Nano-silver antibacterial melt-blown non-woven fabric and production method thereof

A melt-blown non-woven fabric and nano-silver antibacterial technology, which is applied in the field of nano-silver antibacterial melt-blown non-woven fabric and its production, can solve the problems of inability to form cloth, low strength, easy clumping, etc., and achieves hard breaking and good strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

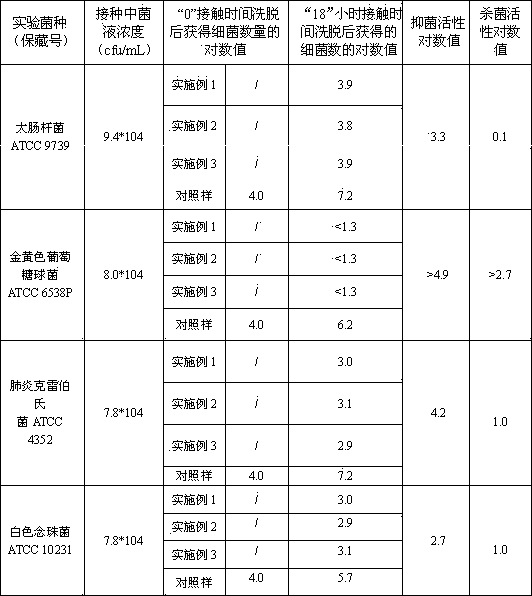

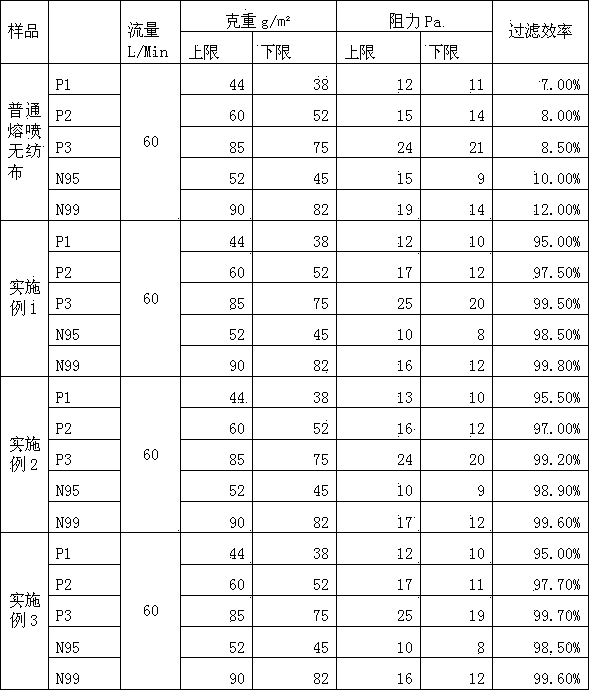

Examples

Embodiment 1

[0024] 1. Preparation of nano-silver antibacterial powder:

[0025] 3% by weight of silver nitrate, 95% of zirconium phosphate, and 2% of zinc oxide are used to make a mixed nano-silver antibacterial powder of ≤50 microns; To become silver phosphate, zinc oxide is added during the exchange process.

[0026] 2. Preparation of nano-silver antibacterial melt-blown non-woven fabric

[0027] (a), material preparation: 200 grams of nano-silver antibacterial powder, 20 grams of stearic acid, and 30 grams of polypropylene wax.

[0028] (b) Mix the above ingredients evenly and set aside.

[0029] (c), use polypropylene chips as masterbatch base material

[0030] Weigh 1000 grams of polypropylene slices, 30 g of bis-(γ-triethoxysilylpropyl) tetrasulfide and the mixture in step (b), stir evenly, place in a twin-screw, melting temperature is 230-250 degrees, and form nano Silver antibacterial masterbatch.

[0031] Then mix the antibacterial masterbatch and polypropylene slices evenly...

Embodiment 2

[0034] 1. Preparation of nano-silver antibacterial powder:

[0035] 5% by weight of silver nitrate, 91% of zirconium phosphate, and 4% of zinc oxide are made into a mixed nano-silver antibacterial powder of ≤50 microns; To become silver phosphate, zinc oxide is added during the exchange process.

[0036] 2. Preparation of nano-silver antibacterial melt-blown non-woven fabric

[0037] (a), material preparation: 200 grams of nano-silver antibacterial powder, 50 grams of stearic acid, and 50 grams of polypropylene wax.

[0038] (b) Mix the above ingredients evenly and set aside.

[0039] (c), use polypropylene chips as masterbatch base material

[0040] Weigh 1000 grams of polypropylene fiber slices and mix them evenly with the mixture of step (b).

[0041] Add titanate coupling agent: 20 grams of bis(acetylacetonate) diisopropyl titanate to the mixture of polypropylene slices and (b) and stir evenly, place in twin-screw, melting temperature 230-250 degrees, Form nano-silver...

Embodiment 3

[0045] 1. Preparation of nano-silver antibacterial powder:

[0046] Exchange 4% silver nitrate by weight and 94% zirconium phosphate in water to form silver phosphate, add 2% zinc oxide during the exchange process, and make mixed nano-silver antibacterial powder ≤ 50 microns.

[0047] 2. Preparation of nano-silver antibacterial melt-blown non-woven fabric

[0048] (a), material preparation: 150 grams of nano-silver antibacterial powder, 35 grams of stearic acid, and 40 grams of polypropylene wax.

[0049] (b) Mix the above ingredients evenly and set aside.

[0050] (c), using polyester chips as masterbatch base material

[0051] Weigh 1000 grams of polyester chips, and mix them evenly with the mixture of step (b).

[0052] Add silane series coupling agent: 30 grams of bis-(γ-triethoxysilylpropyl) tetrasulfide to the mixture of polyester slices and (b) and stir evenly, place in twin-screw, melting temperature 230~ 250 degrees to form nano-silver antibacterial masterbatch. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Fiber fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com