Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Fullness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

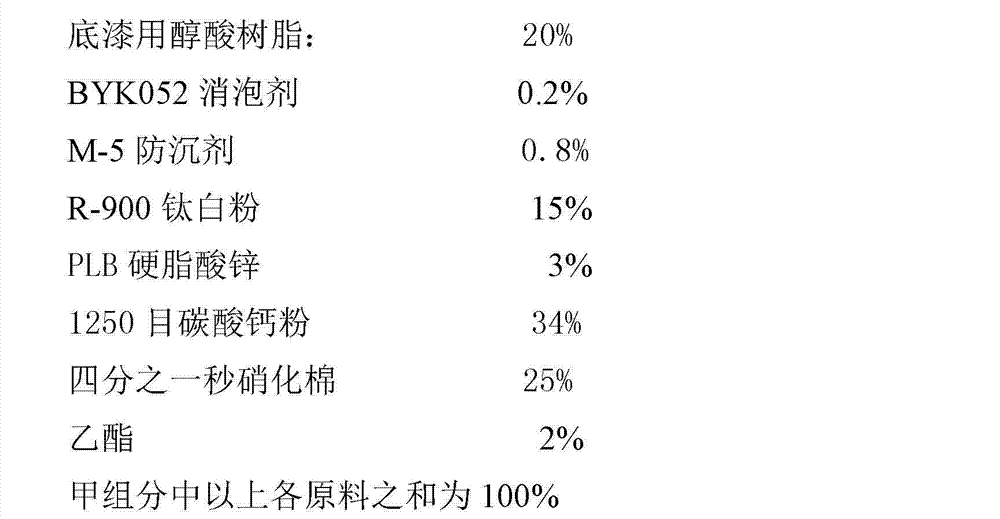

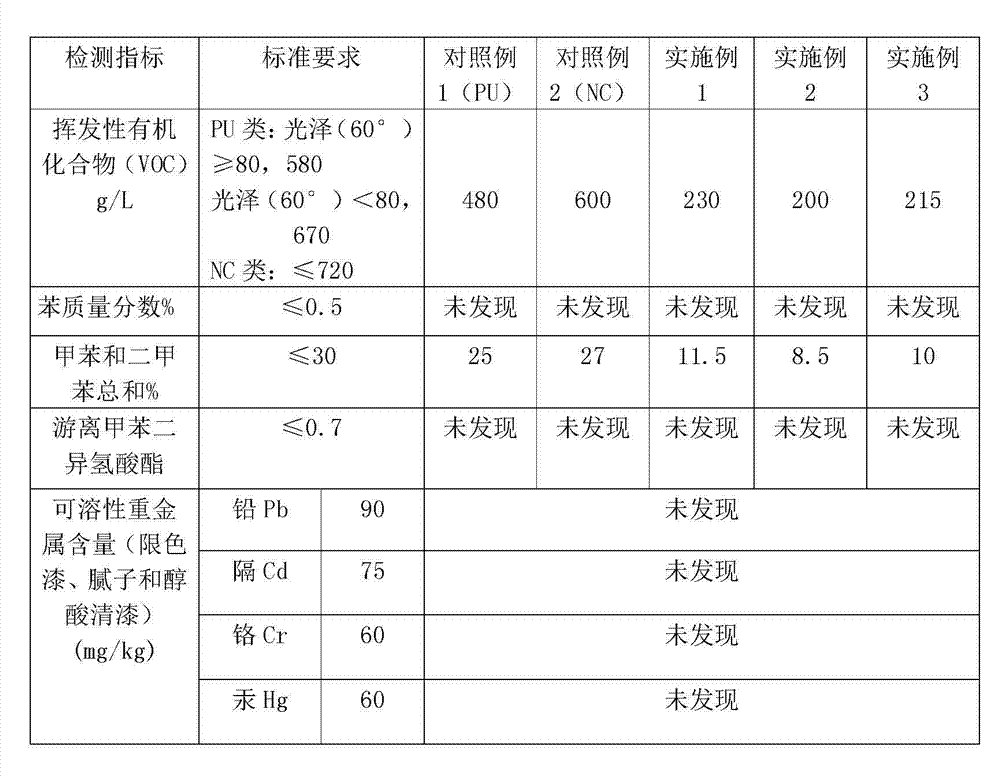

Preparation method of alkyd resin

InactiveCN102408551AImprove adhesionFullnessCosmetic preparationsToilet preparationsPolymer scienceNitrocellulose

The invention relates to a preparation method of alkyd resin. The preparation method comprises the following specific steps: (1) adding neopentyl glycol, trihydroxymethyl propane, phthalic anhydride, hydrogenated phthalic anhydride and antioxidant to a reaction container, and heating to carry out melt esterification on the materials at the temperature of 200-240 DEG C; (2) when esterification is carried out to an acid value being 40-45 mgKOH / g, cooling to 120-160 DEG C, and adding short-chain synthetic fatty acid and an aliphatic hydrocarbon solvent; (3) heating to carry out reflux esterification at the temperature of 180-200 DEG C, and diluting with acetic acid ester organic solvent when the acid value is smaller than or equal to 8 mgKOH / g; and (4) cooling to 100 DEG C and filtering to obtain alkyd resin. The paint prepared from the alkyd resin obtained in the invention and nitrocellulose has the characteristics of rapid drying, high hardness, good fullness, good adhesion force, and good water resistance.

