Modification Method of Single Hydroxyl Functionalization of Fluorine Resin

A fluorine-containing resin and hydroxyl functional technology, which is applied in the field of modification of single hydroxyl functional group, and can solve problems such as poor selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

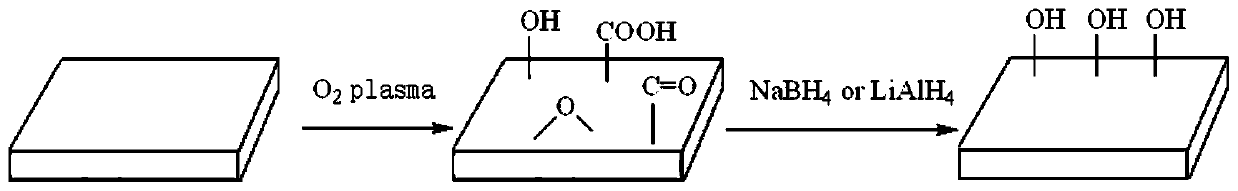

[0027] Modification methods for single hydroxyl functionalization of fluorine-containing resins, including:

[0028] (1) Process the fluororesin F2314 into a thin film with a thickness of 1 μm, put it into the substrate stage of the vacuum chamber of the plasma reactor, evacuate to 1Pa, then pass oxygen until the pressure of the vacuum chamber reaches 10Pa, the irradiation time (etching time) ) is 200s, and the irradiation power is 150W. Stop the discharge, and take out the film after venting with oxygen.

[0029] (2) Dissolve the treated film in anhydrous tetrahydrofuran, add the same mass of sodium borohydride and react at 15° C. for 0.5 hour. After the reaction, the solution was added dropwise to a large amount of distilled water. After the precipitation was complete, the precipitate was washed repeatedly and dried for later use.

Embodiment 2

[0031] Modification methods for single hydroxyl functionalization of fluorine-containing resins, including:

[0032] (1) Process the fluororesin F2314 into a thin film with a thickness of 5 μm, put it into the substrate stage of the vacuum chamber of the plasma reactor, evacuate to 1Pa, then pass oxygen until the pressure of the vacuum chamber reaches 10Pa, the irradiation time (etching time) ) is 200s, and the irradiation power is 150W. Stop the discharge, and take out the film after venting with oxygen.

[0033] (2) Dissolving the treated film in anhydrous tetrahydrofuran, adding the same mass of lithium aluminum hydride and reacting at 15° C. for 3 hours. After the reaction, the solution was added dropwise into a large amount of ethanol, and the precipitate was washed repeatedly after the precipitation was complete, and dried for later use.

Embodiment 3

[0035] Modification methods for single hydroxyl functionalization of fluorine-containing resins, including:

[0036] (1) Process the fluororesin F2314 into a thin film with a thickness of 10 μm, put it into the substrate stage of the vacuum chamber of the plasma reactor, evacuate to 1Pa, then pass oxygen until the pressure of the vacuum chamber reaches 10Pa, the irradiation time (etching time) ) is 600s, and the irradiation power is 250W. Stop the discharge, and take out the film after venting with oxygen.

[0037] (2) Dissolving the treated film in anhydrous tetrahydrofuran, adding the same mass of lithium aluminum hydride and reacting at 15° C. for 1.5 hours. After the reaction, the solution was added dropwise to a large amount of distilled water. After the precipitation was complete, the precipitate was washed repeatedly and dried for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com