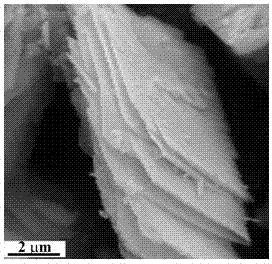

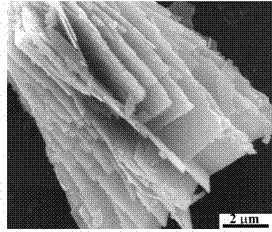

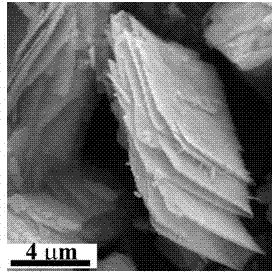

Co3O4 nano lamellar material and preparation method and application thereof

A nanosheet-like, negative electrode material technology, applied in nanotechnology, electrical components, battery electrodes, etc., can solve the problems of low irreversible efficiency, poor cycle stability, and poor structural stability for the first time, and achieve good embedding/extraction electrochemical behavior, Effects of improved rate characteristics, good electrochemical stability and cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Get 3.63g cobalt nitrate (Co(NO 3 ) 2 6H 2 O, analytically pure, Sinopharm Chemical Reagent Company), 2.25g urea (H 2 NCONH 2 , analytically pure, Shanghai Jiuyi Chemical Reagent Co., Ltd.), 9.11g cetyltrimethylammonium bromide (CTAB, analytically pure, Shanghai Chemical Reagent Company) was added to 60ml deionized water, wherein Co(NO 3 ) 2 :CTAB:H 2 NCONH 2 : The molar ratio of water is 1:2:3:266.67, and the whole adding process is carried out under magnetic stirring (81-2 type, Shanghai Sile Instrument Co., Ltd.). After stirring for 40 minutes, move the entire mixed solution into a polytetrafluoroethylene-lined autoclave (100ml, Zhengxin Instrument Factory) with a filling degree of 60%, react at a certain temperature (115°C) for 17.5 hours, and then cool naturally , get the reaction liquid;

[0052] Centrifuge the above reaction solution, control the centrifugation speed to 3300r / min, and the time is 20min. The obtained centrifuged solids are washed 3 times...

Embodiment 2

[0056] Take 3.63 g cobalt nitrate (Co(NO 3 ) 2 6H 2 O, analytically pure, Sinopharm Chemical Reagent Company), 2.25 g urea (H 2 NCONH 2 , analytically pure, Shanghai Jiuyi Chemical Reagent Co., Ltd.), 9.11 g cetyltrimethylammonium bromide (CTAB, analytically pure, Shanghai Chemical Reagent Company) was added to 75 ml deionized water, Co(NO 3 ) 2 : CTAB: H 2 NCONH 2 : The molar ratio of water is 1:2:3:333.33, and the whole adding process is carried out under magnetic stirring (81-2 type, Shanghai Sile Instrument Co., Ltd.). After stirring for 60 minutes, move the entire mixed solution into a polytetrafluoroethylene-lined autoclave (100ml, Zhengxin Instrument Factory) with a filling degree of 75%, react at a certain temperature (120°C) for 18 hours, and then cool naturally. get the reaction solution.

[0057] Centrifuge the above reaction solution, control the centrifugation speed to be 3500r / min, and the time is 30min, and the obtained centrifuged solids are washed 3 ...

Embodiment 3

[0061] Take 3.63 g cobalt nitrate (Co(NO 3 ) 2 6H 2 O, analytically pure, Sinopharm Chemical Reagent Company), 2.25 g urea (H 2 NCONH 2 , analytically pure, Shanghai Jiuyi Chemical Reagent Co., Ltd.), 9.11 g cetyltrimethylammonium bromide (CTAB, analytically pure, Shanghai Chemical Reagent Company) was added to 70 ml deionized water, Co(NO 3 ) 2 : CTAB: H 2 NCONH 2 : The molar ratio of water is 1:2:3:311.12, and the whole adding process is carried out under magnetic stirring (81-2 type, Shanghai Sile Instrument Co., Ltd.). After stirring for 50 minutes, move the entire mixed solution into a polytetrafluoroethylene-lined autoclave (100ml, Zhengxin Instrument Factory) with a filling degree of 70%, react at a certain temperature (120°C) for 18 hours, and then cool naturally. get the reaction solution;

[0062] The above-mentioned reaction solution was centrifuged, and the centrifugation speed was controlled to be 3500r / min, and the time was 25min. The solid matter after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com