Owner:JIANGSU SANMU GROUP CORPORATION

High-hardness unsaturated polyester full-bright top-coat paint and preparation method thereof

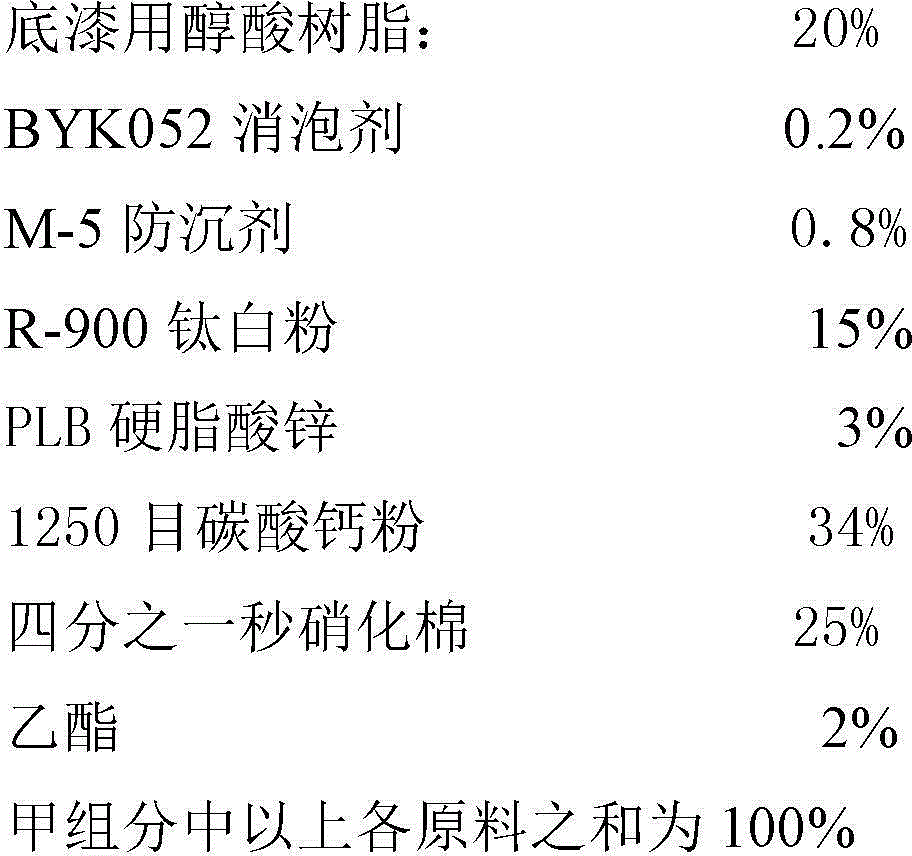

The invention relates to a chemical technology field, concretely, discloses high-hardness unsaturated polyester full-bright top-coat paint and a preparation method thereof. The priming paint contains a first component, cobalt isocaprylate (blue wate), methylethyl ketone peroxide (white water), and styrene, wherein the weight ratio of the first component, to cobalt isocaprylate (blue wate), to methylethyl ketone peroxide (white water) and to styrene is 100:(0.8-2):(1-2.5):(30-40). The high-hardness white unsaturated polyester priming paint and the preparation method resolve the problem that the PU polyurethane paint and nitro cellulose paint have bad hardness, the unsaturated polyester coating has high hardness, and simultaneously, the high-hardness unsaturated polyester full-bright top-coat paint has good fullness, clunging and minute surface effect.

Owner:AODA KOALA PAINT HUIZHOU

Worsted fabric and manufacturing method thereof

The invention discloses a worsted fabric. The worsted fabric comprises a surface layer, a middle layer and an inner layer, wherein the warp yarn and weft yarn of the surface layer are a twined yarn of a strand of 8 to12tex of wool yarn and a strand of 2.2 to 4.4tex of mulberry silk; one kind of the warp yarn and weft yarn of the middle layer is 6.2 to 8.3tex*2 of spun silk, and the other kind of the warp yarn and weft yarn of the middle layer is 6.5tex*2 of metallic silk; and the warp yarn and weft yarn of the inner layer are two strands of twined yarns of mixed yarns of 10 to 12.5tex of wool and cashmere. The invention also discloses a manufacturing method of the worsted fabric, which comprises the following steps of: preparing yarns, preparing twined yarns, warping, weaving, and performing after finishing. The worsted fabric has layering effect and three-dimensional effect, and patterns of the worsted fabric are three-dimensional, full and various.

Owner:嵊州雅戈尔毛纺织有限公司

High-hardness white unsaturated polyester priming paint and preparation method thereof

The invention relates to a chemical technology field, concretely, discloses high-hardness white unsaturated polyester priming paint and a preparation method thereof. The priming paint contains a first component, cobalt isocaprylate (blue wate), methylethyl ketone peroxide (white water), and a diluent, wherein the weight ratio of the first component, to cobalt isocaprylate (blue wate), to methylethyl ketone peroxide (white water) and to diluent is 100:(0.8-2):(1-2.5):(30-40). The high-hardness white unsaturated polyester priming paint and the preparation method resolve the problem that the PU polyurethane paint has bad hardness, the usage of unsaturated polyester paint reduces the VOC content of the paint, and the high-hardness white unsaturated polyester priming paint has good fullness and filling effect.

