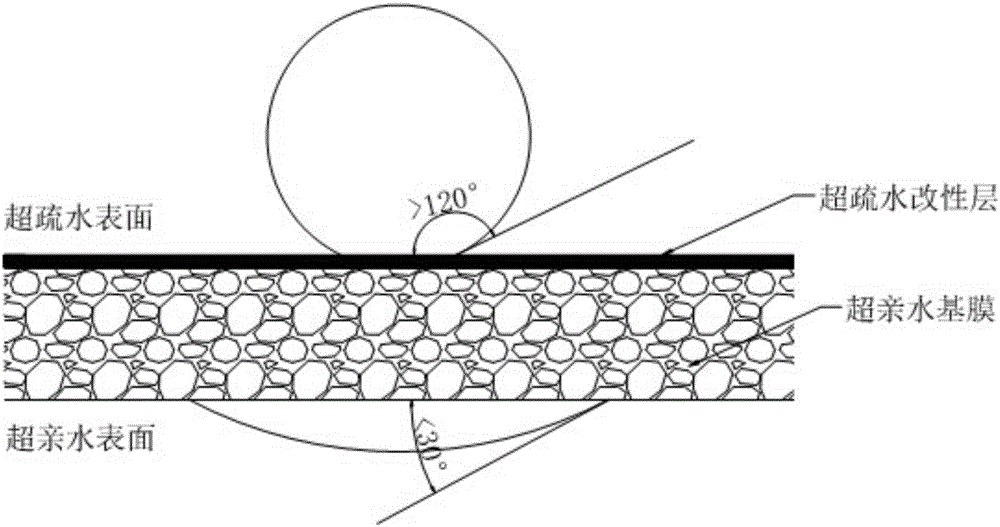

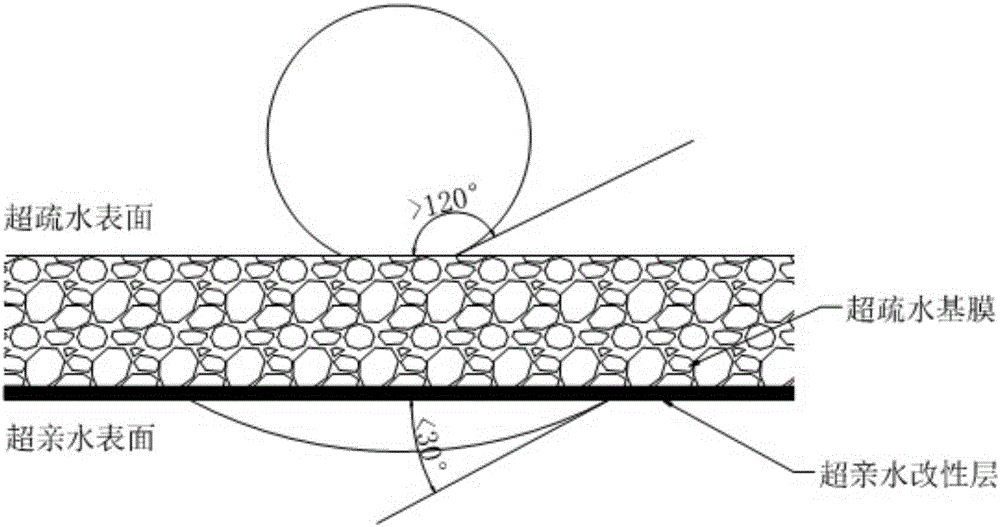

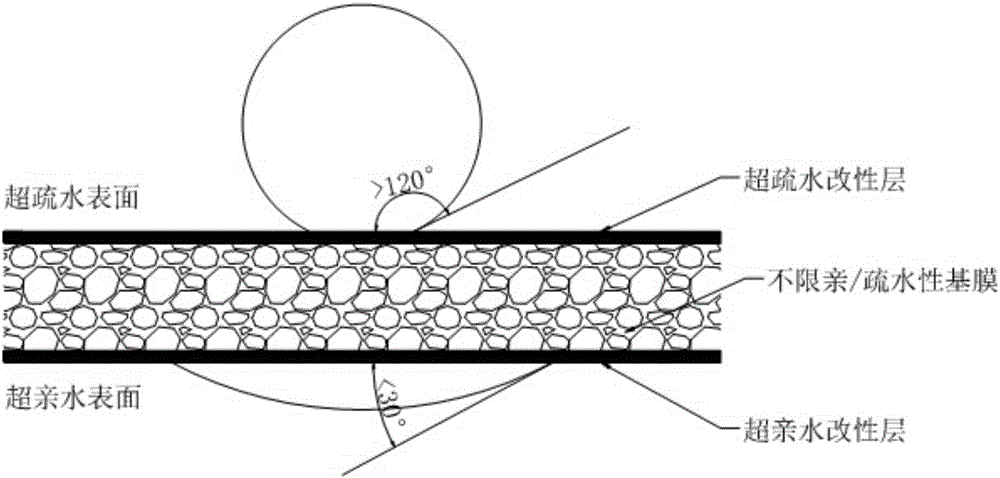

Asymmetric ultra-hydrophilic/hydrophobic dual-property polymer membrane and preparation method thereof

A polymer membrane, asymmetric technology, applied in the field of membrane separation, can solve problems such as impermeability of water droplets, achieve the effect of improving water permeability, reducing direct contact sites and adhesion properties, and improving anti-pollution properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The super-hydrophilic polysulfone hollow fiber gradient membrane (Nanjing Jialejing Membrane Technology Co., Ltd., PS6040) with an average pore size of 0.9 μm, a porosity of 60%, and a film thickness of 200 μm (that is, an inner diameter of 400 μm and an outer diameter of 600 μm) was used as Polymer base film, the modified liquid used is 10wt% glycerol / water mixed solution of fluorine-containing polyurethane copolymer, the mixed volume ratio is 1:15 (v / v), and the surface is hydrophobized by dip coating Modification, wherein the immersion time is controlled at 10min, and its various properties are measured after drying.

[0036] The water contact angle of the superhydrophilic side of the prepared superphilic / hydrophobic amphipathic polymer membrane is 15°, and the water contact angle of the superhydrophobic side is 125°; the water flux on the superhydrophobic side is greater than 10540L / m 2 h 0.1MPa; the water flux on the reverse super-hydrophilic side is less than 6800...

Embodiment 2

