Process and system for recycling and decoloring denim mercerizing alkali and penetrant

A denim and penetrant technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. application and other issues, to achieve the effect of strong operability and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

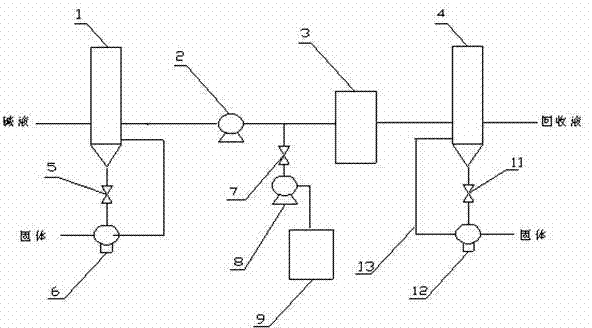

[0026] In the present invention, the recovery and decolorization process of denim mercerizing alkali and penetrant is as follows: put denim mercerizing alkali liquor into the first settling tank 1, after precipitation, most of the impurities and suspended matter in the light alkali liquor are deposited at the bottom, The upper liquid enters the delivery pipeline through the flow pump 2. At the same time, the valve 7 is opened, and the metering pump 8 pumps the decolorizer into the delivery pipeline liquid. The concentration of available chlorine in the delivery pipeline liquid is 10 mg / L. Together with the filtrate, it is sent to the evaporating concentrator 3, and then enters the second settling tank 4 after evaporating and concentrating. The lower sedimentation liquid flows into the first centrifuge 6 through the valve 5, and the centrifuge 6 is started to separate the impurities and suspended solids, and the solid is separated to the waste solid storage tank, and the clear l...

Embodiment 2

[0028] Adopt the substantially same embodiment as embodiment 1, difference is: the concentration of the available chlorine of decolorizing agent in the conveying pipeline liquid is 50mg / L.

Embodiment 3

[0030] Adopt the same implementation mode as Example 1, the difference is: the concentration of available chlorine in the delivery pipeline liquid of the decolorizing agent is 100 mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com