Owner:AODA KOALA PAINT HUIZHOU

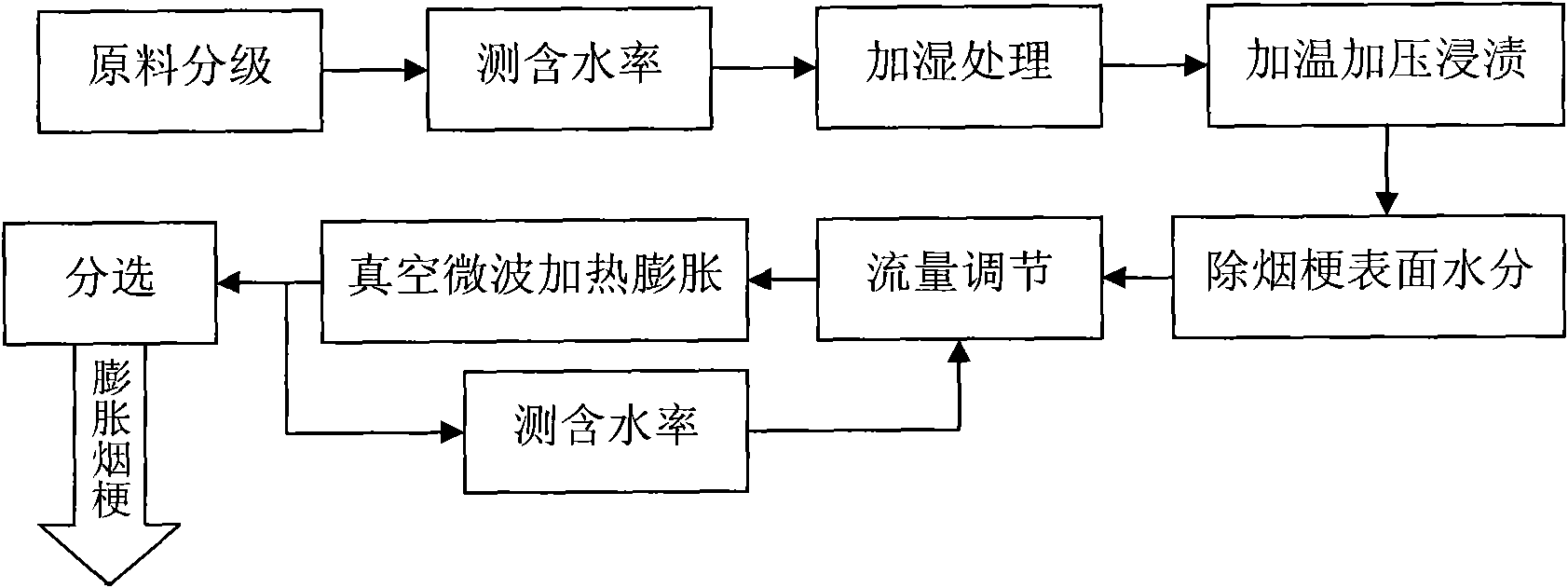

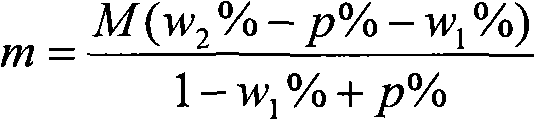

Tobacco stalk expansion method

InactiveCN101862023AUniform moistureUniform expansionTobacco preparationTobacco treatmentMicrowaveEngineering

The invention provides a tobacco stalk expansion method, which comprises the following steps of: grading tobacco stalks, performing impregnation remoistening on the graded tobacco stalks and expanding the tobacco stalks, wherein a microwave heating expansion method is adopted in the expansion of the tobacco stalks; preferably, the microwave heating expansion is performed on the tobacco stalks under a vacuum condition; more preferably, the microwave heating expansion is performed on the tobacco stalks by adopting more than two different kinds of continuous microwave output power under the vacuum condition, wherein the former two kinds of continuous microwave output power are 4.0 to 8.0 kw and 1.5 to 2.5 kw respectively for every kilogram of remoistened tobacco stalks; and the impregnation remoistening comprises the steps of: spraying water onto the tobacco stalks, and performing the impregnation remoistening under the pressure of 0.112 to 0.203 MPa and at the temperature of 50 to 100 DEG C. The expanded tobacco stalk has the characteristics of greater volume that is 1 to 3 times that of the conventional tobacco stalk, uniform expansion, remarkable fragrance, less wood smell, high resilience, the water content of 0.5 to 3 percent, high combustibility, improved intrinsic quality and relatively better smoke characteristic maintenance.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

Environment-friendly UV gloss oil for food packaging and printing

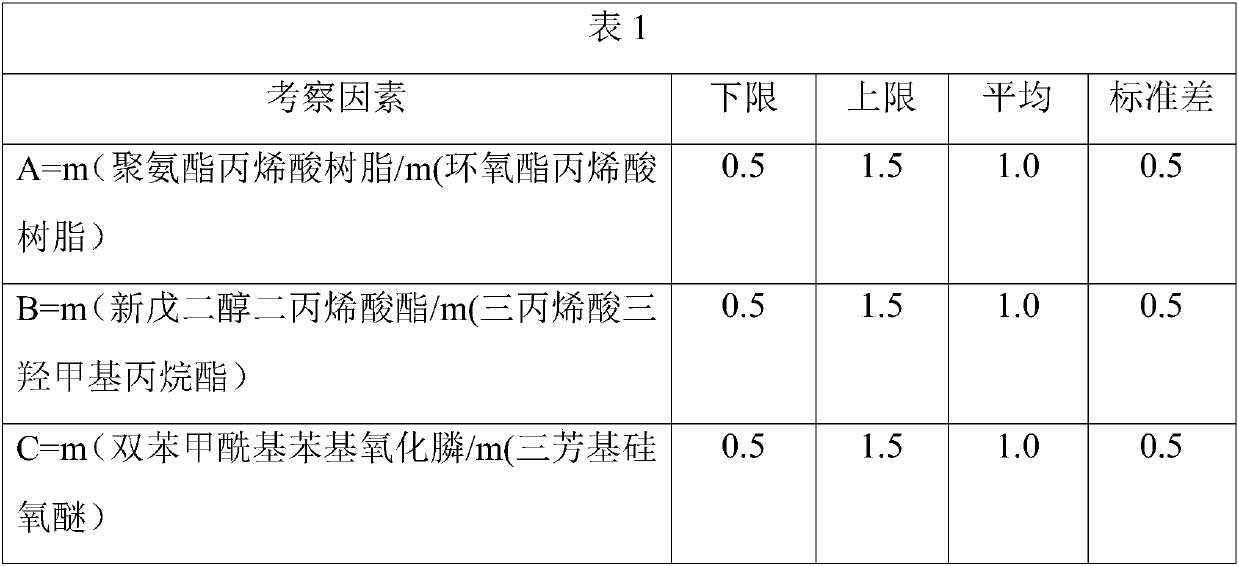

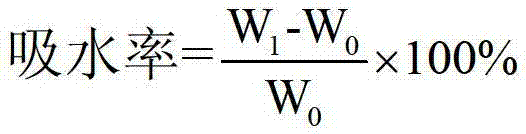

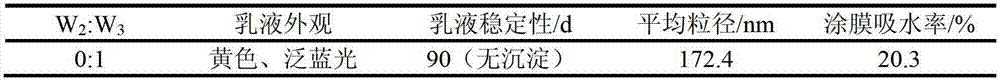

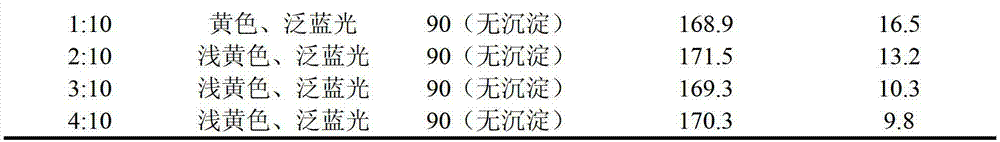

InactiveCN107652873ALow VOC residualLess volatile organicPolyurea/polyurethane coatingsEpoxy resin coatingsIsophoroneHardness

