Drainage plate for silt consolidation, filter cloth and drainage plate core

A technology for drainage boards and plastic drainage boards, which can be used in basic structure engineering, soil protection, construction, etc. It can solve the problems of drainage channel failure, core board cracking and tear resistance, and filter cloth aperture can not be adjusted, so as to improve the effective use Long life, improve lateral pressure resistance, and prevent poor drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

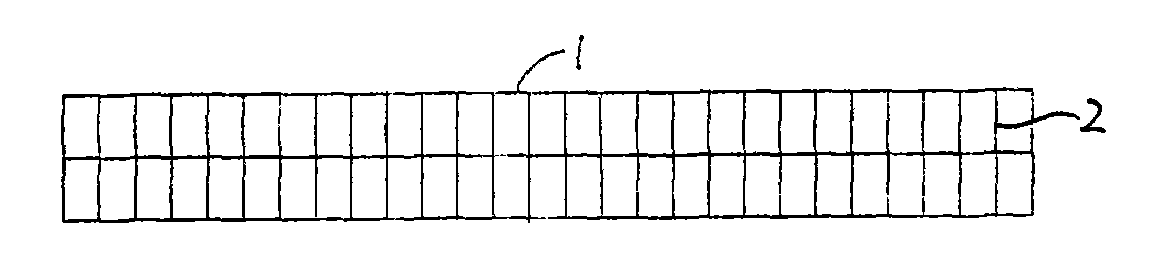

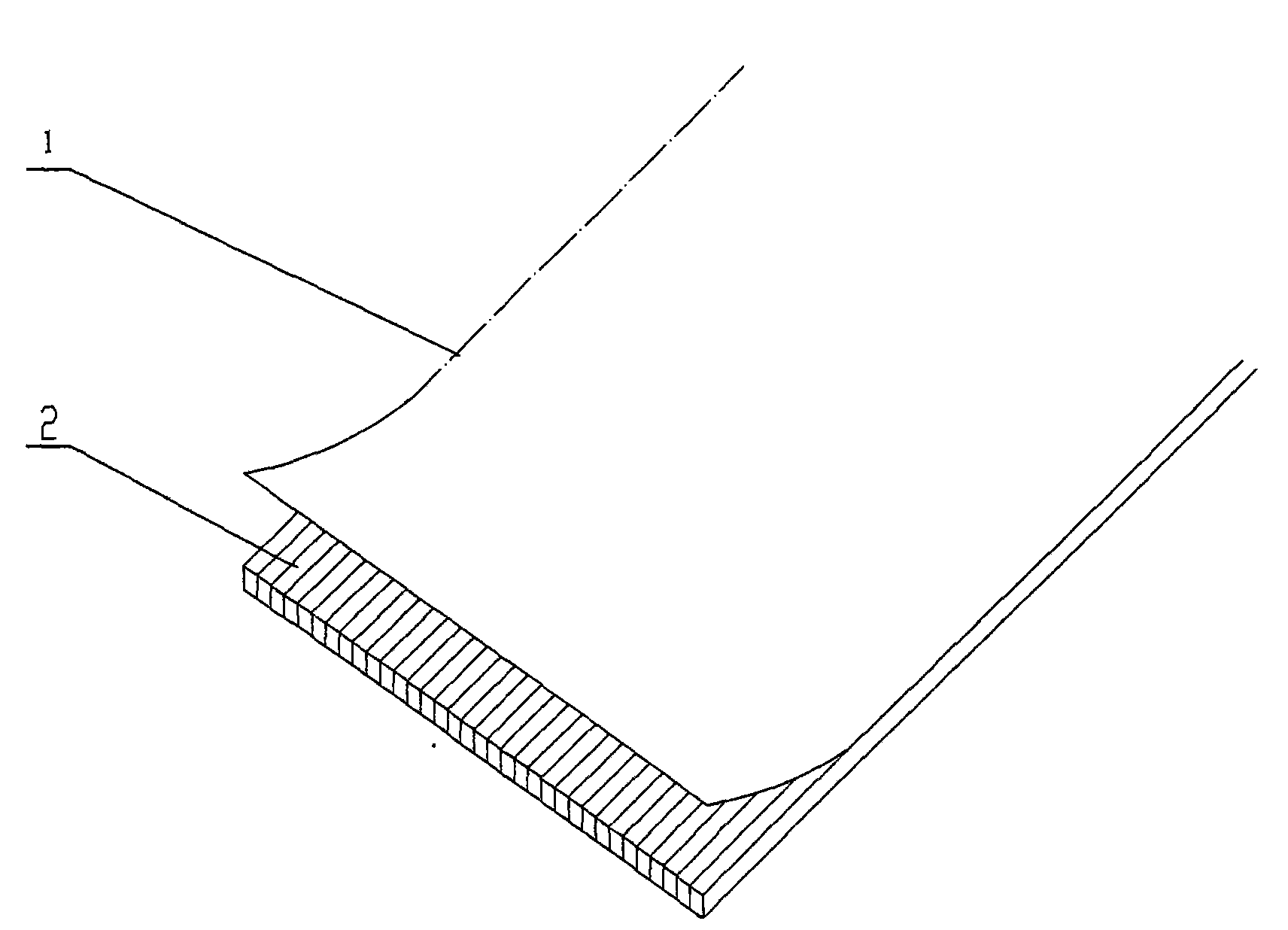

[0019] Embodiment: Referring to the accompanying drawings, the drainage board for sludge consolidation of the present invention, the fibrous silk hot-pressed flat microporous filter cloth 1 is bonded to the harmonica core 2 of the co-polypropylene pultruded ribs on both sides by hot-melt pressure bonding.

[0020] The filter cloth is composed of four kinds of staple fibers with a fiber length of 30-50mm mixed and hot-pressed, of which 40wt% silk diameter is 8D polyester staple fiber, 20wt% silk diameter is 3D polyester staple fiber, 30wt% silk diameter is 4D polypropylene staple fiber, 10wt The % wire diameter is 6D bamboo fiber, mixed evenly and paved to a thickness of about 20-40cm, needle-punched and compressed into a felt, and formed by a flat roll through 180°C hot pressing to obtain a fiber microporous filter cloth felt (chaotic silk felt), with an average pore size of 85 μm .

[0021] The harmonica core is pultruded from co-polypropylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com