Quaternization hadegen amide modified chitosan and method for preparing antibacterial cotton fabric

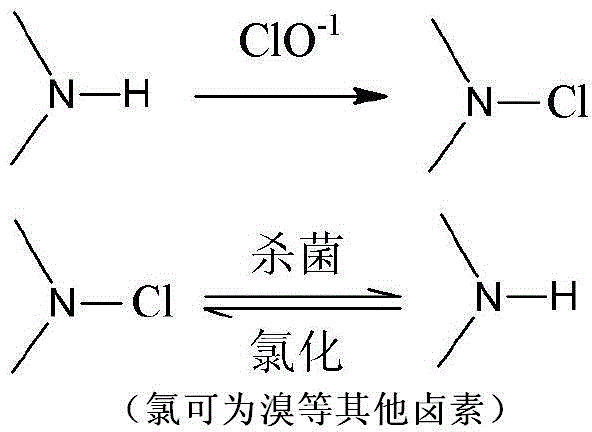

A chitosan, halogenated amine technology, applied in the directions of plant fibers, textiles and papermaking, fiber processing, etc., can solve the problems of limited application, chemical cross-linking and wearability, etc., and achieves simple synthesis method, activation and regeneration. Simple and convenient, broad-spectrum antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Weigh 3.22g (0.02mol) of chitosan in a single-necked flask, add 3.16g (0.02mol) of hydroxymethylhydantoin, then add 50mL of deionized water, and place the single-necked flask in an oil bath environment of 80°C for reaction. And keep stirring, after the deionized water in the flask is condensed and refluxed, react for 30h. After the reaction, cool down, filter the contents of the flask under reduced pressure, wash the obtained solid product with distilled water several times, put it in a vacuum oven at 45°C and dry it for 1 day, and weigh the finally obtained solid powder.

[0041] Then mix the dried solid with 15.2g (0.1mol) 2,3-epoxypropyltrimethylammonium chloride in 50mL isopropanol solution, react at 60°C for 32h, cool to room temperature and filter under reduced pressure after the reaction , the obtained solid was dried at 45° C. for 1 d, and stored for future use.

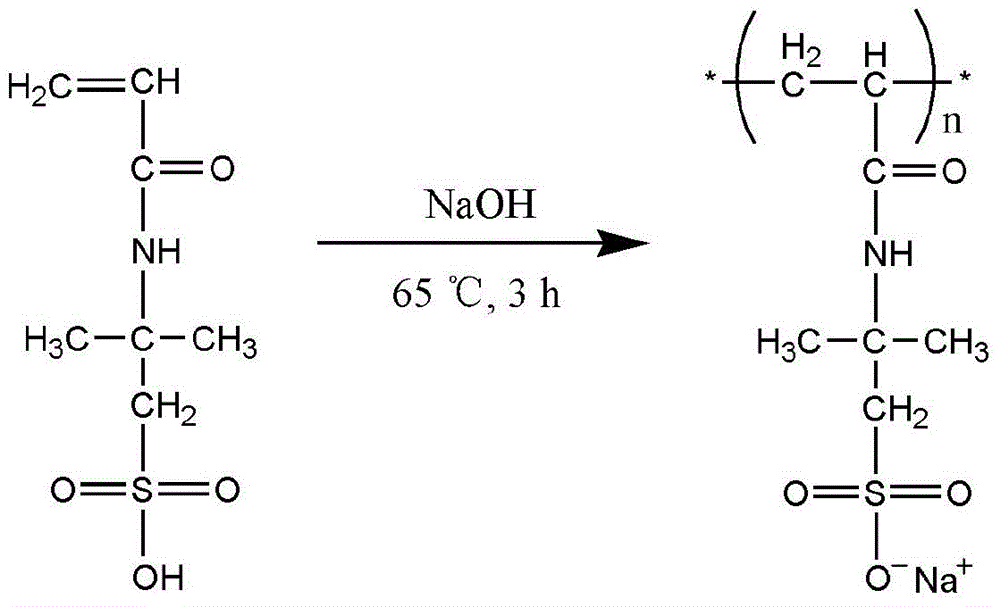

[0042] The synthetic method of poly-2-acrylamido-2-methylpropanesulfonic acid sodium is: take 4.14...

Embodiment 2

[0044] Weigh 3.22g (0.02mol) of chitosan in a single-necked flask, add 3.16g (0.02mol) of hydroxymethylhydantoin, then add 50mL of deionized water, and place the single-necked flask at 100°C in an oil bath environment for reaction. And keep stirring, after the deionized water in the flask is condensed and refluxed, react for 24h. After the reaction, cool down, filter the contents of the flask under reduced pressure, wash the obtained solid product with distilled water several times, put it in a vacuum oven at 45°C and dry it for 1 day, and weigh the finally obtained solid powder.

[0045] Then mix the dried solid with 9.12g (0.06mol) 2,3-epoxypropyltrimethylammonium chloride in 50mL isopropanol solution, react at 80°C for 24h, cool to room temperature and filter under reduced pressure after the reaction , the obtained solid was dried at 45° C. for 1 d, and stored for future use.

[0046]The synthetic method of poly-2-acrylamido-2-methylpropanesulfonic acid sodium is: take 4.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com