Spatial resolution pressure intensity measurement system and method based on vacuum holographic optical tweezers

A space resolution and measurement system technology, applied in vacuum gauges, measuring devices, measuring fluid pressure, etc., can solve problems that are difficult to achieve and achieve good measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

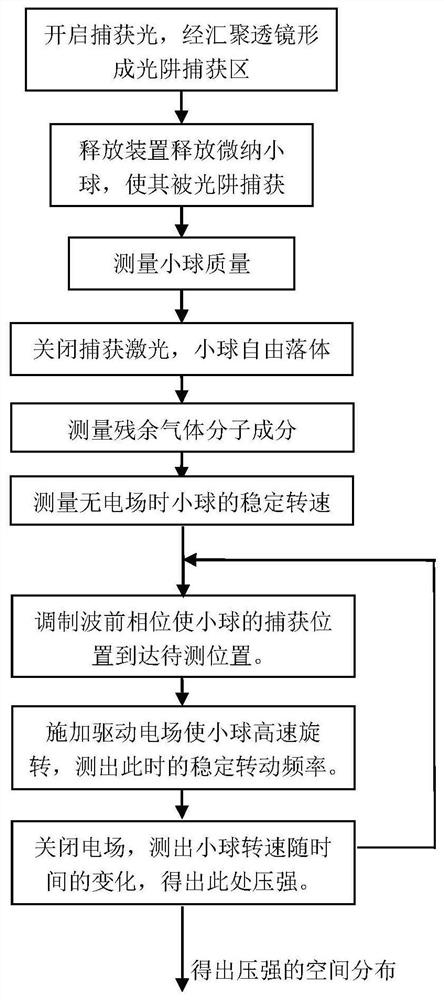

[0057] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

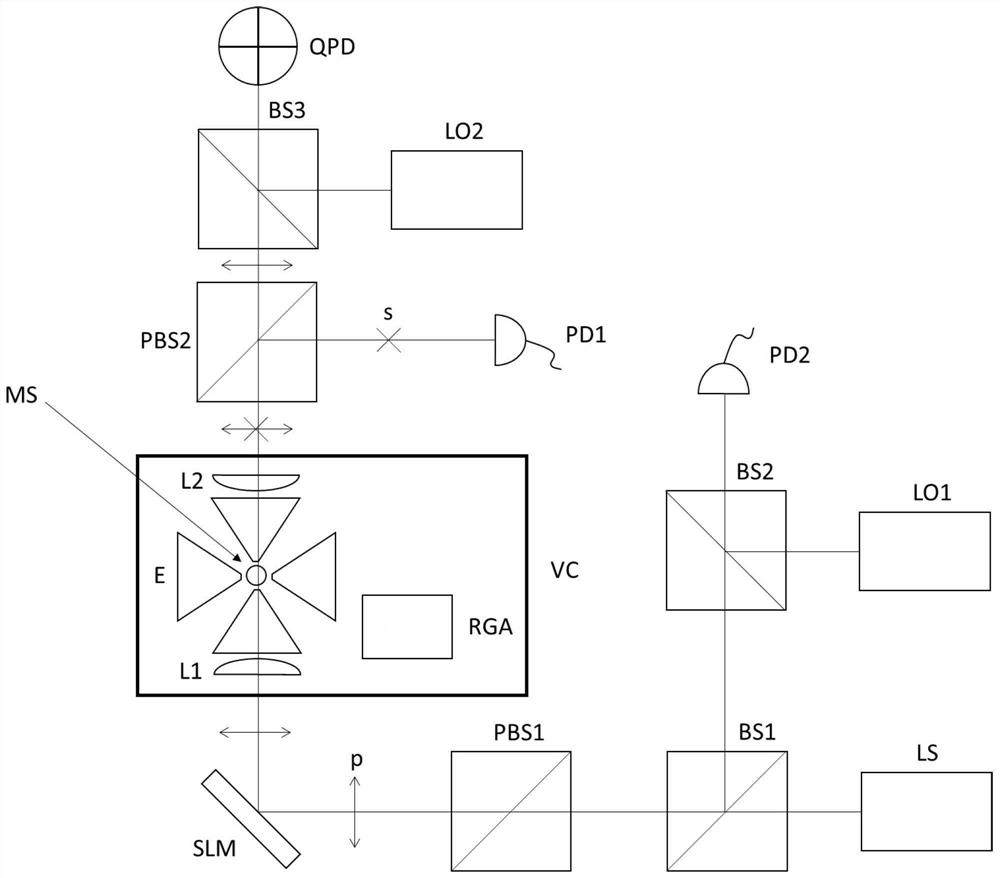

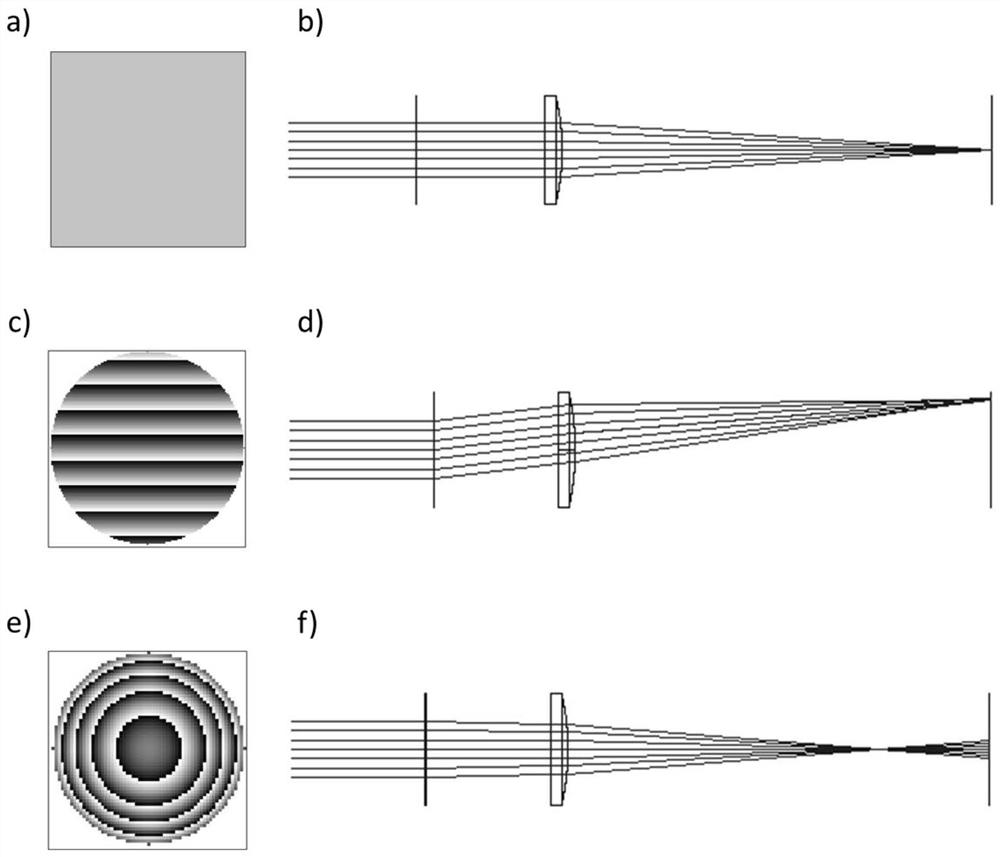

[0058] The vacuum holographic optical tweezers space-resolved pressure measurement system includes vacuum chamber VC, micro-nano particles MS, optical tweezers device and feedback cooling device, driving electric field device E, spatial light modulator SLM, polarization control and detection device and residual gas analyzer RGA; The driving electric field device E includes six electrodes, the polarization control and detection device includes a polarization control device and a polarization detection device, the polarization control device uses a first polarization beam splitter PBS1, and the polarization detection device includes a second polarization beam splitter PBS2 and a first photodiode PD1 , the first photodiode PD1 is used to detect optical signals, the optical tweezers device includes the first convex lens L1 and the second convex lens L2; the opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com