DOPO-based symtriazine ring hydrogenated benzimidazole epoxy curing agent and preparation method thereof

A technology of benzimidazole epoxy and s-triazine, which is applied in the field of hydrogenated benzimidazole epoxy curing agent and its preparation, can solve the problem that it cannot be used to prepare flame-retardant epoxy resin, has large hydroxyl group hindrance, and has no curing effect. and other issues, to achieve the effect of improving the service temperature and mechanical properties, strong molecular rigidity, and improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

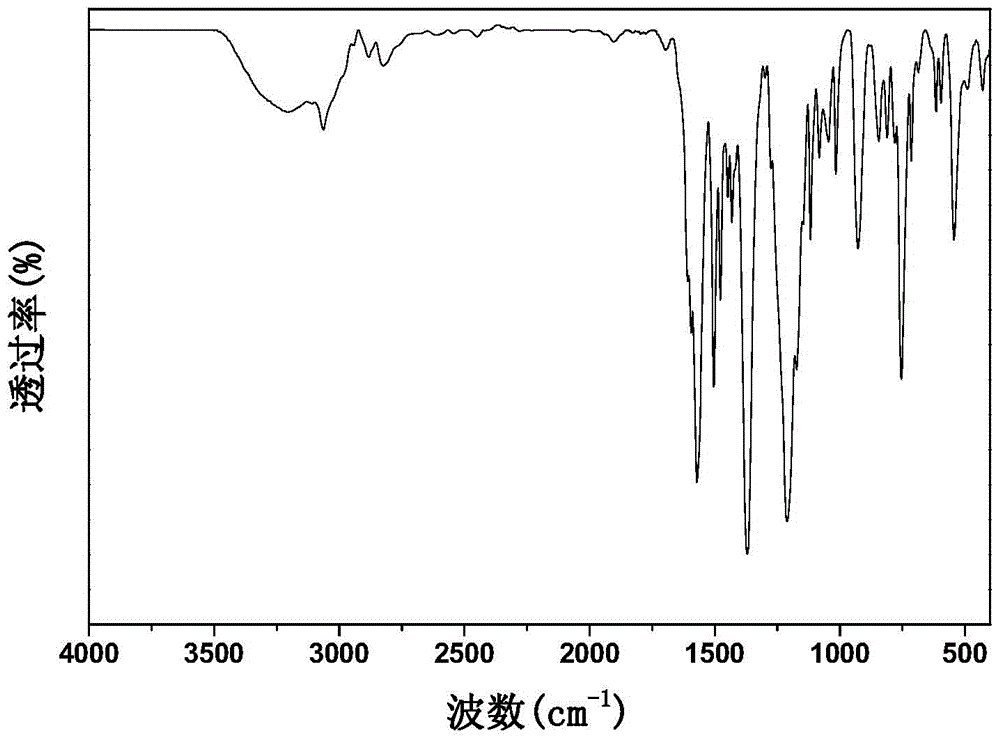

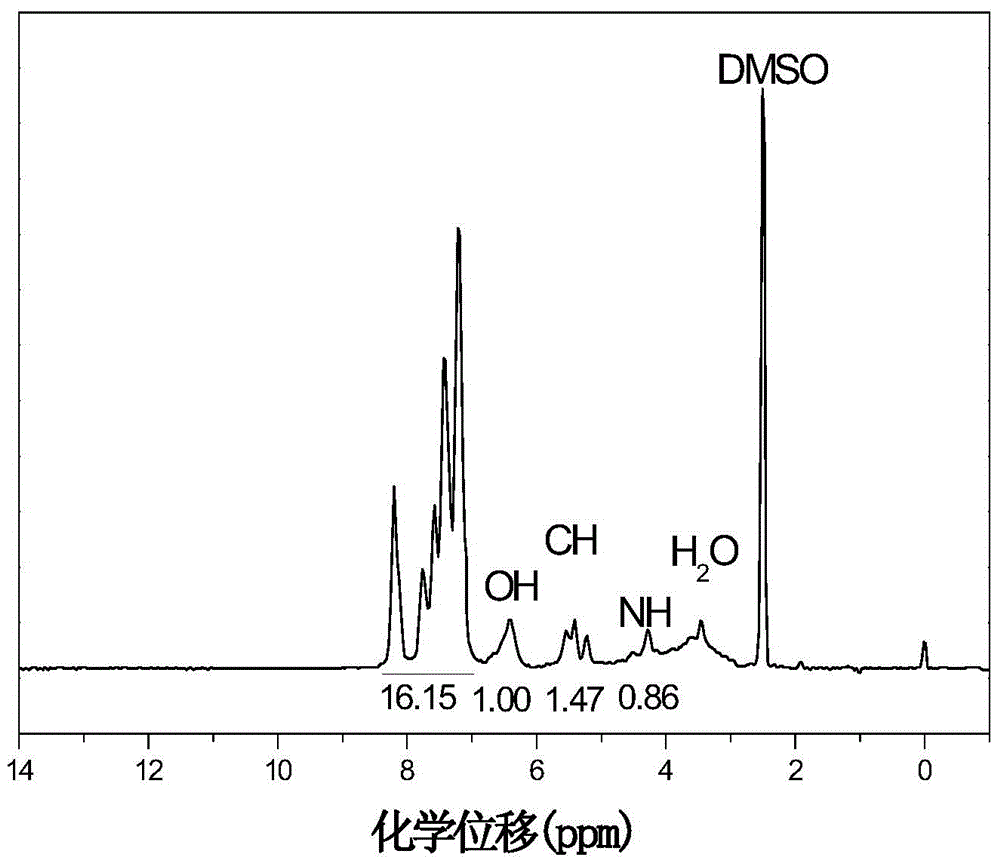

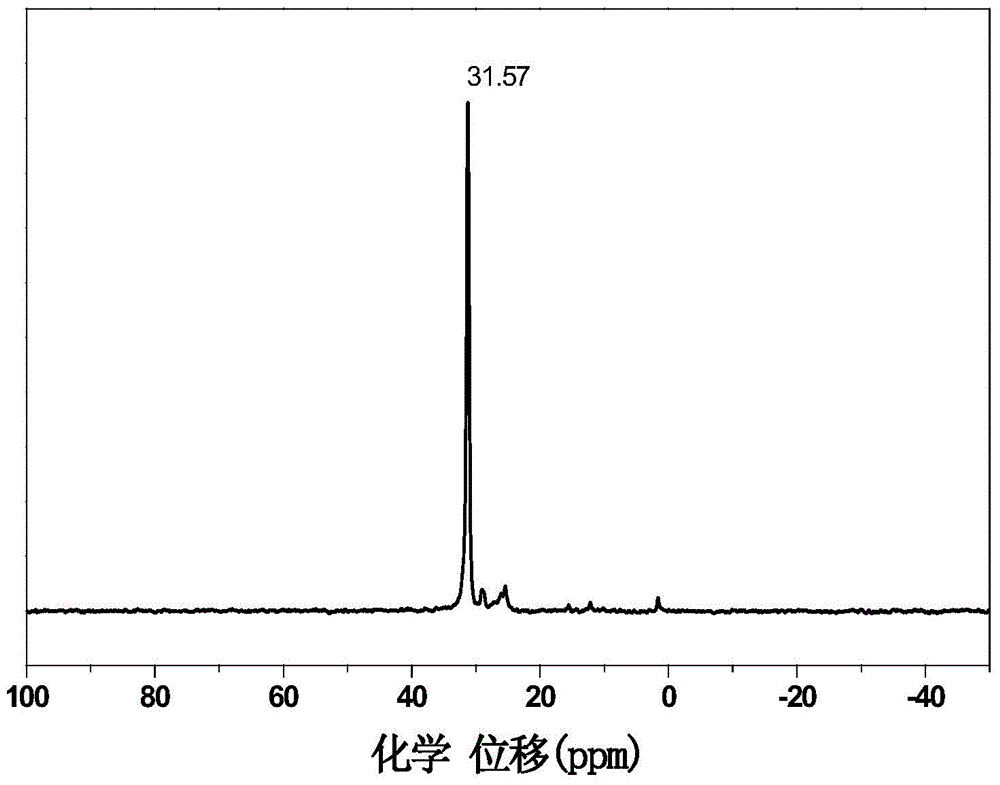

[0032] The first step, add 200ml of toluene and 18.5g of cyanuric chloride to the reaction kettle, after the cyanuric chloride is completely dissolved in toluene, add 35.5g of p-hydroxybenzaldehyde and 11.4g of sodium hydroxide, feed nitrogen, and heat to 50°C, reacted under stirring for 10 hours, cooled, filtered, and distilled the filtrate under reduced pressure to obtain a white solid, which was washed three times with deionized water, and then recrystallized with ethyl acetate to obtain a white needle-like crystal, which was