High-temperature resistant phenolic resin weak gel profile control plugging agent

A technology of profile control and water blocking agent and phenolic resin, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of formation damage, poor oil-water selectivity, etc., achieve long validity period, high gel strength, improve freezing The effect of glue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

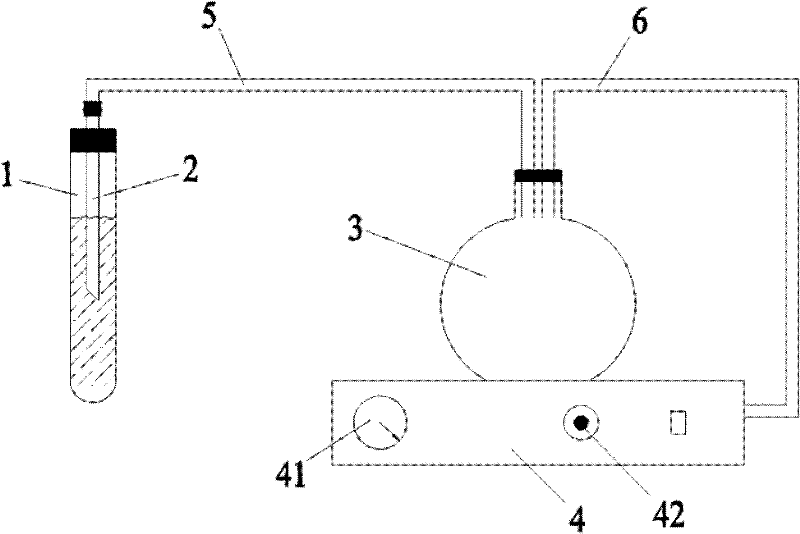

Image

Examples

Embodiment 1

[0060] Example 1. Selective plugging performance test of profile control water shutoff agent on rock core

[0061] This embodiment provides a profile control water shutoff agent, which is prepared according to the following steps:

[0062] Slowly add 0.5 g of anionic polyacrylamide (the polyacrylamide has a molecular weight of 1200, a degree of hydrolysis of 23%, and a solid content of 90%) into 98.6 ml of water, stir and mature for 3 hours, and then add 0.8 g A new type of phenolic resin cross-linking agent and 0.1 g of ammonium nitrate were stirred completely, and then transferred to a constant temperature oven at 70°C for 24 hours to obtain a profile control water shutoff agent.

[0063] The above-mentioned profile control and water shutoff agent was tested for selective plugging performance on rock cores. In this test, for low-permeability reservoirs, cores from low-permeability reservoirs are selected, and their permeability is shown in Table 3.

[0064] table 3

[006...

Embodiment 2

[0075] Embodiment 2, plugging strength test

[0076] This embodiment provides a profile control water shutoff agent, which is prepared according to the following steps:

[0077] Slowly add 0.5 g of anionic polyacrylamide (the polyacrylamide has a molecular weight of 1200, a degree of hydrolysis of 23%, and a solid content of 90%) into 98.6 ml of water, stir and mature for 3 hours, and then add 0.8 g The new phenolic resin cross-linking agent and 0.1 g of ammonium nitrate were stirred completely, transferred to a constant temperature oven at 70°C, and kept warm for 24 hours to obtain the profile control water shutoff agent.

[0078] A gel plugging experiment was carried out on the above-mentioned profile control water shutoff agent, in which the plugging strength of the gel can be described by the breakthrough pressure, and the specific test steps are as follows:

[0079] 1. Saturate the core with water;

[0080] 2. Under the external pressure of 4MPa, inject profile control ...

Embodiment 3

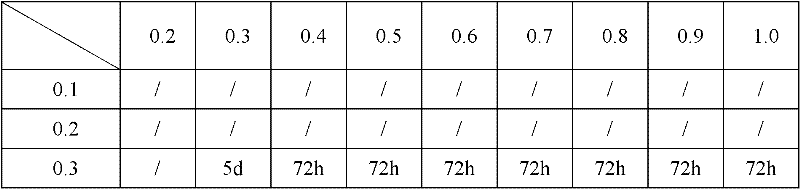

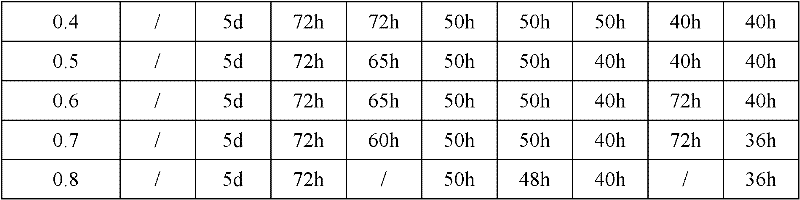

[0086] Embodiment 3, the influence test of degree of salinity on gel cross-linking performance

[0087] This embodiment provides a profile control water shutoff agent, which is prepared according to the following steps:

[0088] Will weigh 0.5 g of anionic polyacrylamide (the molecular weight of the polyacrylamide is 1200, the degree of hydrolysis is 23%, and the solid content is 90%), slowly added to 98.6 ml of four different simulated brines (the concentration of brine is as follows: (shown in Table 4) was stirred and matured for 3 hours, then added 0.8 grams of new phenolic resin crosslinking agent and 0.1 grams of ammonium nitrate and stirred completely, transferred to a constant temperature oven at 70°C for 24 hours to obtain four different profile control and plugging Aqua (see Table 6).

[0089] Different qualities of sodium chloride and calcium chloride were added to distilled water to prepare simulated brine with different salinity, and the salinity was characterized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com