Microstructure body and manufacturing method thereof

A technology for microstructures and manufacturing methods, which can be used in nanostructure manufacturing, anodization, nanotechnology, etc., and can solve problems such as inability to ensure continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] "The first embodiment of the method of manufacturing a microstructure"

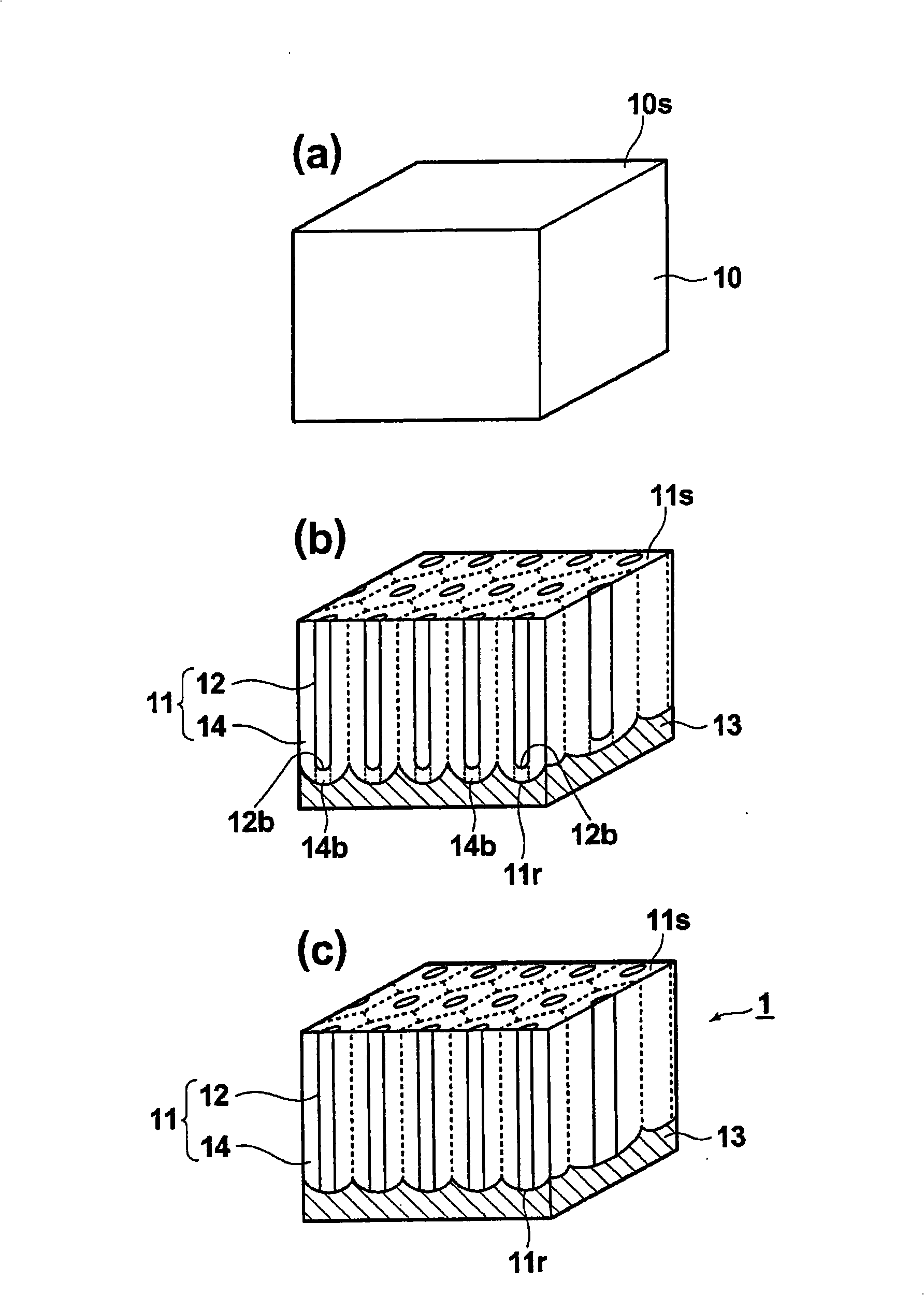

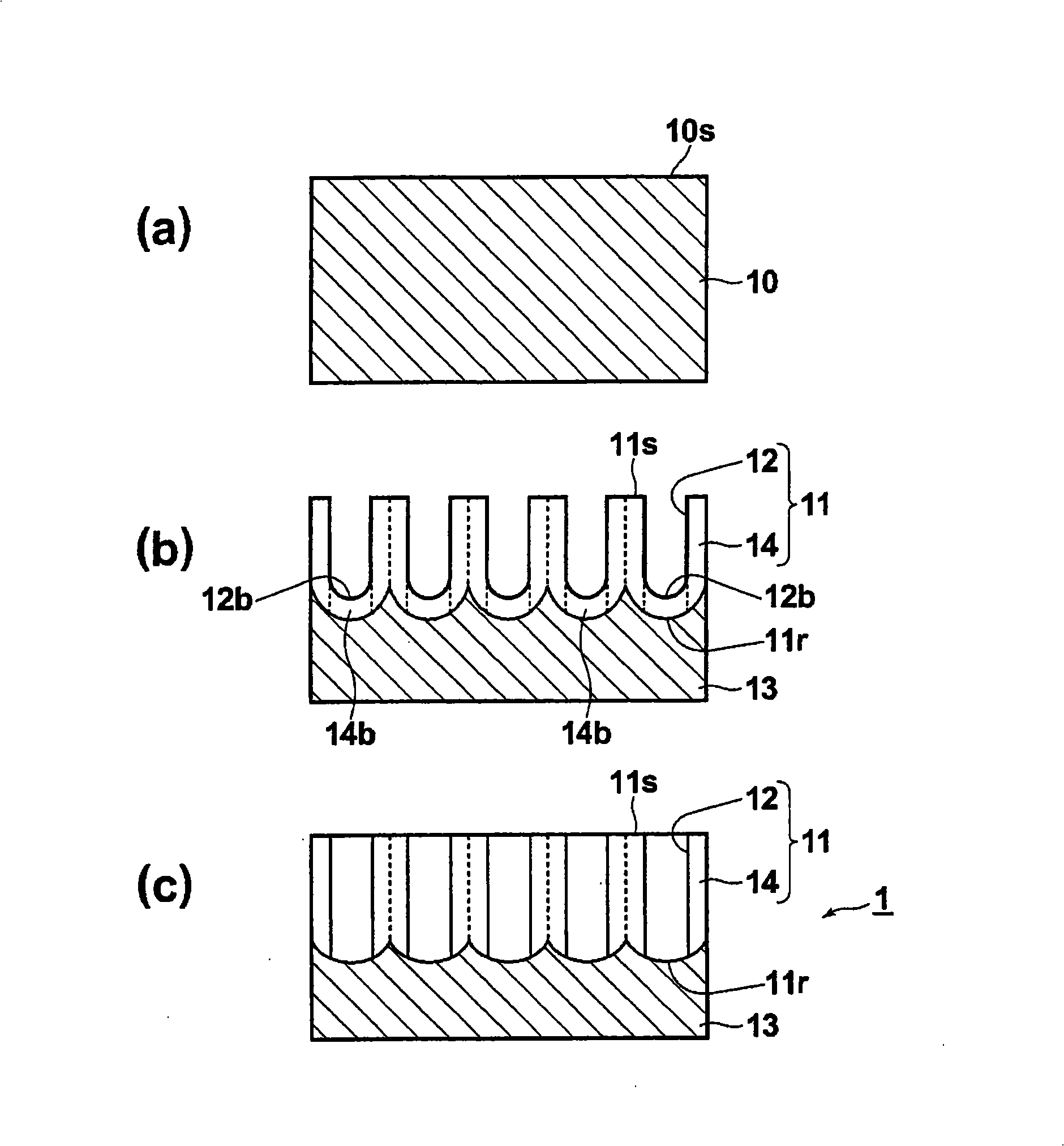