The invention relates to the field of UV gloss oil, in particular to environment-friendly UV gloss oil for food packaging and printing. The environment-friendly UV gloss oil comprises, by weight, 8-45% of prepolymer, 8-65% of active monomer, 1-15% photoinitiator, 0.05-2% of defoamer, 0.05-2% of flatting agent, 5-10% of thickener, 5-35% of solvent and 5-10% of isophorone. Free radical photoinitiator and cationic photoinitiator are added at the same time; through oxygen inhibition resisting and post-curing effects of cations, photocuring effect is enhanced, migration of the photoinitiators is reduced, and the environment-friendly UV gloss oil has the advantages of high solution resistance, good glossiness, high hardness and environment friendliness.

Owner:DONGGUAN POLYTECHNIC

Preparation method of acrylic-resin-modified water-based nitrocellulose emulsion for paint

The invention provides a preparation method of an acrylic-resin-modified water-based nitrocellulose emulsion for paint, which comprises the following steps: in an oxygen-free environment, reacting dehydrated dibutyltin dilaurate, isophorone diisocyanate tripolymer and N-methylpyrrolidone dissolved dimethylolpropionic acid at 40-45 DEG C for 1 hour, adding butanone dissolved nitrocellulose at 72 DEG C to react for 2 hours, cooling to 40 DEG C, regulating the pH value of the reaction solution to 8-9, cooling to room temperature, and adding water into the reaction solution while stirring uniformly to obtain a water-based nitrocellulose emulsion; and physically mixing the water-based acrylic emulsion and water-based nitrocellulose emulsion at room temperature to obtain the acrylic-resin-modified water-based nitrocellulose emulsion for paint. The preparation technique is simple; and the prepared acrylic-resin-modified water-based nitrocellulose emulsion for paint has the advantages of high stability, high flexibility, high adhesive force, certain fullness, yellowing resistance, water resistance and no pollution.

Owner:SHAANXI UNIV OF SCI & TECH

Polyester fully-drawn slub yarn and preparation method thereof

InactiveCN102828278AGood orientationEnsure productivityNew-spun product collectionFilament forming substance formingPolyesterBreaking strength

The invention discloses a polyester fully-drawn slub yarn and a preparation method thereof. On the basis of not changing the conventional FDY (fully-drawn yarn) production device, the polyester fully-drawn slub yarn is produced by using a one-step method implemented through adding a polymethyl methacrylate additive (mass percentage: 0.5-3.0%) into a polyester chip and then carrying out drawing on an obtained mixture at a drawing speed of 4600-5000m / min. The radial fineness ratio of the obtained slub yarn is 1.20-1.60 / l, the length of a thick section of the slub yarn is 15-40mm, and the slub density is 5-15 / m; and the breaking strength is 2.70-3.40 cN / dtex, and the breaking elongation is 40-80%. The polyester fully-drawn slub yarn prepared by using the technical scheme of the invention has the characteristics of high output, low cost, good quality, stable performance, high added values of products, and obvious price-performance advantages, and achieves the purposes of energy conservation, emission reduction, environmental protection, clean production and benefit incensement.

Owner:SUZHOU UNIV

Production method of breathable leather

ActiveCN103898773AImprove hydrolysis resistanceReduce manufacturing costLaminationLamination apparatusProduction lineSurface layer

The invention relates to a production method of breathable leather. The condition that in a production method of the breathable leather, environment pollution in the production process is free and the problem of product breathability is available can be solved at present can not be splved. The production method comprises the following steps: (1) preparing a sizing agent, wherein the sizing agent consists of polyurethane resin and color chips in a weight ratio of 100:1.2, and the viscosity of the sizing agent is adjusted to be 1500cps; (2) mounting release paper onto a PU (Polyurethane) production line, firstly, drying the release paper at 100 DEG C, subsequently coating the release paper with the sizing, and furthermore, drying at 140 DEG C so as to obtain a half-finished product; (3) printing a dry method surface layer of the release paper with patterns and glossiness by using a three-edition printing machine; (4) compounding the release paper with a piece of base cloth by using a binding agent; and (5) washing in water by using a graining machine; and (6) inspecting to be qualified to obtain a breathable leather product. By adopting the production method, the product breathability can be solved.

Owner:ZHEJIANG SHENTENG COATED FABRICS

Production technology for orderly dacron bamboo node yarns of identical specification

The invention discloses a production technology for orderly dacron bamboo node yarns of identical specification. The production technology for the orderly dacron bamboo node yarns of identical specification is characterized in that the production technology comprises the following steps that (1) polyester raw materials are sliced and conveyed to a material wetting bin, and ventilation drying is carried out after pre-crystallization; (2) under the melting condition, slices enter a screw extrusion machine, and then enter a spinning box after filtration; (3) the slices enter a spinning assembly for filament production after being metered through a metering pump; (4) side air blasting cooling is carried out, and oil is applied; (5) traction, stretching and heat shaping are carried out; (6) winding and forming are carried out through a winding head, and products are formed. The identical-specification orderly dacron bamboo node yarns prepared through the production technology have super-linen-imitated and super-wool-imitated styles and effects of being moisture absorbable, breathable, dry and comfortable in hand feeling, full in touch sense and good in drapability and wearing comfortableness and the like, and have the advantages of having the super-linen-imitated and super-wool-imitated styles and effects and being good in function and performance, obvious in cost performance and the like.

