Pulsator washing machine and water saving method

A pulsator washing machine and water level technology, applied in the field of washing machines, can solve the problems of unable to wash clothes, limited inner bucket volume, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

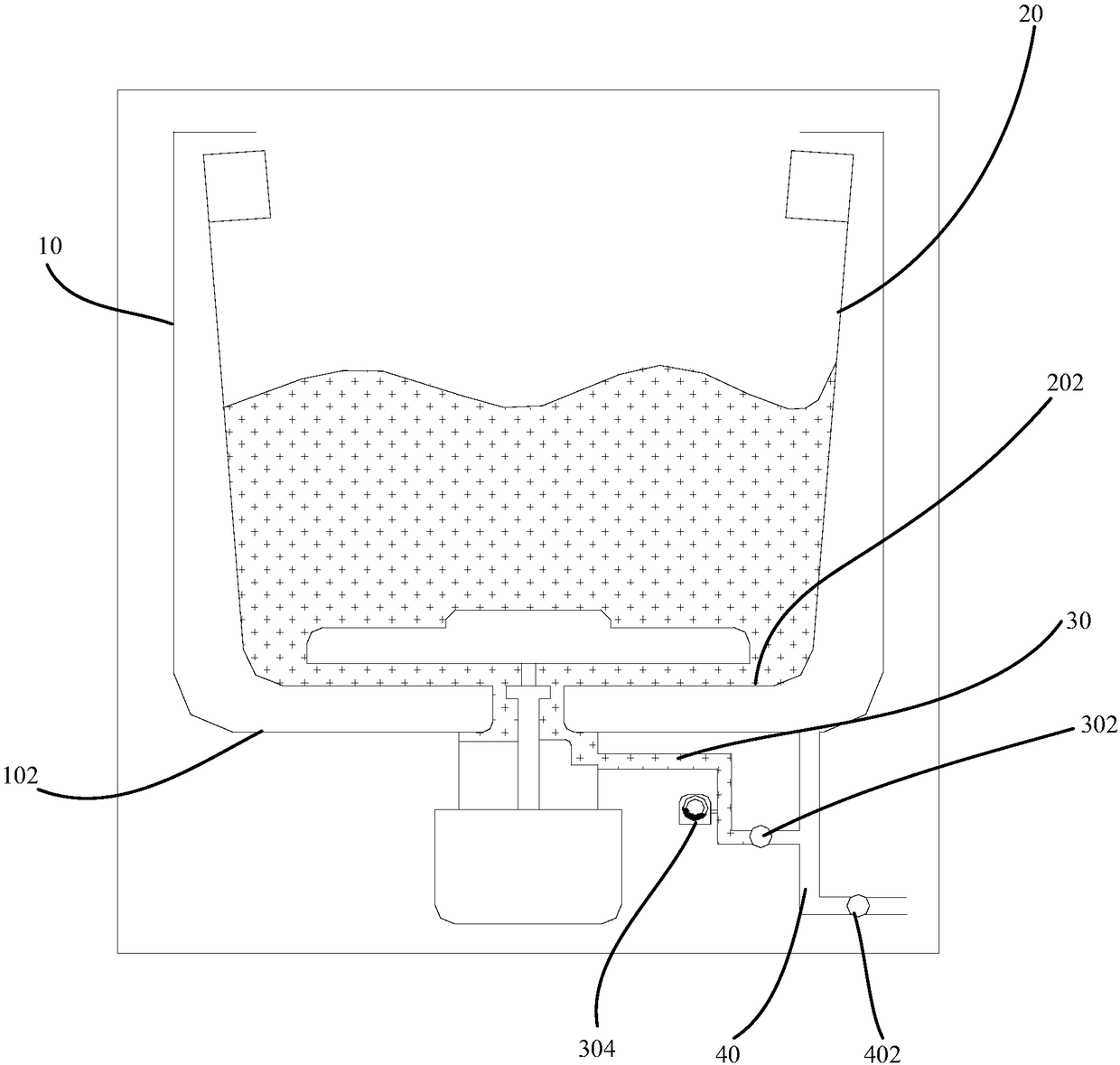

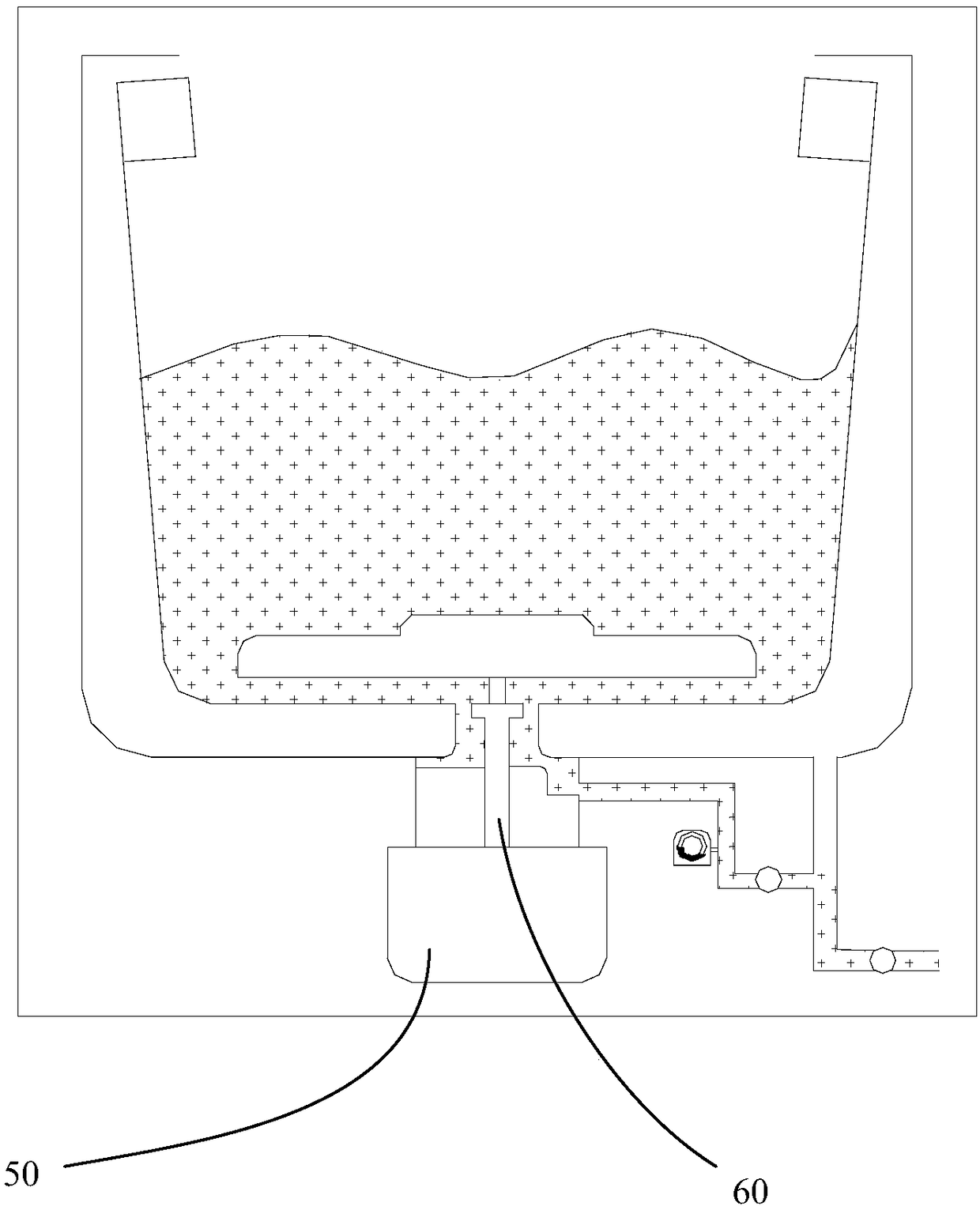

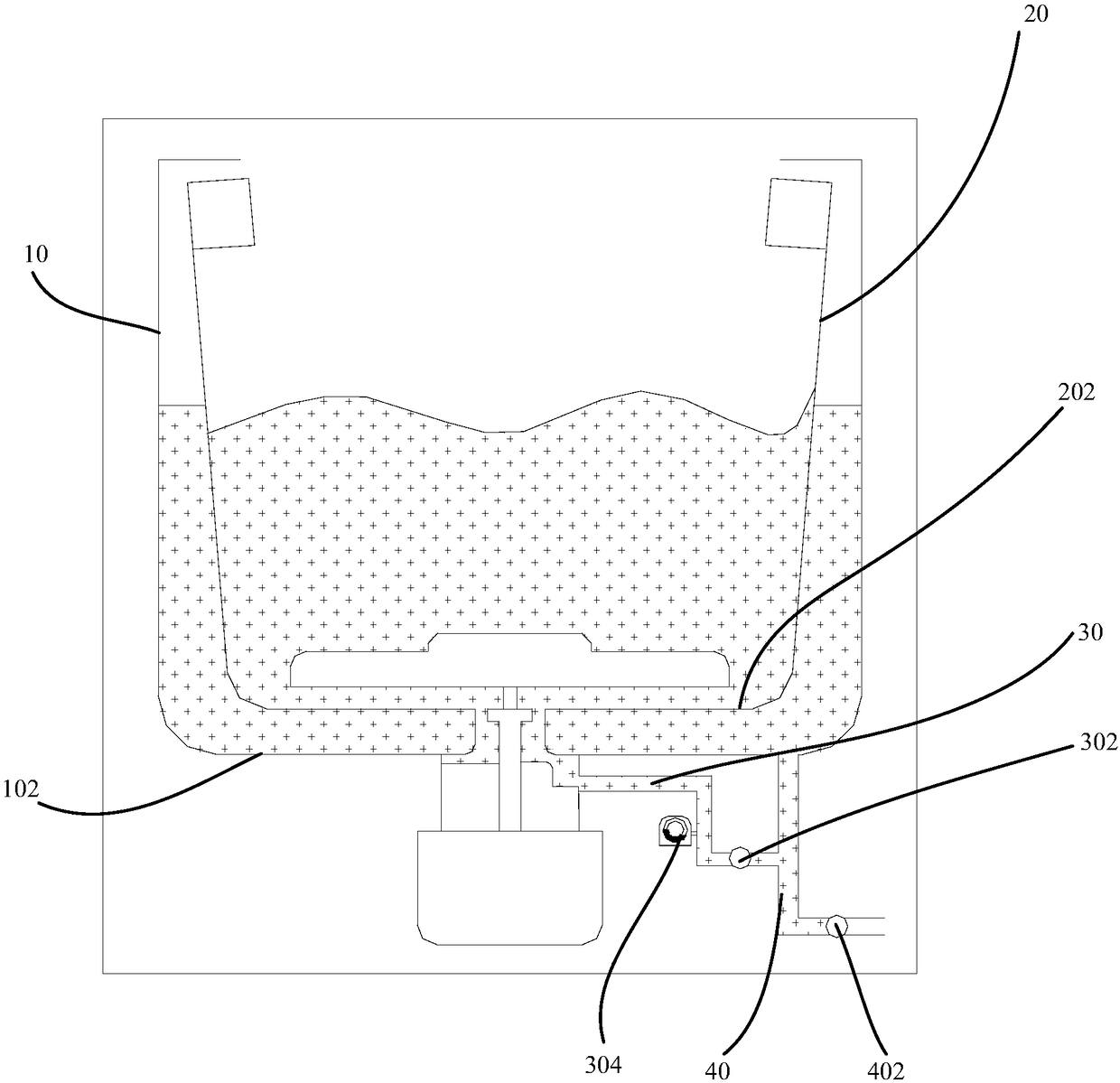

[0038] figure 1 A schematic cross-sectional view of a pulsator washing machine according to an embodiment of the present invention is shown. Such as figure 1 As shown, the wave-wheel washing machine according to the first embodiment proposed by the present invention includes: an outer tub

[0039] 10, and the inner barrel 20 coaxially arranged in the outer barrel 10; the first pipeline 30, the two ends of the first pipeline 30 respectively communicate with the outer barrel 10 and the inner barrel 20; the first valve 320 is arranged in the corresponding first pipeline 30

