Jean warp sizing slurry and sizing process

A warp sizing and denim technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of increasing the mechanical tensile length and action time of wet sizing, inability to eliminate air pollution, and increasing warp elongation. Reduced sizing rate, reduced end breaks, and improved weaving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

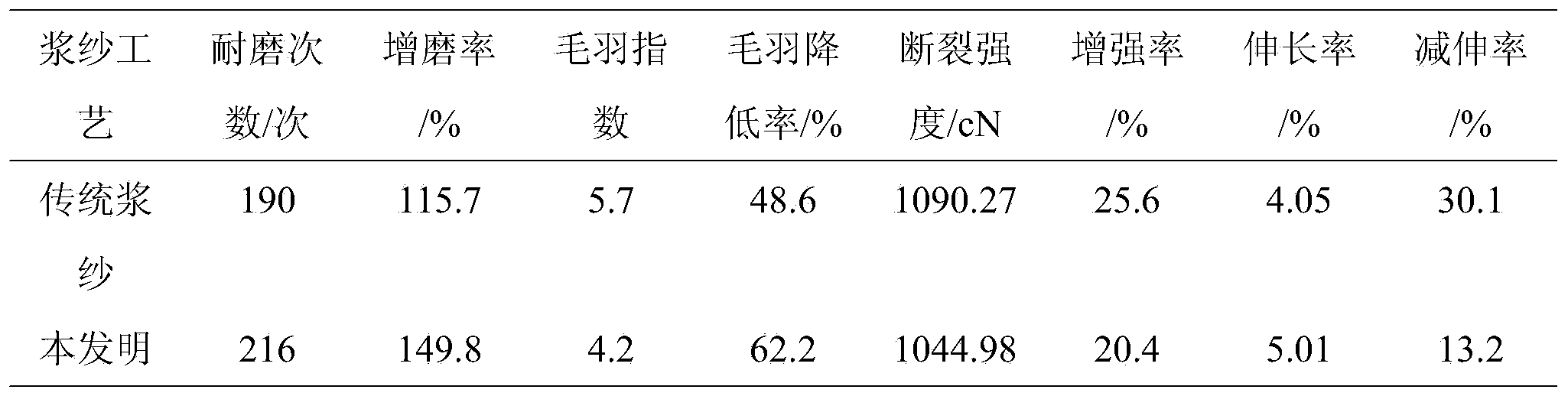

Image

Examples

Embodiment 1

[0040] Raw materials: DSC-14 starch 120kg, PVA 10kg, LMA-95 synthetic slurry 25kg, emulsified oil 16kg, smoothing agent 3kg.

[0041] Process: In the normal pressure mixing tank, first put 75% of the total amount of water, put in PVA, then put in DSC-14 starch, LMA-95 synthetic slurry, emulsified oil and smoothing agent in turn, stir at high speed for 5 minutes, turn on Steam until the pot boils, when the temperature reaches 95°C, boil the slurry for 20 minutes, add water to make up the volume, and the solid content of the slurry is 15.0%.

Embodiment 2

[0043] The sizing process is carried out in accordance with the following procedures: warp creel → washing tank → multi-tank dyeing → washing tank → high-pressure press equipment → size tank → drying room → car head → weaving shaft; among them, the sizing speed: 30m / min; Tank temperature: above 95°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com