Slightly-creased nylon/cotton elastic fabric and production process thereof

A production process, Nylon Cotton technology, applied in fabric surface trimming, textile material treatment, folded textile material preservation, etc., can solve the problems of reduced fabric strength, no elasticity, no micro-wrinkle aesthetics, etc., and achieve resistance to sweat stains And good friction resistance, strong elastic effect, and the effect of enhancing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

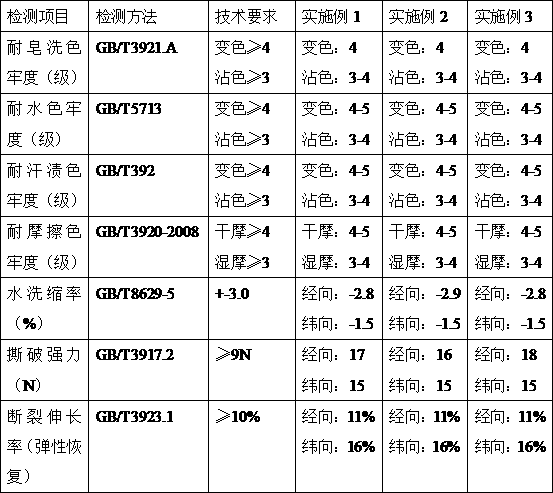

Examples

Embodiment 1

[0030] The manufacture technology of slightly wrinkled polyamide-cotton elastic fabric comprises the following steps:

[0031] Step 1, rolling: connect the textile gray cloth, prepare the length required for dyeing, and roll;

[0032] Step 2, cold stacking: put the rolled textile gray cloth in step 1 at 90°C at a speed of 50m / min for cold stacking in the chemical tank for 24 hours, the amount of additives in the chemical tank is as follows: NaOH50g / L , refining enzyme 10g / L, degreasing agent 3g / L, hydrogen peroxide 15g / L;

[0033] Step 3, shaping and pre-shrinking: carry out shaping and pre-shrinking of the textile gray cloth after cold stacking in step 2 on an open-width setting machine, the temperature is 180°C, the speed is 30m / min, and the width is 170cm;

[0034] Step 4: Enzyme washing and hair removal in the tank, and the pre-shrunk textile gray cloth in step 3 is put into the overflow dyeing machine:

[0035] ① Acid flushing tank: Add 1g / L of glacial acetic acid based...

Embodiment 2

[0046] The manufacture technology of slightly wrinkled polyamide-cotton elastic fabric comprises the following steps:

[0047] Step 1, rolling: connect the textile gray cloth, prepare the length required for dyeing, and roll;

[0048] Step 2, cold stacking: put the rolled textile gray cloth in step 1 at 85°C at a speed of 45m / min for cold stacking through the chemical tank for 25 hours, the amount of additives in the chemical tank is as follows: NaOH45g / L , refining enzyme 5g / L, degreasing agent 1g / L, hydrogen peroxide 10g / L;

[0049] Step 3, shaping and pre-shrinking: carry out shaping and pre-shrinking of the textile gray cloth after step 2 cold stacking on the open-width setting machine, the temperature is 175°C, the speed is 25m / min, and the width is 168cm;

[0050] Step 4: Enzyme washing and hair removal in the tank, and the pre-shrunk textile gray cloth in step 3 is put into the overflow dyeing machine:

[0051] ① Acid flushing tank: Add 0.8g / L of glacial acetic acid b...

Embodiment 3

[0062] The manufacture technology of slightly wrinkled polyamide-cotton elastic fabric comprises the following steps:

[0063] Step 1, rolling: connect the textile gray cloth, prepare the length required for dyeing, and roll;

[0064] Step 2, cold stacking: put the rolled textile gray cloth in step 1 at 95°C at a speed of 55m / min for cold stacking through the chemical tank for 23 hours, the amount of additives in the chemical tank is as follows: NaOH55g / L , refining enzyme 15g / L, degreasing agent 5g / L, hydrogen peroxide 20g / L;

[0065] Step 3, shaping and pre-shrinking: carry out shaping and pre-shrinking of the textile gray cloth after step 2 cold stacking on the open width setting machine, the temperature is 185°C, the speed is 35m / min, and the width is 173cm;

[0066] Step 4: Enzyme washing and hair removal in the tank, and the pre-shrunk textile gray cloth in step 3 is put into the overflow dyeing machine:

[0067] ① Acid flushing tank: add glacial acetic acid 1.2g / L bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com