Manufacturing method of washable non-curling knitting collars and cuffs

A production method and leading technology, applied in the direction of knitting, weft knitting, bleaching products, etc., can solve the problems of affecting the service life of the leader, reducing the strength and wear resistance of the leader, and improving the dimensional stability and washability. Beneficial for recycling and penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Piece dyed knitted leader

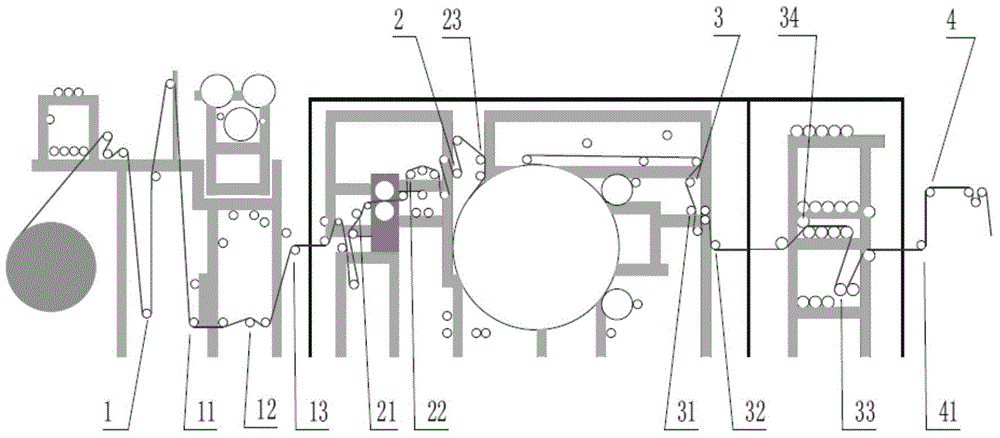

[0044] This embodiment provides a method for making a washable non-curling piece dyed knitted leader, taking the production of 44S / 1X6Navy ribbed knitted leader as an example, such as figure 1 As shown in the technological process, it comprises the following steps:

[0045] Knitting: use 14G40 flat knitting machine to weave, the size is 43cmX9cm, 150 pieces in total;

[0046] Scouring: The treatment agent used is ONE containing 1.5g / L refining agent, 2g / L NaOH solution with a mass concentration of 50%, and 1.5g / L 27.5% H 2 o 2 The treatment agent of the solution is scoured under the condition that the treatment temperature is 95°C and the treatment time is 45min;

[0047] Enzyme washing: use the washing solution containing 1g / L Cellusoft Combi and adjust the pH value to 4.5-5.5 with NaAC and HAC, and perform enzyme washing at a treatment temperature of 45°C and a treatment time of 50 minutes;

[0048] Dyeing: including coloring...

Embodiment 2

[0058] Example 2 Yarn-dyed knitted leaders

[0059] This embodiment provides a method for making a washable non-curling yarn dyed knitted leader, taking the production of 80S / 2X6 dark blue and light blue interlaced and ribbed knitted collar as an example, such as figure 2 As shown in the technological process, it comprises the following steps:

[0060] Knitting: use 14G90 flat knitting machine to weave, the size is 43.5cmX9cm, 150 pieces in total;

[0061] Washing and degreasing: use a treatment agent containing 0.2g / L penetrating agent FKS, 2g / L degreaser JINTERGE LCF-185, and 1g / L dispersant AVOLAN IS, at a treatment temperature of 70°C and a treatment time of 30 minutes, Treated twice in a row.

[0062] Enzyme washing: use the lotion containing 2g / L cellulase Cellusoft CR, the pH of the lotion is 6.5-7.5, and the enzyme washing is carried out under the conditions of the treatment temperature of 45°C and the treatment time of 40 minutes;

[0063] Rolling and drying: Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com