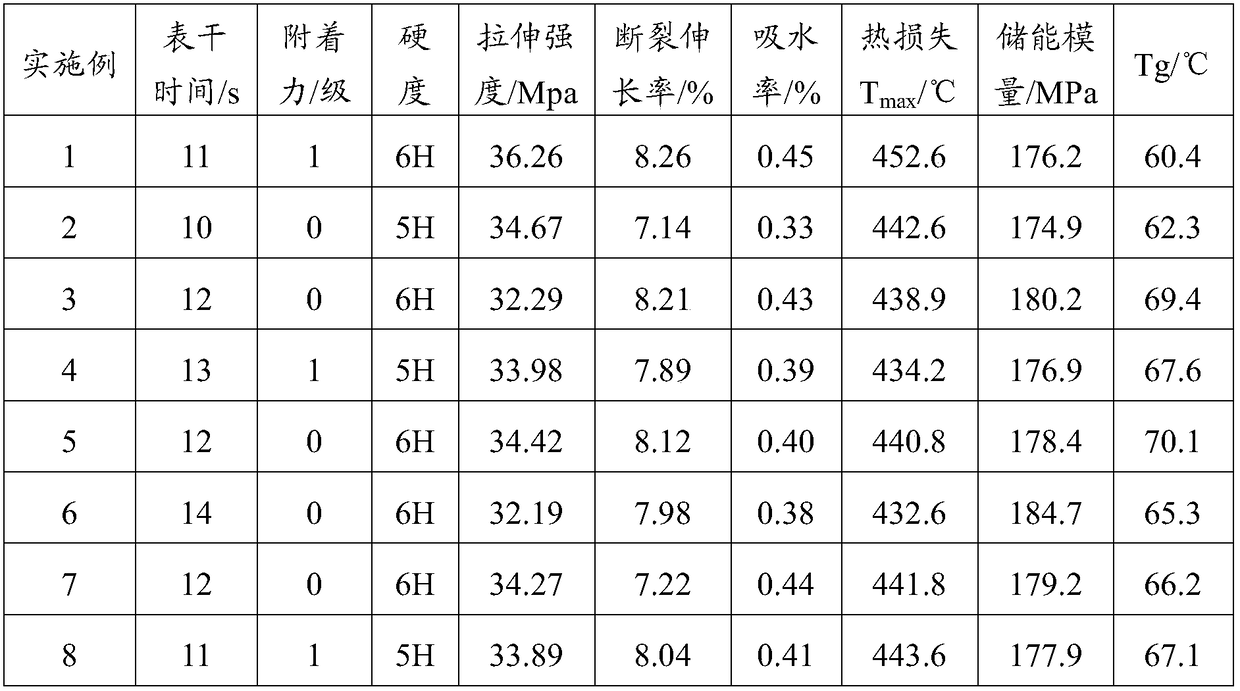

Examples

Embodiment 1

[0033] Embodiment 1 tung oil-based UV curing prepolymer

[0034] The preparation method comprises the following steps:

[0035] (1) In terms of parts by mass, add 31.2 parts of tung oil D-A reaction product and 1.8 parts of deionized water into a three-necked flask with a stirring device and a condensing device, mix well, and react at a temperature of 80°C and stirring 4h, completely hydrolyze the anhydride bond in the tung oil D-A reaction product, then add 74 parts of epichlorohydrin and 3.64 parts of benzyltriethylammonium chloride, raise the temperature to 110°C, keep the reaction for 3h, then lower the temperature to 65°C, keep warm for 10min, add 64 parts of sodium hydroxide and 176 parts of calcium chloride, stir and mix well, then react for 4 hours at a temperature of 65°C, after the reaction is completed, dissolve the reaction solution in acetone and filter it with diatomaceous earth. Then remove excess epichlorohydrin and acetone in the filtrate by rotary distillati...

Embodiment 2

[0037] Embodiment 2 castor oil-based UV curing prepolymer

[0038] The preparation method comprises the following steps:

[0039] (1) In terms of parts by mass, add 15.6 parts of castor oil D-A reaction product and 0.9 part of deionized water into a three-necked flask with a stirring device and a condensing device. React for 2 hours to completely hydrolyze the acid anhydride bond in the castor oil D-A reaction product, then add 37 parts of epichlorohydrin and 3.64 parts of benzyltriethylammonium chloride, raise the temperature to 90°C, keep the reaction for 2 hours, then lower the temperature Lower to 55°C, keep warm for 10 minutes, add 32 parts of sodium hydroxide and 88 parts of calcium chloride, stir and mix well, and react for 3 hours at a temperature of 55°C. After the reaction, dissolve the reaction solution with acetone and use diatomaceous earth Filter through filter paper, then remove excess epichlorohydrin and acetone in the filtrate by rotary distillation at 40°C t...

Embodiment 3

[0041] Embodiment 3 linseed oil-based UV curing prepolymer

[0042] The preparation method comprises the following steps:

[0043] (1) In terms of parts by mass, add 25.6 parts of linseed oil D-A reaction product and 1.5 parts of deionized water into a three-necked flask with a stirring device and a condensing device. React for 3 hours to completely hydrolyze the anhydride bonds in the linseed oil D-A reaction product, then add 56 parts of epichlorohydrin and 2.46 parts of benzyltriethylammonium chloride, raise the temperature to 100°C, keep the reaction for 2.5 hours, and then add Lower the temperature to 60°C, keep it warm for 10 minutes, add 48 parts of sodium hydroxide and 127 parts of calcium chloride, stir and mix well, and react at a temperature of 60°C for 3.5 hours. After the reaction, dissolve the reaction solution with dichloromethane Filter with diatomaceous earth filter paper, then remove excess epichlorohydrin and dichloromethane in the filtrate by rotary distil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com