Vacuum drying at 80°C for 12 h yielded 2,4,6-tris(4-formylphenoxy)-1,3,5-s-triazine ring, which was subjected to FT-IR, 1 H-NMR, 13 C-NMR and MS analysis, the results obtained are consistent with the results published by Ziya Erdem Koc et al. in Journal of Hazardous Materials183, (2010): 251-255.

[0033]In the second step, add 220ml of dioxane and 44.1g of 2,4,6-tri(4-formylphenoxy)-1,3,5-s-triazine ring into the reaction kettle, until 2,4,6 ‐Tris(4...

Embodiment 2

[0041] The first step, add 350ml of xylene and 18.5g of cyanuric chloride to the reaction kettle, then slowly add 34.2g of p-hydroxybenzaldehyde and 69g of potassium carbonate, feed nitrogen, heat to 70°C and reflux for 10 hours, cool and filter , the filtrate was distilled under reduced pressure, the resulting white solid was washed 3 times with deionized water and then recrystallized with ethyl acetate to obtain white needle crystals, which were dried in vacuum at 80°C for 12 hours to obtain 2,4,6-tri(4-aldehyde phenoxy)-1,3,5-s-triazine ring.

[0042] In the second step, add 260ml of acetonitrile and 47.5g of 2,4,6-tri(4-formylphenoxy)-1,3,5-s-triazine ring in the reaction kettle, add 44.3g of DOPO, and feed nitrogen, React at 80°C for 6 hours, remove acetonitrile by distillation