Movable-arm-type powder bed powder spreading device

A technology of powder spreading device and moving arm, which is applied in the direction of loading/unloading, transportation and packaging, etc. It can solve the problems of low speed of powder spreading device, low material utilization rate, and affecting work reliability, so as to save the time of powder transportation, The powder spreading structure design is simple to ensure the smooth effect of powder spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

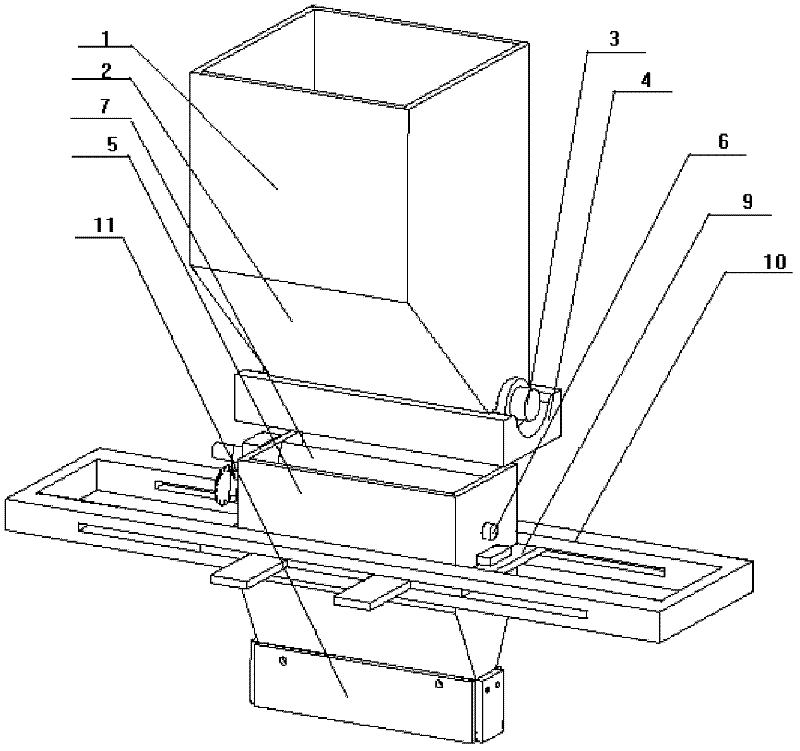

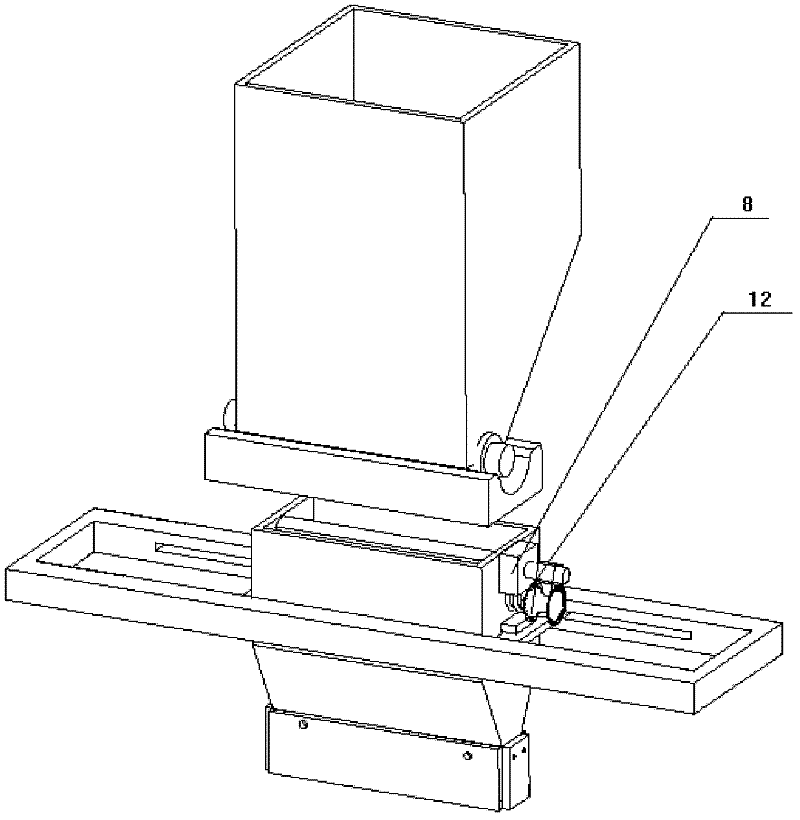

[0034] The device of the invention includes a quantitative powder feeding device, a transmission device and powder spreading equipment. The structure of each part of the present invention will be described in more detail below by means of examples, but the following examples are only illustrative, and the protection scope of the present invention is not limited by these examples.

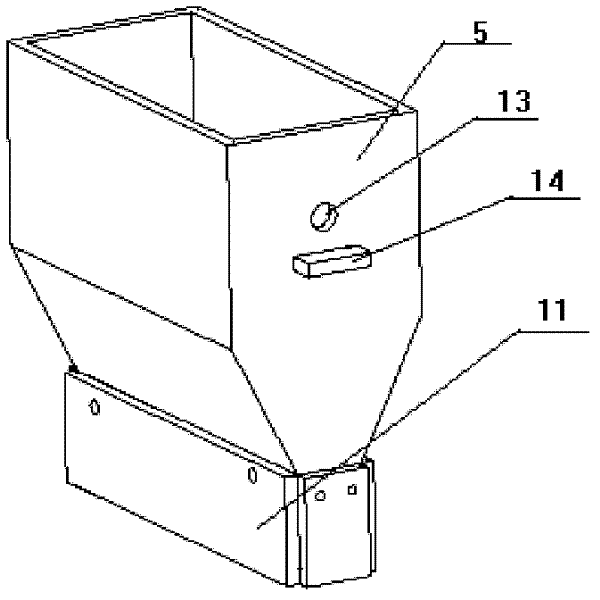

[0035] Such as figure 1 As shown, the quantitative powder feeding device includes a powder storage box 1, a powder feeding roller 3, a fixed plate 4, and is equipped with a corresponding rotating motor. The powder storage box 1 is fixed above the working chamber. The powder storage box 1 is funnel-shaped. 4 is provided with a powder outlet corresponding to the powder outlet at the bottom of the powder storage box 1, which plays a role in quantitative powder feeding. The powder feeding roller 3 is installed between the powder outlet and the fixed plate 4, and is driven by an external rotating motor....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com