Water scour-resistant superhydrophobic composite membrane and preparation method and application thereof

A super-hydrophobic and water-scouring technology, applied in textiles and papermaking, complete sets of equipment for the production of artificial threads, filament/thread forming, etc., can solve problems such as loss of application value, loss of superhydrophobic properties of materials, etc., and achieve great potential for economic benefits , Excellent water erosion resistance, simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

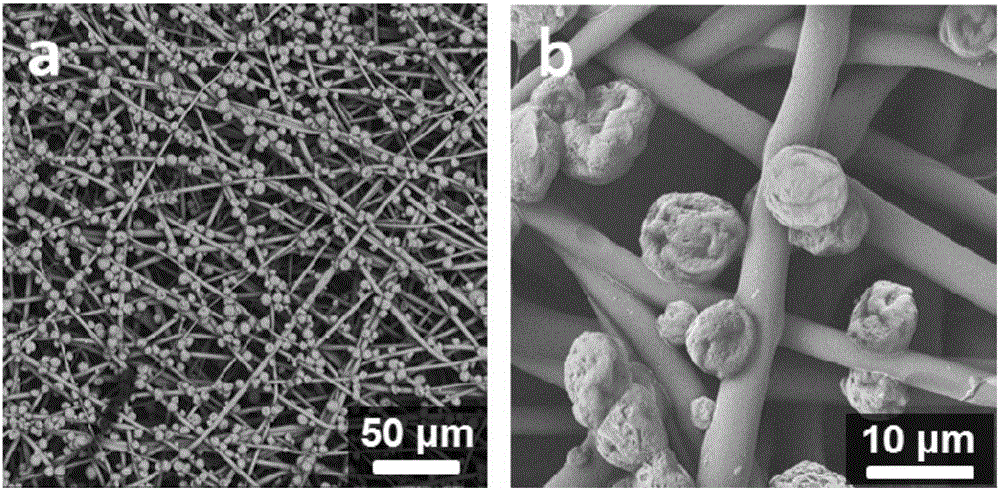

[0045] (1) The triblock copolymer polystyrene-poly(ethylene-butylene)-polystyrene (SEBS, M w =8.45×10 4 g / mol, the block volume ratio of PS is 30%) dissolved in tetrahydrofuran (THF), the concentration of SEBS is controlled to be 14wt%, after the solution is prepared, it is stirred at 25°C for 6-8 hours to a uniform spinning solution; Spin this solution to prepare SEBS fibers, control the feed rate of the solution to be 2mL / h, the spinning voltage to be 10kV, the collection distance to be 15cm, the ambient temperature to be 25°C, and the ambient humidity to be 50%. 20 cm, drum rotation speed 50r / min, the solution was electrospun for 20 min to prepare SEBS fiber membrane. The average fiber diameter is 8 μm.

[0046] (2) The same SEBS is dissolved in tetrahydrofuran (THF) and N,N-dimethylformamide (DMF), the mass concentration of SEBS is controlled to be 14wt%, the mass ratio of THF and DMF is 80:20, and the solution is prepared Stir at 25 DEG C for 6 to 8 hours to a homogene...

Embodiment 2

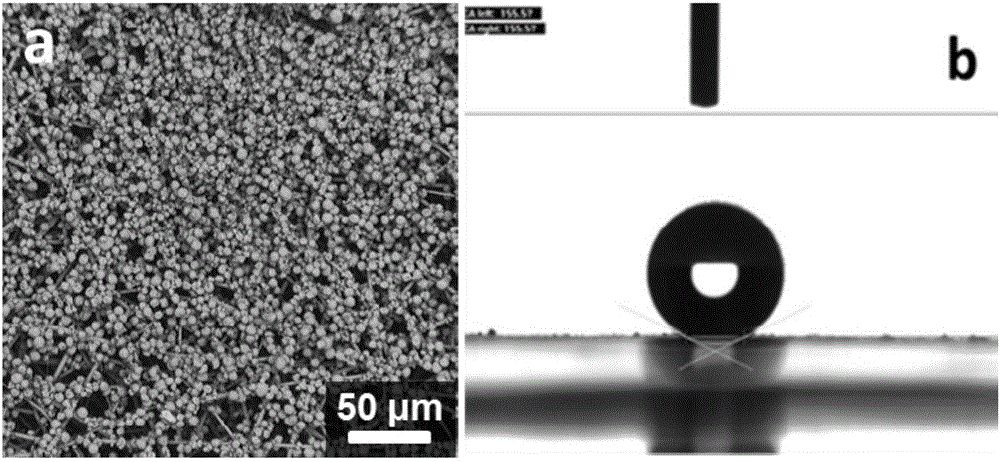

[0049] (1) The triblock copolymer polystyrene-poly(ethylene-butylene)-polystyrene (SEBS, M w =8.45×10 4 g / mol, the block volume ratio of PS is 30%) dissolved in tetrahydrofuran (THF), the concentration of SEBS is controlled to be 14wt%, after the solution is prepared, it is stirred at 25°C for 6-8 hours to a uniform spinning solution; This solution is spun to prepare SEBS fiber, and the feeding rate of control solution is 2mL / h, and spinning voltage is 20kV, and collection distance is 20cm, and ambient temperature is 25 ℃, and ambient humidity is 50%, adopts flat-plate yarn take-up device to collect, the The SEBS fiber membrane was prepared by solution electrospinning for 20min. The average fiber diameter is 8 μm.

[0050] (2) The same SEBS is dissolved in tetrahydrofuran (THF) and N,N-dimethylformamide (DMF), the mass concentration of SEBS is controlled to be 14wt%, the mass ratio of THF and DMF is 80:20, and the solution is prepared Stir at 25 DEG C for 6 to 8 hours to a ...

Embodiment 3

[0053] (1) The triblock copolymer, polystyrene-ethylene-butylene-styrene (SEBS, M w =8.45×10 4 g / mol, the block volume ratio of PS is 30%) dissolved in tetrahydrofuran (THF), the concentration of SEBS is controlled to be 14wt%, after the solution is prepared, it is stirred at 25°C for 6-8 hours to a uniform spinning solution; Spin this solution to prepare SEBS fibers, control the feed rate of the solution to be 2mL / h, the spinning voltage to be 20kV, the collection distance to be 20cm, the ambient temperature to be 25°C, and the ambient humidity to be 70%. 5cm, the rotating speed of the drum is 500r / min, and the drum is connected to negative high voltage -30kV, and the solution is electrospun for 20min to prepare the SEBS fiber membrane. The average fiber diameter is 8 μm.

[0054] (2) the same SEBS is dissolved in tetrahydrofuran (THF), and the mass concentration of SEBS is controlled to be 8wt%. After the solution is prepared, it is stirred at 25°C for 4 hours to a homogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Antenna | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com