Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

157 results about "Visual defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Visual defect - impairment of the sense of sight. vision defect, visual disorder, visual impairment. amaurosis - partial or total loss of sight without pathology of the eye; caused by disease of optic nerve or retina or brain. amblyopia - visual impairment without apparent organic pathology.

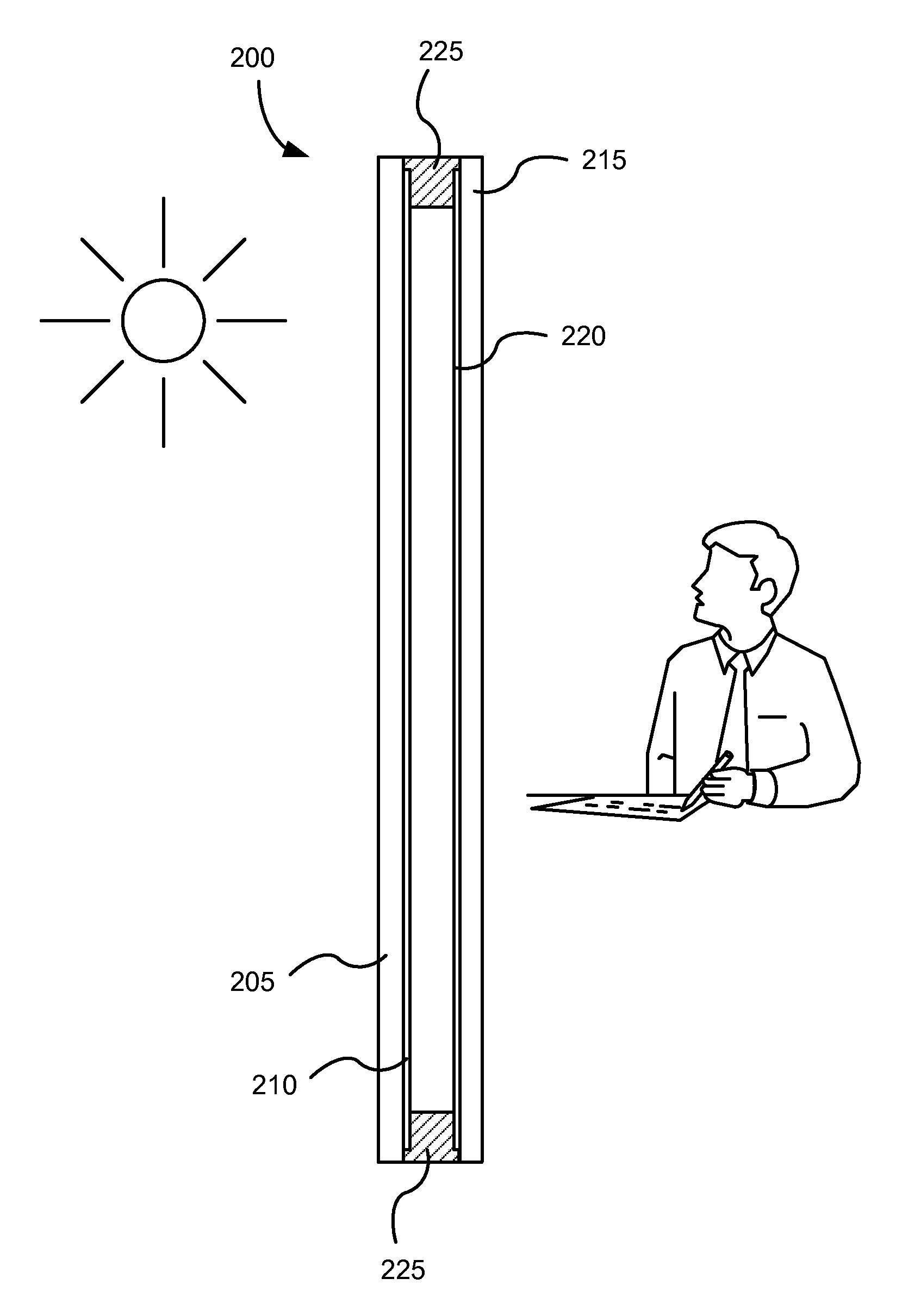

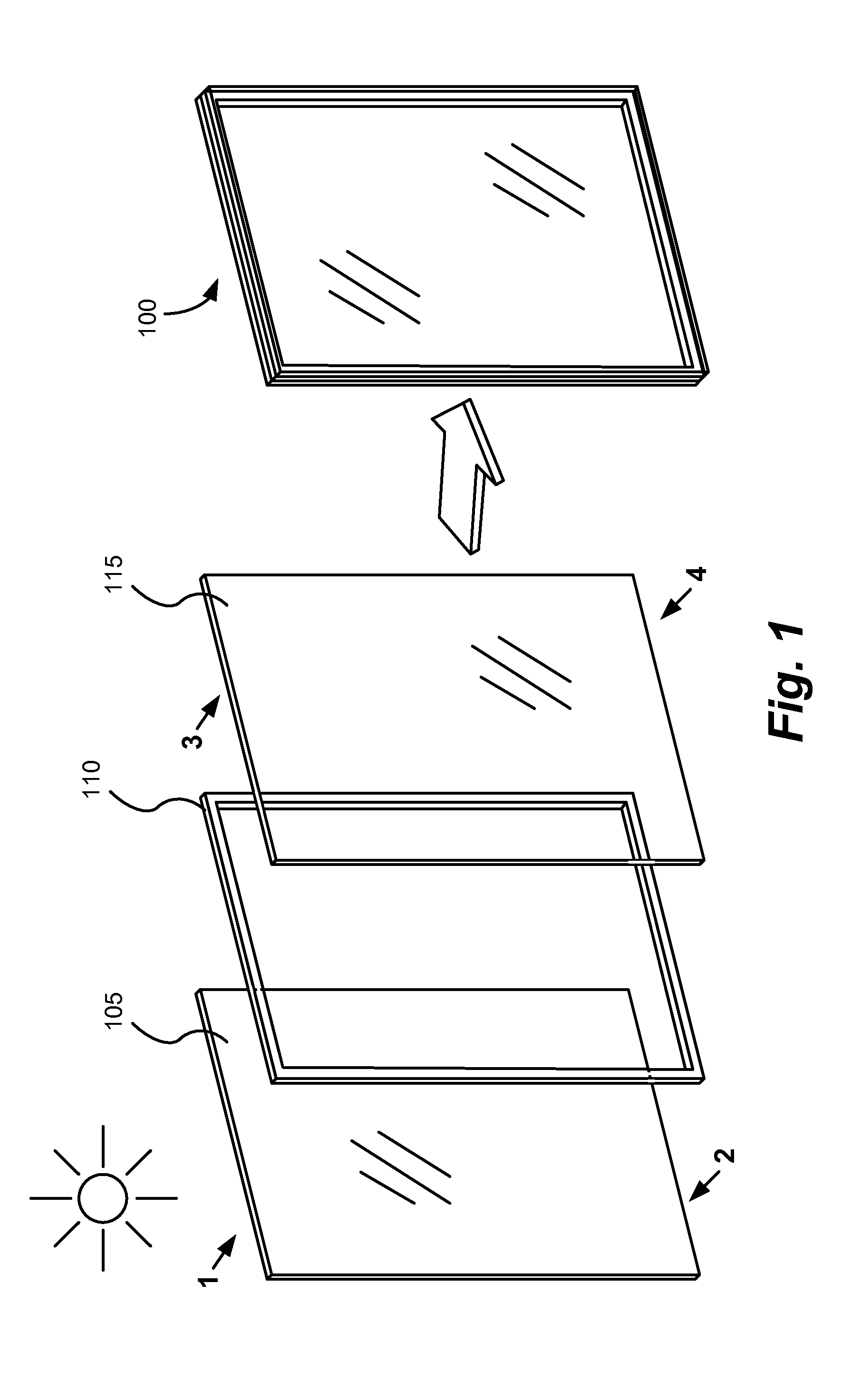

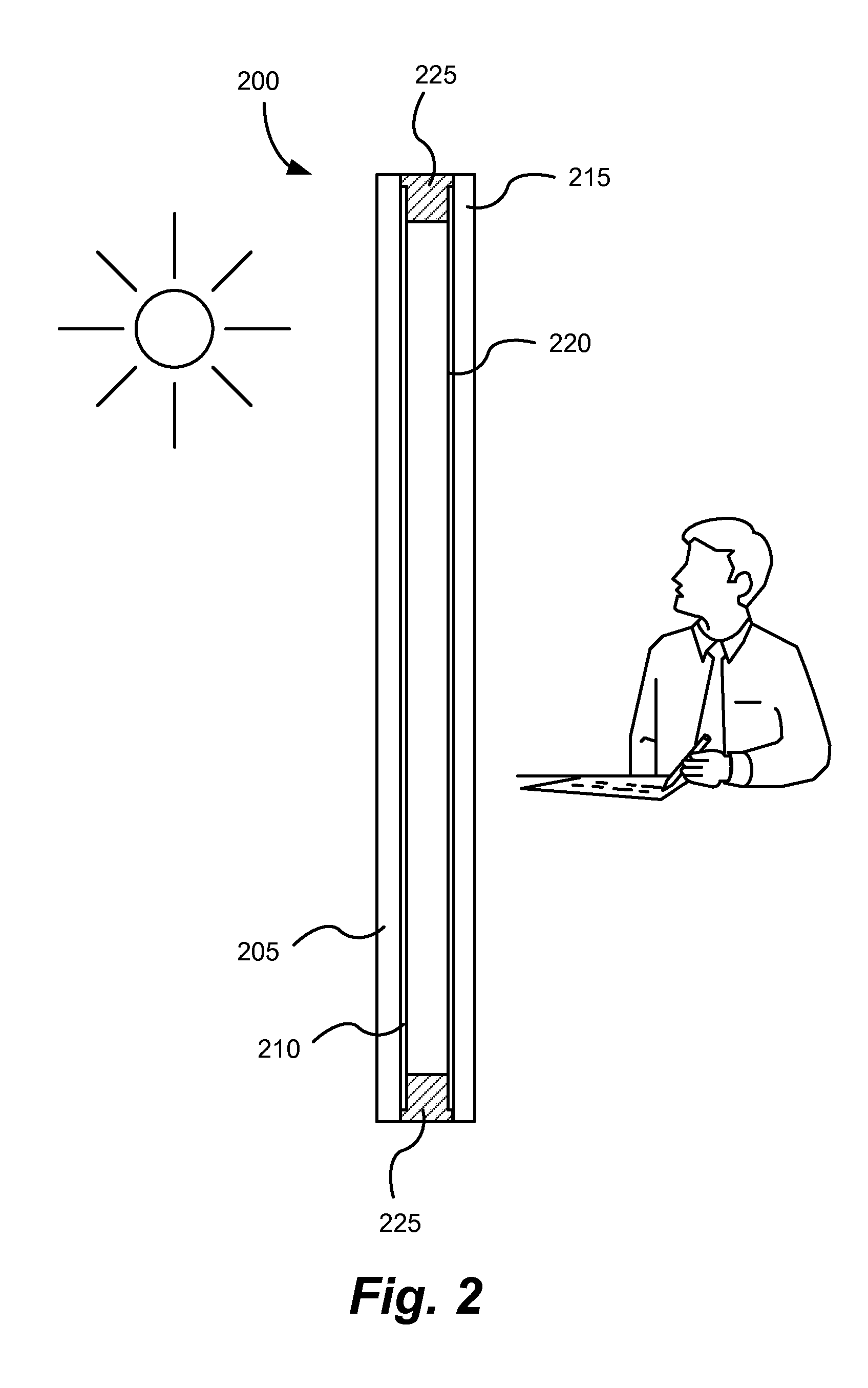

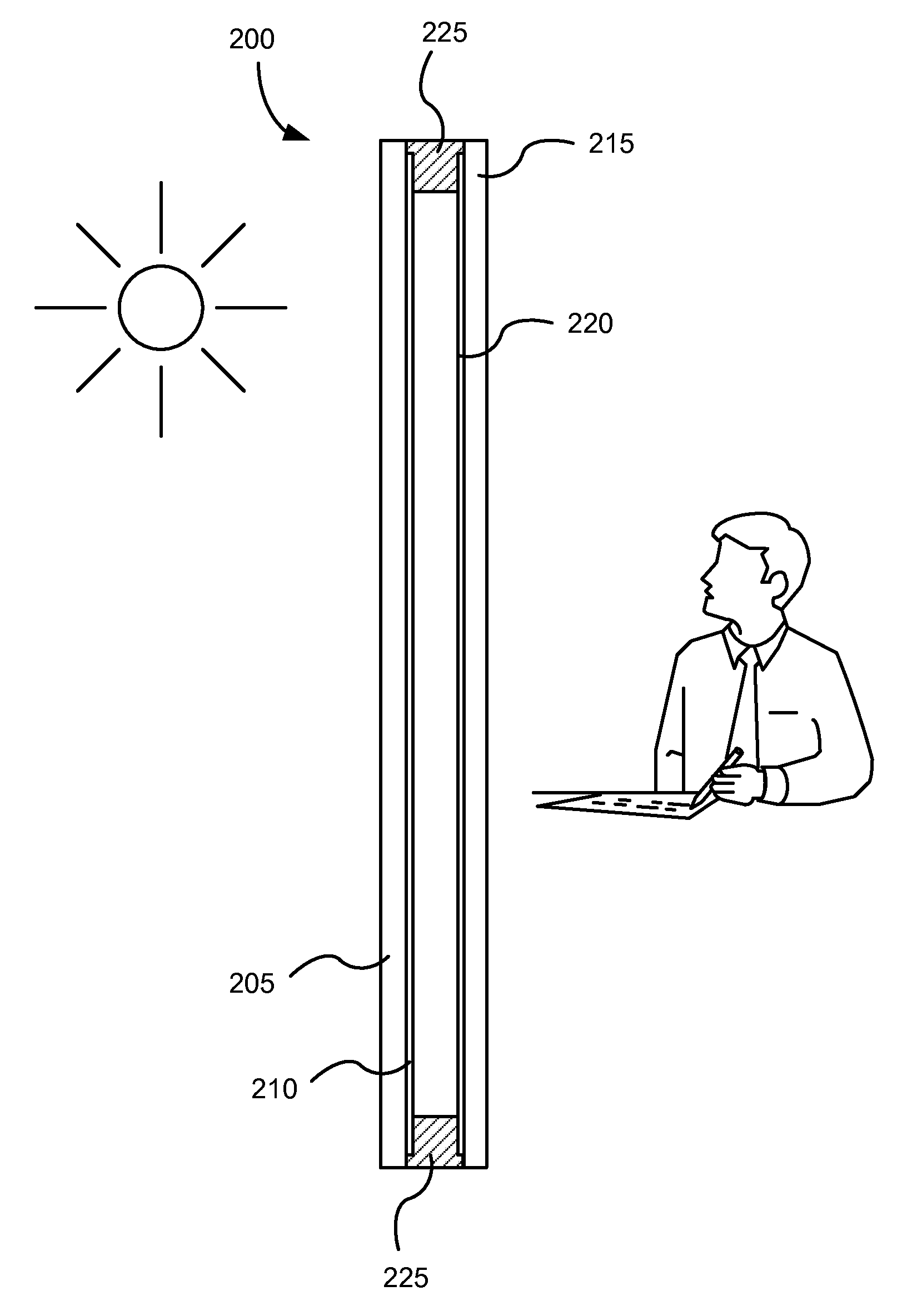

Multi-pane electrochromic windows

ActiveUS20120033287A1Increased defectivityGood choiceTransparent/reflecting heating arrangementsLaminationElectricityElectrochromism

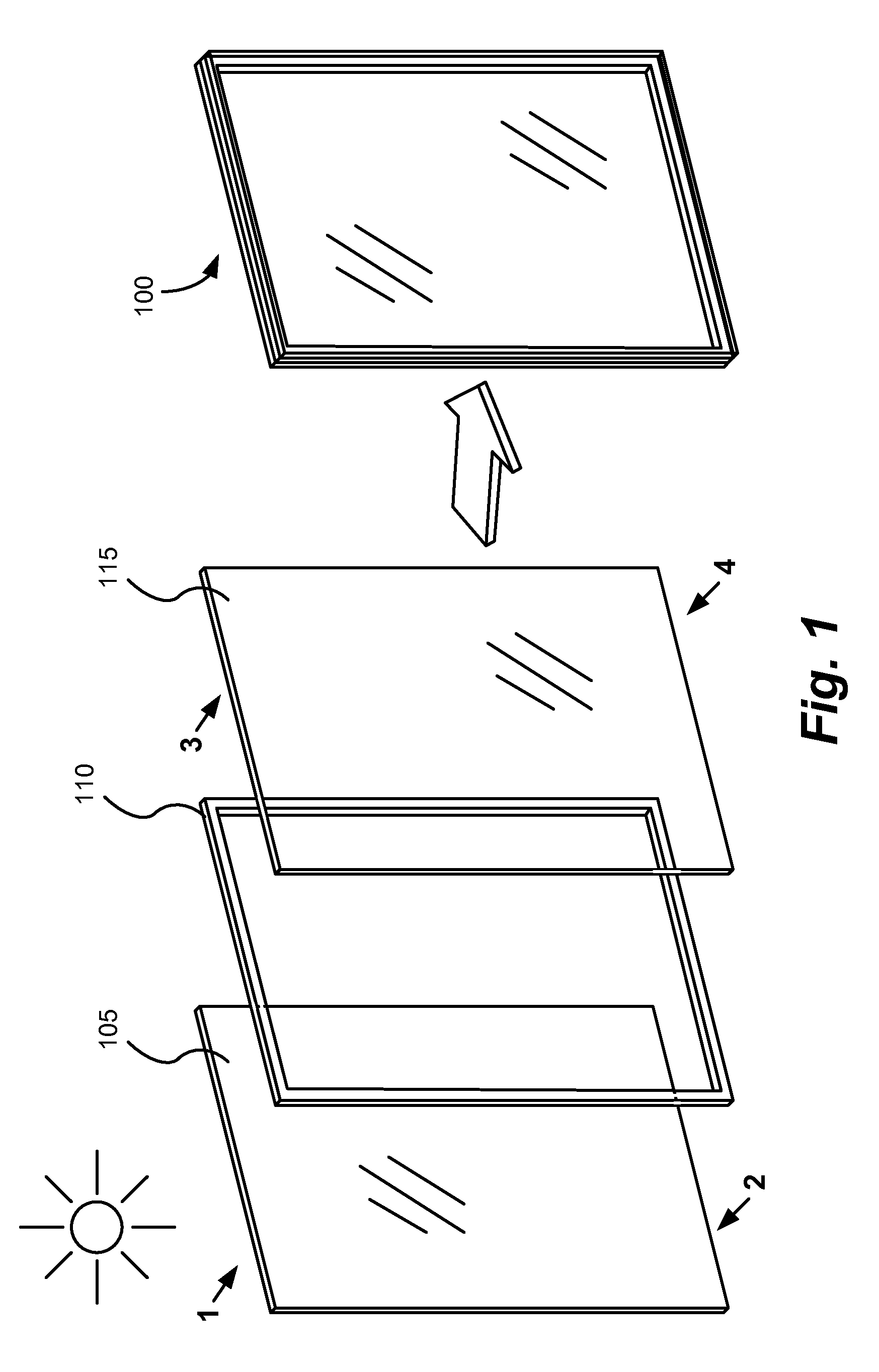

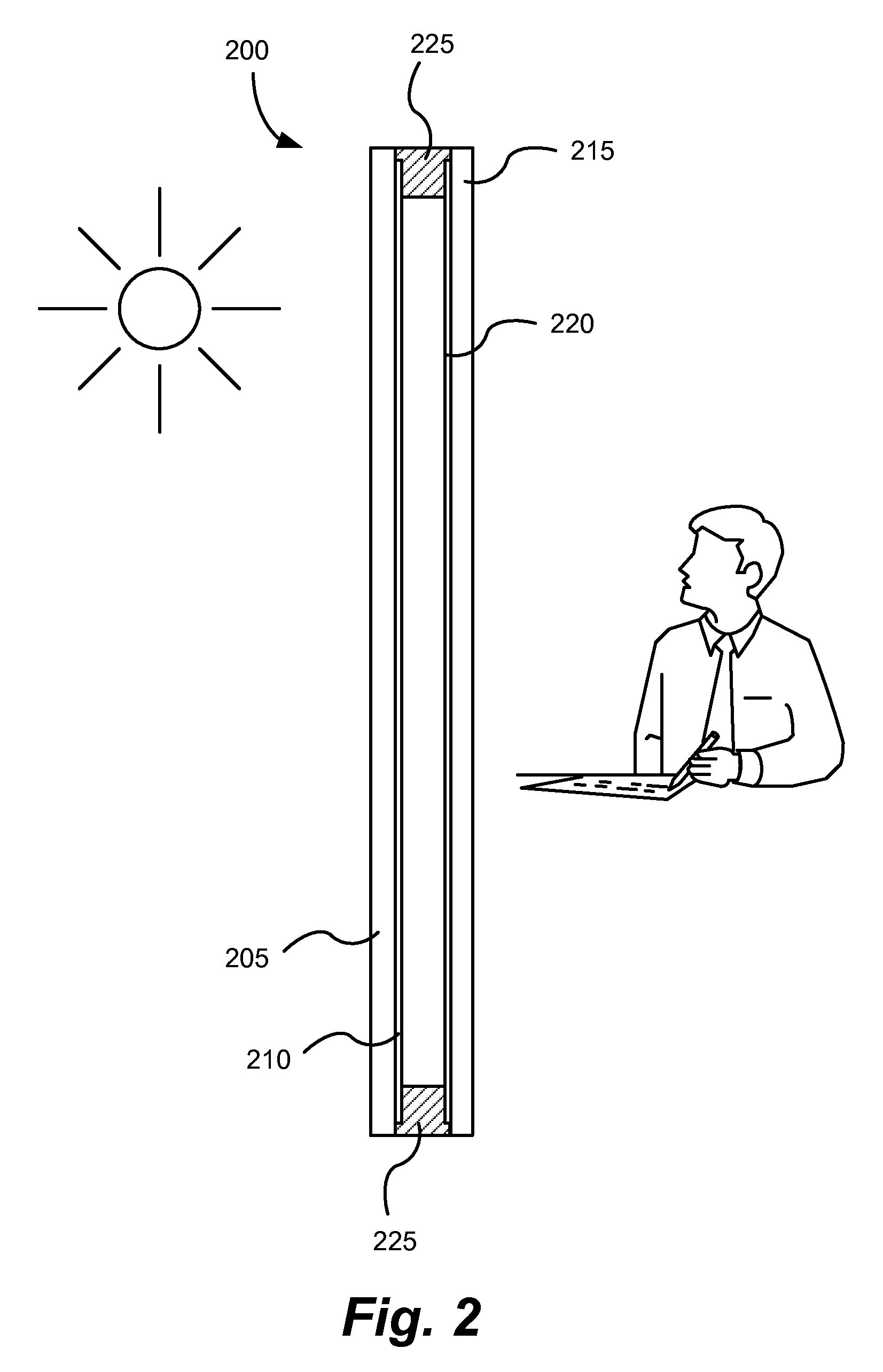

Window units, for example insulating glass units (IGU's), that have at least two panes, each pane having an electrochromic device thereon, are described. Two optical state devices on each pane of a dual-pane window unit provide window units having four optical states. Window units described allow the end user a greater choice of how much light is transmitted through the electrochromic window. Also, by using two or more window panes, each with its own electrochromic device, registered in a window unit, visual defects in any of the individual devices are negated by virtue of the extremely small likelihood that any of the visual defects will align perfectly and thus be observable to the user.

