Laser-guided electrospinning direct writing device

An electrospinning direct writing, laser-guided technology, used in textiles and papermaking, fiber processing, spinneret assemblies, etc. The operator's operation level has a great influence, and the nanofiber arrangement is difficult to control, etc., to achieve the effects of precise positioning and patterning preparation, prolonging the movement time and solvent evaporation time, and achieving orderly and controllable deposition and precise positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

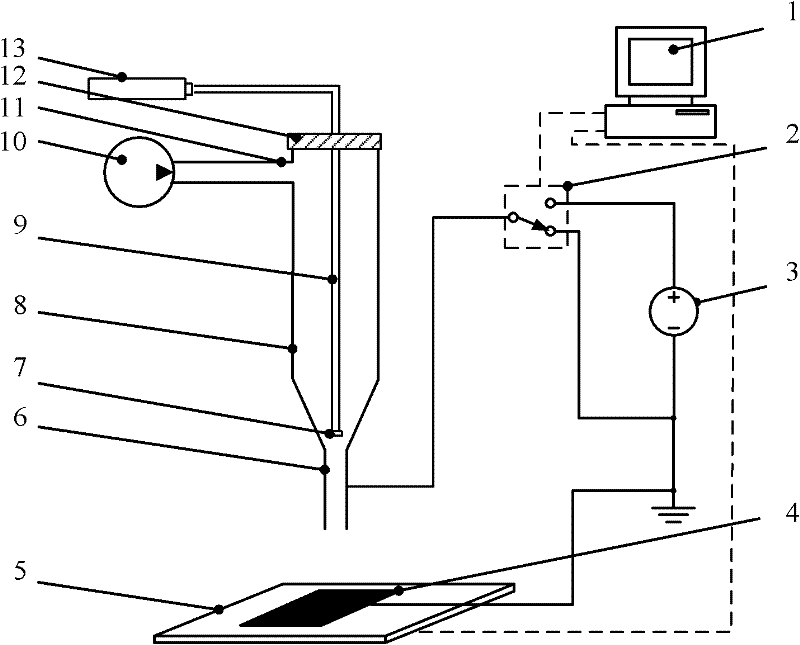

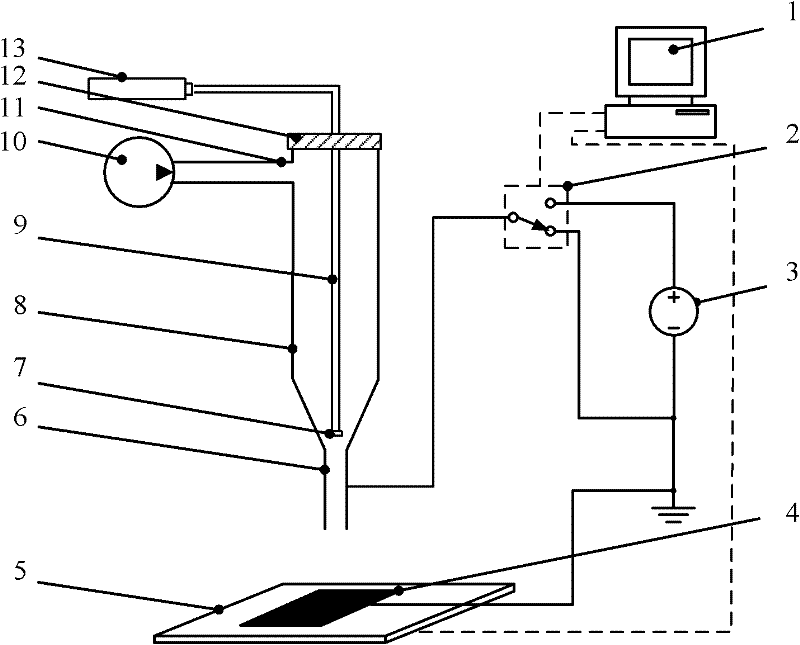

[0017] see figure 1 The embodiment of the present invention is provided with a computer 1, a high voltage relay 2, an electrostatic high voltage power supply 3, a hollow spray head 8, a collimating and focusing lens group 7, an optical fiber 9, a sealing end cap 12, a laser 13, a liquid supply pump 10, and a liquid supply pipe 11 , collecting plate 4 and motion platform 5.

[0018] The output terminal of the controller 1 is connected to the control terminal of the high-voltage relay 2, the normally open terminal of the high-voltage relay 3 is connected to the positive pole of the electrostatic high-voltage power supply 3, the normally-closed terminal of the high-voltage relay 2 is connected to the negative pole of the electrostatic high-voltage power supply 3 and the collecting plate 4 and then grounded, and the high-voltage relay 2 is common The end is connected with the conductor nozzle 6 located at the front end of the hollow nozzle, and the conductor nozzle 6 is coaxial wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com