Welding condition monitoring device

a condition monitoring and welding technology, applied in the direction of manufacturing tools, non-electric welding apparatus, television systems, etc., can solve the problems of insufficient image contrast, inability to present a complete image distinctly showing both the high luminance welding portion and the low luminance bead portion, and the object image taken by a single ccd camera does not allow the observer to grasp the welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

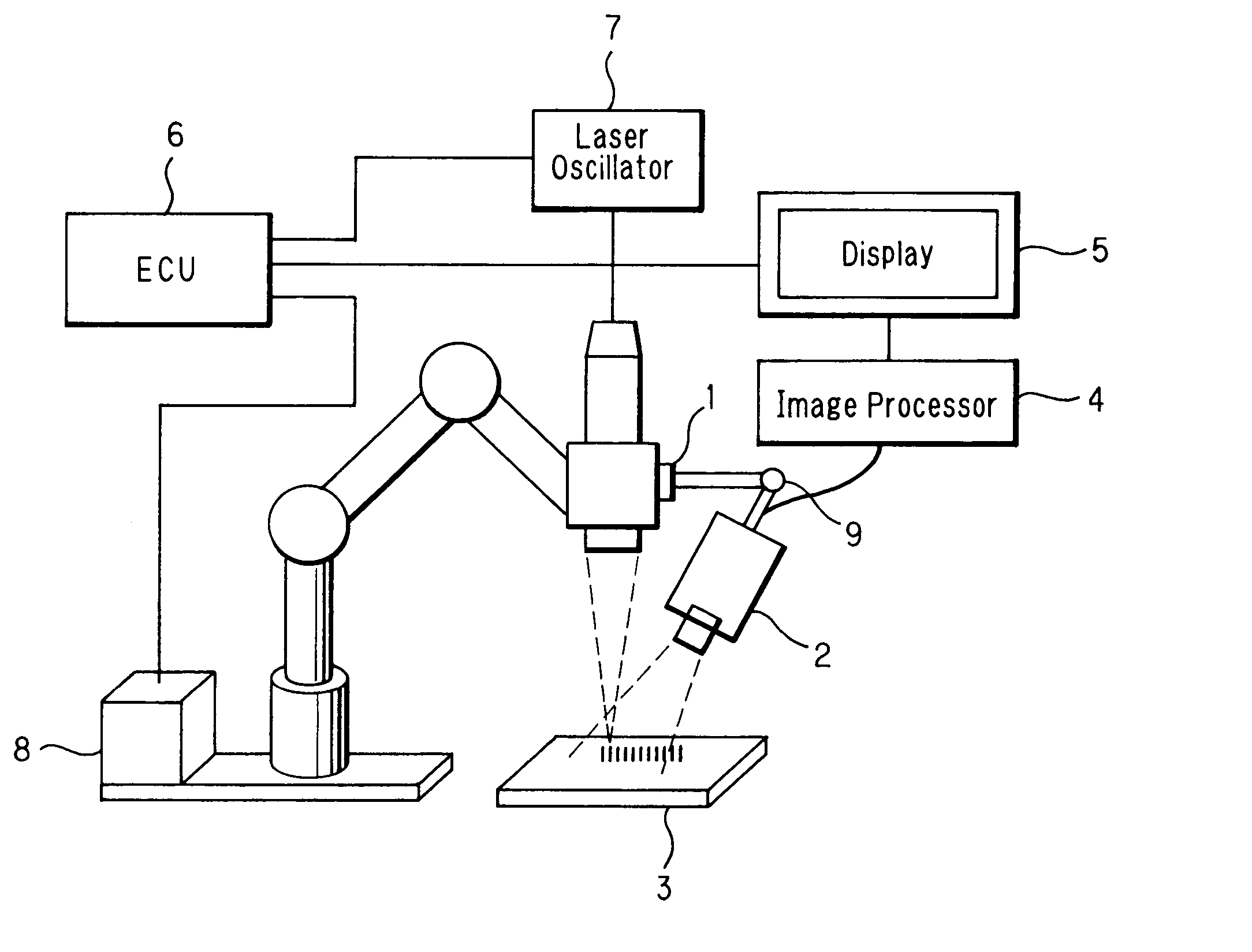

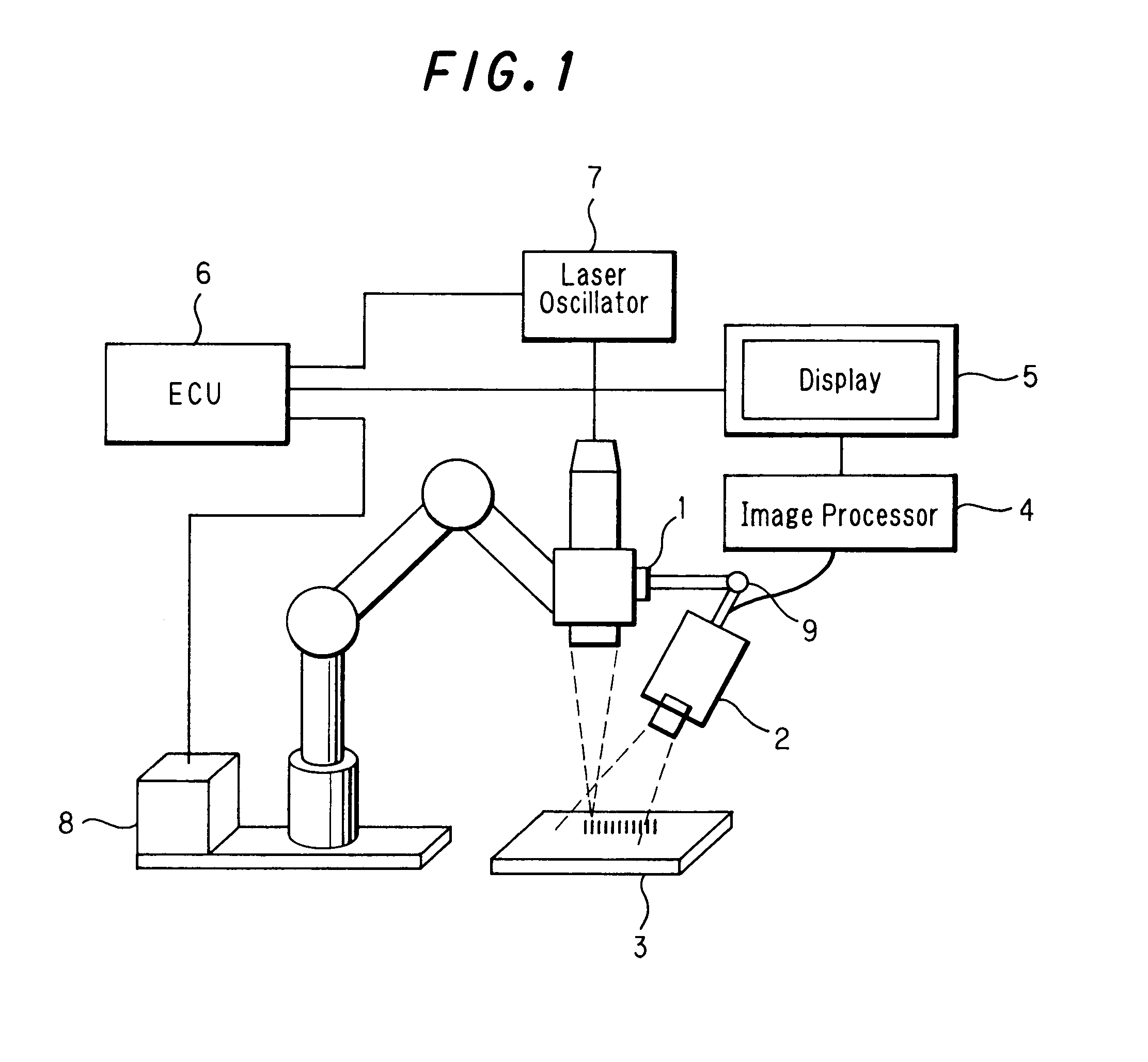

[0065]FIG. 1 illustrates an exemplary construction of a welding condition monitoring system in which a CMOS type camera 2 comprising an image sensor is attached to a portion of a welding head 1 of a laser beam welding robot for taking an image of a welding work portion of members 3 to be joined together. The image taken by the camera is transferred to an image processing unit 4 whereby it is processed and then displayed on a screen of a display unit 5. At the same time, the image processing unit 4 examines the welding condition based on data from the image taken by the CMOS camera and transfers the resultant data to an electronic control unit (ECU) 6 which in turn changeably controls parameters of welding conditions such as a welding position and laser beam intensity in accordance with the observed welding state. In FIG. 1, numerals 7 and 8 designate a laser oscillator and a robot driver respectively. All components are operated under the control from the ECU 6.

