Desizing, enzyme-washing and bleaching integrated one-bath process

A fermented washing and process technology, applied in the field of textile and garment washing, can solve the problems of unstable treatment quality, pollution of the working environment and natural environment, corrosion damage to equipment, etc., to achieve excellent bleaching finishing effect, improve grade and added value, reduce CO2 The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A one-bath process for desizing, fermenting, washing and bleaching, the specific process steps of the process are:

[0047] (1) Add 800 liters of water and 100 kg of denim clothing to the industrial washing machine, turn on the steam heating, and raise the temperature to 50°C;

[0048] (2) Turn off the steam;

[0049] (3) Add 2% o.w.f desizing, yeast and washing two-in-one enzyme powder, and treat for 30 minutes;

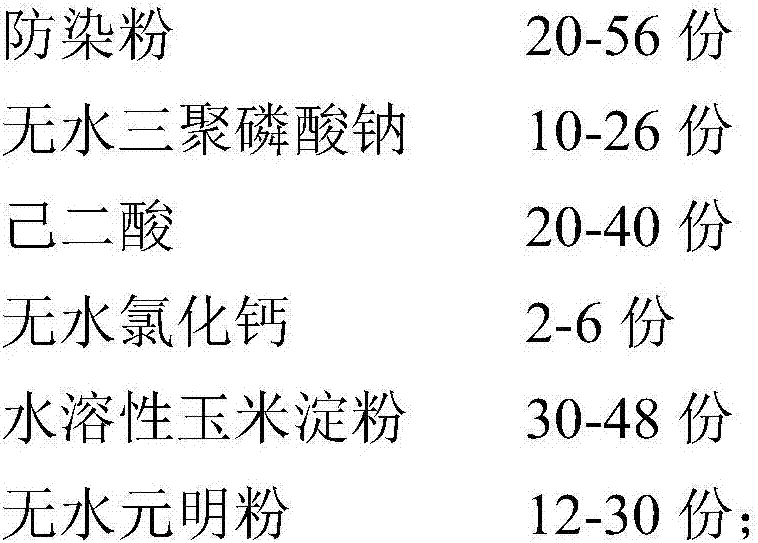

[0050] The raw materials contained in the desizing, fermentation and washing two-in-one enzyme powder and the parts by weight of each raw material are: compound enzyme (a mixture of desizing enzyme and neutral cellulase, the mass ratio of the two is 1:1) 16 56 parts, anti-dyeing powder (C16-C18 fatty alcohol polyoxyethylene ether, active matter content greater than or equal to 99.9%, the pH value of its 5% aqueous solution is 7.5, and the flash point is greater than 100 ° C), 56 parts, anhydrous sodium tripolyphosphate 26 parts, 40 parts of adipic acid, 6 p...

Embodiment 2

[0068] A one-bath process of desizing, fermentation, washing and bleaching, the specific process steps of the desizing, fermentation, washing and bleaching one-bath process are:

[0069] (1) Add 600 liters of water and 60 kg of denim clothing to the industrial washing machine, turn on the steam heating, and raise the temperature to 60°C;

[0070] (2) Turn off the steam;

[0071] (3) Add 0.8% o.w.f desizing enzyme washing two-in-one enzyme powder, and treat for 50 minutes;

[0072] The raw materials contained in the desizing, fermentation and washing two-in-one enzyme powder and the parts by weight of each raw material are: compound enzyme (a mixture of desizing enzyme and neutral cellulase, the mass ratio of the two is 1:6) 6 20 parts, anti-dyeing powder (C16-C18 fatty alcohol polyoxyethylene ether, active matter content greater than or equal to 99.9%, the pH value of its 5% aqueous solution is 6.5, and the flash point is greater than 100 ° C), 20 parts, anhydrous sodium trip...

Embodiment 3

[0090] A one-bath process of desizing, fermentation, washing and bleaching, the specific process steps of the desizing, fermentation, washing and bleaching one-bath process are:

[0091] (1) Add 700 liters of water and 80 kg of denim clothing to the industrial washing machine, turn on the steam heating, and raise the temperature to 55°C;

[0092] (2) Turn off the steam;

[0093] (3) Add 1.4% o.w.f desizing enzyme washing two-in-one enzyme powder and treat for 40 minutes;

[0094] The raw materials contained in the desizing, fermentation and washing two-in-one enzyme powder and the parts by weight of each raw material are: compound enzyme (a mixture of desizing enzyme and neutral cellulase, the mass ratio of the two is 1:3.5)11 38 parts, anti-dyeing powder (C16-C18 fatty alcohol polyoxyethylene ether, active substance content greater than or equal to 99.9%, pH value of its 5% aqueous solution is 7, flash point greater than 100 ° C), 38 parts, anhydrous sodium tripolyphosphate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com