Polarized light splitting device and method for manufacturing the same

A technology for separating components and polarizing light, which is applied in the direction of optical components, optics, instruments, etc., can solve problems such as deterioration of optical characteristics, and achieve the effect of preventing deterioration of optical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments of the present invention will be described.

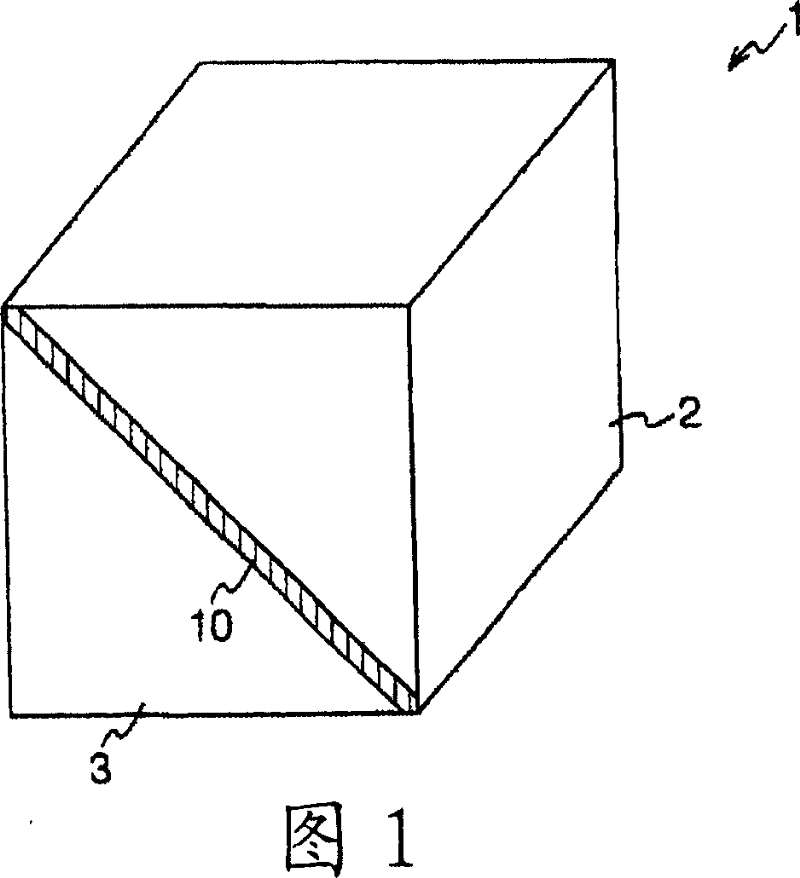

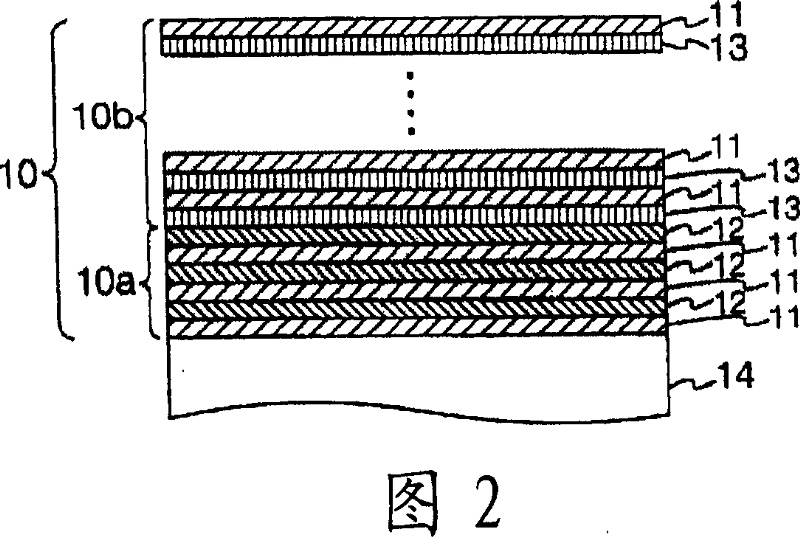

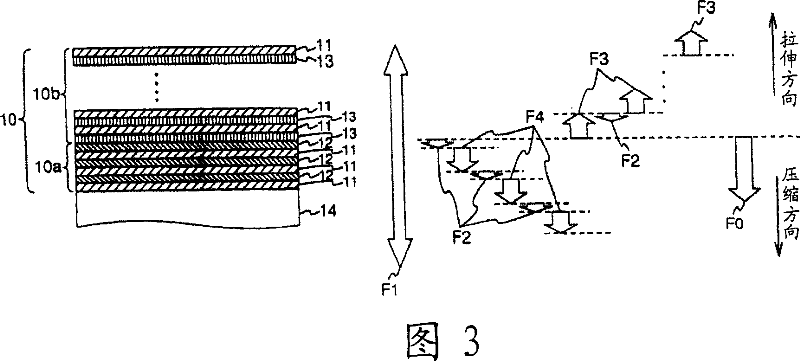

[0034]FIG. 1 is a diagram showing the structure of a polarization separation element according to an embodiment of the present invention.

[0035] The polarized beam splitter (polarized light splitting element) 1 of this embodiment shown in FIG. 1 is configured as a cube by joining two right-angled triangular prisms 2 and 3 through a polarized light splitting film 10, for example, it has a predetermined Polarized light components (P polarized light) are transmitted, and on the other hand, other polarized light components (S polarized light) are reflected.

[0036] The polarized light separation film 10 is a film having a property of selectively transmitting either S-polarized light and P-polarized light, and selectively reflecting the other. In addition, the polarized light separation film 10 will be described later.

[0037] In addition, in the polarization beam splitter 1 of the present embodiment conf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com