Catalyst, preparation method thereof and Fischer-Tropsch method

A catalyst and catalyst carrier technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as poor selectivity of Fischer-Tropsch reaction catalysts, and achieve selectivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] According to the preparation method of the catalyst provided by the present invention, the method comprises using the first catalyst carrier powder and / or the first catalyst carrier precursor powder to prepare the inner core, and the second catalyst carrier powder and / or the compound loaded with the active metal component The second catalyst support precursor powder is coated on the inner core, wherein the first catalyst support powder and / or the first catalyst support precursor powder and the second catalyst support powder material and / or the second catalyst support precursor Powder is the same.

[0018] The diameter of the inner core is 1-6mm, preferably 1.5-4mm, and the amount of the second carrier catalyst powder makes the thickness of the outer layer 0.05-3mm, preferably 0.1-1.5mm. The amount of the compound of the active metal component is such that, based on the total weight of the catalyst, the content of the active metal component is 1-60%, preferably 5-50%, in...

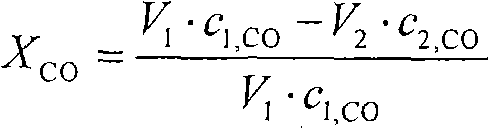

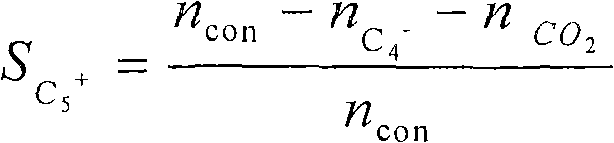

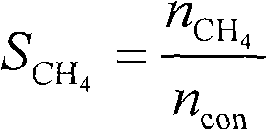

Embodiment 1

[0031] The powders used are pseudo-boehmite (SB powder from Sasol Company). First, use a 1.5mm cylindrical orifice to extrude on a twin-screw extruder. After the extruded strips are balled into balls, measure the average The diameter is 3mm, and the SB powder that is used to form a ball is 125 grams altogether. Immerse 28 grams of unroasted pseudo-boehmite in 13 milliliters of cobalt nitrate solution with a mass concentration of 4.9 mol / L. After drying, add 1 gram of water to every 3 grams of pseudo-boehmite. Add water to the pseudo-boehmite powder of cobalt nitrate, and spray the powder into the ball forming machine. Afterwards, the sample was dried at 140° C. for 4 hours and calcined at 300° C. for 4 hours to obtain catalyst Al. The average diameter of the inner core is 3mm, and the average thickness of the outer layer is 0.10mm.

Embodiment 2

[0033] The powders used are all pseudo-boehmite (CL powder from Changling Catalyst Factory). First, use a 1.5mm cylindrical orifice plate to extrude on a twin-screw extruder. The average diameter of the ball is 3mm, and the CL powder used to form a ball is 125 grams in total. Immerse 56 grams of unroasted pseudo-boehmite in 30 milliliters of ferric nitrate solution with a mass concentration of 4 mol / L. After drying, add 1 gram of water to every 2 grams of pseudo-boehmite. Add water to the pseudo-boehmite powder of ferric nitrate, and spray the powder into the ball forming machine. Afterwards, the sample was dried at 140°C for 4 hours and calcined at 410°C for 4 hours to obtain catalyst A2. The average diameter of the inner core is 3mm, and the average thickness of the outer layer is 0.2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com