Porous bubble electrostatic spinning device

A bubble electrospinning, high-voltage electrostatic technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of large performance impact, easy needle blockage, low output, etc., to achieve simple equipment and production. The effect of high efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

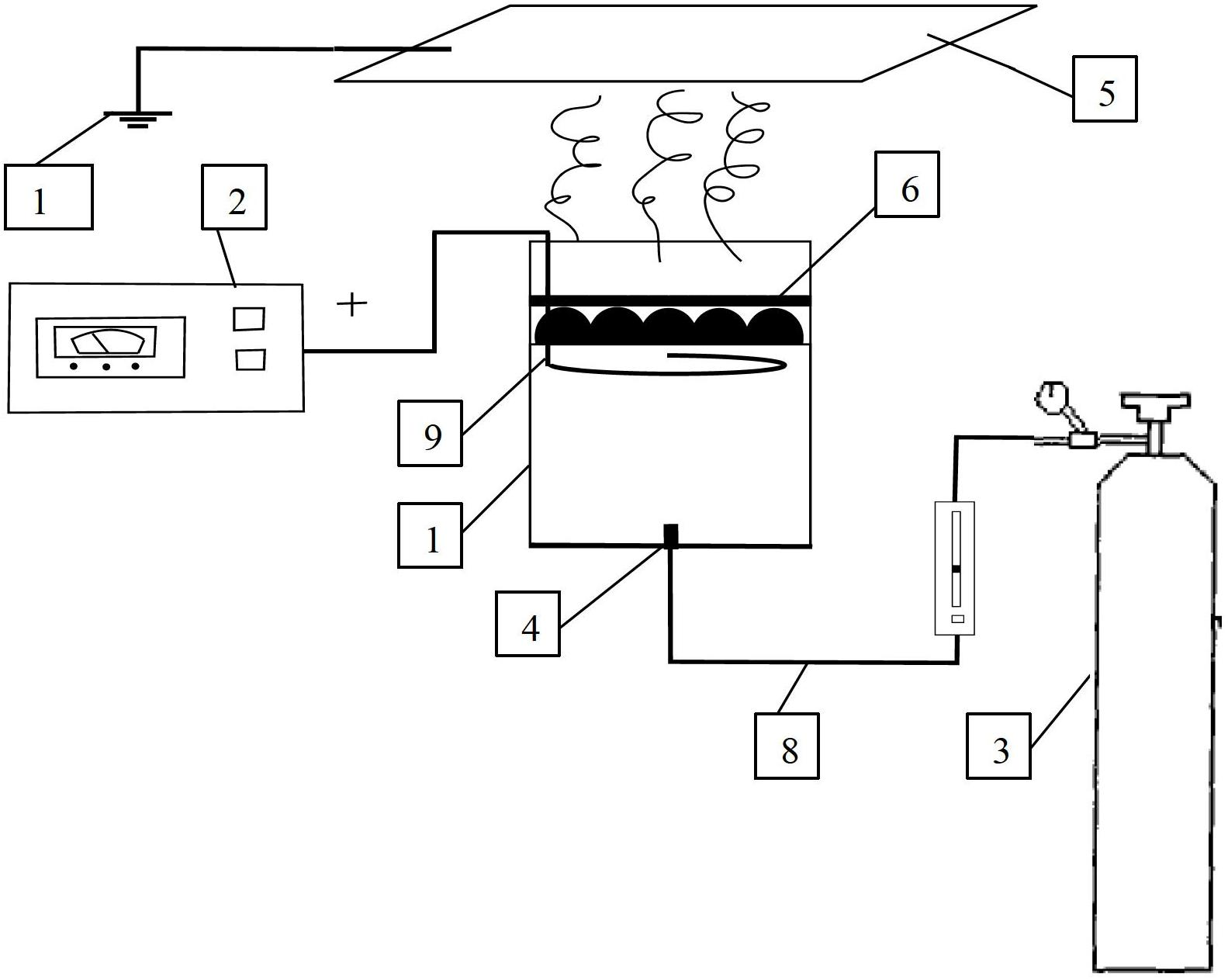

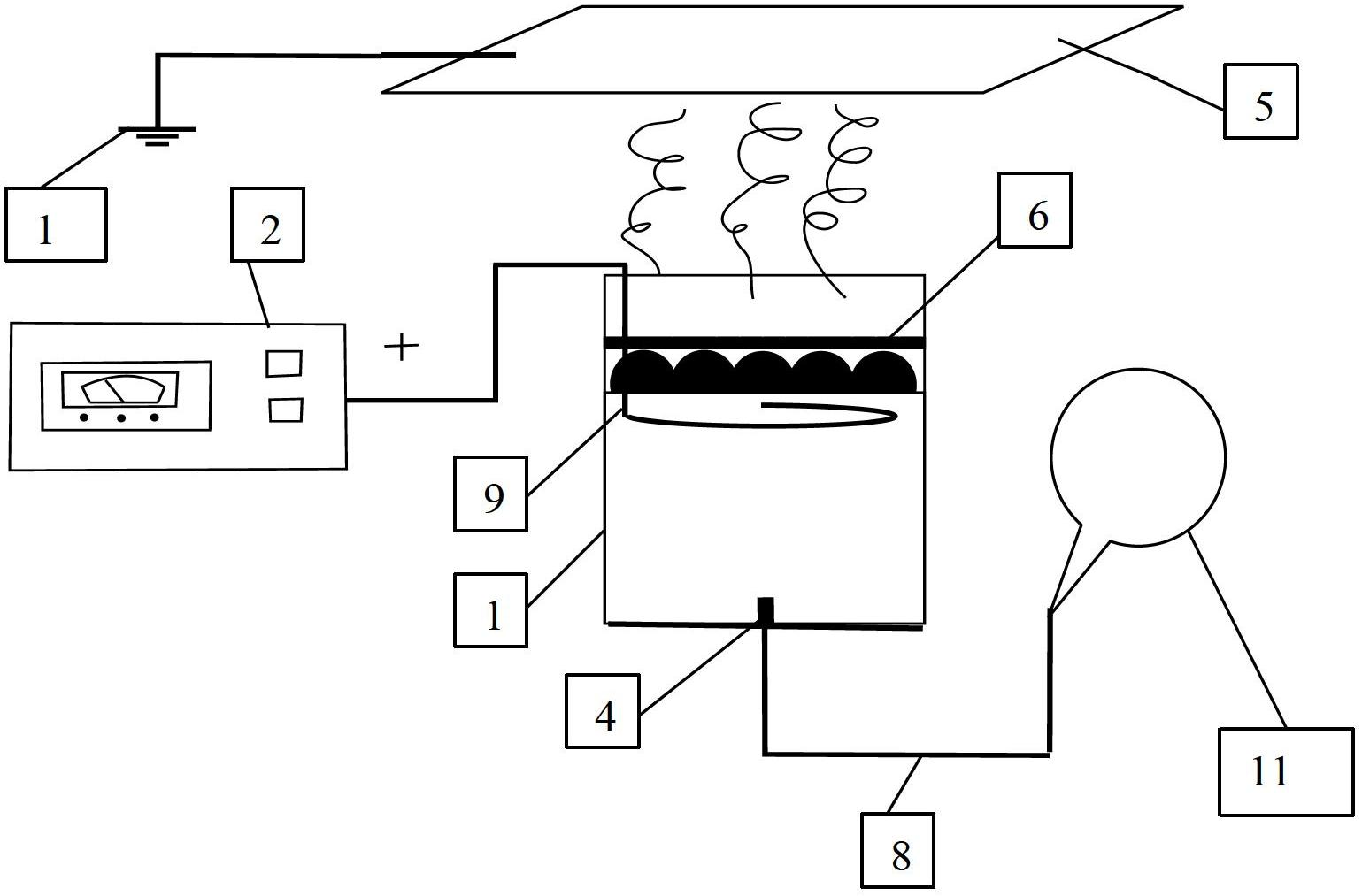

[0022] The invention discloses a porous bubble electrospinning device capable of realizing high efficiency, low energy consumption and continuous mass production of micron or nanometer fibers, so as to make up for the deficiencies and defects of the prior art and meet the needs of production and life.

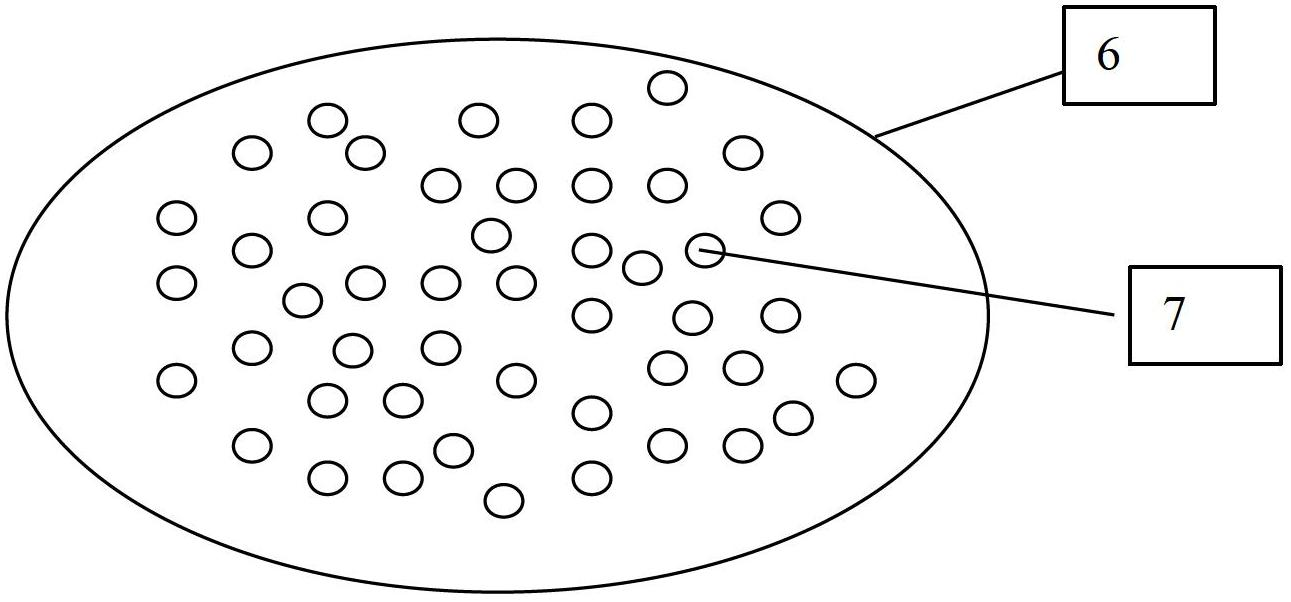

[0023] The porous bubble electrospinning device includes a liquid storage tank, a high-voltage electrostatic generator, an air pump, a nozzle located at the bottom of the liquid storage tank and extending vertically upwards, and a receiving plate directly above the liquid storage tank, and the nozzle passes through an air guide tube It is connected with the air pump, the receiving plate is connected with a ground electrode, the upper end of the liquid storage pool is open, and the liquid storage pool is connected with the high-voltage electrostatic generator through a metal electrode, and an intermediate plate is arranged in the liquid storage pool. A number of small holes whose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com