Owner:ZHONGRUN SCI & TECH

High-performance waterborne dual-component stoving varnish and preparation method thereof

InactiveCN106349910AReduce energy consumptionIncrease productionAntifouling/underwater paintsPaints with biocidesWaxEmulsion

The invention discloses a high-performance waterborne dual-component stoving varnish. The high-performance water-based dual-component stoving varnish is prepared from, by weight, 40-70 parts of waterborne polyurethane dispersoid, 1-10 parts of polyurethane curing agent, 5-30 parts of amino resin, 0.1-0.5 part of pH adjusting agent, 1-10 parts of pure acrylic resin emulsion, 0.1-0.5 part of waterborne multifunctional additive, 0.1-0.5 part of waterborne dispersing agent, 0.1-0.5 part of waterborne wetting agent, 10-30 parts of titanium dioxide, 1-7 parts of coalescing agents, 0.1-0.5 parts of waterborne antifoaming agent, 3-10 parts of tetrapod-shaped zinc oxide whisker powder, 0.5-1.5 parts of flatting agent, 0.5-1.5 parts of waterborne thickening agent, 1-5 parts of drier, 1-5 parts of flame retardant, 1-10 parts of wax emulsion, and 10-40 parts of water. The high-performance waterborne dual-component stoving varnish has the advantages that the product is free from poison and odor, and is energy-saving and environment-friendly, and able to reduce energy consumption.

Owner:YUNNAN KUNHUI NENGTONG TECH CO LTD

Waterborne tall oil alkyd resin emulsion and preparation method thereof

The invention provides waterborne tall oil alkyd resin emulsion and a preparation method thereof. Waterborne alkyd resin is prepared by taking tall oil extracted from papermaking waste liquid as a raw material; a preparation process comprises: (1) taking the tall oil to react with diethanolamine to prepare tall oil diethanolamide; (2) preparing a polyester intermediate by taking the tall oil diethanolamide and dibasic acid with a sulfonic group to react with dihydric alcohol; (3) taking the polyester intermediate, vegetable oil, fatty acid, polyatomic alcohol and polybasic acid to react and adding de-ionized water and dispersing to prepare alkyd resin water dispersoid. The tall oil extracted from the papermaking waste liquid is effectively utilized, and an application range of the tall oil is also expanded.

Owner:FOSHAN GUOHUA CHEM IND

Cotton and wool fiber blended fabric

The invention discloses a cotton and wool fiber blended fabric which is formed by blending long staple cotton and fine wool. The weight ratio of the long staple cotton in the whole blended fabric is 80%-90%, and the weight ratio of the fine wool in the whole blended fabric is 10%-20%. The long staple cotton comes from Xinjiang, and the fine wool comes from Australian Merino. The cotton and wool fiber blended fabric has the advantages of lasting heat insulation, comfort and breathability, original brightness and color brilliance of the fabric can be kept for a long term while the antibacterial performance is reinforced, the cotton and wool fiber blended fabric is soft in touch and natural in elasticity, and users can have rich velvet feeling.

Owner:SHANGHAI CONCH APPL

Highly heat-shrinkable polyamide fibers, and filament-mixed yarn and woven or knit fabric each including same

ActiveCN109072491AGood flexibilityHigh Density with High Soft FeelWeft knittingWarp knittingYarnPolymer science

Provided is woven or knit fabric which gives senses of denseness, bulkiness, and softness. Highly heat-shrinkable polyamide fibers can be provided, the fibers having a glass transition temperature (Tg) of 85-95 DEG C, a degree of shrinkage with boiling water (B) of 30-50%, and a stress of heat shrinkage (H) of 0.20 cN / dtex or greater.

Owner:TORAY IND INC

Moisture-absorbing loop pile polyester carpet and manufacturing method thereof

PendingCN111809409AImprove water absorptionDehydration fastConstructions elementsCoatingsPolyesterPolymer science

The invention discloses a moisture-absorbing loop pile polyester carpet and a manufacturing method thereof. The moisture-absorbing loop pile polyester carpet comprise a base cloth layer and a carpet face layer. The carpet face layer is formed by Z-twist-direction yarn through self-twisting during tufting on the base cloth layer, and the Z-twist-direction yarn is formed by stranded and doubled polyester filament fiber through machining. The moisture-absorbing loop pile polyester carpet has super-high water absorbing quality and quick-drying performance, good heat retention property, good filling power and a gentle and slippery hand feel, the hand feel of the carpet is similar like the texture of cotton, the full weight is high, and lint falling is avoided.

Owner:KUNSHAN YIJIAJU TEXTILE CO LTD

Inorganic fire-prevention rust-prevention coating for steel structures and preparation method thereof

InactiveCN103205143AImprove high temperature resistanceHigh temperature resistance solutionFireproof paintsAlkali metal silicate coatingsMetasilicateGranularity

The invention discloses an inorganic fire-prevention rust-prevention coating for steel structures and a preparation method thereof. The coating is a mixture of powder and colloid. The weight ratio of power to colloid is 1:(0.8-1.2). The colloid is potassium metasilicate. The powder is prepared from the following components in percentage by weight: 5-40% of magnesium mountain powder, 5-40% of talcum powder, 4-35% of silica powder and 4-25% of silicon aluminium powder. The granularity of the magnesium mountain powder is 2500-6500 meshes, the granularity of the talcum powder is 2000-6000 meshes, the granularity of the silica powder is 3000-8000 meshes, and the granularity of the silicon aluminium powder is 600-2000 meshes. According to the preparation method of the inorganic fire-prevention rust-prevention coating for steel structures, provided by the invention, the powder and the colloid are mixed uniformly. The inorganic fire-prevention rust-prevention coating for steel structures has good high-temperature-resistant performance and good rust-prevention effect.

Owner:王建文

Oil-in-water emulsion-type hair cosmetic

InactiveCN102131493APromote absorptionGood spreadabilityCosmetic preparationsHair cosmeticsAlcoholOil phase

Provided is an oil-in-water emulsion-type hair cosmetic which is highly compatible with the hair and easily spreadable thereon, does not fall in drops in using, and has a transparent or translucent and beautiful gel-like appearance while having a rich texture and exerting a high repairing effect comparable to oil-based hair-care products. The oil-in-water emulsion-type hair cosmetic, comprises: (a) 0.1 to 10 mass% of a silicone compound selected from among a high-molecular silicone having a gummy nature or a viscosity of 1,000,000 cs or higher, a silicone hydroxyl-modified at both ends, an amino-modified silicone, an ammonium-modified silicone and a polyalkylene glycol-modified silicone; (b) 0.5 to 79 mass% of dimethylpolysiloxane having a viscosity of 100 cs or lower; (c) 1 to 25 mass% of a polyhydric alcohol; and (d) 1 to 10 mass% of a hydrophilic surfactant, wherein the content of the oily phase is 50-80 mass%, and the composition ratio by mass of (a) to (b) is 1:100 to 1:5.