Owner:VIEW INC

Multi-pane electrochromic windows

ActiveUS8270059B2Increased defectivityGood choiceTransparent/reflecting heating arrangementsLight protection screensElectricityElectrochromism

Window units, for example insulating glass units (IGU's), that have at least two panes, each pane having an electrochromic device thereon, are described. Two optical state devices on each pane of a dual-pane window unit provide window units having four optical states. Window units described allow the end user a greater choice of how much light is transmitted through the electrochromic window. Also, by using two or more window panes, each with its own electrochromic device, registered in a window unit, visual defects in any of the individual devices are negated by virtue of the extremely small likelihood that any of the visual defects will align perfectly and thus be observable to the user.

Owner:VIEW INC

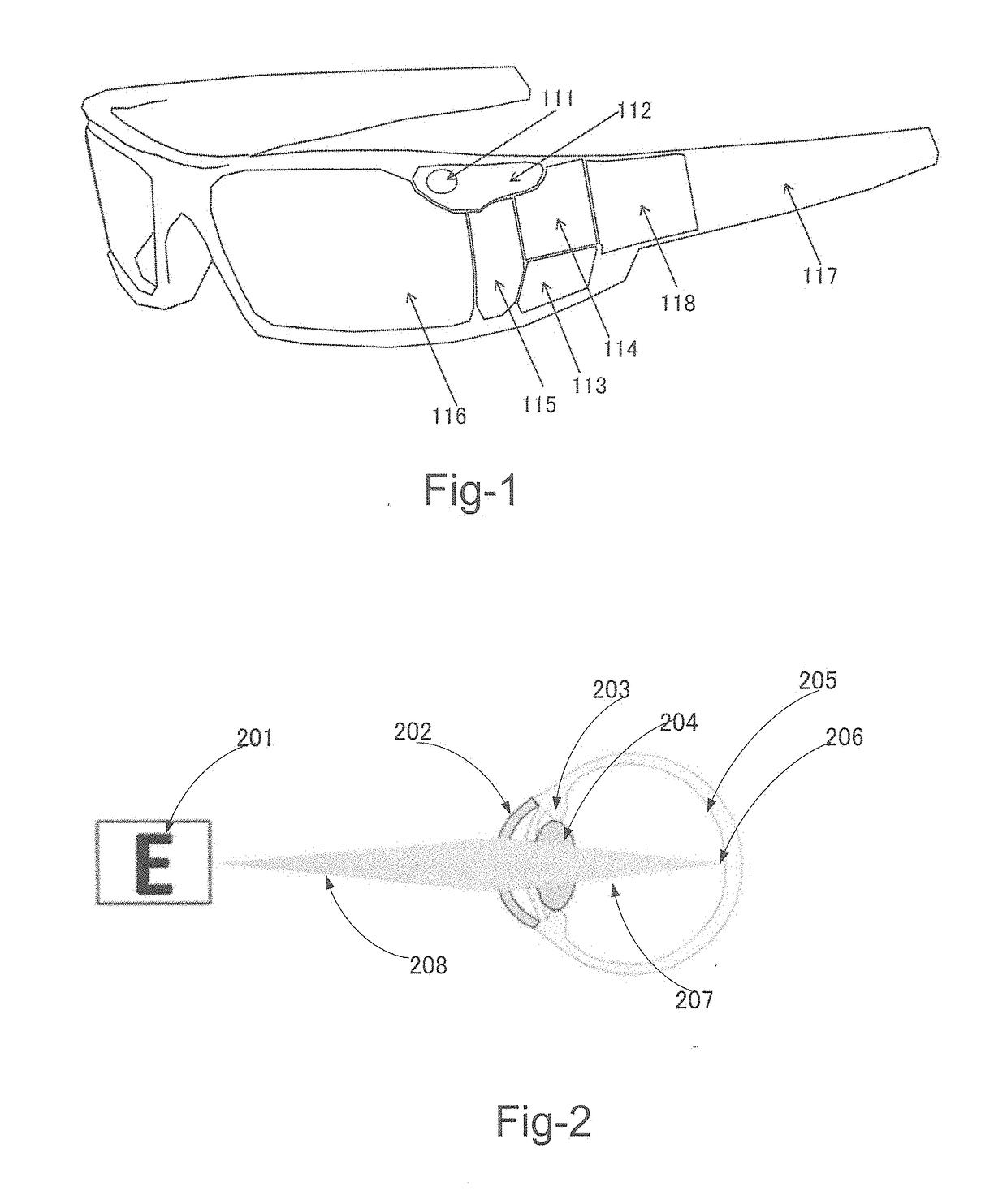

Wearable image manipulation and control system with correction for vision defects and augmentation of vision and sensing

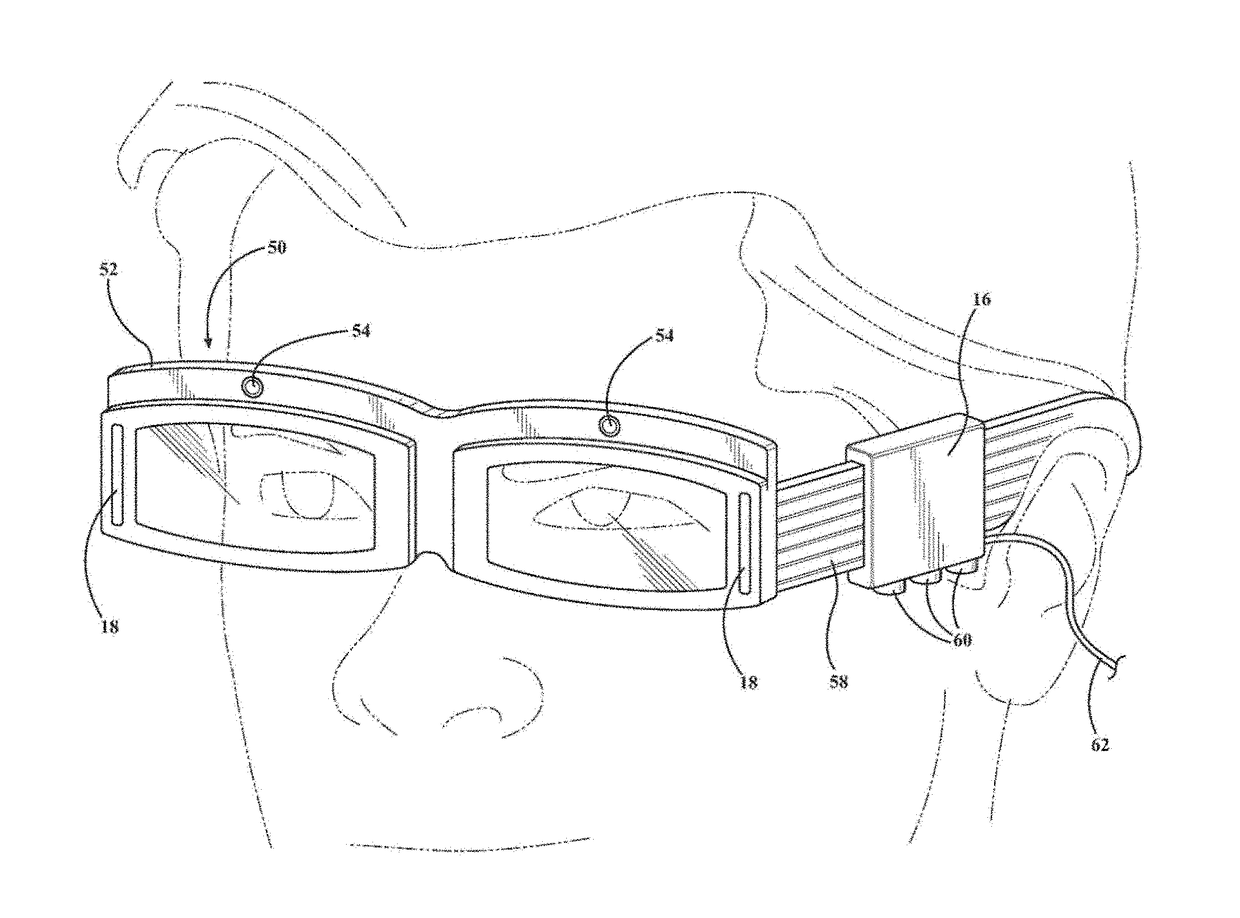

PendingUS20180249151A1Increase chanceDefect correctionPhysical therapies and activitiesSurgeryControl systemProjection system

A wearable image manipulation system comprising a camera input system, an image projection system, where the image projection system is capable of being worn by a user, and a processor in communication with the camera input system and the image projection system such that the processor is capable of receiving an image from the camera input system, modifying the image to produce a modified image, and displaying the modified image on the image projection system. The camera input system may comprise a contact lens with a camera mounted thereon. Additionally or alternately, the system may be capable of tracking a user's eye movement to accurately capture where the user is looking with the camera input system.

Owner:RAYTRX LLC

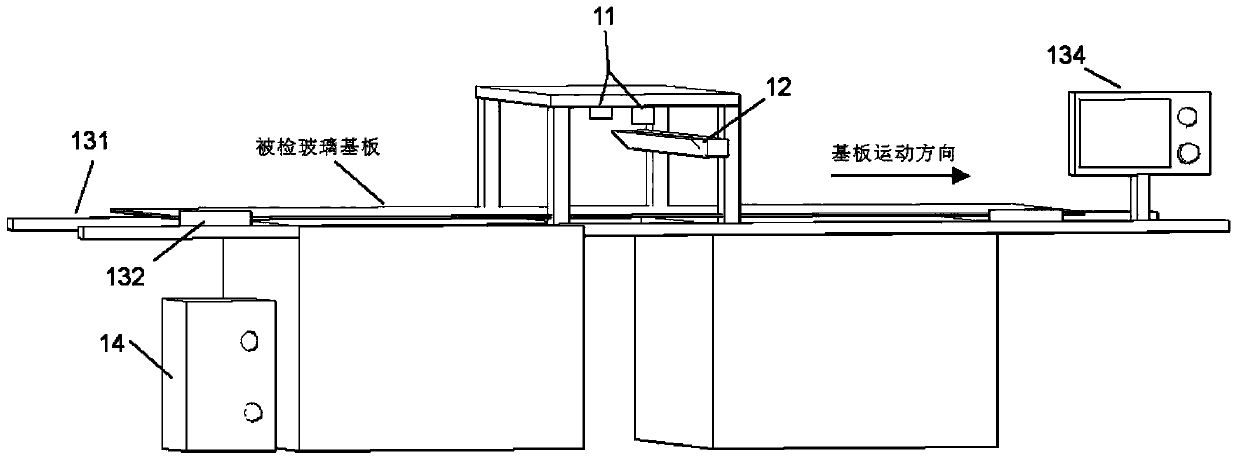

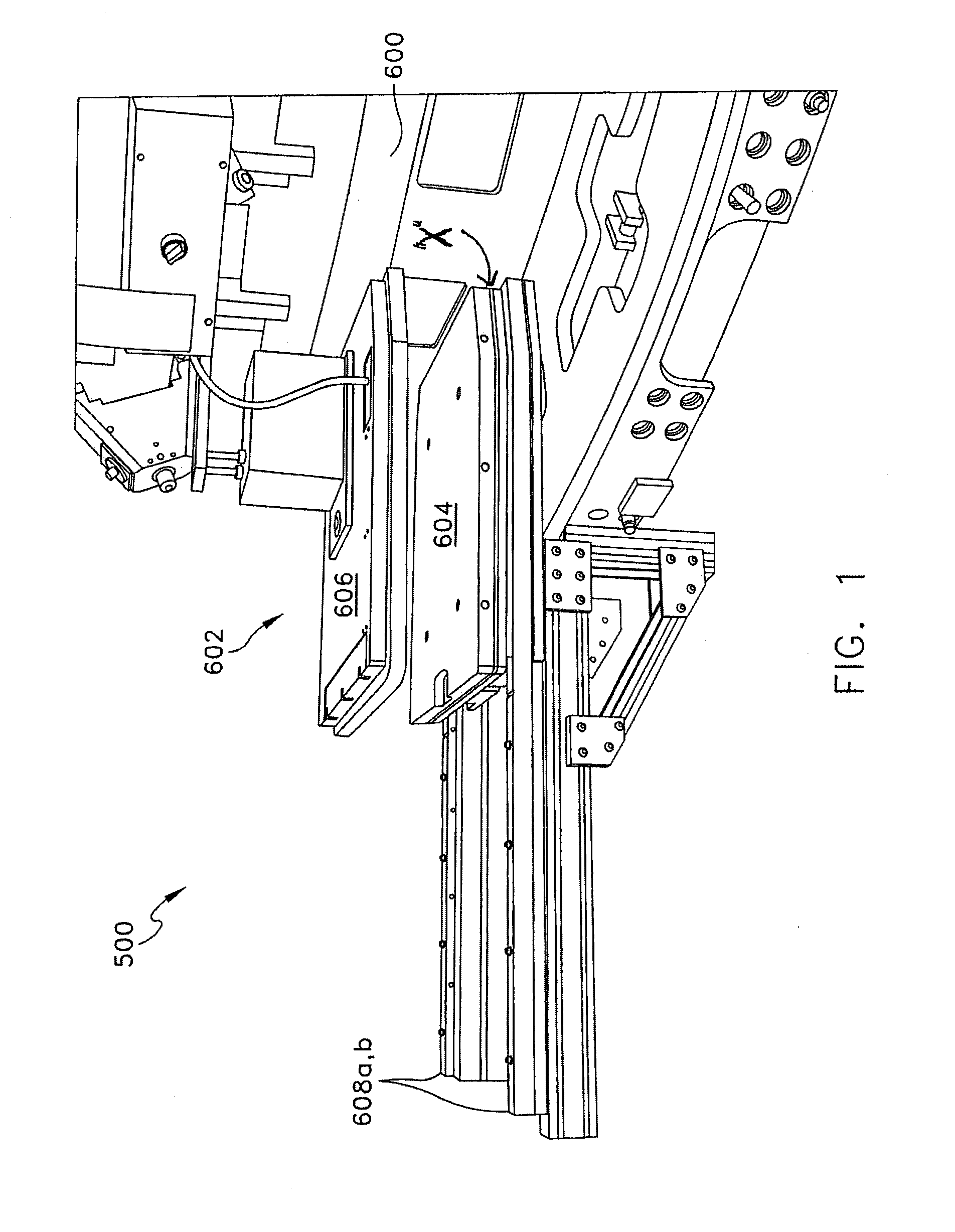

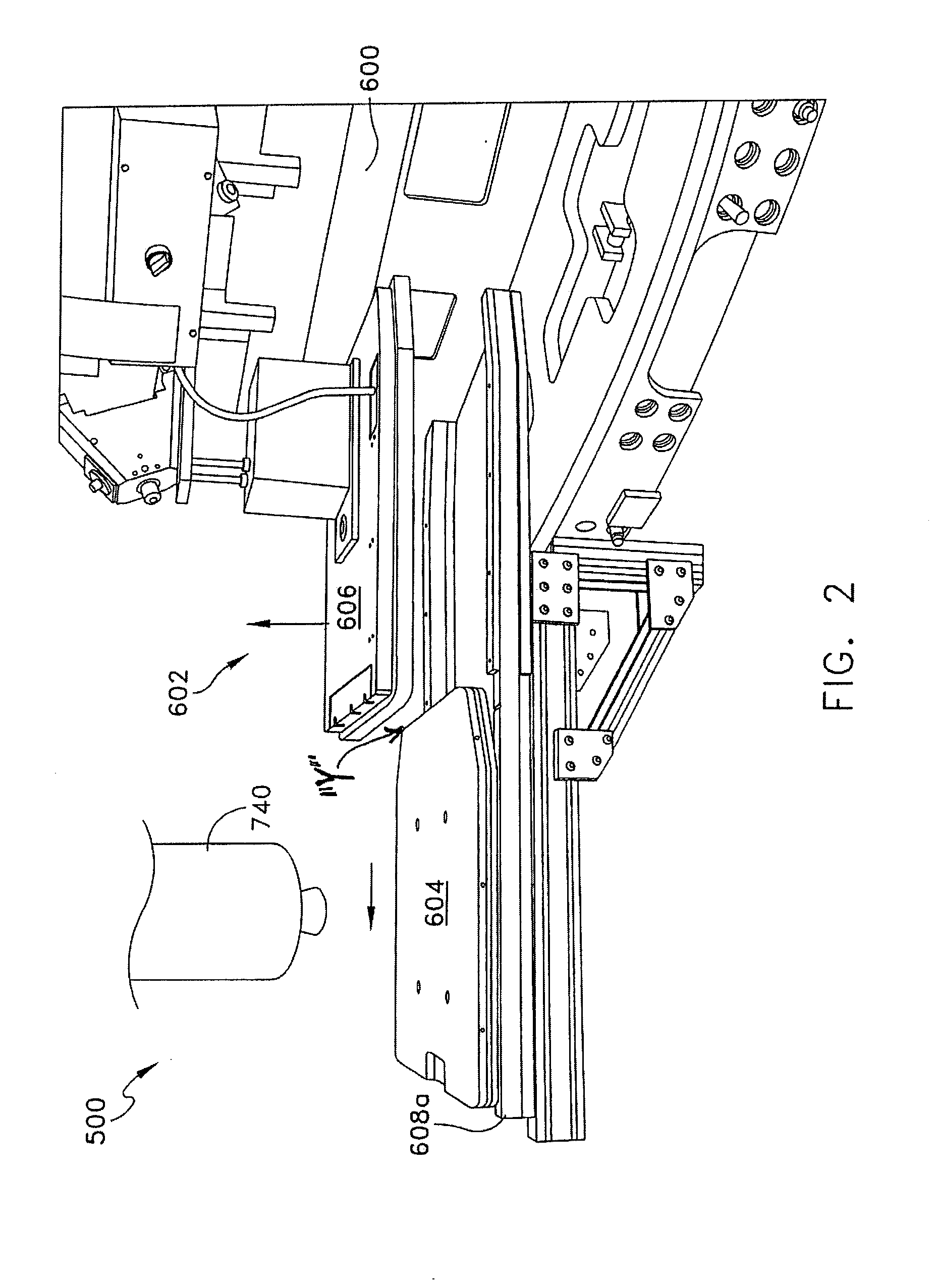

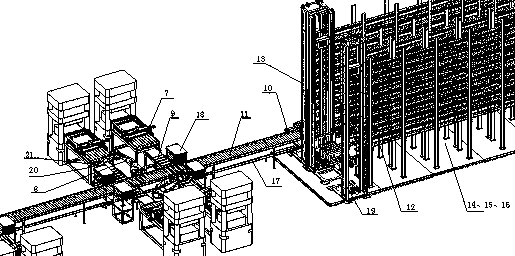

Multi-vision defect detecting equipment and method for large-size LCD glass substrate in production line

ActiveCN103913468ARealize online real-time detectionReal-time communicationMaterial analysis by optical meansTransmissionProduction lineSupport vector machine

The invention discloses a multi-vision defect detecting equipment and a multi-vision defect detecting method for a large-size LCD glass substrate in a production line. For the equipment, a linear scanning imaging detection system is adopted for acquiring the high-definition gray image of an LCD glass substrate to be detected, and the equipment is simple in structure and convenient to operate; according to the method disclosed by the invention, the acquired image is processed, a kmeans clustering method is adopted to carry out defect existence judgment on the processed image of the LCD glass substrate, and by making the defect regions, the defect category is judged by a classification method of a support vector machine (SVM), and the defect quantity is counted. Processed image and detection results are transmitted to an office in real time by a filed bus control system for operators on duty to check, and the field production parameters are transmitted, so that remote monitoring of the system is realized.