under reduced pressure, wash the obtained solid twice with ethanol and ethyl acetate, and dry in vacuum at 80°C for 12 hours to obtain white powder DOPO-based aldehyde phenoxy-1,3,5-homo triazine ...

Embodiment 3

[0045] The first step is to add 250ml of dioxane and 18.5g of cyanuric chloride into the reaction kettle, then slowly add 40.3g of p-hydroxybenzaldehyde and 53g of sodium carbonate, blow in nitrogen, heat to 70°C, and stir for 10 hours , cooled, filtered, and the filtrate was distilled under reduced pressure, and the obtained solid was washed with deionized water for 3 times and then recrystallized with ethyl acetate to obtain white needle-like crystals, which were vacuum-dried at 80°C for 12 hours to obtain 2,4,6-tri( 4‐formylphenoxy)‐1,3,5‐s-triazine ring.

[0046] The second step, add 260ml of acetonitrile in the reactor to neutralize 47.5g of 2,4,6-tris(4-formylphenoxy)-1,3,5-s-triazine ring, add 44.3g of DOPO, and blow in nitrogen , reacted at 80°C for 6 hours, distilled off acetonitrile under reduced pressure, washed the obtained solid twice with ethanol and ethyl acetate, and dried in vacuum at 80°C for 12h to obtain white powder DOPO-based aldehyde phenoxy-1,3,5 ‐S-tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com