Owner:SHISEIDO CO LTD

Preparation method of selenium-enriched grape vinegar

InactiveCN107805589AIncrease nutritionAdd flavorMicroorganism based processesVinegar preparationAlcoholFood flavor

The invention mainly relates to the technical field of food processing and discloses a preparation method of selenium-enriched grape vinegar. The preparation method comprises the following steps: preparing raw materials; carrying out primary fermentation; carrying out secondary fermentation; filtering; packaging. The selenium-enriched grape vinegar has abundant nutrients, is sour and sweet and palatable, and has a rich fruit aroma; the selenium content reaches 7.31mu g / 100g; the variety of fruit vinegar in the market is enriched, and the requirements on nutrients and mouthfeel of consumers aremet; grape leaves are added into grape pulp and wastes are changed into valuable materials; nutrients and flavor of the grape vinegar are increased; the health-care function of the grape vinegar is enhanced and the grape vinegar has the effects of stopping bleeding and eliminating swelling, promoting a gastrointestinal function and protecting heart and cerebral vessels; alcohol fermentation is firstly carried out and beneficial components in the raw materials are sufficiently leached out; infectious microbes in the raw materials are killed and the fruit vinegar has a pure mouthfeel; yeast selenium is added and acetic acid bacteria are introduced to carry out acetic acid fermentation; and a bitter mouthfeel of the grape leaves is removed; the aroma of the fruit vinegar is increased so thatthe grape vinegar has the abundant mouthfeel, and is sour and sweet and palatable.

Owner:全椒玉屏山庄葡萄种植专业合作社

Aqueous exterior wall coating with temperature control mildew resistance and preparation method of coating

ActiveCN109608971ASensitive to temperatureGood weather resistanceAntifouling/underwater paintsPaints with biocidesPhenolChemical stability

The invention belongs to the field of coatings, and particularly relates to an aqueous exterior wall coating with temperature control mildew resistance and a preparation method of the coating. The coating comprises the following components: an isopropyl acrylamide modified acrylate emulsion, an organosilicone modified acrylate emulsion, isothiazolinone, lightweight calcium carbonate, talc powder,a dispersing agent, a levelling agent and deionized water, wherein the isopropyl acrylamide modified acrylate emulsion is prepared from the following components: N-isopropyl acrylamide, butyl acrylate, acrylic acid, allyloxypropyl alkyl phenol polyether, a dialkyl sulfosuccinate salt of allyl, ammonium persulfate and deionized water. The coating provided by the invention is a novel exterior wall anti-mildew coating capable of controlling a release speed of an anti-mildew agent at different temperatures, has high mildew resistance, good weather resistance, light and thermal stability, chemicalstability, stain resistance, wash resistance, corrosion resistance and self-cleaning performance, and also has gloss and fullness. The invention also provides the preparation method of the coating.

Owner:ZIBO VOCATIONAL INST

Hydrophilic copper ion antibacterial AB double-color yarn and spinning process thereof

The invention relates to the field of yarn spinning, in particular to hydrophilic copper ion antibacterial AB double-color yarn. The hydrophilic copper ion antibacterial AB double-color yarn comprises 4 to 8 weight percent of Capron copper ion antibacterial fiber and 92 to 96 percent of McNoffen ultrafine regenerated cellulose fiber. The two types of fiber are spun into the yarn through the spinning process. The hydrophilic copper ion antibacterial AB double-color yarn has the advantages of full surface impression, stereoscopic impression, antibacterial property and hygroscopicity, can be applied to high-grade underwear, leisure outerwear, household textiles and the like, and can meet the demands of customers for functionality and diversity of textiles.

Owner:江苏泗水纺织有限公司

Tobacco stalk expansion method

InactiveCN101862023BUniform moistureUniform expansionTobacco preparationTobacco treatmentMicrowaveEngineering

The invention provides a tobacco stalk expansion method, which comprises the following steps of: grading tobacco stalks, performing impregnation remoistening on the graded tobacco stalks and expanding the tobacco stalks, wherein a microwave heating expansion method is adopted in the expansion of the tobacco stalks; preferably, the microwave heating expansion is performed on the tobacco stalks under a vacuum condition; more preferably, the microwave heating expansion is performed on the tobacco stalks by adopting more than two different kinds of continuous microwave output power under the vacuum condition, wherein the former two kinds of continuous microwave output power are 4.0 to 8.0 kw and 1.5 to 2.5 kw respectively for every kilogram of remoistened tobacco stalks; and the impregnation remoistening comprises the steps of: spraying water onto the tobacco stalks, and performing the impregnation remoistening under the pressure of 0.112 to 0.203 MPa and at the temperature of 50 to 100 DEG C. The expanded tobacco stalk has the characteristics of greater volume that is 1 to 3 times that of the conventional tobacco stalk, uniform expansion, remarkable fragrance, less wood smell, high resilience, the water content of 0.5 to 3 percent, high combustibility, improved intrinsic quality and relatively better smoke characteristic maintenance.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