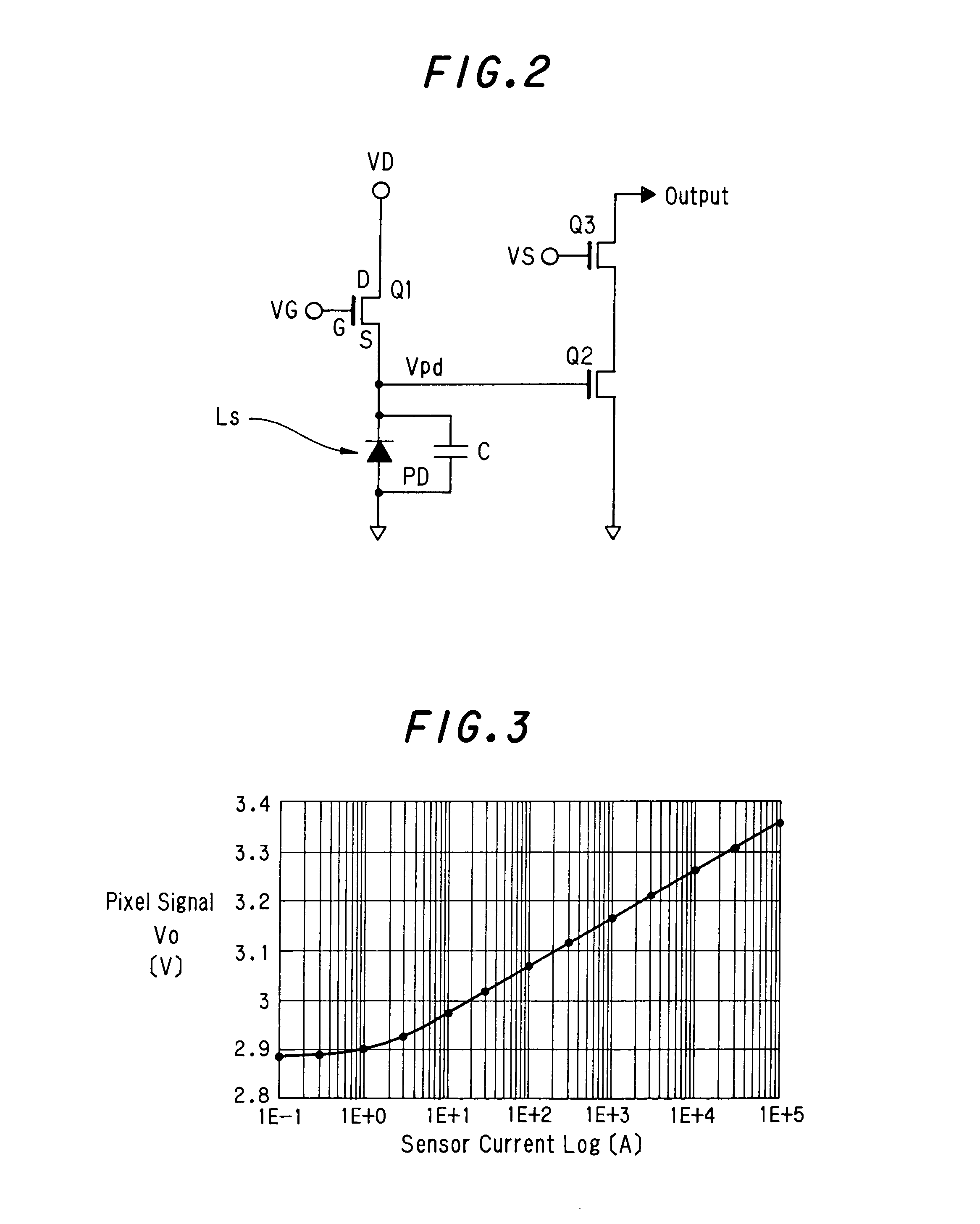

[0066] The CMOS type...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com