Owner:HUNAN UNIV

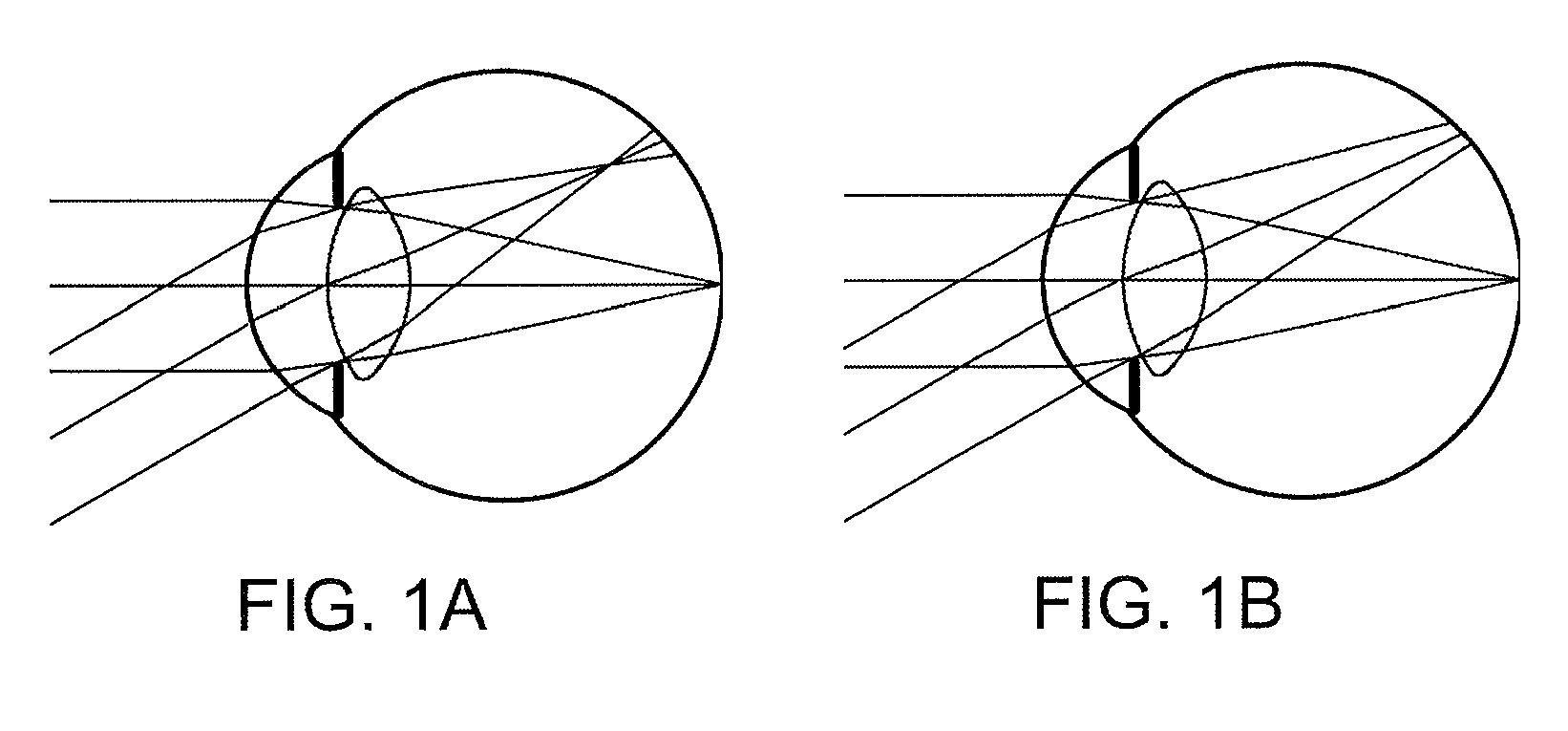

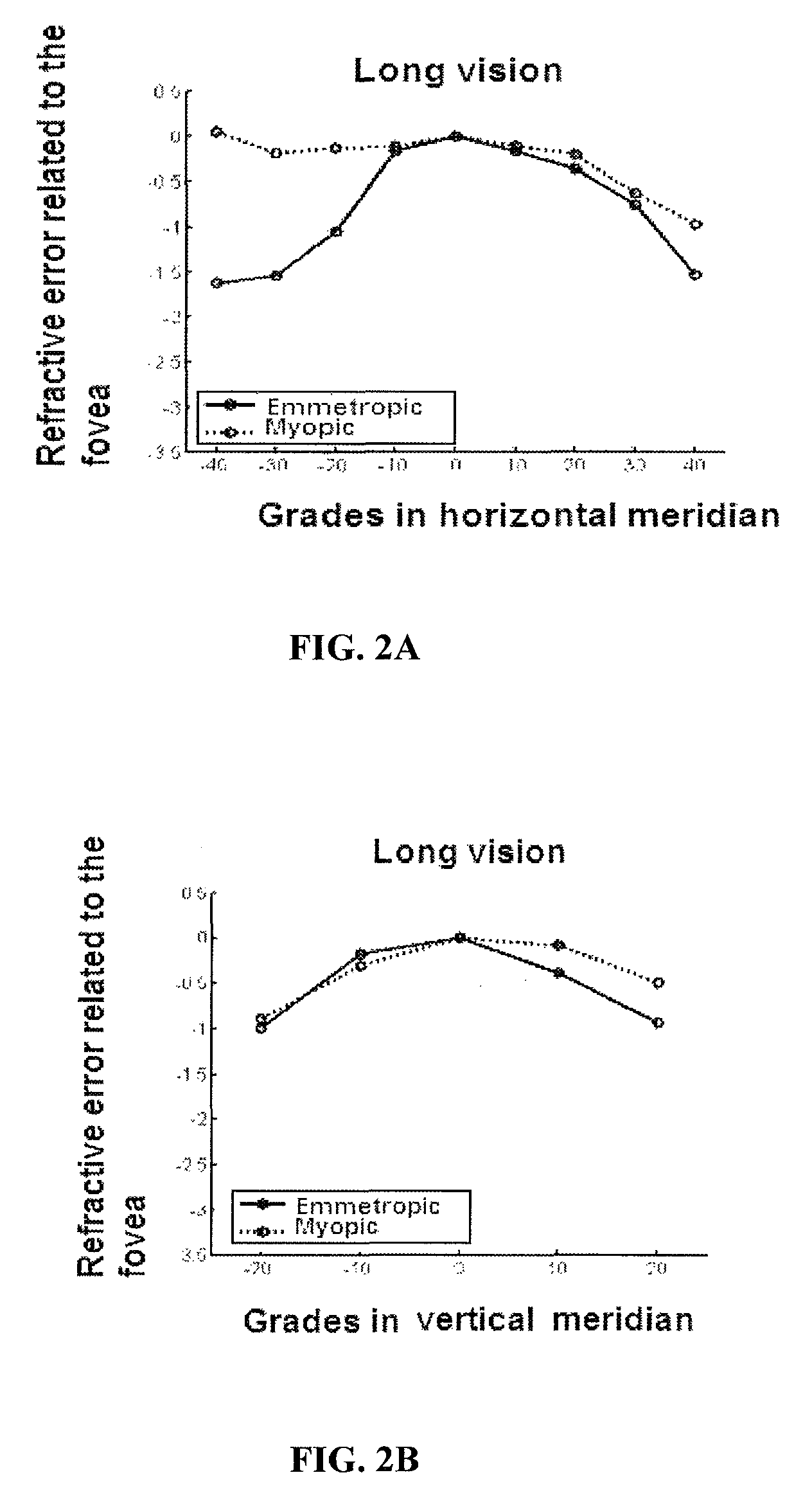

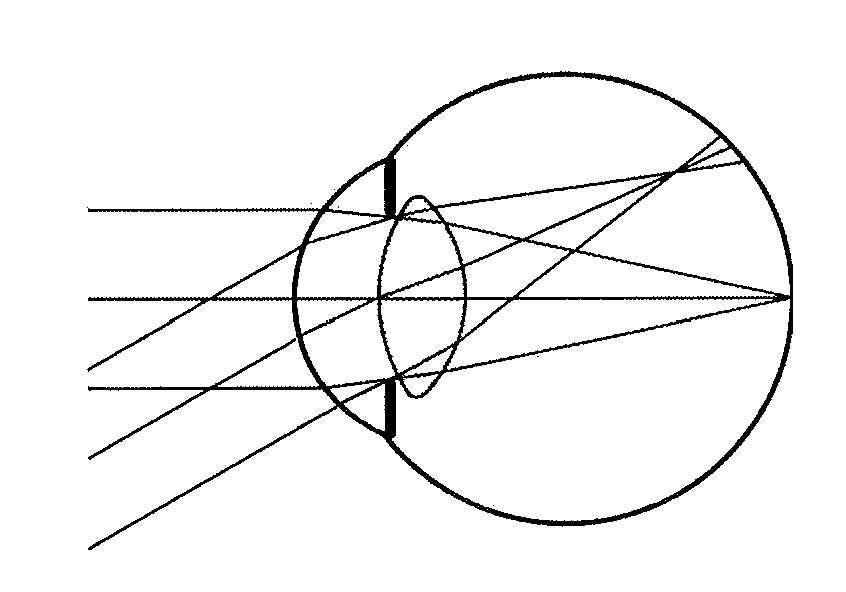

Excimer laser unit and relative control method for performing cornea ablation to reduce presbyopia

ActiveUS20060195074A1Mitigates presbyopiaLaser surgerySurgical instrument detailsPhotoablationHyperopic astigmatism

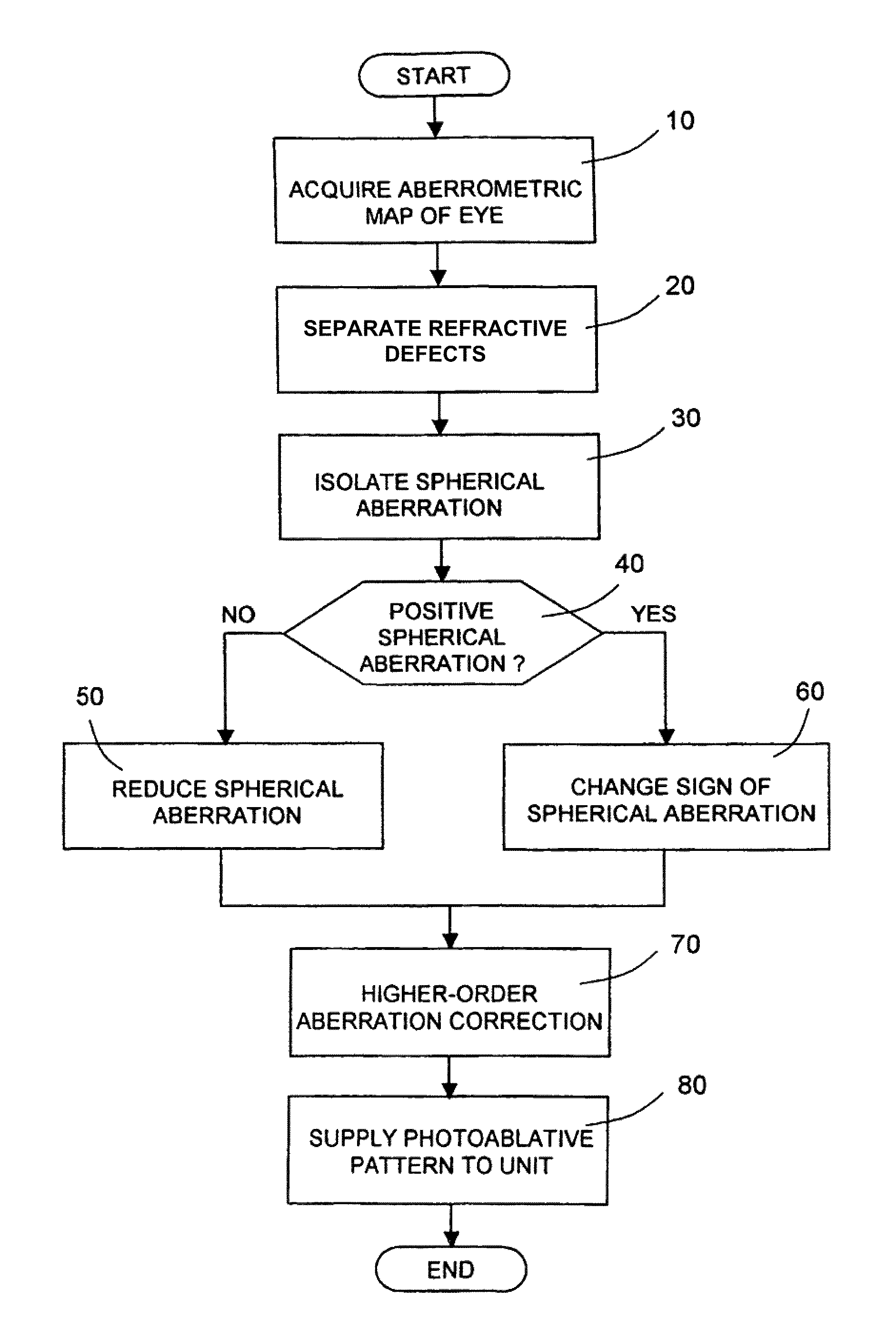

There are described an excimer laser unit and a method of controlling the unit to perform cornea ablation to reduce presbyopia, wherein the excimer laser unit is controlled to form on the cornea a photoablative pattern inducing a fourth-order ocular aberration, in particular a positive spherical aberration. More specifically, an aberrometric map of the eye is first acquired indicating the visual defects of the eye, which include second-order visual defects such as hypermetropia, astigmatism, and myopia, and higher-order visual defects such as spherical aberration; if the detected spherical aberration is negative, it is reduced by numerically increasing its absolute value to obtain an overcorrect photoablative inducing positive spherical aberration; conversely, if the detected spherical aberration is positive, its sign is changed and its absolute value increased numerically to obtain an overcorrect photoablative pattern inducing positive spherical aberration; and the photoablative pattern so generated is supplied to the excimer laser unit for implementation on the cornea.