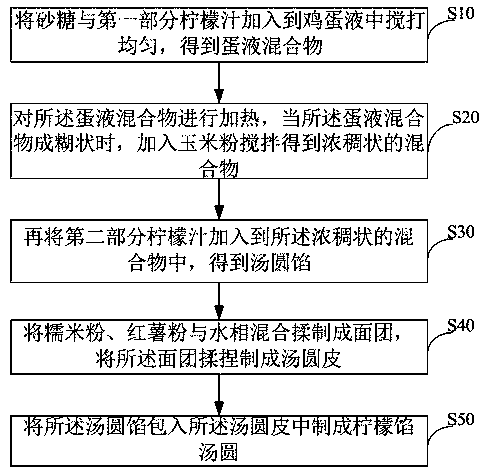

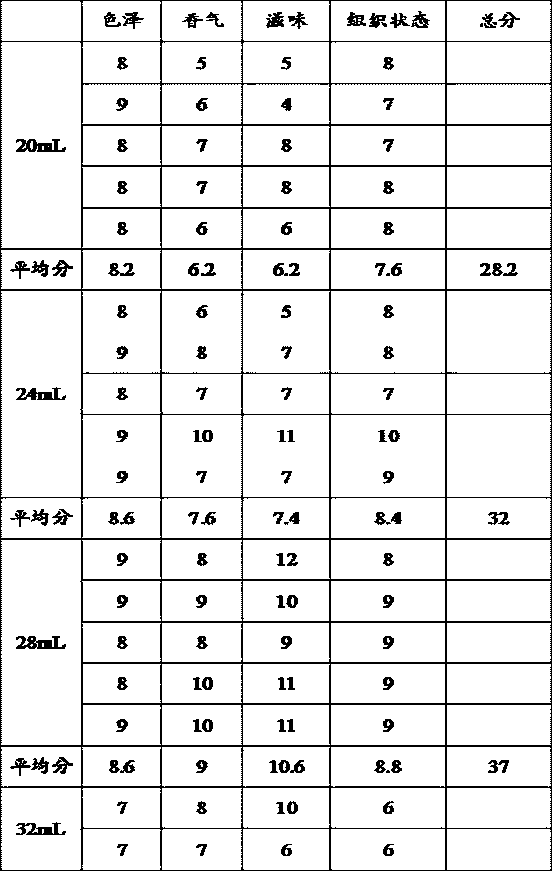

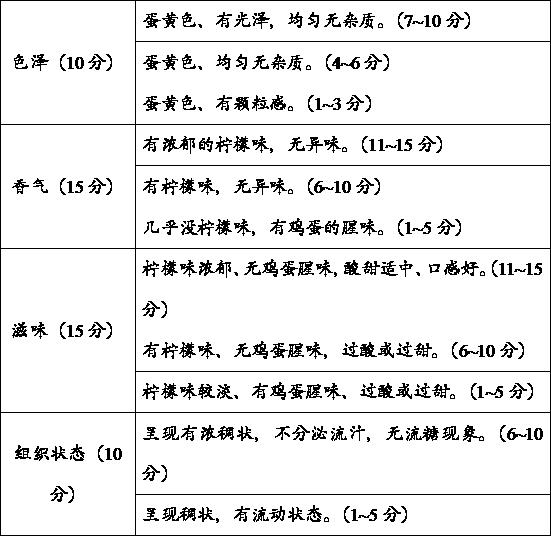

Glutinous rice balls with lemon stuffing and preparation method thereof

InactiveCN109198418ARefreshing tasteStrong aromaFood coatingFood ingredient as flavour affecting agentHorticultureCitric acid

The invention discloses glutinous rice balls with lemon stuffing and a preparation method thereof. According to the glutinous rice balls with the lemon stuffing and the preparation method thereof, lemon fruits are squeezed into lemon juice, and used as a raw material for preparing the glutinous rice balls; and thus, the problems of high sugar content, high fat content, high calorie, sweet and greasy taste and the like of traditional glutinous rice balls are solved. By using egg liquid and the lemon juice for preparing the stuffing of the glutinous rice balls, the prepared glutinous rice ballswith the lemon stuffing are refreshing in taste, not too sweet, not greasy and mellow in aroma; moreover, the glutinous rice balls with the lemon stuffing also have certain mind-refreshing and consciousness-restoring functions. By adding the whipped egg liquid, the stuffing becomes looser so as to have taste of the glutinous rice balls with the lemon stuffing improved; moreover, the problems of difficult molding and the like caused by relatively low solid content and rich citric acid of the lemon juice are also solved.

Owner:HEYUAN POLYTECHNIC

Preparation method and product of self-emulsification type water-based NC (nitrocellulose) emulsion

InactiveCN107857860ASimple preparation processFullnessPolyurea/polyurethane coatingsFiberWater based

The invention provides a preparation method of self-emulsification type water-based NC (nitrocellulose) emulsion. Under the nitrogen gas protection, dibutyltin dilaurate, HDI (hexamethylene diisocyanate) and DMBA (dimethylolbutanoic acid) subjected to dehydration treatment are added into a four-mouth flask; reaction is performed for 1h at 45 DEG C; then, NC subjected to butanone dissolution is added; the temperature is raised to 75 DEG C; reaction is performed for 2h; then, the temperature is lowered to 40 DEG C; triethylamine salt with the identical amount of substance as the DMBA is added; reaction is performed for 40min; next, the temperature is lowered to 25 DEG C; under the high-speed stirring, 50ml of deionized water is added into reaction liquid for emulsification; reaction is performed for 30min; the self-emulsification type water-based NC emulsion is obtained. The invention also discloses the self-emulsification type water-based NC emulsion prepared by the method. The preparation process is simple; the prepared emulsion has excellent performance of high stability, good flexibility, high adhesive force, certain fullness, yellowing resistance, water resistance and green andenvironment-friendly effects.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of processing method of cotton Tencel double-sided fleece fabric with improved fluff uniformity

ActiveCN111005186BGood wash appearanceImprove orderLiquid/gas/vapor removalTextile treatment by spraying/projectingTextile printerPolymer science

The invention discloses a method for processing a cotton tencel double-faced fleece fabric with improved fluff uniformity, which comprises the following steps: the cotton tencel blended yarn fabric is singed, enzyme desizing, rebleaching, soft finishing, napping, and humidification Shearing, drying and shearing, printing or dyeing, and post-finishing process, the cotton tencel double-faced fleece fabric is obtained. In the humidification and shearing process, steam box or atomization method is used to humidify the cloth surface. The covering rate of the weft yarn on the surface of the fabric is 66% to 88%, and the moisture content of the cloth surface after humidification in the humidification and shearing process is 80% to 90%. The cotton and tencel blended yarn fabric of the present invention has good fluff uniformity, and the fabric has a very good appearance after washing. After washing, the fluff is not clustered and messy, and has a plump wool feeling, and at the same time, the strength of the fluff is not damaged. .