[0040] In the process, the opening and closing of the first valve 320 controls the opening and closing of the first pipeline 30 .

[0041] In this embodiment, the outer tub 10 plays the role of holding water when washing more clothes; the inner tub 20 and the outer tub 10 are coaxially arranged to facilitate the rotation of the inner tub 20 during dehydration and the arrangement of the inner space; the fir...

Embodiment 2

[0056] In the second embodiment of the present invention, an electronic weighing device is added, which is arranged at the bottom of the tub 10 and is electrically connected with the microcontroller.

[0057] The laundry to be washed is weighed by the electronic scale, and the electrical signal corresponding to the weight is sent to the microcontroller, so that the microcontroller determines the washing water level according to the weight of the laundry.

Embodiment 3

[0059] According to the technical solution of the present invention, there may also be a third embodiment:

[0060] The first pipeline 30 of the pulsator washing machine is a three-way pipe, and the three openings of the three-way pipe are respectively the first port, which is arranged on the bottom plate 202 of the inner tub, the second port, which is arranged on the bottom plate 102 of the outer tub, and the third port, facing The space between the outer tub 10 and the inner tub 20; the three ports of the three-way pipe are also respectively provided with a first valve 320, a second valve 402 and a third valve, and the second pipeline 40 of the washing machine is a drain pipe, which is placed on the bottom plate of the outer tub. 102 communicates with the second port of the three-way pipe through the opening and closing of the second valve 402 .

[0061] When there are few clothes and water-saving washing is performed, all valves are closed, and only the inner tub 20 is wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com