Manufacturing method of electrical contact

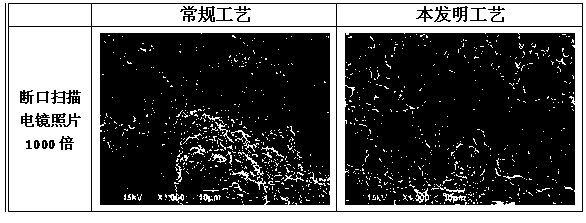

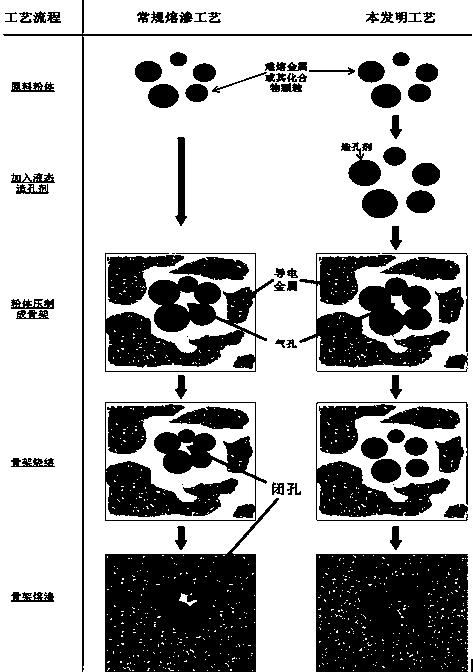

A manufacturing method and technology of electrical contacts, which are applied to circuits, electrical switches, electrical components, etc., can solve the problems of reducing the bonding strength of product organization, unable to completely eliminate closed pores, etc., and achieve improved infiltration performance, uniform and dense organization, and organization. more effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

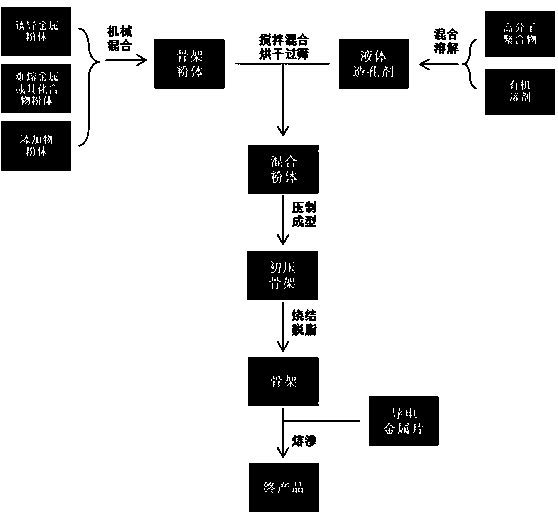

Method used

Image

Examples

Embodiment 1

[0028] Preparation of liquid pore-forming agent: first place isopropanol in a water-bath heating agitator at a temperature of 50°C, and set the speed at 100rpm, then continuously and slowly add polyacrylate for 5 minutes, and keep warm for 1 hour until it is completely dissolved ;

[0029] To prepare AgW50 electrical contact products: mix Ag powder and W powder in a mass ratio of 30:70 to form a skeleton powder. Put the skeleton powder in the mixer, turn on the mixer, set the speed to 10rpm, then let go of the faucet under the container, drop 3%wt liquid pore-forming agent into the mixer at a constant speed, the flow rate is 0.5L / min, and stir for 5min , and then sieve and dry. The dried powder is pressed into a skeleton in a special mold according to the drawing specifications. Arrange the skeleton on the graphite plate, put it into the sintering furnace, under the protection of hydrogen atmosphere, sinter at 300°C for 1 hour, remove the pore-forming agent, and form a u...

Embodiment 2

[0031] Preparation of liquid pore-forming agent: first place isopropanol in a water bath heating stirrer, the temperature is 70°C, and the speed is set to 300rpm, then continuously and slowly add polyacrylate for 30 minutes, keep warm for 1 hour until it is completely dissolved ;

[0032] To make AgWC40 products, mix Ag powder and WC powder at a mass ratio of 50:50 to form a skeleton powder. Put the skeleton powder in the mixer, turn on the mixer, set the speed to 30rpm, then let go of the faucet under the container, drop 5%wt liquid pore-forming agent into the mixer at a uniform speed, the flow rate is 1L / min, stir for 30min, and then Sieve and dry. The dried powder is pressed into a skeleton in a special mold according to the drawing specifications. Arrange the skeleton on a graphite plate, put it into a sintering furnace, and sinter at 600°C for 5 hours under the protection of a hydrogen atmosphere to remove the pore-forming agent. After the skeleton is cooled, take it o...

Embodiment 3

[0034] Preparation of liquid pore-forming agent: first place isopropanol in a water-bath heating agitator at a temperature of 80°C, and set the speed at 400rpm, then continuously and slowly add polyacrylate for 0.5 hours, and keep warm for 2 hours until it is completely dissolved ;

[0035] To make CuW95 products, mix Cu powder and W powder at a mass ratio of 15:85 to form a skeleton powder. Put the skeleton powder in the mixer, turn on the mixer, set the speed to 50rpm, then let go of the faucet under the container, and drop 0.1%wt liquid pore-forming agent into the mixer at a uniform speed, the flow rate is 2L / min, stir for 50min, and then Sieve and dry. The dried powder is pressed into a skeleton in a special mold according to the drawing specifications. Arrange the skeleton on a graphite plate, put it into a sintering furnace, and sinter at 500°C for 2 hours under the protection of a hydrogen atmosphere to remove the pore-forming agent. After the skeleton is cooled, tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com