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

A production process of isotactic ordered polyester slub yarn

ActiveCN104451919BMoisture-absorbing and breathableFeel dryMelt spinning methodsStretch-spinning methodsPolyesterYarn

The invention discloses a production technology for orderly dacron bamboo node yarns of identical specification. The production technology for the orderly dacron bamboo node yarns of identical specification is characterized in that the production technology comprises the following steps that (1) polyester raw materials are sliced and conveyed to a material wetting bin, and ventilation drying is carried out after pre-crystallization; (2) under the melting condition, slices enter a screw extrusion machine, and then enter a spinning box after filtration; (3) the slices enter a spinning assembly for filament production after being metered through a metering pump; (4) side air blasting cooling is carried out, and oil is applied; (5) traction, stretching and heat shaping are carried out; (6) winding and forming are carried out through a winding head, and products are formed. The identical-specification orderly dacron bamboo node yarns prepared through the production technology have super-linen-imitated and super-wool-imitated styles and effects of being moisture absorbable, breathable, dry and comfortable in hand feeling, full in touch sense and good in drapability and wearing comfortableness and the like, and have the advantages of having the super-linen-imitated and super-wool-imitated styles and effects and being good in function and performance, obvious in cost performance and the like.

Owner:ZHONGRUN SCI & TECH

Water-based exterior wall paint with temperature control and anti-mildew performance and preparation method thereof

ActiveCN109608971BSensitive to temperatureGood weather resistanceAntifouling/underwater paintsPaints with biocidesPowder talcAmmonium sulfate

The invention belongs to the field of coatings, and particularly relates to an aqueous exterior wall coating with temperature control mildew resistance and a preparation method of the coating. The coating comprises the following components: an isopropyl acrylamide modified acrylate emulsion, an organosilicone modified acrylate emulsion, isothiazolinone, lightweight calcium carbonate, talc powder,a dispersing agent, a levelling agent and deionized water, wherein the isopropyl acrylamide modified acrylate emulsion is prepared from the following components: N-isopropyl acrylamide, butyl acrylate, acrylic acid, allyloxypropyl alkyl phenol polyether, a dialkyl sulfosuccinate salt of allyl, ammonium persulfate and deionized water. The coating provided by the invention is a novel exterior wall anti-mildew coating capable of controlling a release speed of an anti-mildew agent at different temperatures, has high mildew resistance, good weather resistance, light and thermal stability, chemicalstability, stain resistance, wash resistance, corrosion resistance and self-cleaning performance, and also has gloss and fullness. The invention also provides the preparation method of the coating.

Owner:ZIBO VOCATIONAL INST

Preparation method of acrylic-resin-modified water-based nitrocellulose emulsion for paint

The invention provides a preparation method of an acrylic-resin-modified water-based nitrocellulose emulsion for paint, which comprises the following steps: in an oxygen-free environment, reacting dehydrated dibutyltin dilaurate, isophorone diisocyanate tripolymer and N-methylpyrrolidone dissolved dimethylolpropionic acid at 40-45 DEG C for 1 hour, adding butanone dissolved nitrocellulose at 72 DEG C to react for 2 hours, cooling to 40 DEG C, regulating the pH value of the reaction solution to 8-9, cooling to room temperature, and adding water into the reaction solution while stirring uniformly to obtain a water-based nitrocellulose emulsion; and physically mixing the water-based acrylic emulsion and water-based nitrocellulose emulsion at room temperature to obtain the acrylic-resin-modified water-based nitrocellulose emulsion for paint. The preparation technique is simple; and the prepared acrylic-resin-modified water-based nitrocellulose emulsion for paint has the advantages of high stability, high flexibility, high adhesive force, certain fullness, yellowing resistance, water resistance and no pollution.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of high hardness unsaturated polyester white primer and preparation method thereof

The invention relates to a chemical technology field, concretely, discloses high-hardness white unsaturated polyester priming paint and a preparation method thereof. The priming paint contains a first component, cobalt isocaprylate (blue wate), methylethyl ketone peroxide (white water), and a diluent, wherein the weight ratio of the first component, to cobalt isocaprylate (blue wate), to methylethyl ketone peroxide (white water) and to diluent is 100:(0.8-2):(1-2.5):(30-40). The high-hardness white unsaturated polyester priming paint and the preparation method resolve the problem that the PU polyurethane paint has bad hardness, the usage of unsaturated polyester paint reduces the VOC content of the paint, and the high-hardness white unsaturated polyester priming paint has good fullness and filling effect.

Owner:AODA KOALA PAINT HUIZHOU

A kind of water-based tall oil alkyd resin emulsion and preparation method thereof

The invention provides waterborne tall oil alkyd resin emulsion and a preparation method thereof. Waterborne alkyd resin is prepared by taking tall oil extracted from papermaking waste liquid as a raw material; a preparation process comprises: (1) taking the tall oil to react with diethanolamine to prepare tall oil diethanolamide; (2) preparing a polyester intermediate by taking the tall oil diethanolamide and dibasic acid with a sulfonic group to react with dihydric alcohol; (3) taking the polyester intermediate, vegetable oil, fatty acid, polyatomic alcohol and polybasic acid to react and adding de-ionized water and dispersing to prepare alkyd resin water dispersoid. The tall oil extracted from the papermaking waste liquid is effectively utilized, and an application range of the tall oil is also expanded.

Owner:FOSHAN GUOHUA CHEM IND

High heat-shrinkable polyamide fiber and blended yarn and fabric using the polyamide fiber

ActiveCN109072491BGood flexibilityHigh Density with High Soft FeelWeft knittingWarp knittingPolymer scienceHigh density

The present invention provides fabrics with high density, fullness and softness. It is possible to provide a highly heat-shrinkable polyamide fiber with a glass transition temperature (Tg) of 85-95°C, a boiling water shrinkage rate (B) of 30-50%, and a heat-shrinkage stress (H) of 0.20 cN / dtex or more.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com