Owner:CARL ZEISS MEDITEC AG

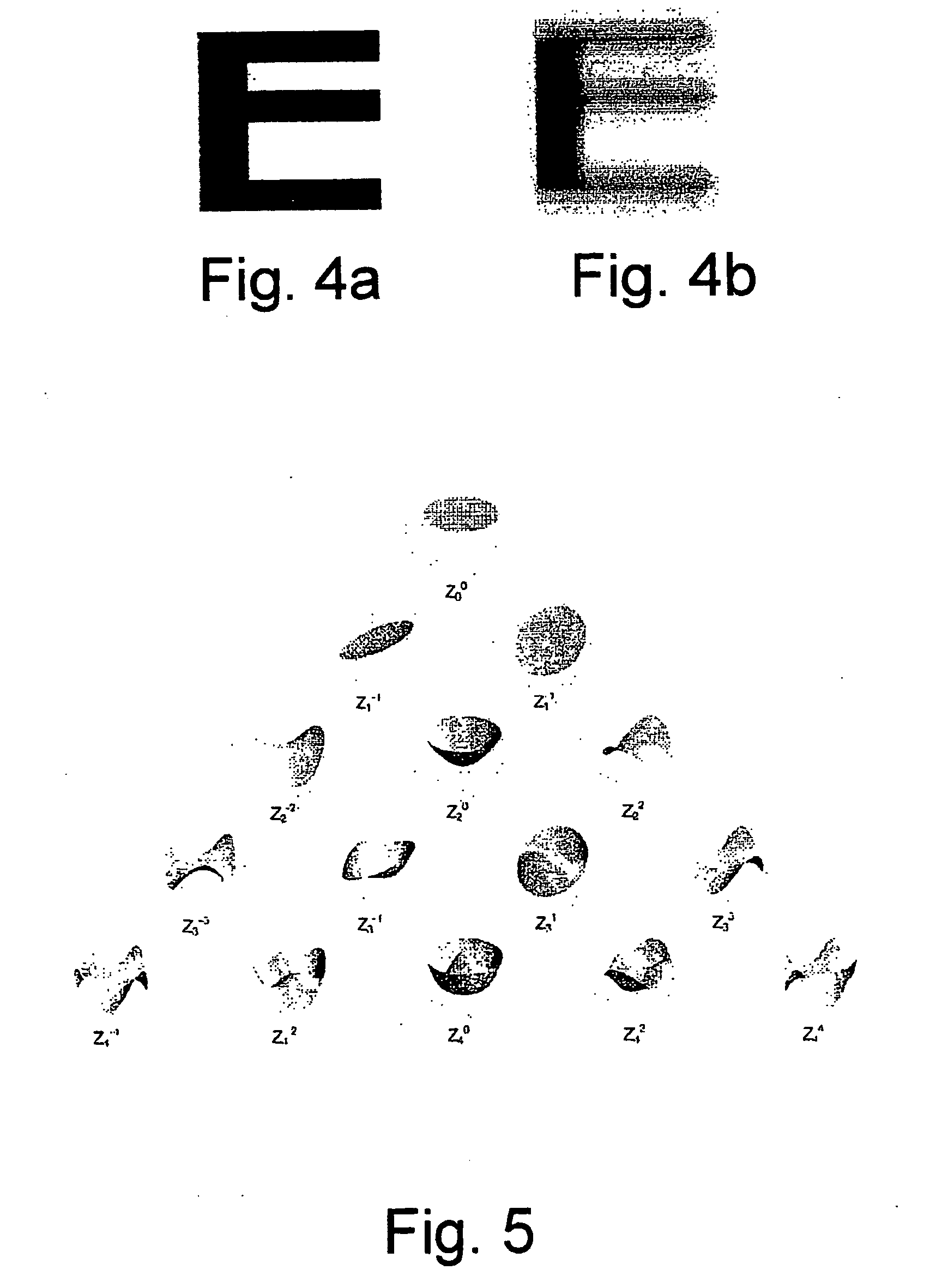

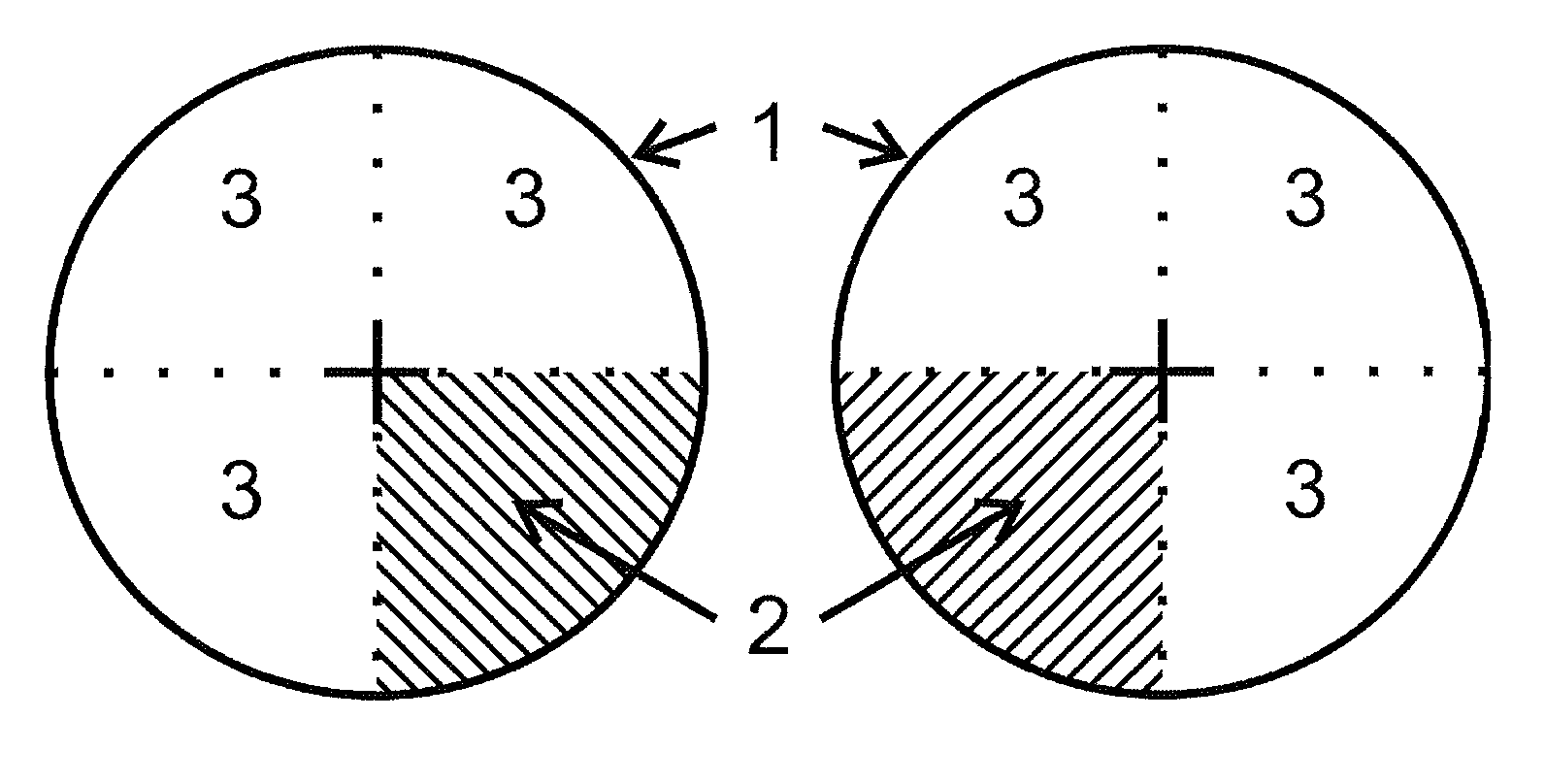

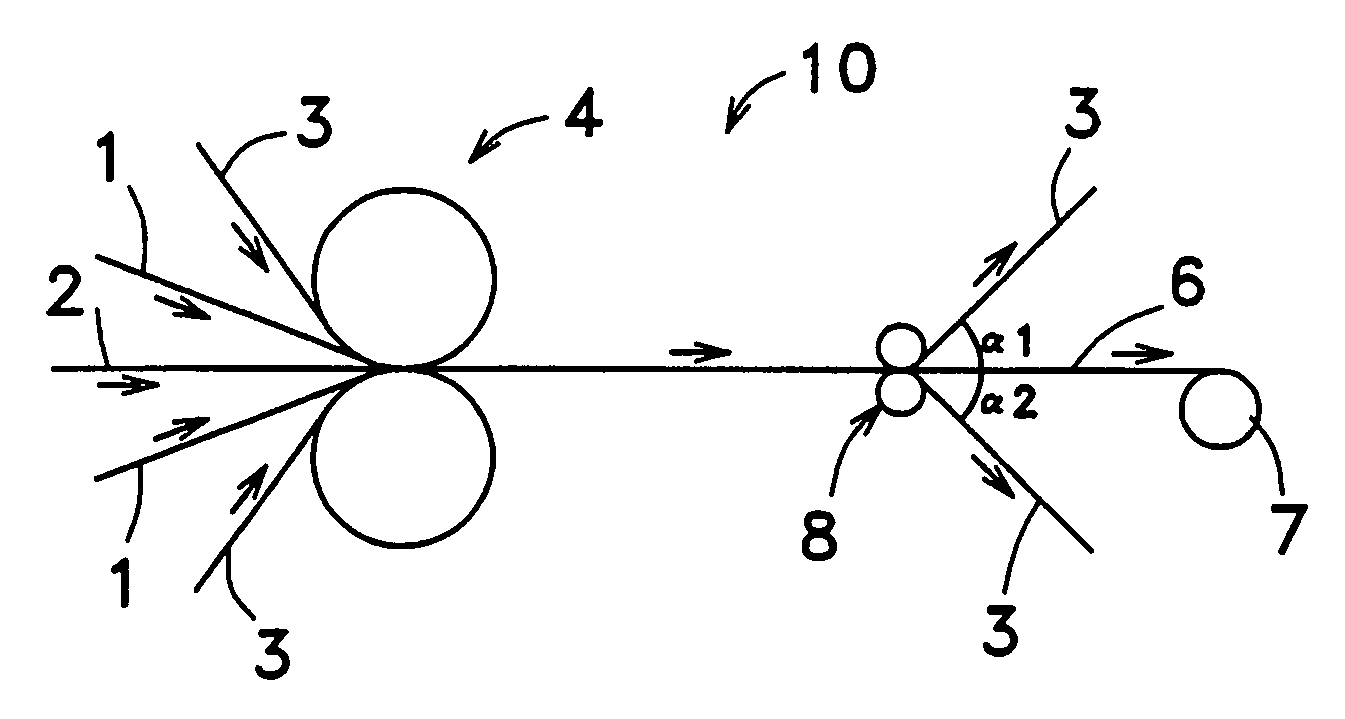

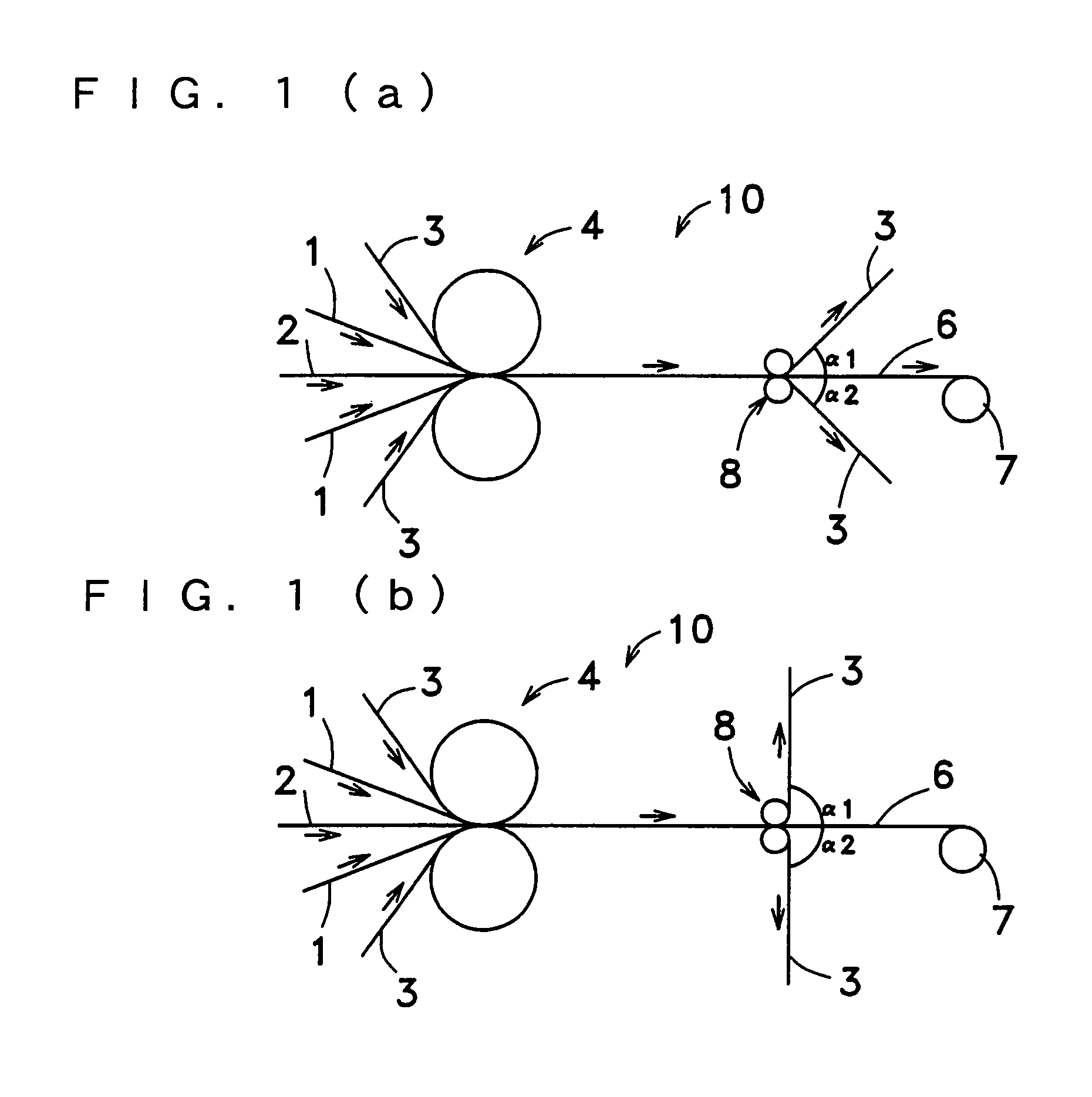

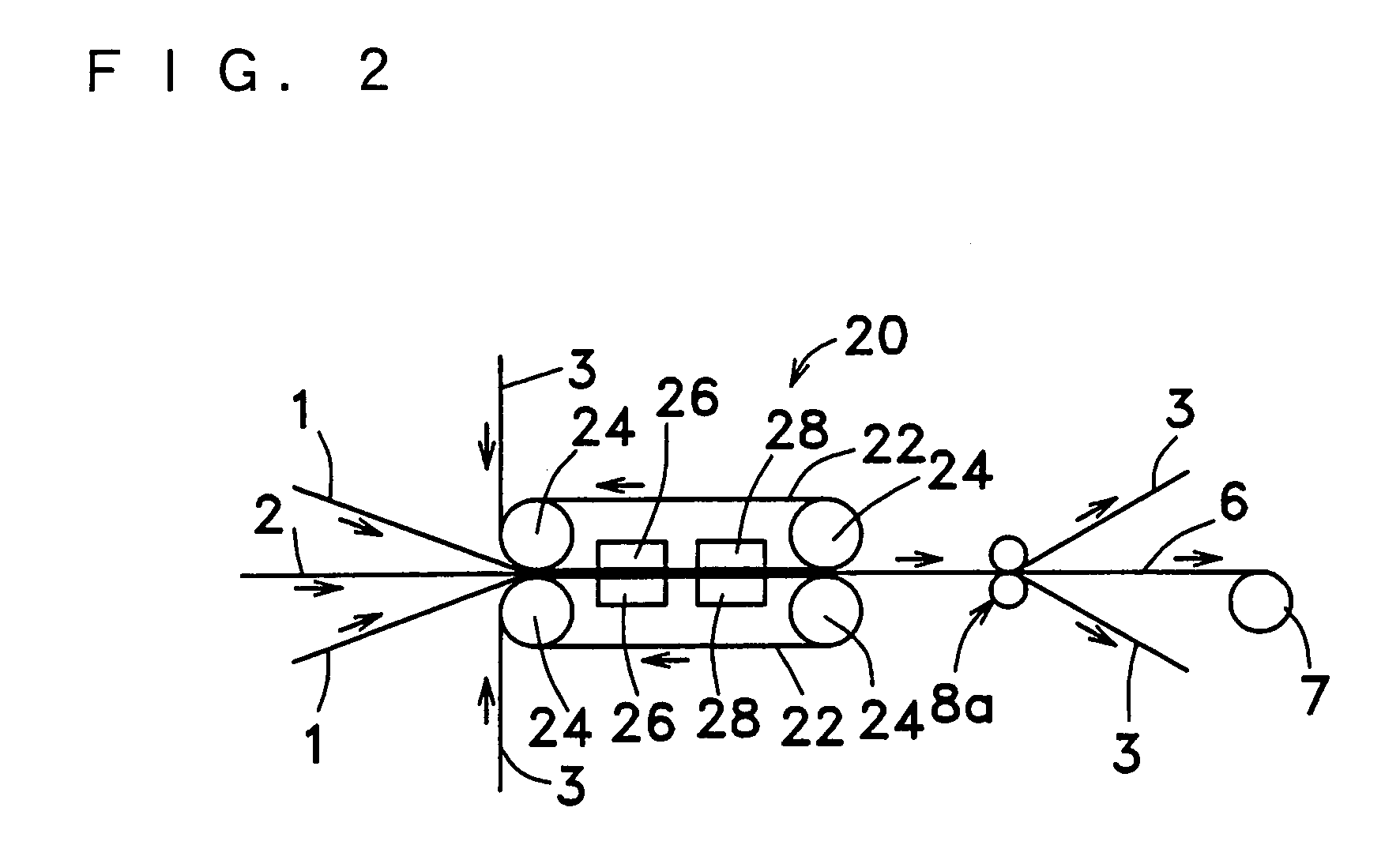

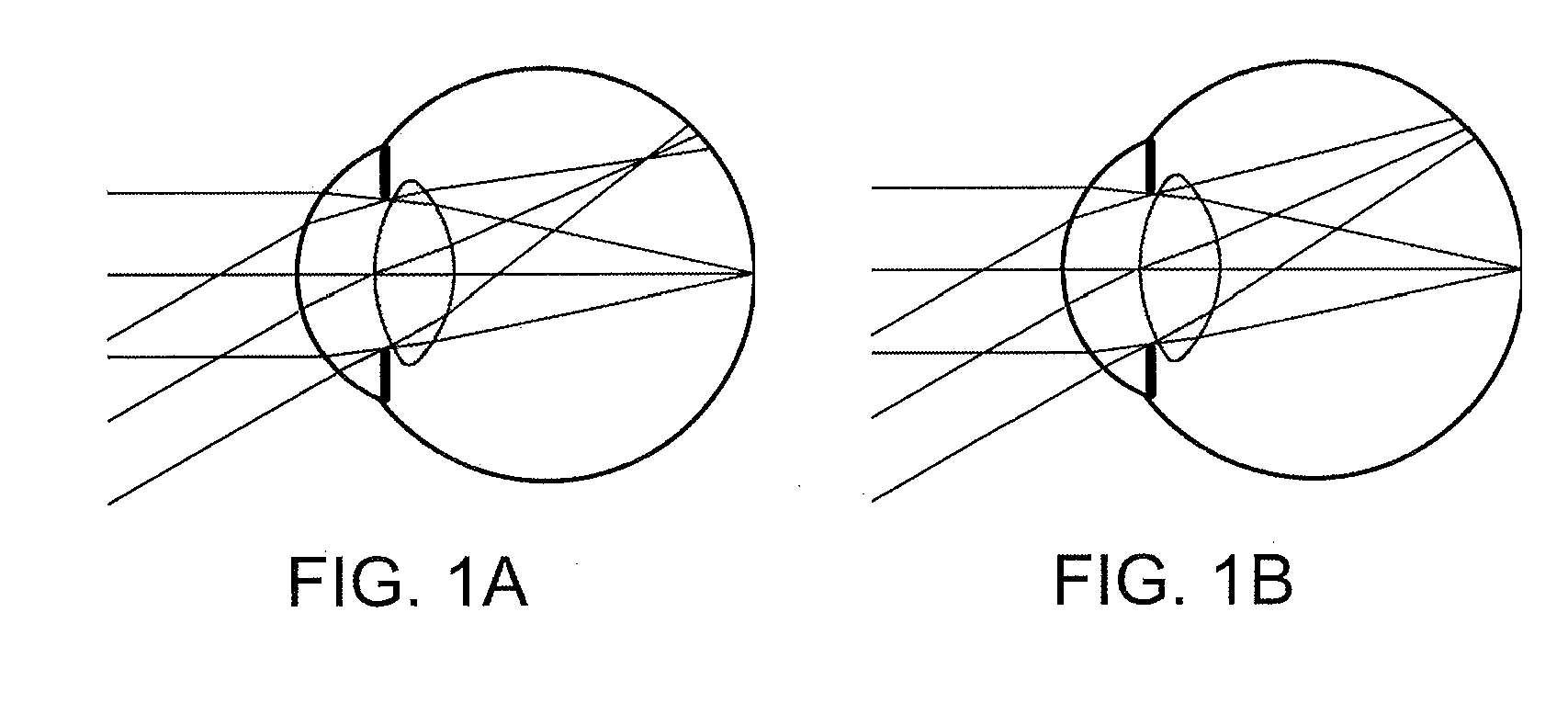

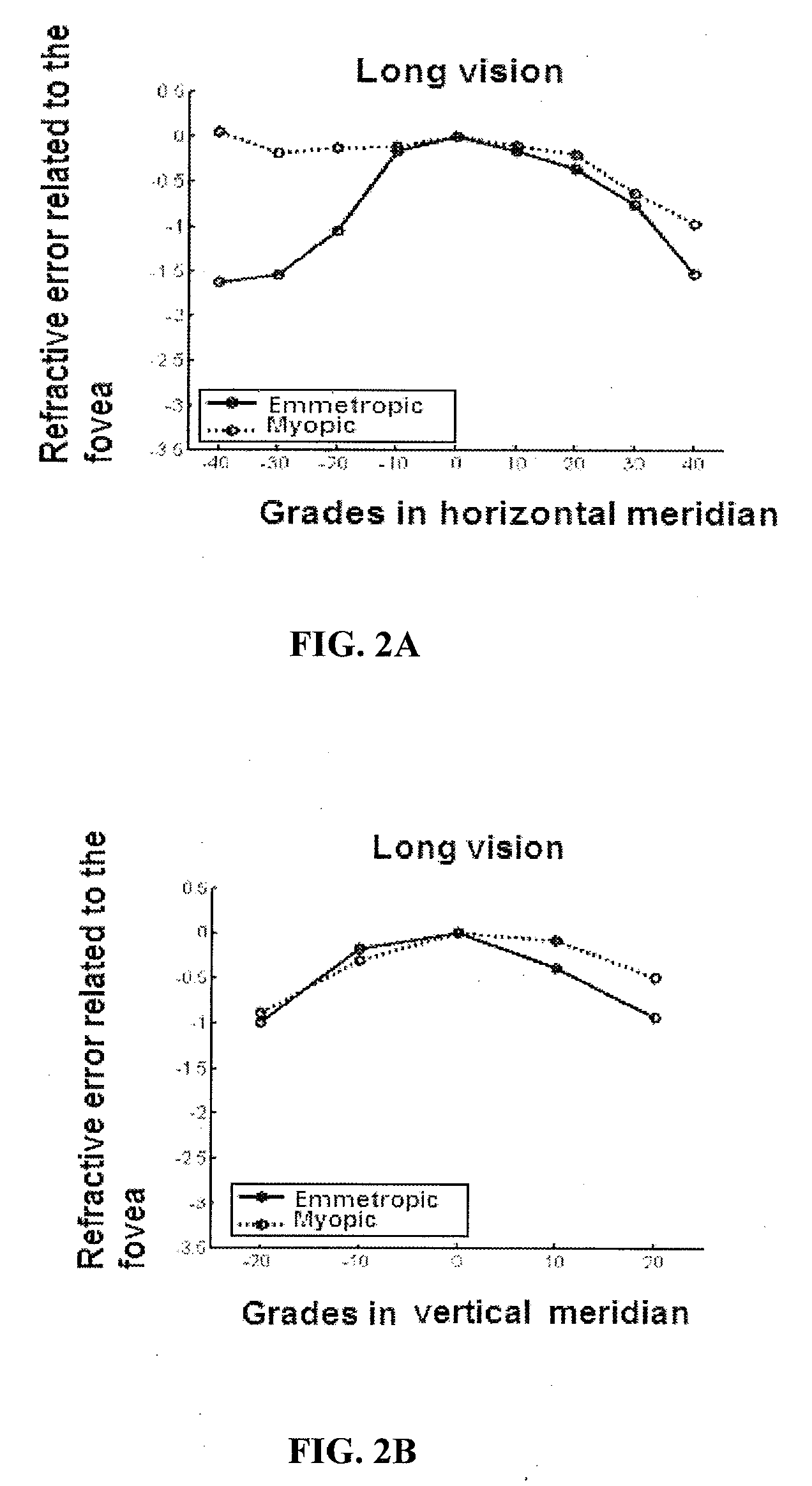

Device for asymmetrical refractive optical correction in the peripheral retina for controlling the progression of myopia

Optical device (1) for modifying the optics of the eye in its peripheral retina as prophylaxis of the progression of myopia, that it consists in a lens in which its inferior nasal quadrant (2) modifies the strength in a progressive and controlled manner from the center to the outer zone of the lens. The rest of the quadrants (3) of device (1) have a configuration of a graduated crystal or flat crystal, depending, respectively, on whether the user has some visual defect that requires optical correction or lacks said defect. The lens can be either an optical lens, a contact lens or electro-optical systems.

Owner:UNIVERSITY OF MURCIA

Artificial lens, in particular a contact or intraocular lens, for correcting presbyopia, possibly associated with other visual defects, and relative production method

InactiveUS20070279585A1High of long vision acuityDrawback can be obviatedSpectales/gogglesEye diagnosticsIntraocular lensVisual perception

An artificial lens (1) (contact lens or intraocular lens) for correcting presbyopia, possibly associated with other refractive defects, has at least one region (5) having a fourth-order spherical aberration in OSA notation greater than −1.5 μm and less than zero μm, and possibly associated with a basic vertex power for correcting refractive defects, and with higher-order aberrations for improving vision acuity. The lens is produced by ablating a surface of a base body of the lens by means of an appropriately controlled laser device, and according to a given photoablative pattern to induce the desired aberration.

Owner:STUDIO BOL DI GIUSEPPE BOLLINI +1

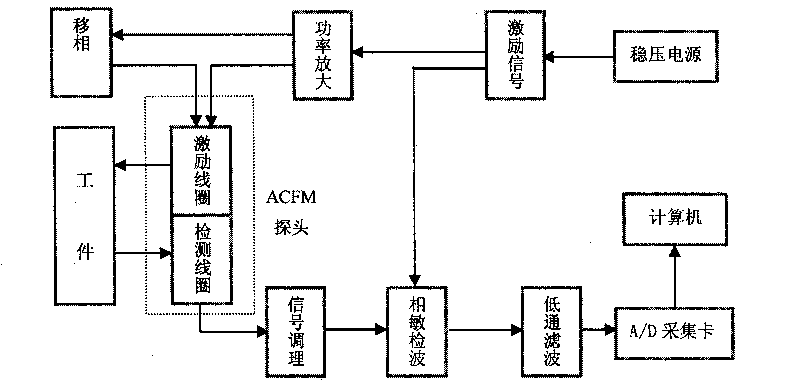

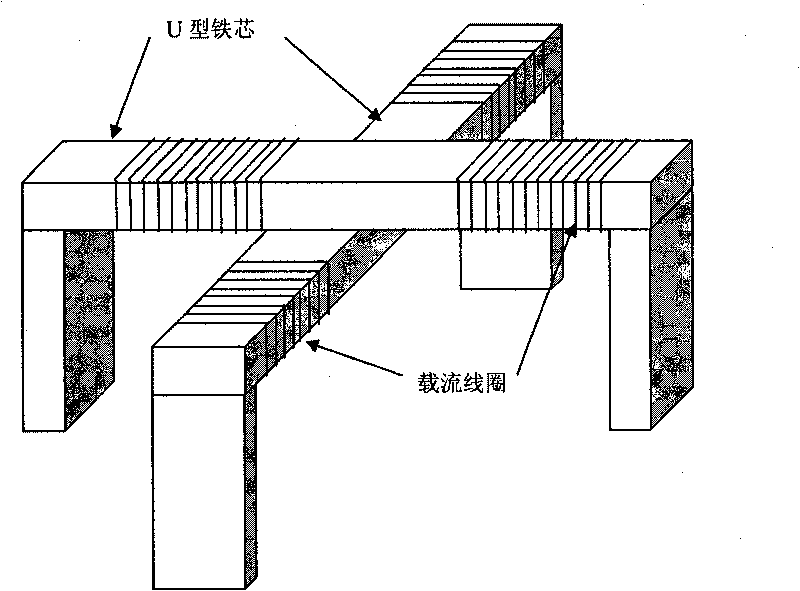

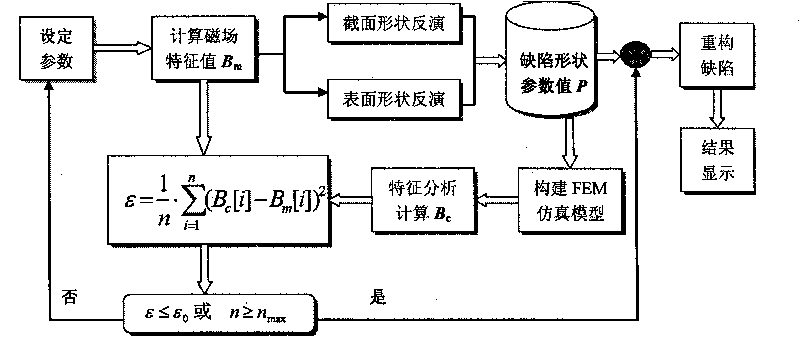

ACFM intelligent visual defect detection system

InactiveCN101701934AImprove intelligenceHigh degree of visualizationElectric/magnetic contours/curvatures measurementsUsing electrical meansThree dimensional shapeCorrelation analysis

The invention discloses an intelligent visual defect detection system based on an AC magnetic field. The system comprises a probe, an auxiliary circuit and system detection software and uses a defect quantification and shape reconstruction algorithm. An excitation part of the probe adopts a double-U-shaped structural design and consists of a mangan zinc ferrite iron core and two sets of orthogonal current-carrying coils, a detection part adopts a two-dimensional array structure, and the array probe adopts a lifting-releasing type traveling mode. The hardware processing of detection signals comprises signal conditionings such as amplification, filtering, and the like and also introduces an original excitation signal as a reference signal to carry out phase sensitive detection and low-pass filtering on the detection signals. The signals are sent into a computer through an A / D acquisition card, then the detection software is used for carrying out digital filtering and correlation analysis on the signals to draw a magnetic induction intensity curve and a butterfly diagram in real time, and size quantification and three-dimensional shape inversion are realized through the defect quantification and the shape reconstruction algorithm. The intelligent visual defect detection system gives a full play of the advantages of the computer and greatly improves the intellectualized and visual levels of AC magnetic field detection.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

