Water-saving preparation device for washing basic magnesium carbonate in grading circulation mode

A preparation device and cycle washing technology, applied in the direction of magnesium carbonate, etc., can solve the problems of large water consumption, and achieve the effect of reducing the amount of sulfuric acid, reducing the amount of sulfuric acid, and increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

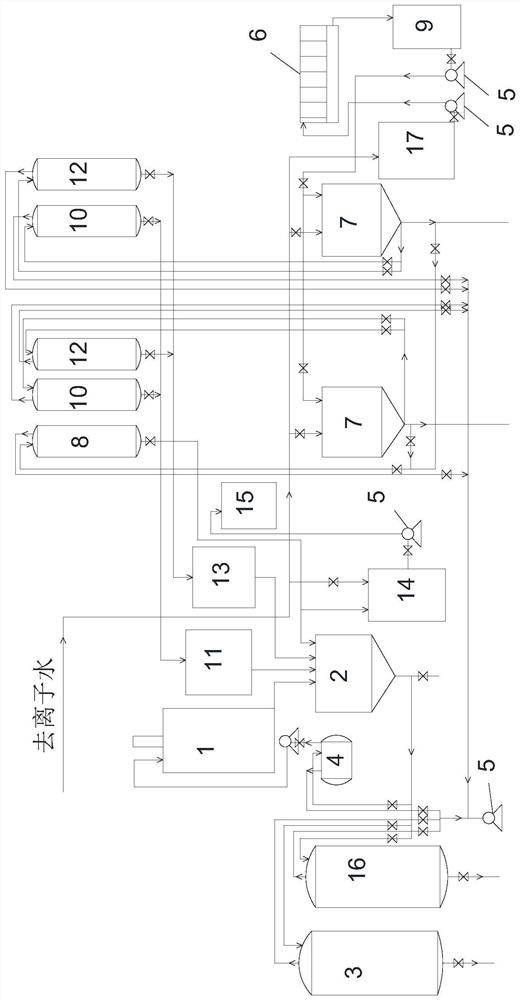

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, a kind of water-saving preparation device of graded circulation washing basic magnesium carbonate provided by the embodiment of the present invention comprises a reaction tank 1, a primary washing plate 2 and a mother liquor tank 3 connected in sequence by pipelines, and also includes a secondary mother liquor tank 4, The liquid inlet of the secondary mother liquor tank 4 communicates with the liquid outlet of the primary washing tray 2 through a pipe, and the liquid outlet of the secondary mother liquor tank 4 communicates with the flushing port of the reaction tank 1 .

[0025] Specifically, the reaction tank 1, the primary washing dish 2 and the mother liquor tank 3 are existing equipment prepared by basic mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com