Microfluid electrostatic spinning device

A microfluidic device and electrospinning technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., to achieve the effects of short process flow, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

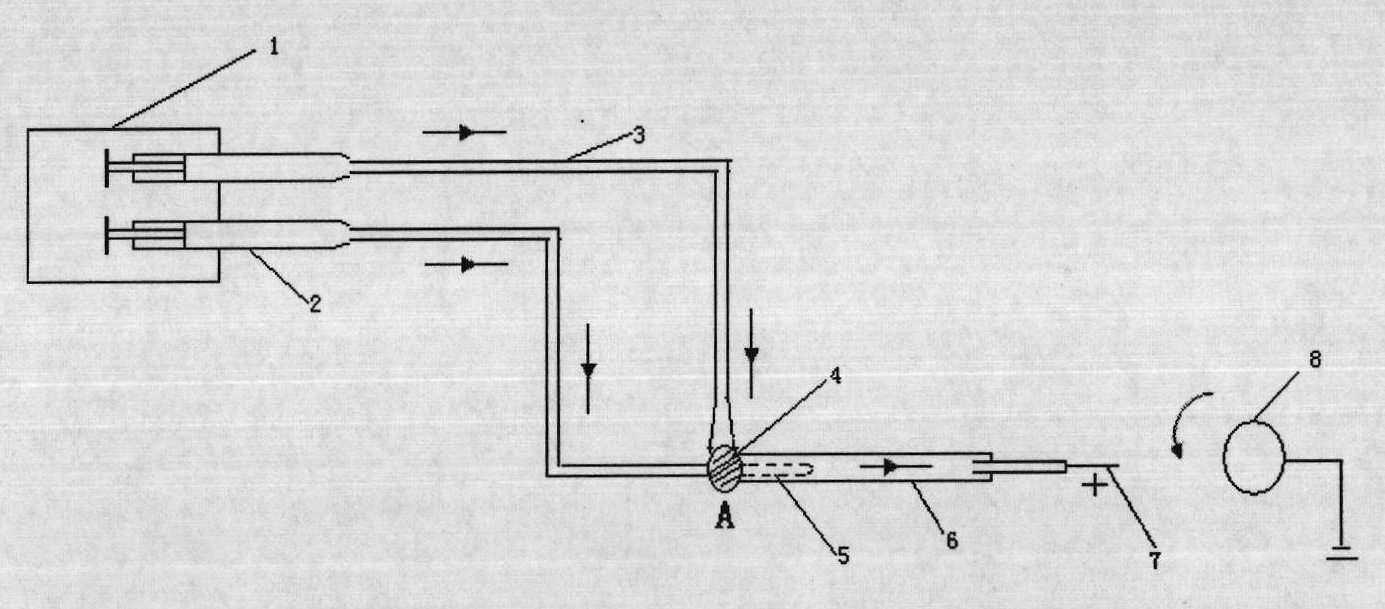

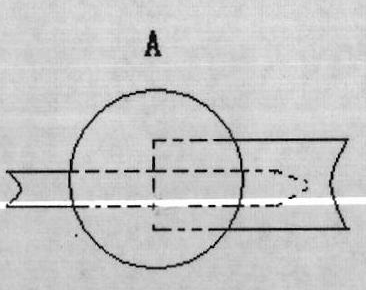

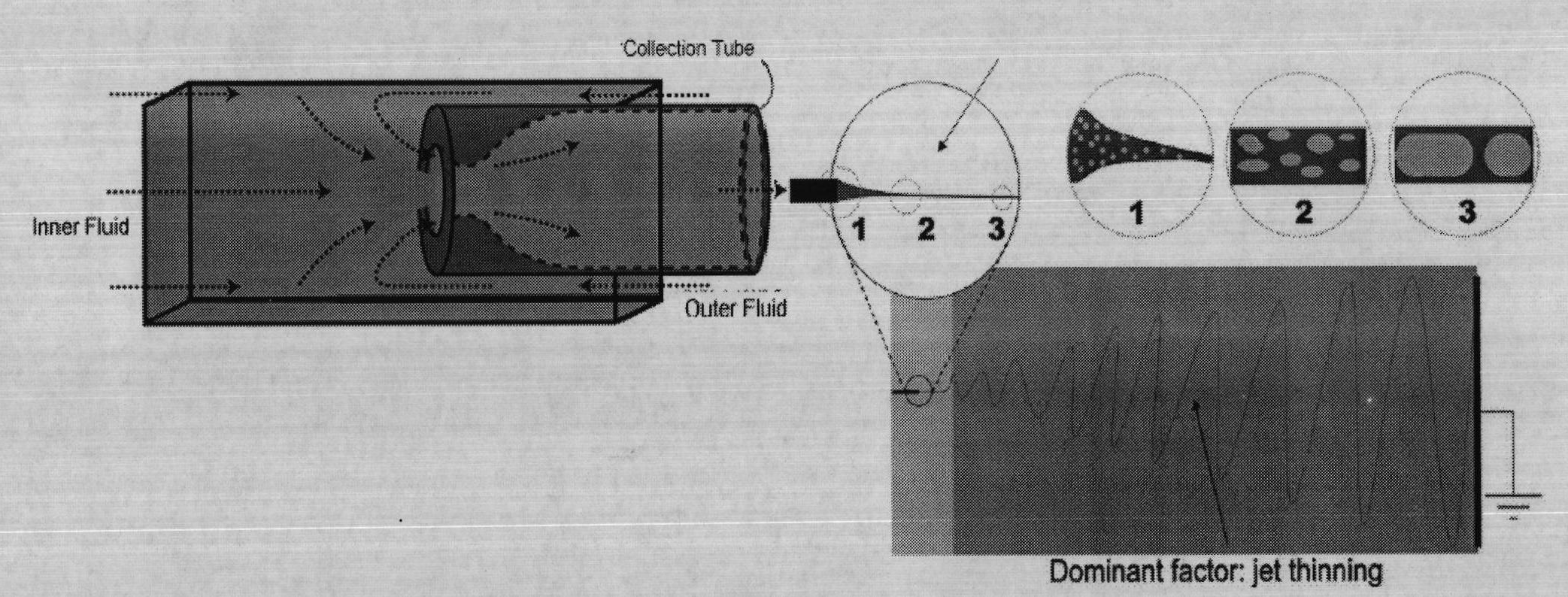

[0013] A microfluidic electrospinning device for preparing a microfluidic-assisted two-phase solution with a predictable structure and a finely regulated composition ratio, which is adopted in the present invention, mainly includes a dual-channel syringe pump 1, a microfluidic device (4, 5, 6 , 7), four parts of drum collection device 8 and high voltage power supply. Among them, the high-voltage power supply adopts DW-P503-4AC CD high-voltage DC power supply; the flow rate of the spinning solution in the inner and outer tubes is controlled by JZB-1800D dual-channel injection pump; the drum is driven by QJ1510S DC stable power supply. The spinning process is as follows: turn on the switch of the dual-channel syringe pump to adjust the flow rate ratio of the inner and outer capillaries corresponding to the syringe → turn on the high-voltage power supply, adjust the voltage, start spinning → turn on the DC stable power supply, and the drum rotates → adjust the flow rate ratio of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com