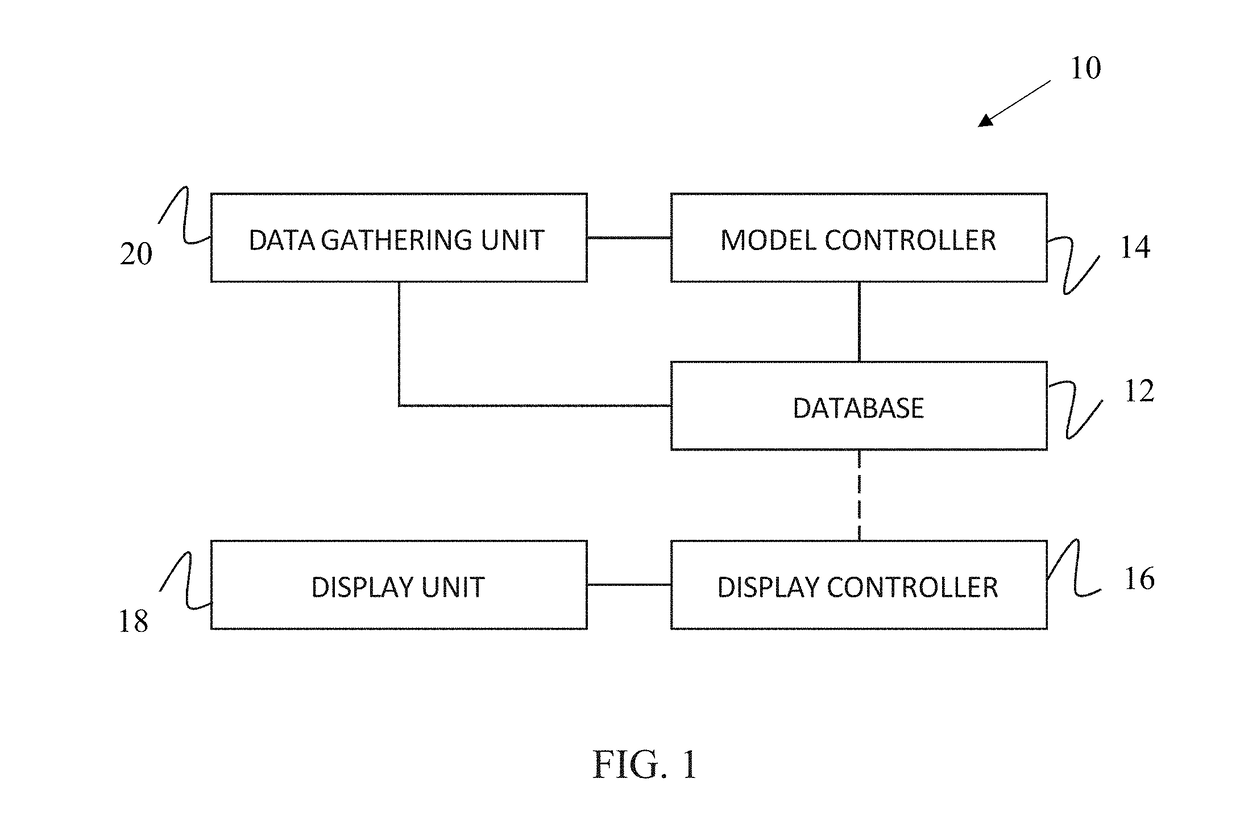

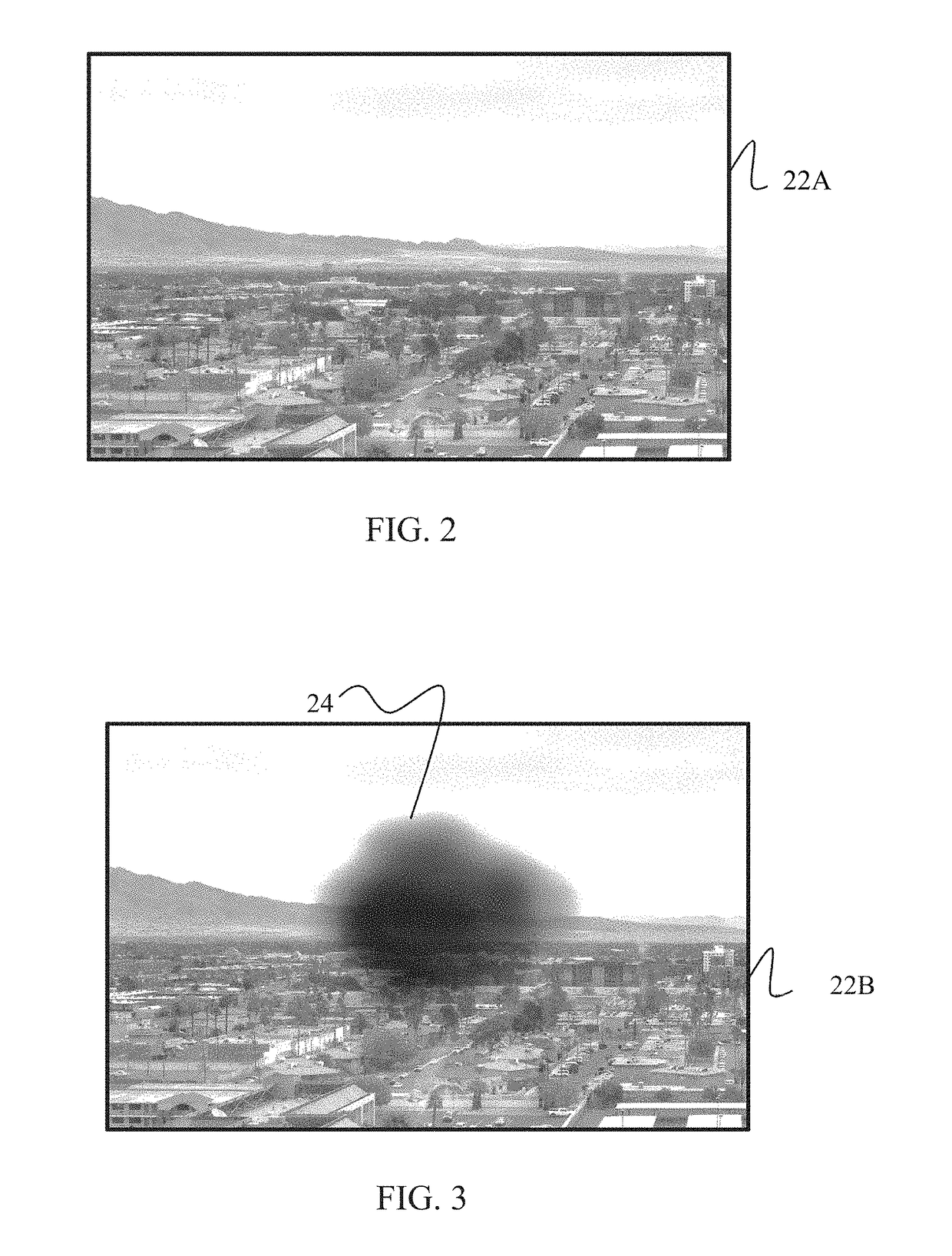

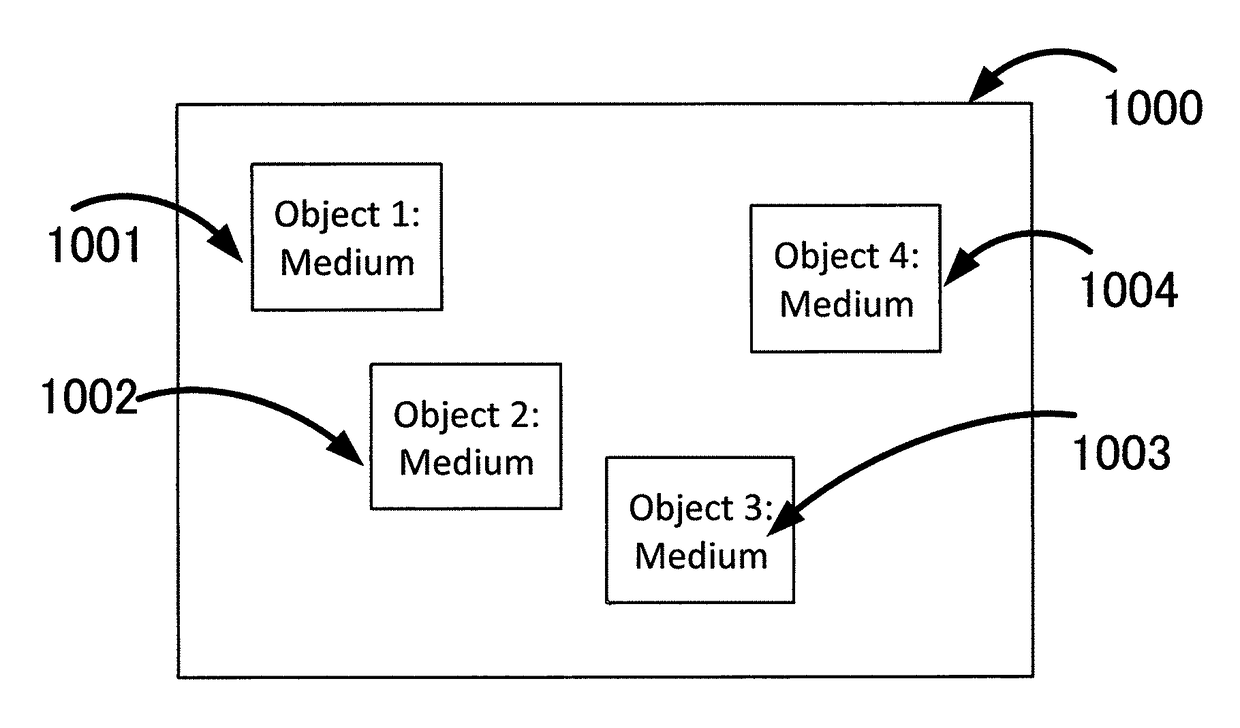

System and method for sensory defect simulation

ActiveUS20060058619A12D-image generationAnalogue computers for chemical processesReal-time simulationVisual perception

A visual defect simulation system receives a functional field map produced by an MRI system that relates locations in a patient's brain to locations in the patient's field of view. Planned medical operations are indicated at locations in the patient's brain and any resulting vision loss is simulated with a revised functional field map. A scene is displayed and an impairment overlay is produced from the revised functional field map that blocks the scene at locations corresponding to simulated vision loss. The overlay is translated over the scene in response to viewer eye movements detected by a vision-tracking system to present a real-time simulation of the resulting vision loss.

Owner:MCW RES FOUND INC

Method and device for manufacturing laminated plate

InactiveUS7101455B1Small surface roughnessLamination ancillary operationsLayered product treatmentWrinkle skinInter layer

The present invention provides a method for producing a laminate suitable for a flexible circuit board which is free from visual defects such as wrinkles and curls that appear when a plurality of laminating materials containing a thermally fusible laminating material are formed by thermally laminating these materials each other using a thermal-press forming device, which comprises the steps of: arranging a heat resistant protective material between a pressing surface and the laminating materials, laminating the materials by thermal pressure at not lower than 200° C., wherein the bonded laminating materials are in contact with the protective material, cooling the bonded laminating materials, and peeling off the protective material from the bonded laminating materials, whereby the laminate with less nonuniformity in pressurization, a uniform surface, and a good inter-layer adhesion, and the method and device for producing the laminate can be provided, more particularly, the thermal pressure and forming is performed by a thermal-press forming device having at least a pair of metal rolls.

Owner:KANEKA CORP

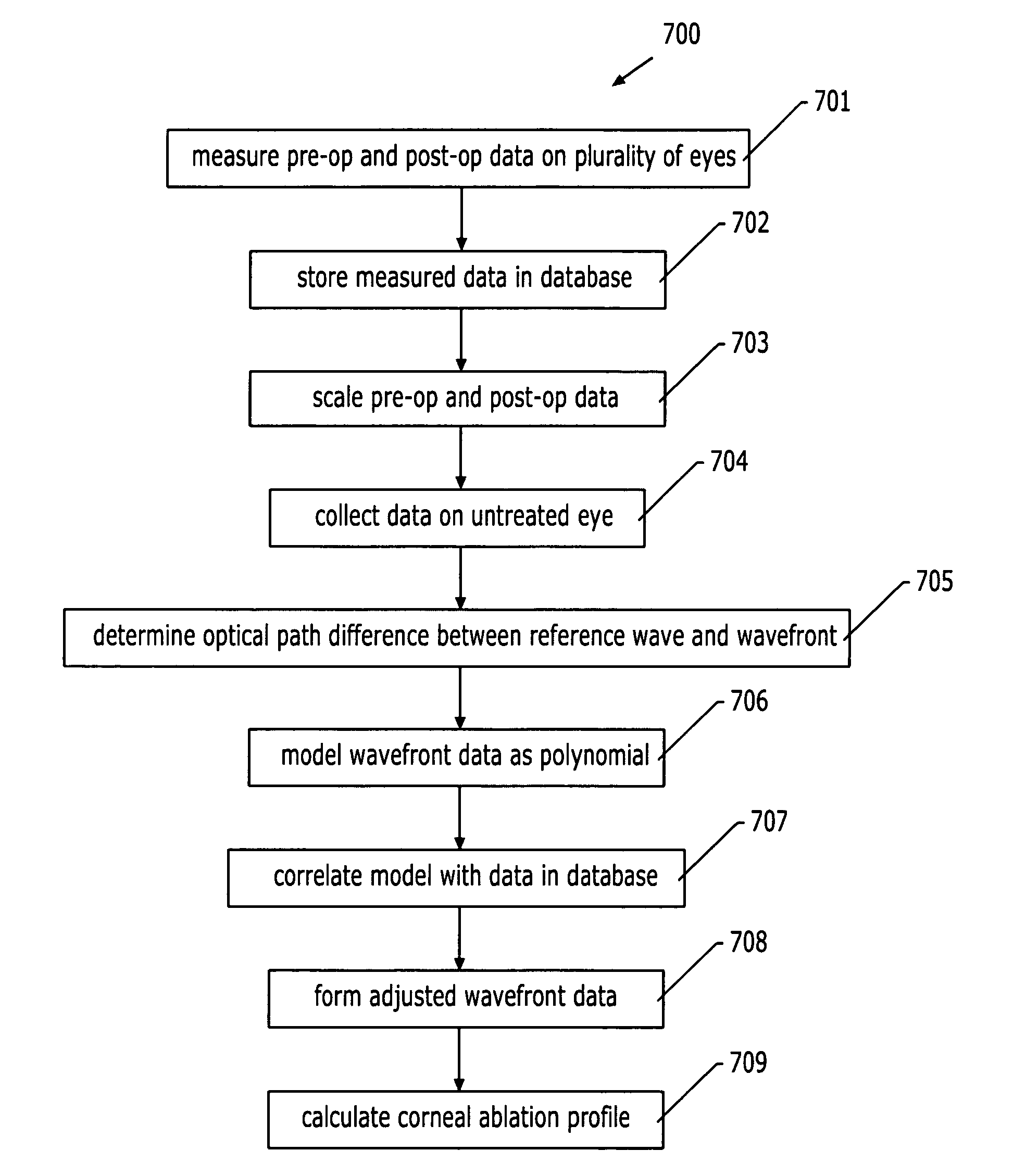

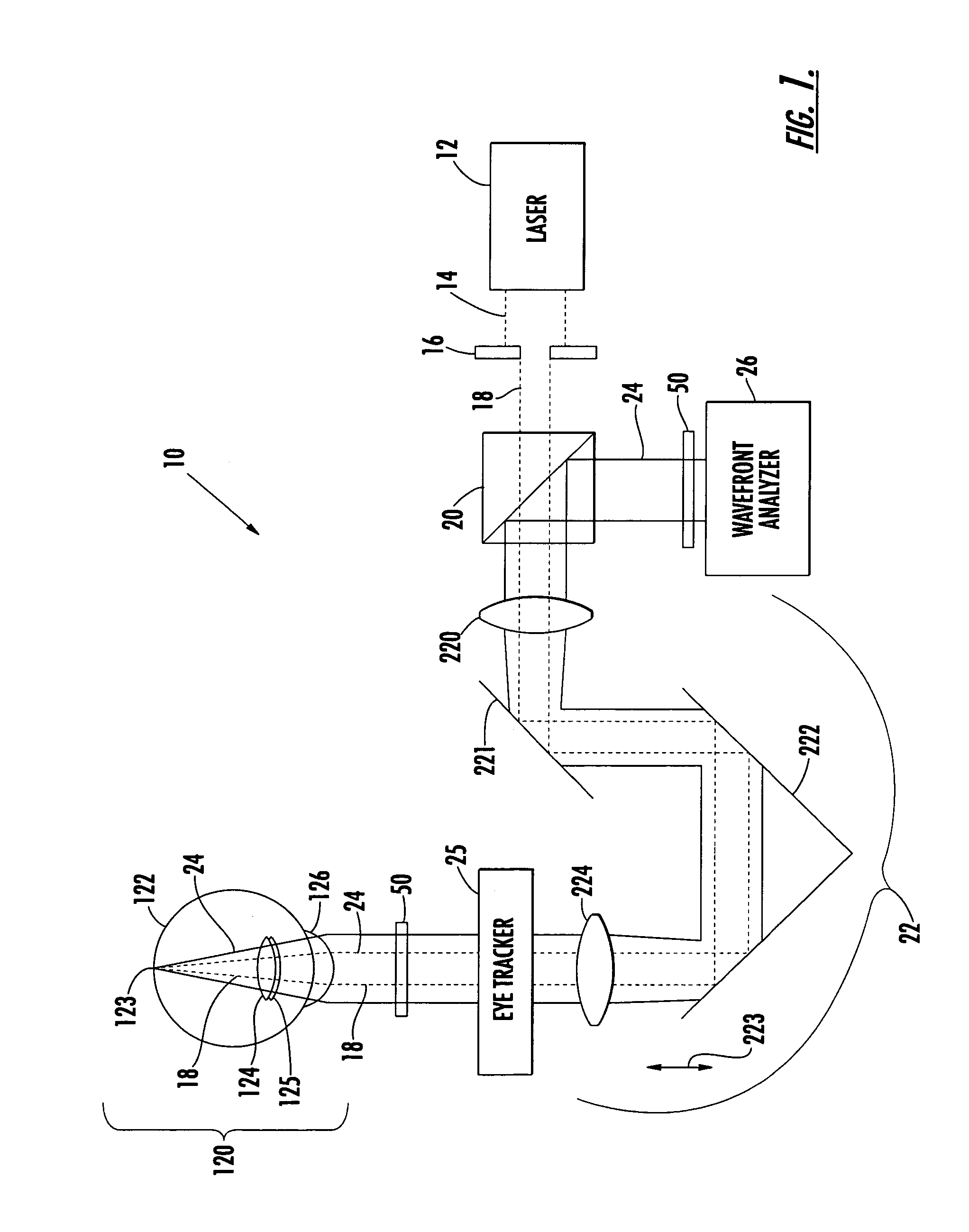

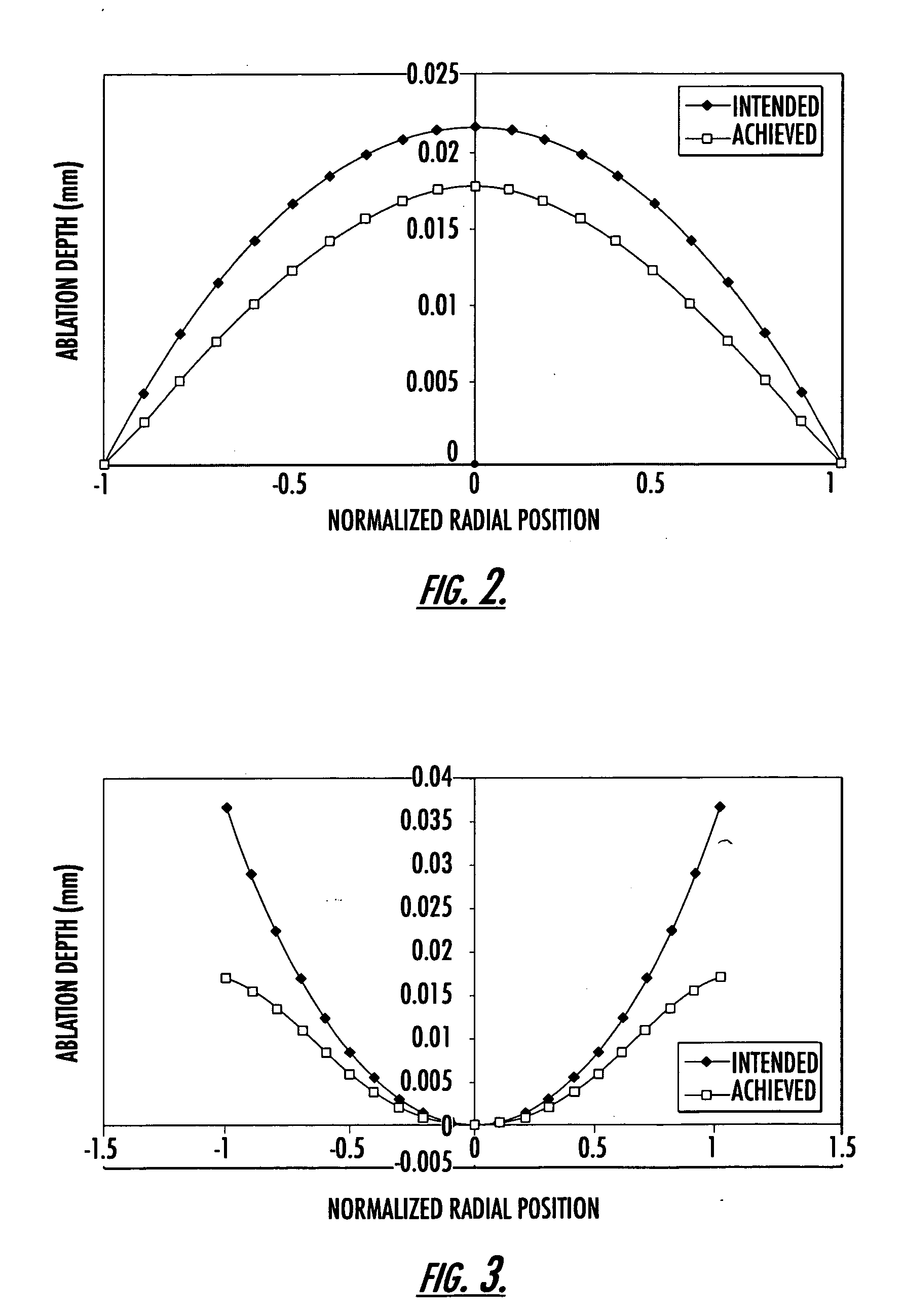

Optimization of ablation correction of an optical system and associated methods

A system and method for converting measured wavefront data into an ablation profile for correcting visual defects includes providing measured wavefront data on an aberrated eye by a method such as known in the art. The measured wavefront data are correlated with accumulated data on previously treated eyes. Next an adjustment is applied to the measured wavefront data based upon the correlating step. This adjustment is used to form adjusted wavefront data for input to a wavefront data correction algorithm to calculate an ablation profile therefrom. The wavefront data correction algorithm may be modeled as, for example, Zernike polynomials with adjusted coefficients.

Owner:ALCON INC

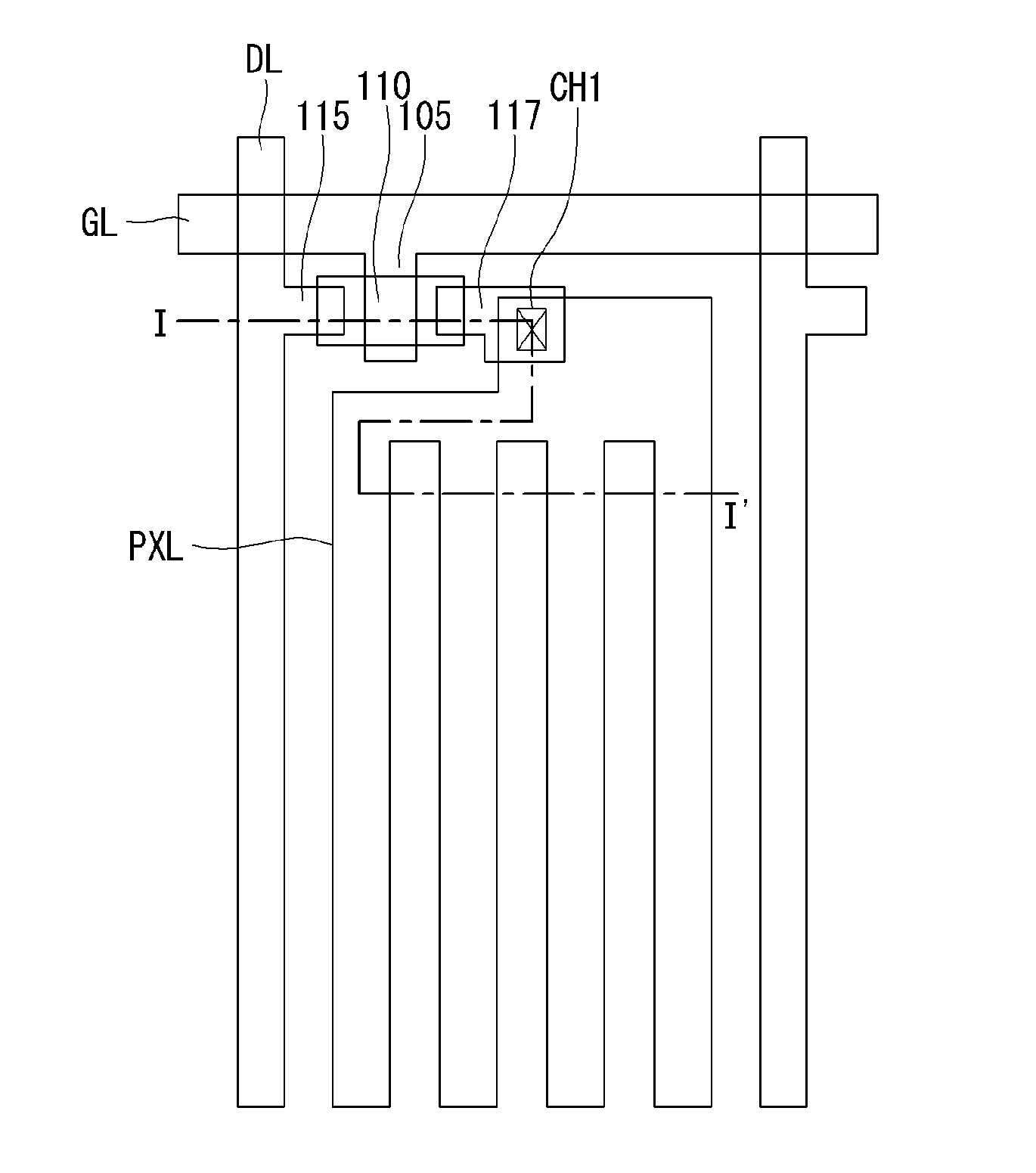

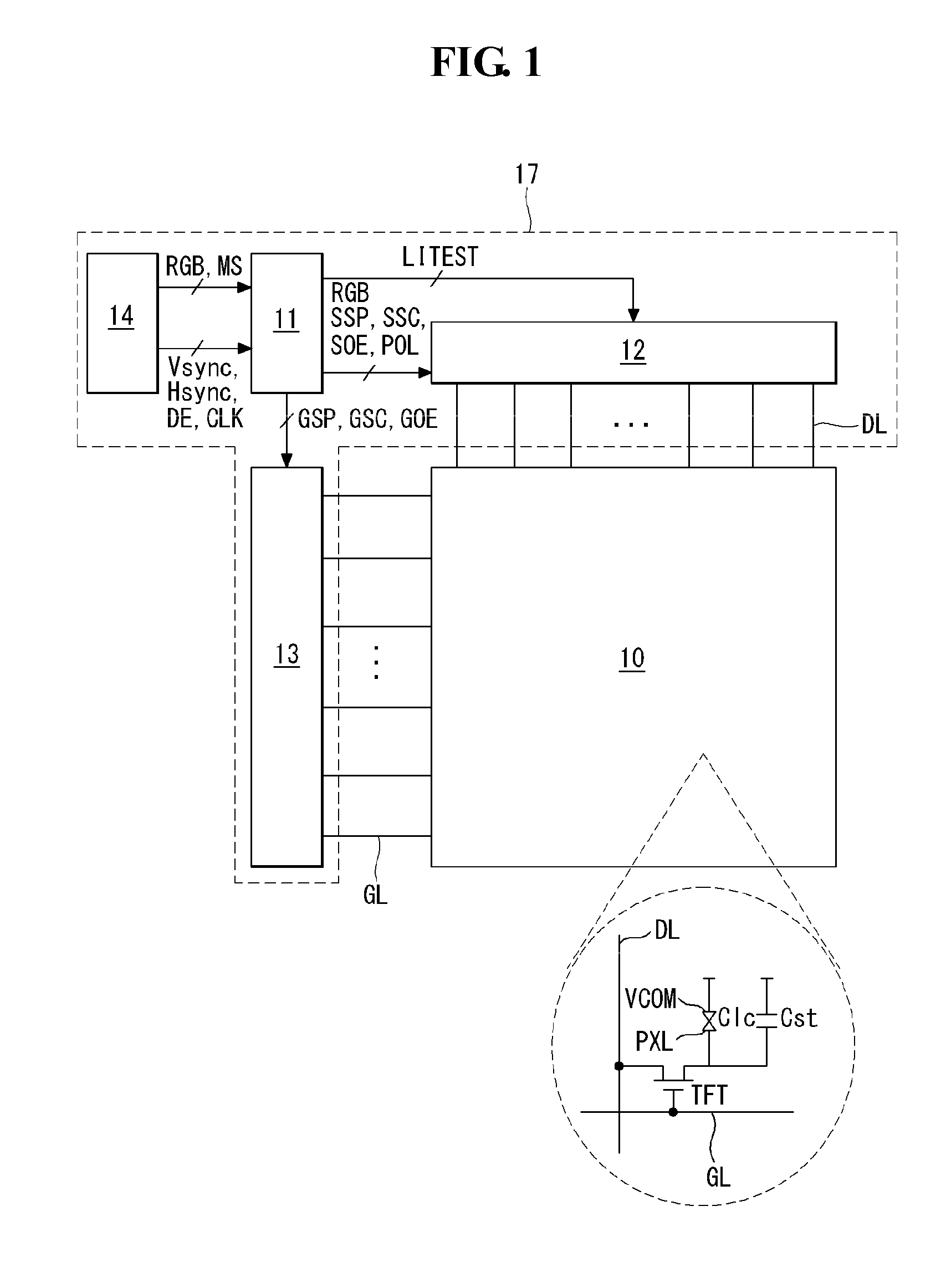

Display device and method of manufacturing the same

ActiveUS20160026044A1Reduce power consumptionMinimal visual defectsTransistorSolid-state devicesDisplay deviceSemiconductor