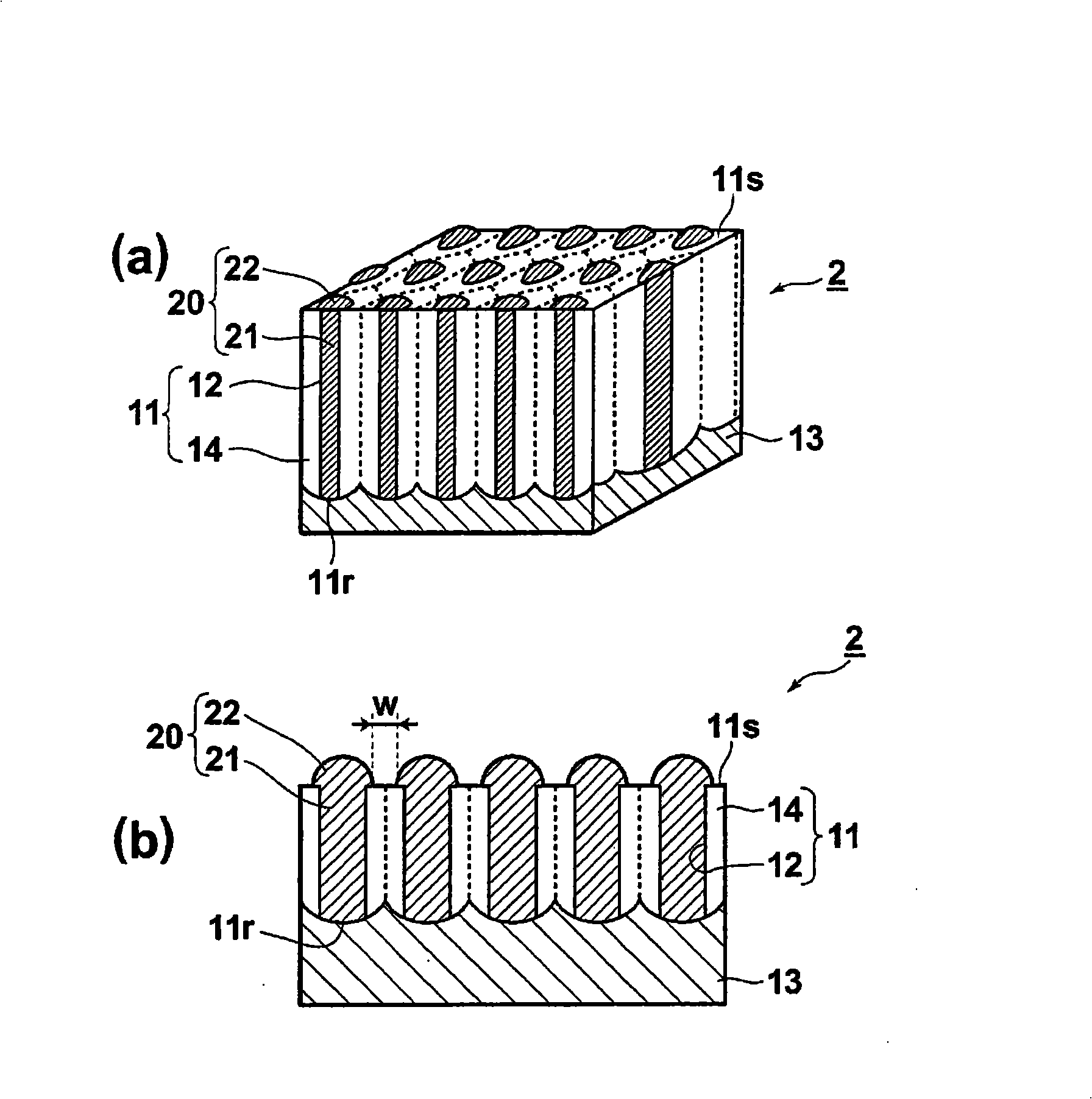

[0051] A first embodiment of the method for producing a microstructure according to the present invention will be described with reference to the drawings. figure 1 and figure 2 It is a process diagram showing the manufacturing method, figure 1 is a stereogram, figure 2 With figure 1 Corresponding sectional view.

[0052] First, as the anodized metal body 10, an anodized metal body 10 ( figure 1 (a), figure 2 (a)). The shape of the anodized metal body 10 is not limited, and examples thereof include a plate shape and the like. In addition, it may be used in the form of having a support such as one in which the anodized metal body 10 is formed into a layered film on a support.

[0053] Next, the anodized metal body 10 is anodized until halfway, an aluminum oxide (Al 2 o 3 ) layer composed of anodized film (anodized part, anodized body) 11. Such as figure 1 (b), figure 2 As shown in (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com