Cladded quartz sand fracturing support agent for oil production

A fracturing proppant and quartz sand technology, applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of low strength, low crushing resistance, high price, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

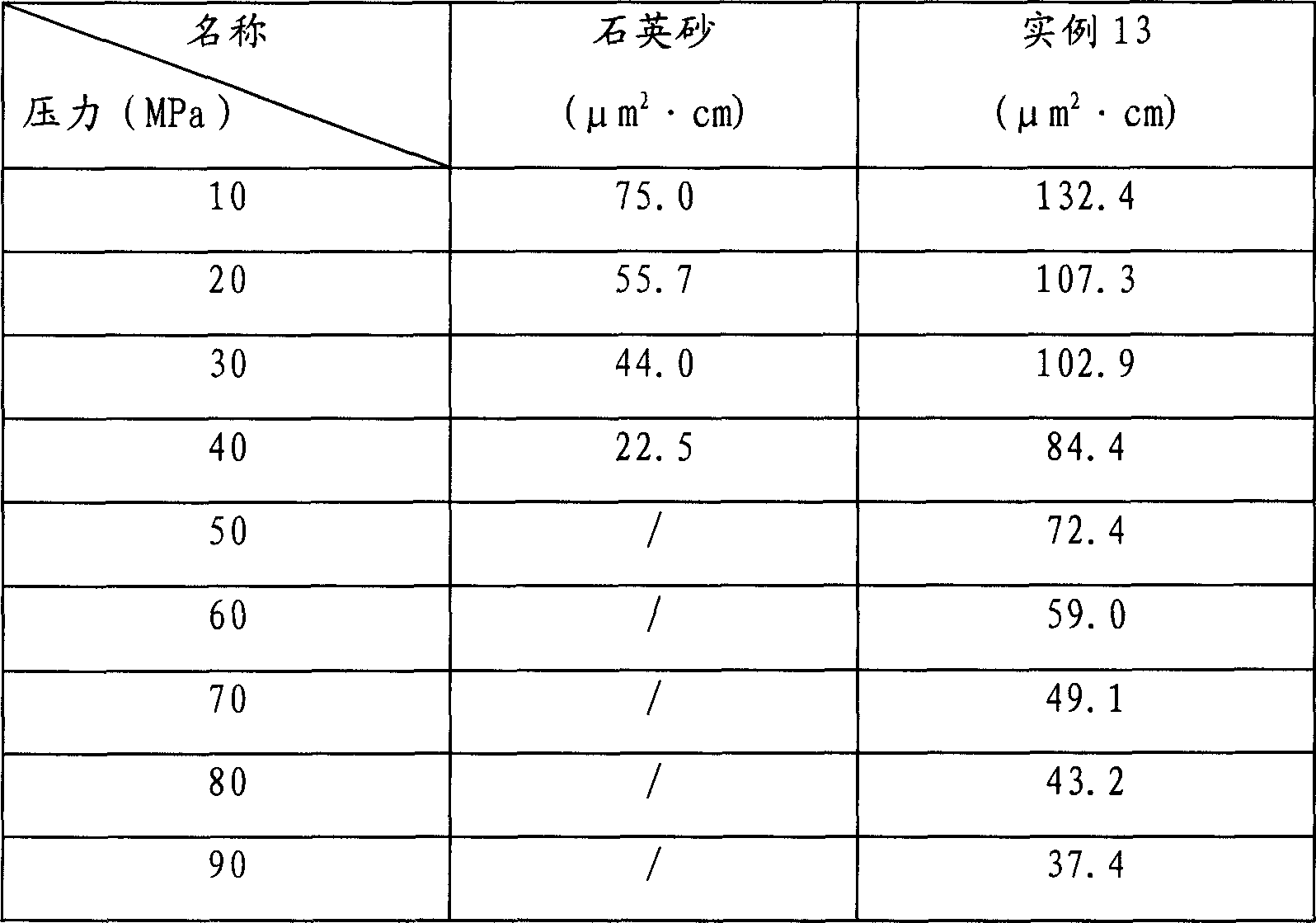

Examples

Embodiment 1

[0030] Heat 3kg of quartz sand 20 / 40 mesh to 260°C and put it into a sand mixer for stirring. When the temperature drops to 200°C, add 3g of phenolic resin and stir evenly, then add curing agent hexamethylenetetramine to cure the resin film. Add the lubricant calcium stearate and stir evenly before the resin starts to solidify and agglomerate (block). It is best to cool, crush and sieve to obtain the finished high-strength proppant.

[0031] The weight ratio of the added amount of calcium stearate to resin is 0.1:100, 0.5:100, 1:100, 5:100, 10:100 respectively.

Embodiment 2

[0033] Heat 3kg of quartz sand 20 / 40 mesh to 260°C and put it into a sand mixer for stirring. When the temperature drops to 200°C, add 30g of phenolic resin and stir evenly, then add curing agent hexamethylenetetramine to cure the resin film. Add the lubricant calcium stearate and stir evenly before the resin starts to solidify and agglomerate (block). It is best to cool, crush and sieve to obtain the finished high-strength proppant.

Embodiment 3

[0035] Heat 3kg of quartz sand 20 / 40 mesh to 260°C and put it into a sand mixer for stirring. When the temperature drops to 200°C, add 120g of phenolic resin and stir evenly, then add curing agent hexamethylenetetramine to cure the resin film. Add the lubricant calcium stearate and stir evenly before the resin starts to solidify and agglomerate (block). It is best to cool, crush and sieve to obtain the finished high-strength proppant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com