A display device optimized to operate in a low frame rate mode under certain predetermined conditions is provided. To reduce pixel discharge during the low frame rate mode, the display device employees the TFTs with metal oxide semiconductor layer, the optical alignment layer with an upper portion and a lower portion having different resistivity. In addition, a passivation layer is provided between the optical alignment layer and the pixel or the common electrode for compensating the low resistivity of the lower portion of the optical alignment layer. As such, various visual defects associated with the pixel discharge can be reduced even when the display device is operating under the low frame rate mode.

Owner:LG DISPLAY CO LTD

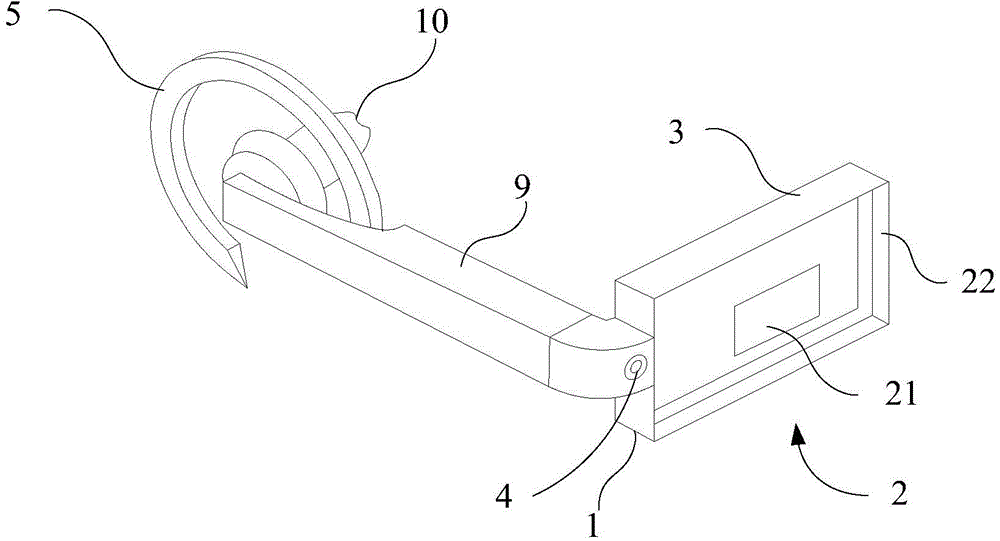

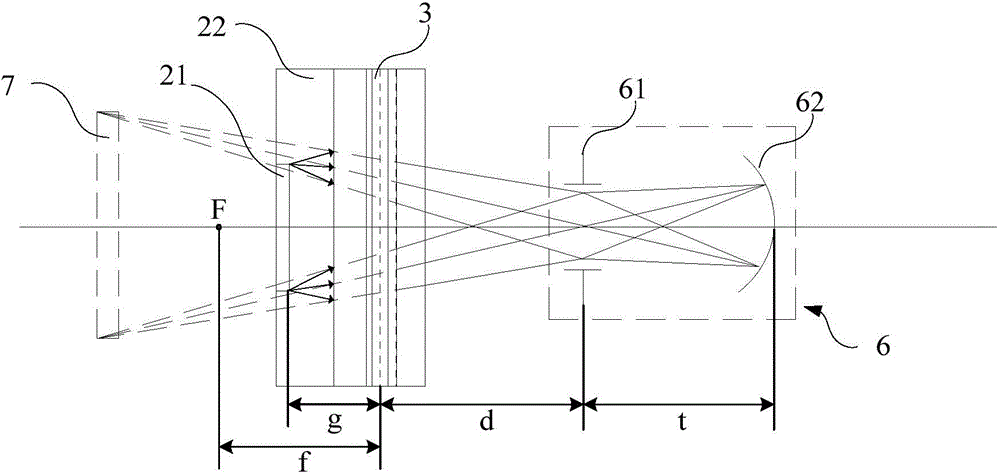

Zoom head-worn equipment

The invention discloses zoom head-worn equipment, belongs to the field of wearable display equipment, and solves problems of discomfort and damage to eyes of people with visual defects in use in the prior art. The zoom head-worn equipment comprises a lens frame, a display screen and a zoom lens. The display screen and the zoom lens are indirectly or directly fixed on the lens frame. The zoom lens is arranged at one side, which is close to the human eyes, of the display screen. The display screen is used for displaying image information. Focal length of the zoom lens is adjustable, and the appropriate focal length is adopted to refract light rays from the display screen to the pupils of the human eyes so as to be imaged on the retinas of the human eyes. The zoom head-worn equipment is suitable for groups with different eyesight, and damage to the eyes can also be avoided.

Owner:SHENZHEN MAGIC EYE TECH CO LTD

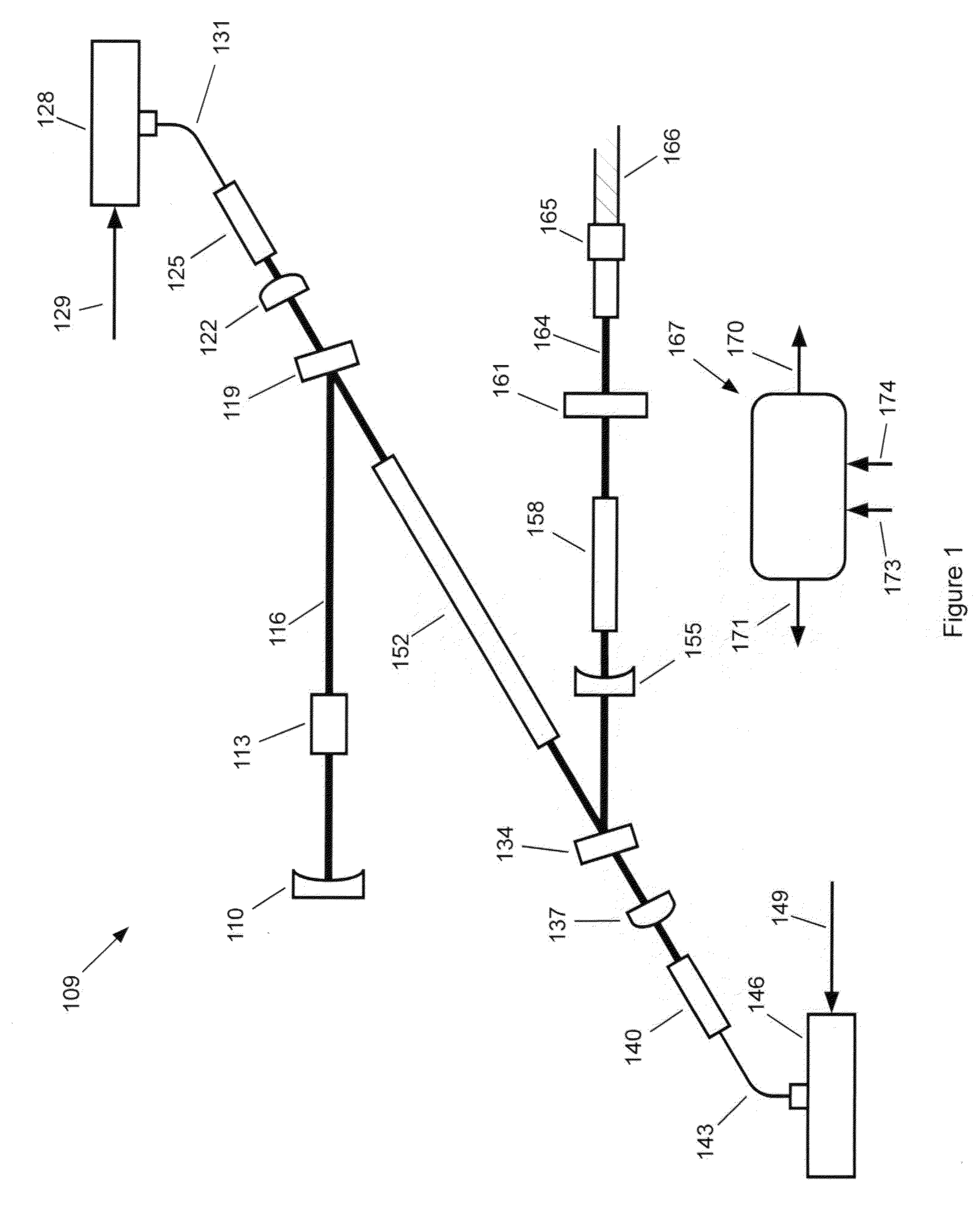

Automated Non-Invasive Capsulectomy and Anterior Segment Surgical Apparatus and Method

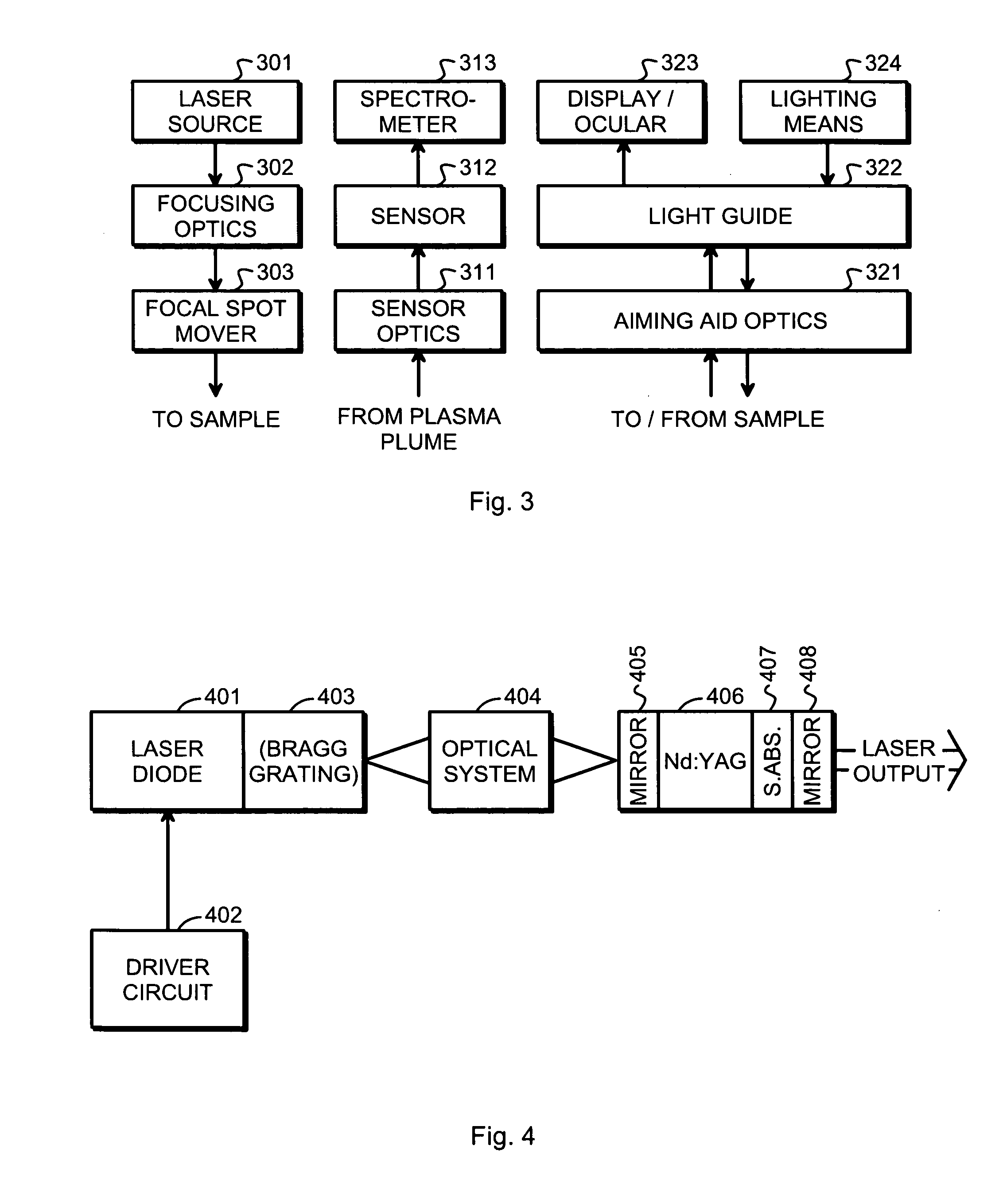

InactiveUS20110245814A1Reduce required pulse energyImprove eyesightLaser surgeryDiagnosticsNd:YAG laserNon invasive

An economical computer-controlled non-invasive laser apparatus and method to perform anterior segment surgery in an eye are disclosed. The laser source may include a pumping laser, a Nd:YAG laser cavity gain media, a stimulated Raman converter crystal, intracavity beam diameter-reducing optics, and an intracavity Q-switching crystal. The laser pulses have a selected wavelength for anterior segment surgery. A laser pulse delivery and treatment control mechanism and method for the practicing surgeon are also provided. The laser pulses and delivery system may be used in anterior segment surgery for cataracts, where the laser pulses may be used to form the capsulotomy, to form the corneal incision or to disintegrate contents of the capsule before removal. The laser and delivery system may also the used to treat a capsule and lens for correcting or preventing presbyopia and to treat a cornea to correct visual deficiencies in an eye.

Owner:LUMEDICA +1

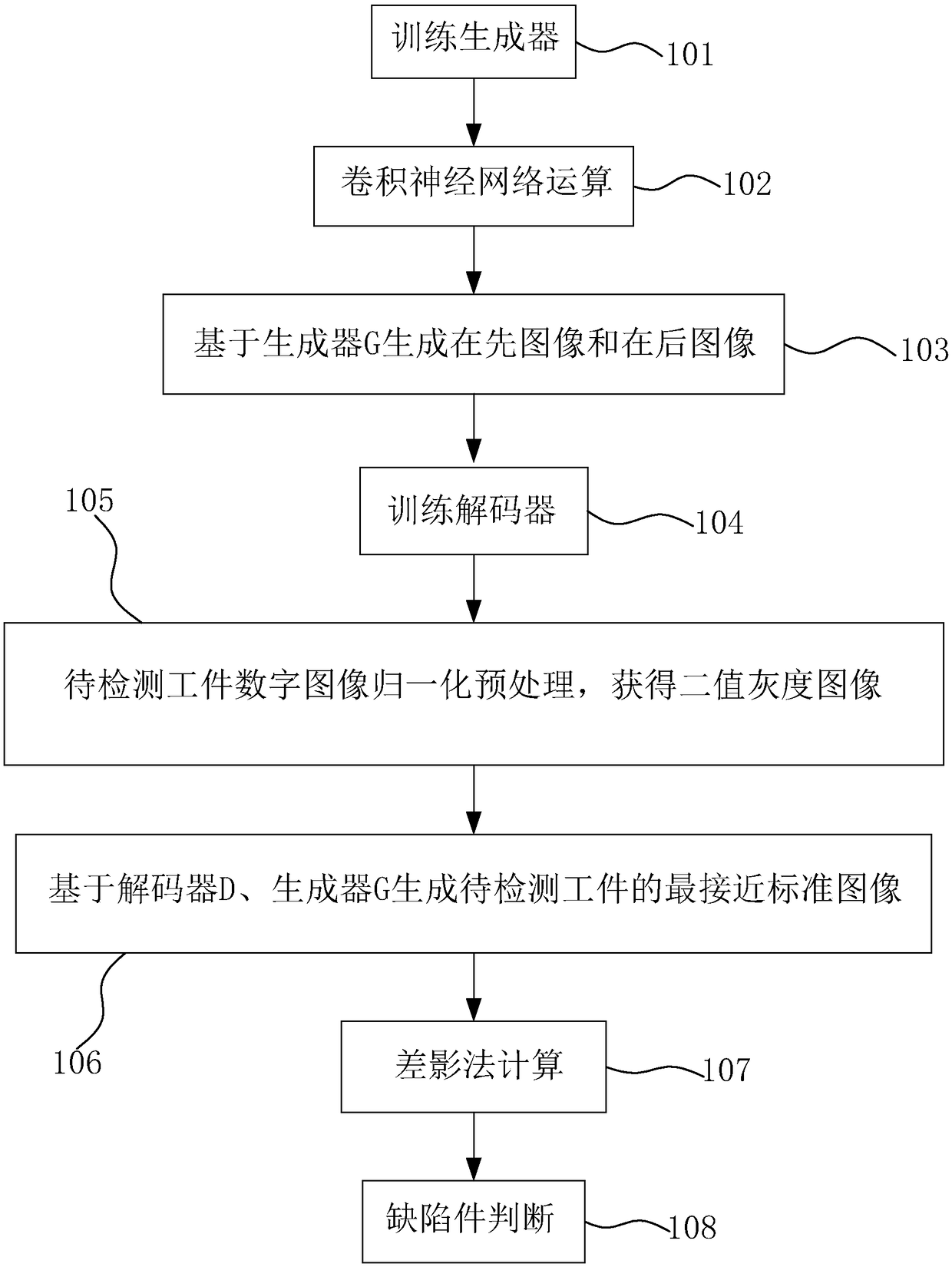

Visual defect detection equipment and detection method thereof

ActiveCN108734690AImprove portabilityImprove general performanceImage enhancementImage analysisGenerative adversarial networkDigital image

The invention relates to and provides visual defect detection equipment and a detection method thereof. The detection method comprises the following steps: acquiring the distribution probability of astandard component digital image by a generative adversarial network, and performing training to obtain a generator G capable of mapping a hidden space vector to the standard component digital image;performing training again to obtain a decoder D capable of realizing mapping from the digital image to the hidden space vector; lastly, inputting a binary gray level image of a detected workpiece obtained by preprocessing into the decoder D and the generator G in sequence to obtain a proximate standard image proximate to the detected workpiece; acquiring a differential value between the binary gray image of the detected workpiece and the proximate standard image by using a difference image method; and comparing the difference value with a threshold value to judge whether the detected workpieceis defective or not. The detection method has the advantages of high portability, high universality, short trial and error time and high detection accuracy.

Owner:SUZHOU HANTE VISUAL TECH CO LTD

Excimer laser unit and relative control method for performing cornea ablation to reduce presbyopia

ActiveUS7887531B2Mitigates presbyopiaLaser surgerySurgical instrument detailsVisual perceptionAstigmatism

There are described an excimer laser unit and a method of controlling the unit to perform cornea ablation to reduce presbyopia, wherein the excimer laser unit is controlled to form on the cornea a photoablative pattern inducing a fourth-order ocular aberration, in particular a positive spherical aberration. More specifically, an aberrometric map of the eye is first acquired indicating the visual defects of the eye, which include second-order visual defects such as hypermetropia, astigmatism, and myopia, and higher-order visual defects such as spherical aberration; if the detected spherical aberration is negative, it is reduced by numerically increasing its absolute value to obtain an overcorrect photoablative inducing positive spherical aberration; conversely, if the detected spherical aberration is positive, its sign is changed and its absolute value increased numerically to obtain an overcorrect photoablative pattern inducing positive spherical aberration; and the photoablative pattern so generated is supplied to the excimer laser unit for implementation on the cornea.

