Method and apparatus for producing high strength, high modulus polyethylene filament by melt drawing

A high-modulus polyethylene and melt-drawing technology, which is applied in the field of high-modulus polyethylene yarn and melt-drawn production of high strength, can solve the problems of difficulty in melt-spinning processing and inability to form filaments, and achieve low cost and environmental protection , The effect of short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The invention adopts organic silicon-modified ultra-high molecular weight polyethylene blending material or ternary blending material composed of ultra-high molecular weight polyethylene, organic silicon and liquid crystal macromolecule as raw materials.

[0041] Ultra-high molecular weight polyethylene blends, using silicone as a modifier for ultra-high molecular weight polyethylene to form blends, its components include ultra-high molecular weight polyethylene 85-97%, organic silicon 3-15%, anti-oxidation Agent 0.2 to 2%.

[0042] The ultra-high molecular weight polyethylene ternary blend is blended by the following components in weight percentage: ultra-high molecular weight polyethylene 88-94%, organic silicon 3-7%, liquid crystal polymer 2-5%, stearic acid Calcium 0.2-2%, antioxidant 0.1-1%.

[0043] The antioxidant used is a phenolic antioxidant, and the phenolic antioxidant is specifically selected from antioxidant 1010 or B215.

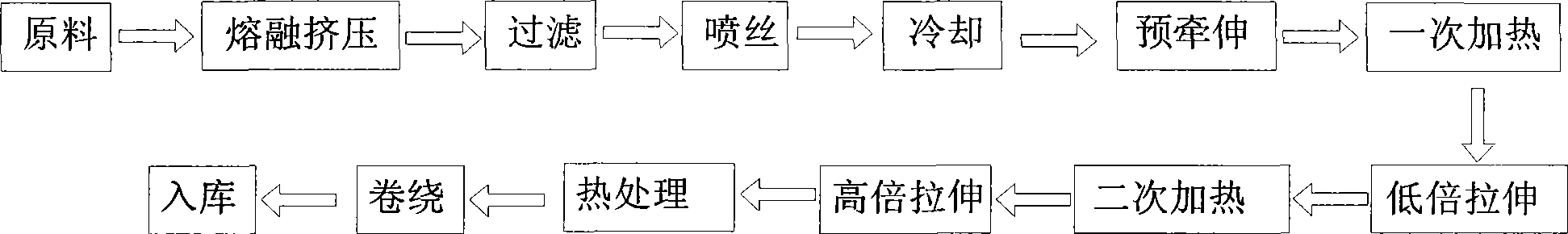

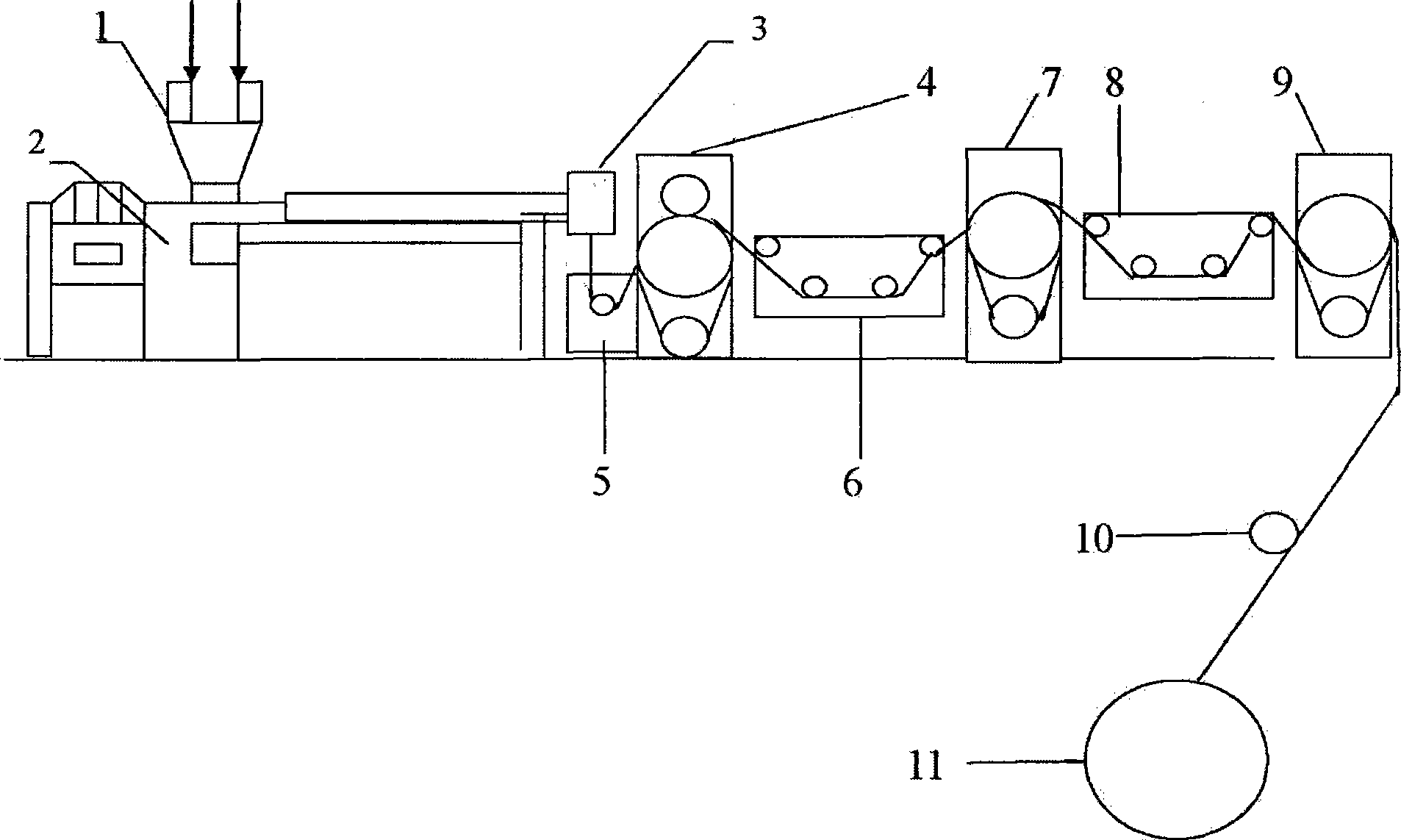

[0044] Such as figure 1 Shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com