[0038] A hydrophilic polysulfone hollow fiber gradient membrane (Nanjing Jialejing Membrane Technology Co., Ltd., PS4530) with an average pore size of 0.5 μm, a porosity of 60%, and a film thickness of 150 μm (that is, an inner diameter of 300 μm and an outer diameter of 450 μm) was used for polymerization The material-based film, the modified liquid used is 12wt% glycerin / water mixed solution of fluorine-containing acrylate copolymer, the mixed volume ratio is 1:20 (v / v), and the surface is hydrophobicized by suction filtration and adsorption. Modification, wherein the suction filtration time is controlled at 60s, and its various properties are measured after drying.

[0039] The water contact angle on the hydrophilic side of the prepared superphilic / hydrophobic amphoteric polymer membrane is 15°, and the water contact angle on the hydrophobic side is 132°; the water flux on the superhydrophobic side is greater than 10080L / m 2 h 0.1MPa; the water flux on the reverse super-hyd...

Embodiment 3

[0041] The super-hydrophilic polyethersulfone flat membrane with an average pore diameter of 0.25 μm, a porosity of 40%, and a film thickness of 300 μm is used as the polymer base membrane, and the modified liquid used is 25 wt% polydimethylsiloxane Methanol / ether mixed solution, the mixing volume ratio is 1:3 (v / v), and its surface is modified by surface transfer printing. The transfer template uses a 60-mesh nylon mesh, which is measured after roller drying. Various properties.

[0042] The prepared superphilic / hydrophobic amphoteric polymer membrane has a water contact angle of 30° on the hydrophilic side and a water contact angle of 120° on the hydrophobic side; the water flux on the superhydrophobic side is greater than 8415L / m 2 h 0.1MPa; the water flux on the reverse super-hydrophilic side is less than 5100L / m 2 ·h·0.1MPa, the water flux on the forward super-hydrophobic side is 65% higher than that on the reverse super-hydrophilic side, and the cleaning water flux reco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com