Owner:CARL ZEISS MEDITEC AG

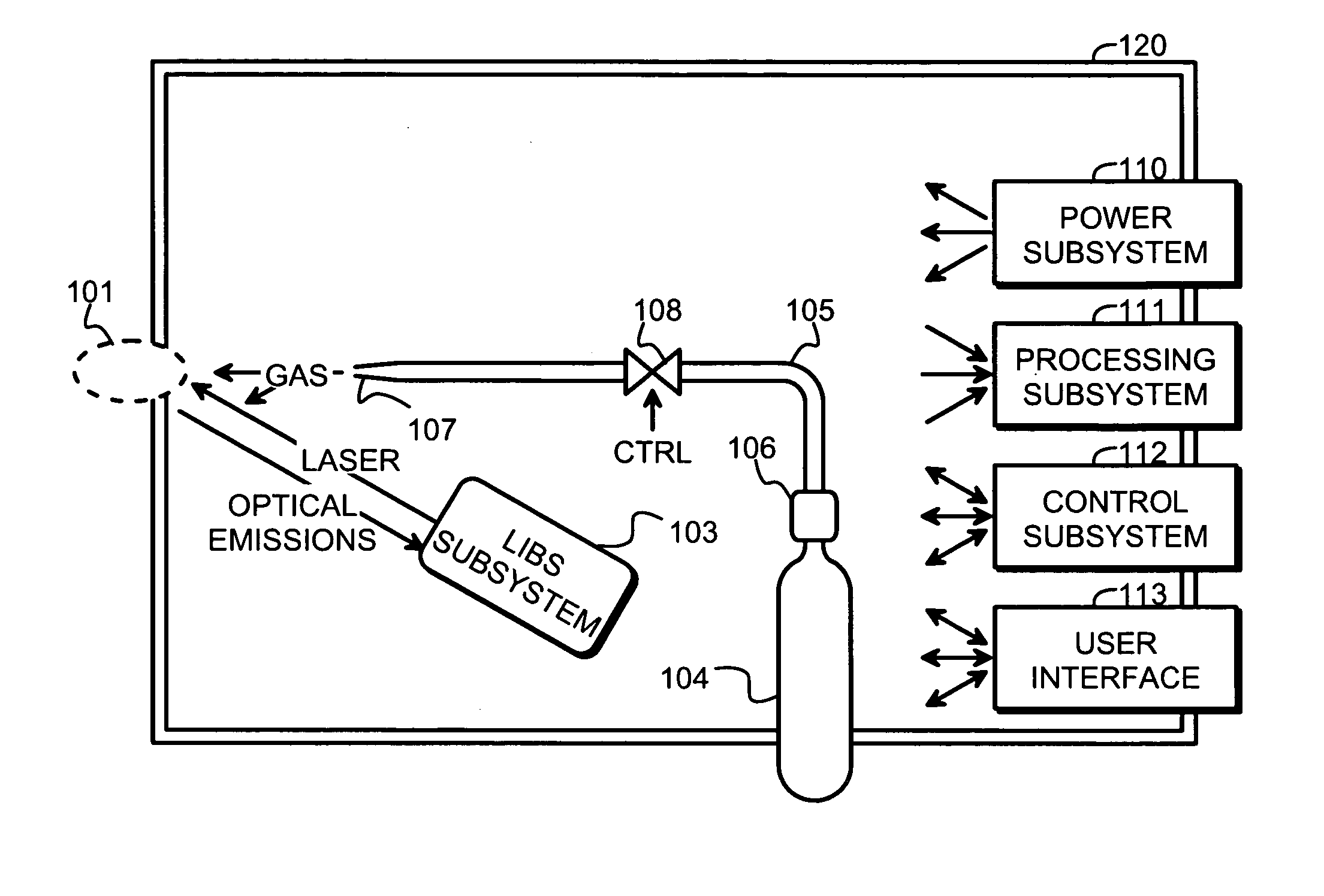

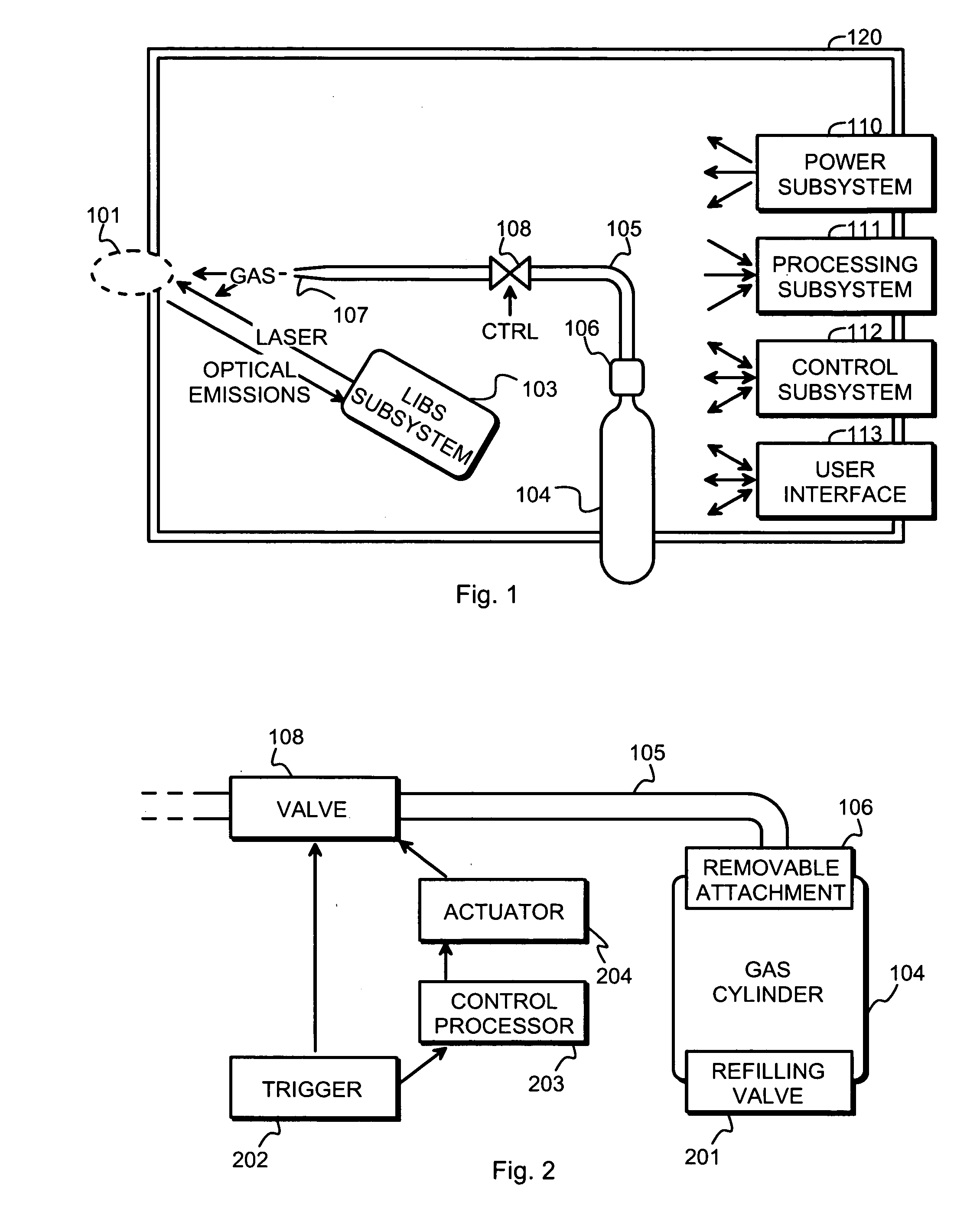

Method and arrangement for non-destructive composition analysis of delicate samples

ActiveUS20060262302A1Easy to useOperating conditionRadiation pyrometrySpectrum investigationNon destructiveComposition analysis

An arrangement and a method are provided for non-destructively analyzing the composition of a delicate sample. The value of the sample depends at least partly on absence of visual defects. A laser source (301) produces a pulsed laser beam, and focusing optics (302) focus said pulsed laser beam into a focal spot on the sample. A sensor (312) receives and detects optical emissions from particles of the sample excited by said pulsed laser beam. A processing subsystem (111) produces information of the composition of the sample based on the optical emissions detected by said sensor (312).

Owner:HITACHI HIGH TECH ANALYTICAL SCI FINLAND OY

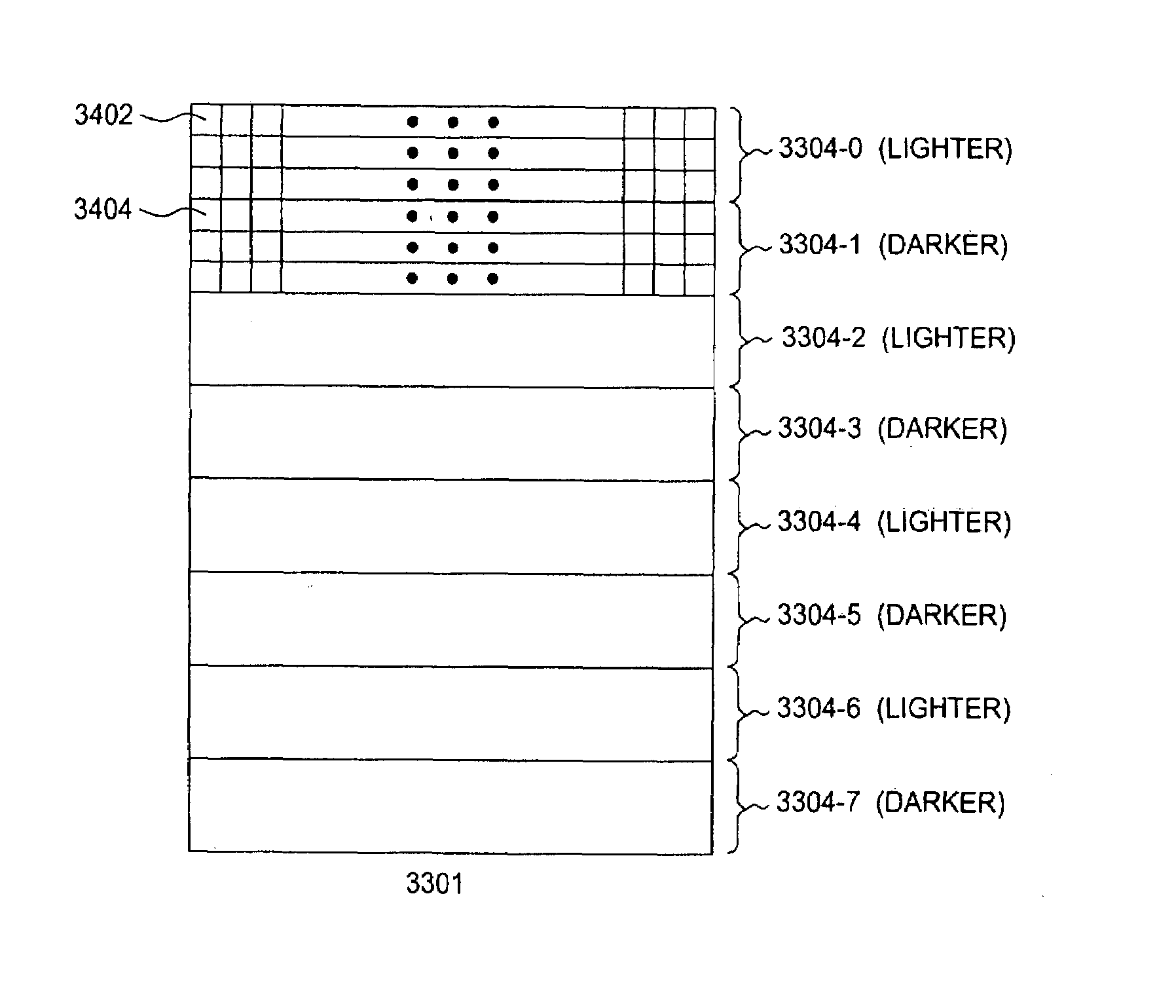

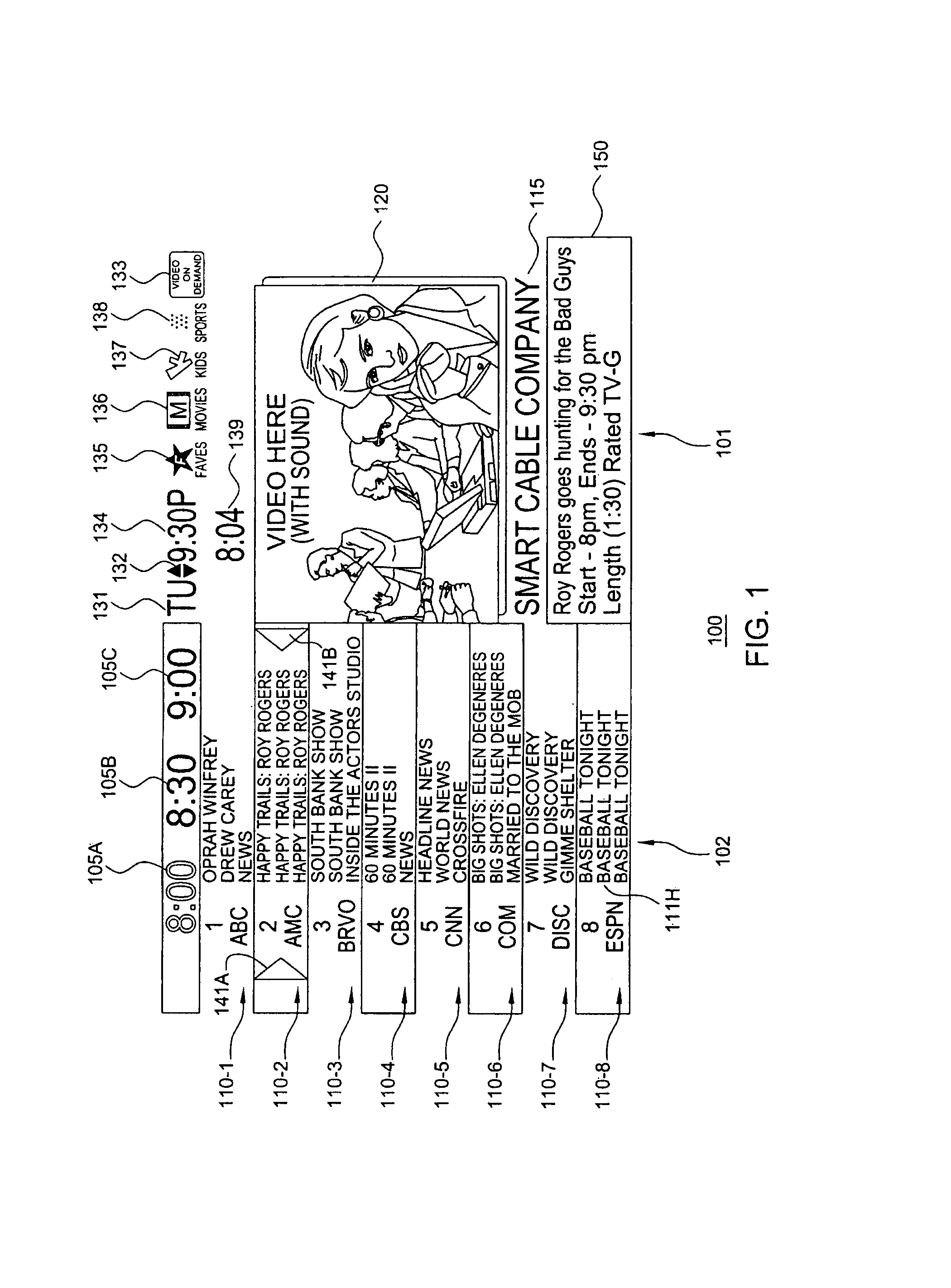

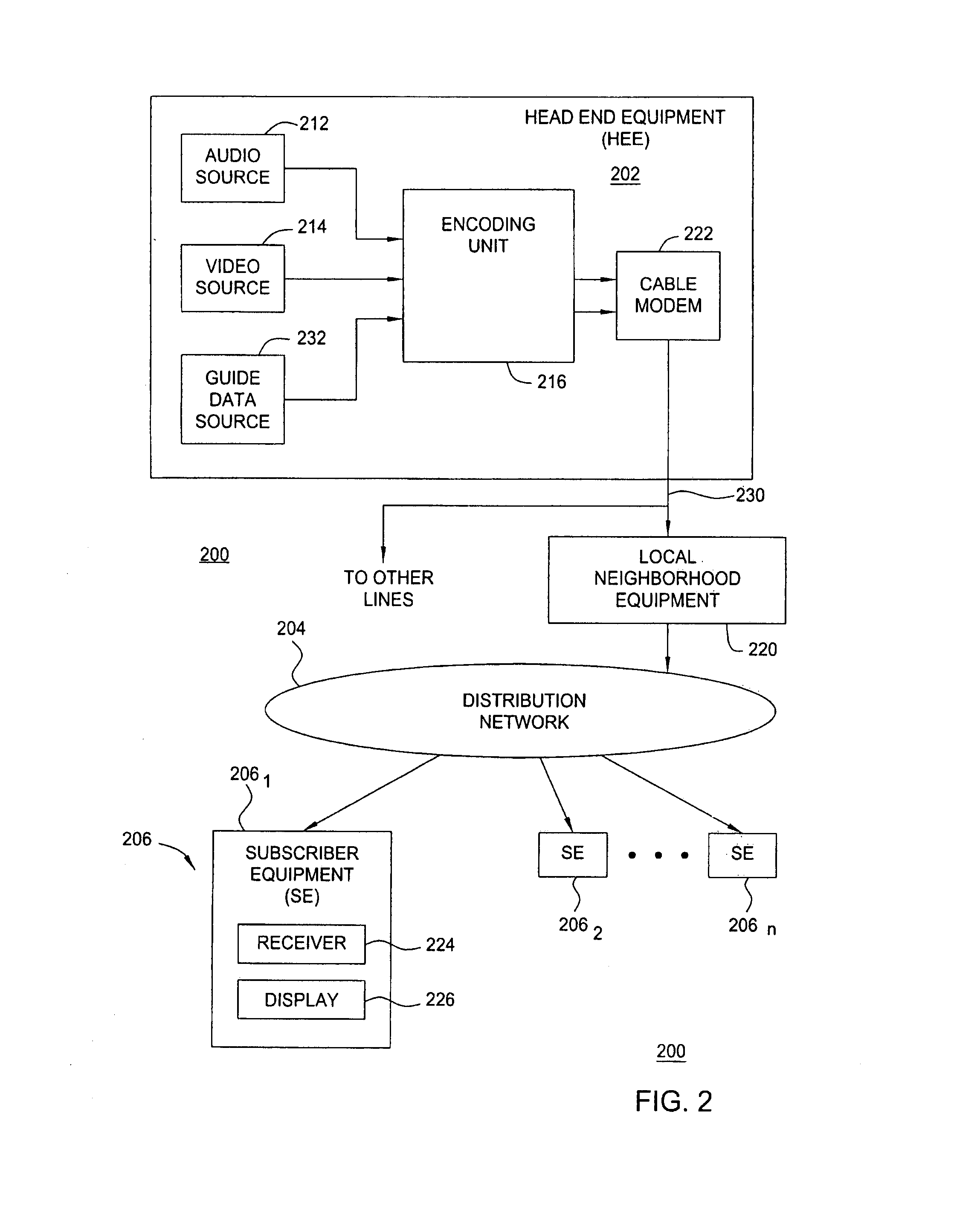

Encoding optimization techniques for encoding program grid section of server-centric interactive programming guide

InactiveUS7254824B1Improve viewing qualityLimit bit rateTelevision system detailsPicture reproducers using cathode ray tubesFrequency filteringQuantization matrix

An interactive program guide (IPG) may include a program grid section and a multimedia section. The program grid section typically contains program information organized in a grid with a time axis and a channel axis. The multimedia section may include video for advertisement, previews, and other purposes. Such an IPG may be rendered and encoded at a server and distributed to client terminals in the form of compressed bit streams.For certain IPGs, the program grid section may comprise alternating stripes of background with different shades (lighter / darker) or different colors. Typically, the alternating background stripes may be used to visually separate text information into timeslots or channels.Blank areas of the background may be “skip” encoded to “save” a portion of the bit rate. Meanwhile, the quantizer stepsize for encoding that section may be lowered so as to utilize the saved bits to improve the viewing quality of the program grid section. Additionally or alternatively, the quantization matrix for encoding the program grid section may be optimized for encoding text (rather than being, for example, a standard quantization matrix).Encoding may be performed on the program grid section such that encoded macroblocks do not cross a border between two stripes. In other words, each encoded macroblock in the program grid section may be within a single stripe. Additionally or alternatively, low-pass frequency filtering may be applied on the background stripes. Such low-pass filtering reduces visual defects due to ringing from edges between stripes.

Owner:CHARTER COMM OPERATING LLC

Reprocessed polyhydroxy amino ether coated polypropylene film

Owner:TORAY PLASTICS AMERICA

Lens designs for treating asthenopia caused by visual defects

The invention provides ophthalmic lenses that provide correction for each of refractive asthenopia, muscular asthenopia and foveal suppression.

Owner:JOHNSON & JOHNSON VISION CARE INC

Device for asymmetrical refractive optical correction in the peripheral retina for controlling the progression of myopia

Optical device (1) for modifying the optics of the eye in its peripheral retina as prophylaxis of the progression of myopia, that it consists in a lens in which its inferior nasal quadrant (2) modifies the strength in a progressive and controlled manner from the center to the outer zone of the lens. The rest of the quadrants (3) of device (1) have a configuration of a graduated crystal or flat crystal, depending, respectively, on whether the user has some visual defect that requires optical correction or lacks said defect. The lens can be either an optical lens, a contact lens or electro-optical systems.

Owner:UNIVERSITY OF MURCIA

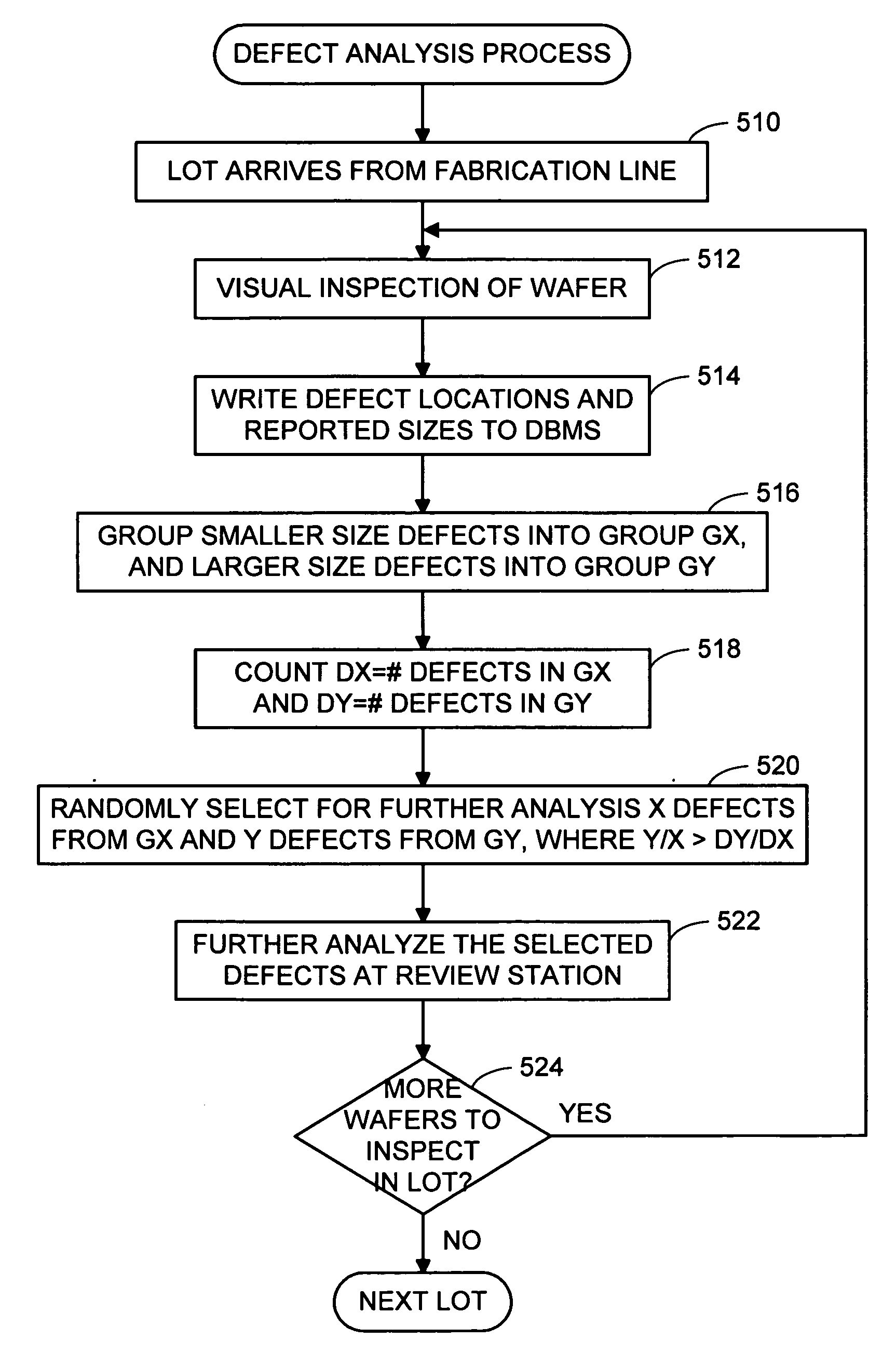

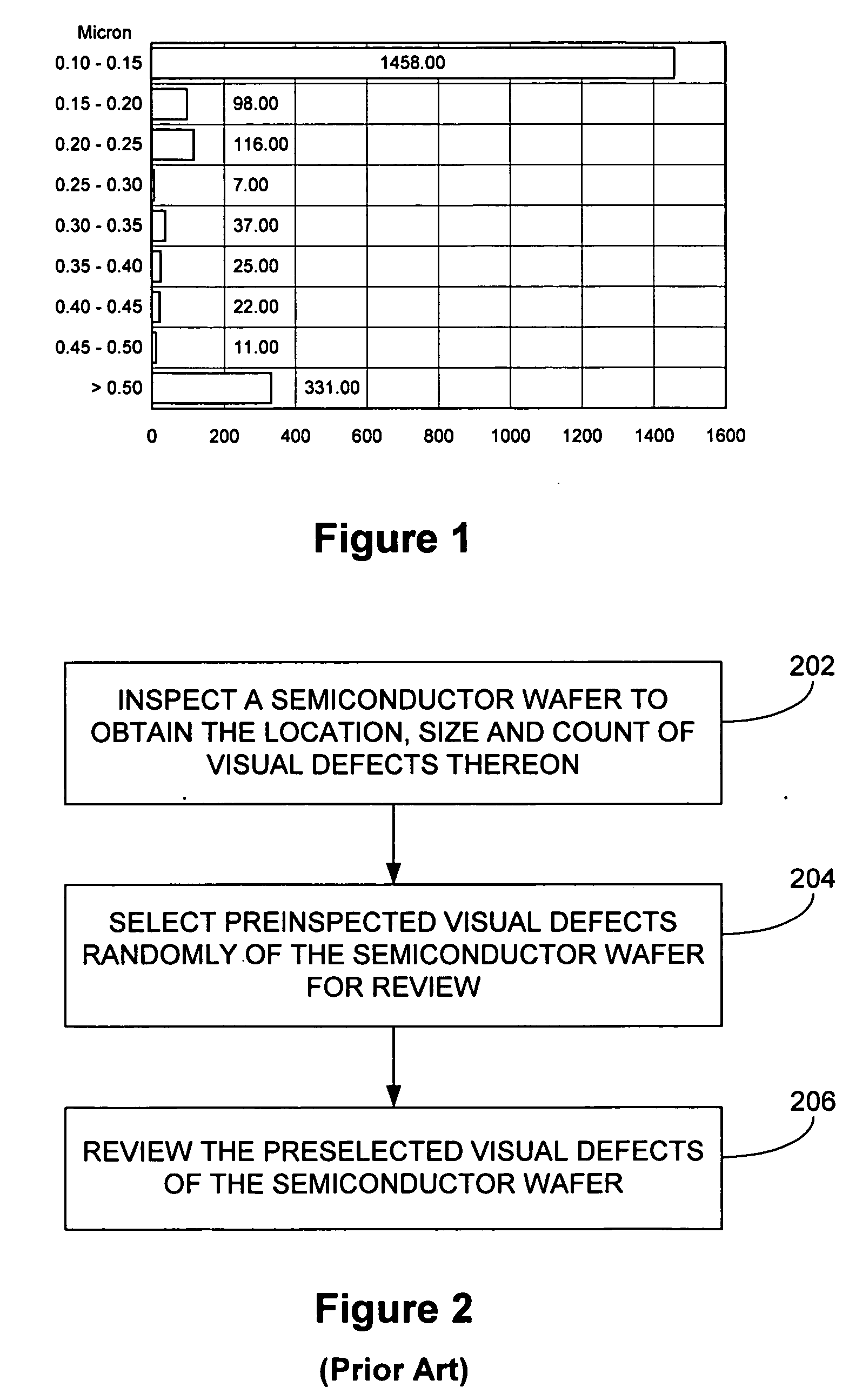

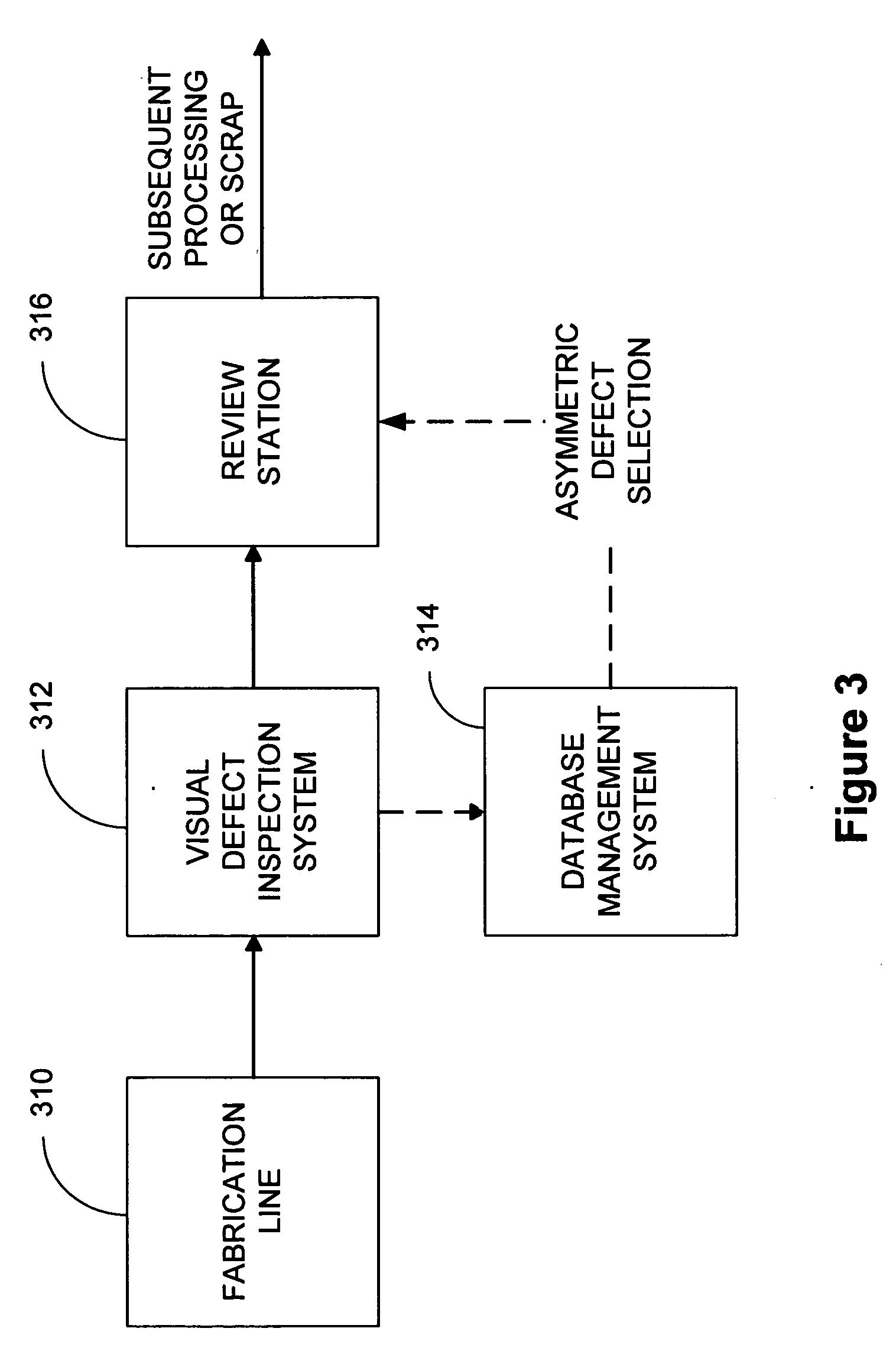

Method and system for analyzing defects of an integrated circuit wafer

ActiveUS20050210423A1Efficient analysisHigh yield-killing defectsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingDefect sizeEngineering

Method and apparatus for efficiently analyzing visual defects of an integrated circuit wafer in the manufacturing process thereof by utilizing an asymmetric visual defect review methodology that can effectively extract high yield-killing defects out of numerous reported defects within the limited capacity and manpower available for review. Roughly described, the method comprises inspecting the semiconductor wafer, thereby obtaining the defect location and defect size, sampling the defects asymmetrically by determining asymmetrical defect review ratios, and thereby reviewing the defects asymmetrically. Also described is a method of asymmetrically sampling visual defects that can effectively extract out high yield-killing defects from a mass of defects by determining asymmetric defect review ratios, and a system for use in sampling visual defects asymmetrically.

Owner:MACRONIX INT CO LTD

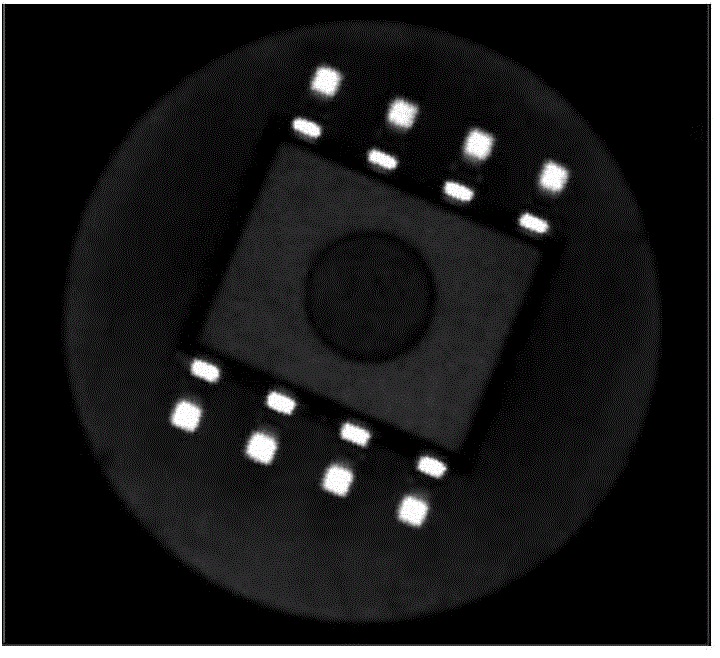

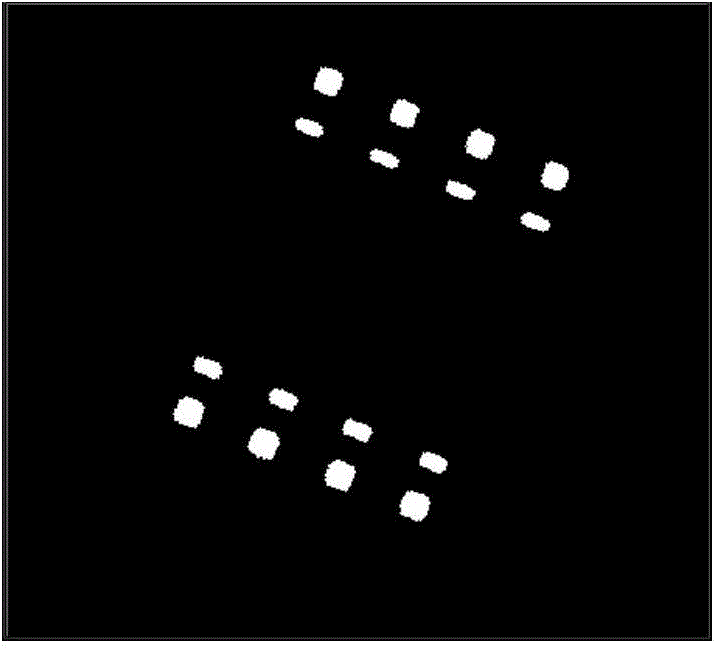

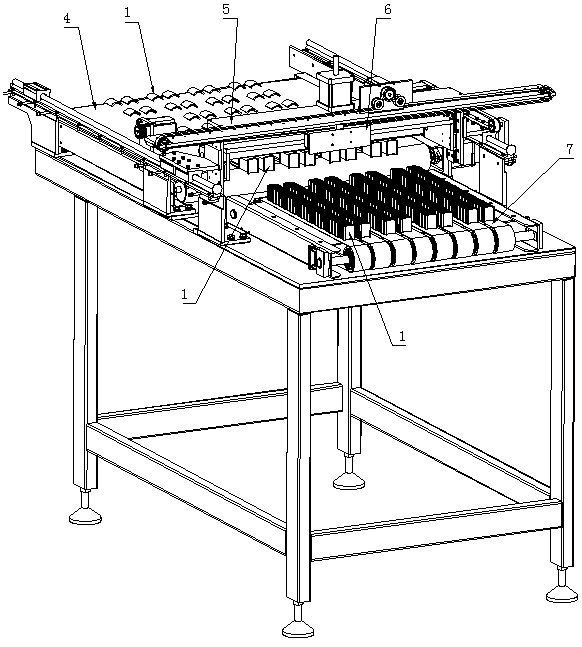

SOP element positioning and defect detecting method based on vision

ActiveCN104933720AStrong precisionImprove stabilityImage enhancementImage analysisVisual field lossVision based

The invention discloses an SOP element positioning and defect detecting method based on vision, and relates to visual positioning and visual defect detecting of an SOP element in a surface mount technology visual system. For solving the problem that the SOP element is insufficient in precision and sensitive to the external environment change when being used for the mounting of a chip mounter, the invention provides a SOP element positioning and defect detecting method based on vision. The method comprises the following steps: checking whether a selected region image meets a luminance requirement; binarizing the selected region image to obtain a binarized image; extracting an outer boundary outline of the binarized image obtained in the second step through the adoption of a canny edge detection extracting method to obtain each outer boundary point set of the binarized image; performing SOP element pin defect detection according to above obtained data. The method is applied to the visual field of the chip mounter.

Owner:宁波智能装备研究院有限公司

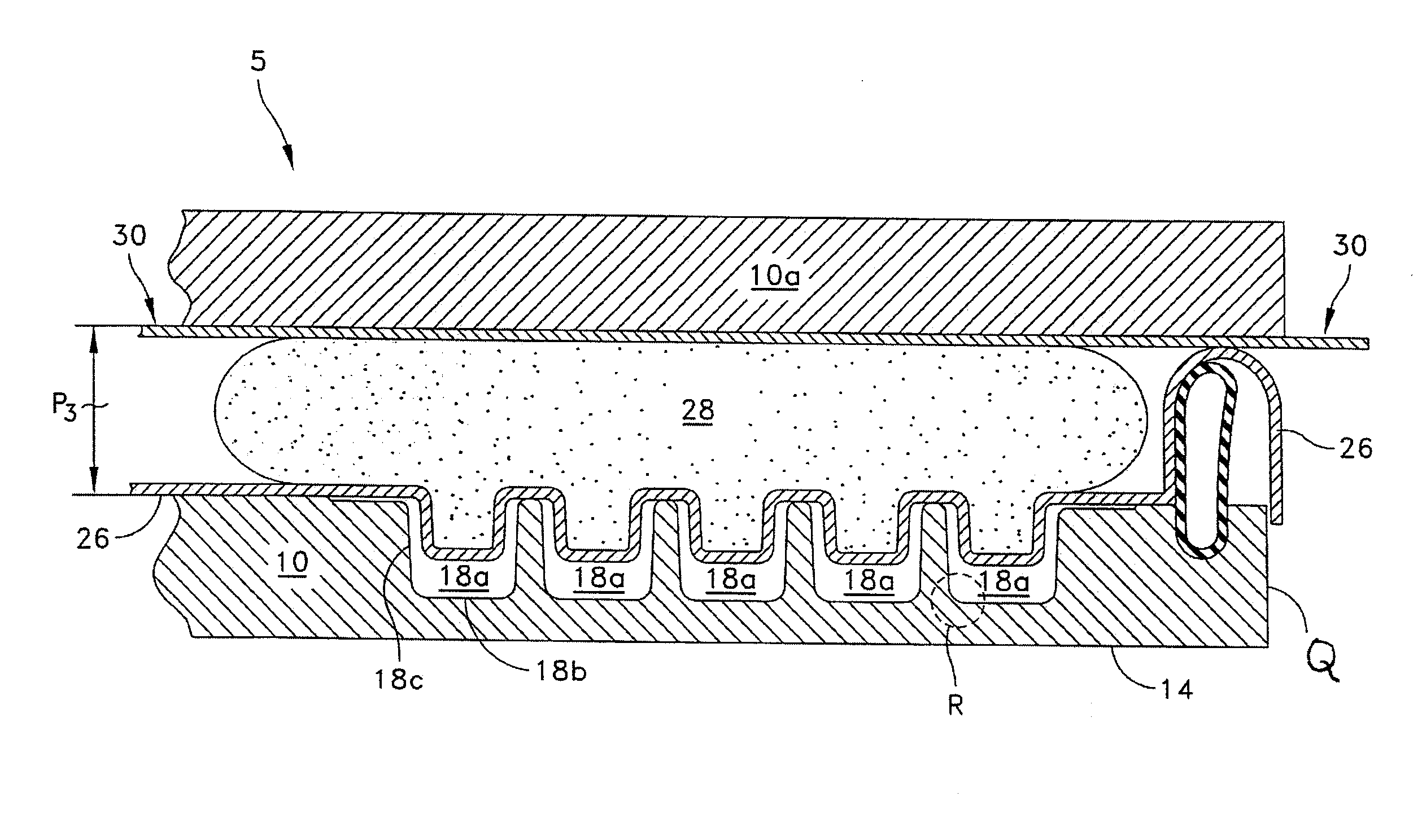

Molding system, method and articles formed thereby

Disclosed herein is a molding system that facilitates the molding of very thick products from materials such as gel and / or mechanically frothed foam, substantially free of visual defects, such as air bubbles, by controlling the rate of mold closure and / or interrupting the mold closure.

Owner:POLYWORKS

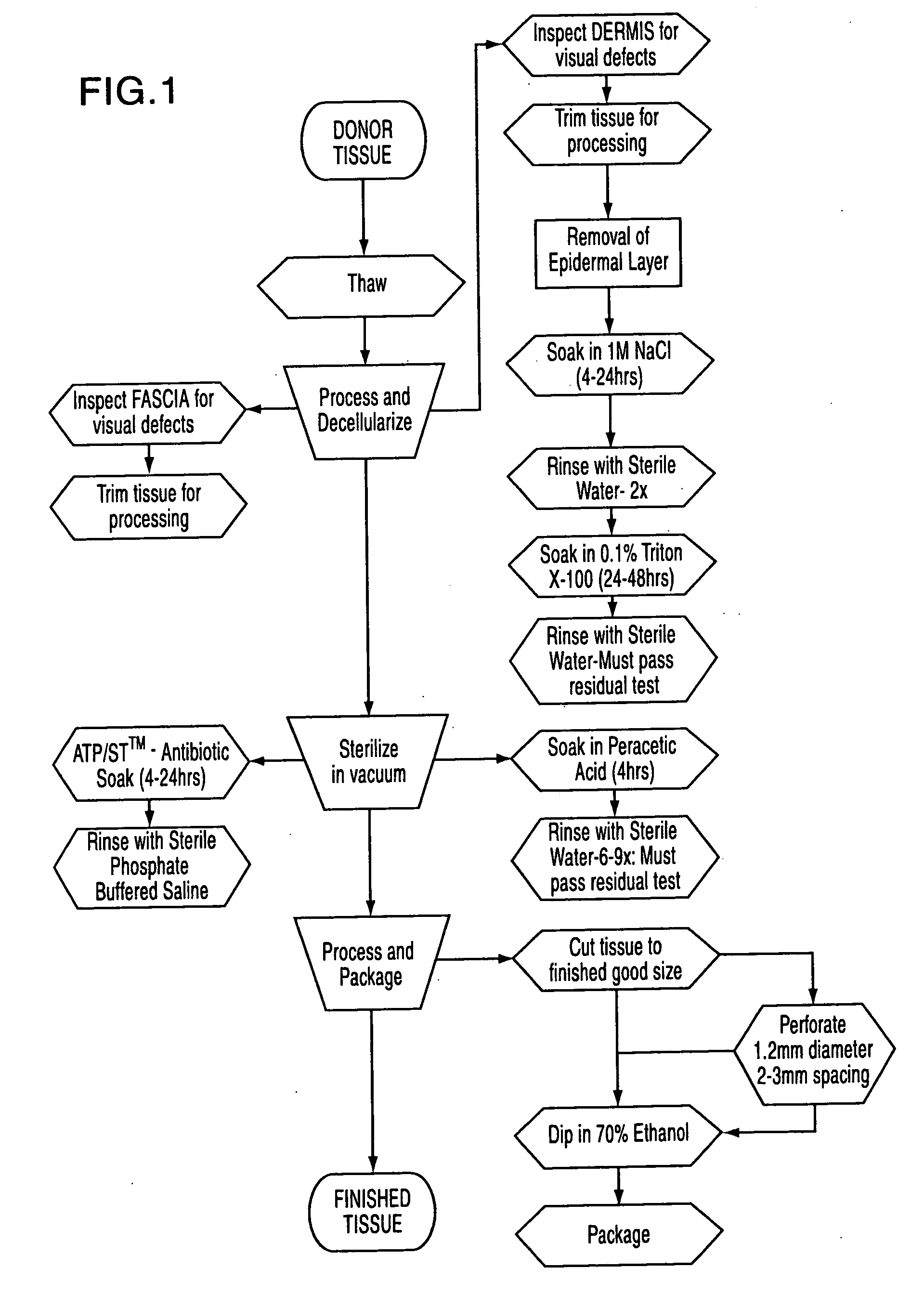

Soft tissue processing

The present invention is a process for preparing soft tissue such as tendons, ligaments, cartilage, fascia, dermis, human valves and human veins for implant in a human and removes cellular components and forms an decellular matrix having as major components collagens and elastins while sterilizing the tissue. The process comprises the following steps: (1) isolating from a suitable donor a desired soft tissue sample of the biological material; (2) processing and decellularizing the soft tissue including inspection for visual defects, trimming and soaking the tissue in a detergent depending on whether the tissue is fascia or dermis and rinsing same with sterile water; (3) sterilizing the soft tissue in a vacuum and soaking the tissue in an antibiotic composition or peracetic acid depending on whether the soft tissue is fascia or dermis and rinsing same; (4) processing the tissue by cutting the tissue to size and perforating the tissue; and (5) dipping the tissue in 70% ethanol and packaging the tissue.

Owner:MUSCULOSKELETAL TRANSPLANT FOUND INC

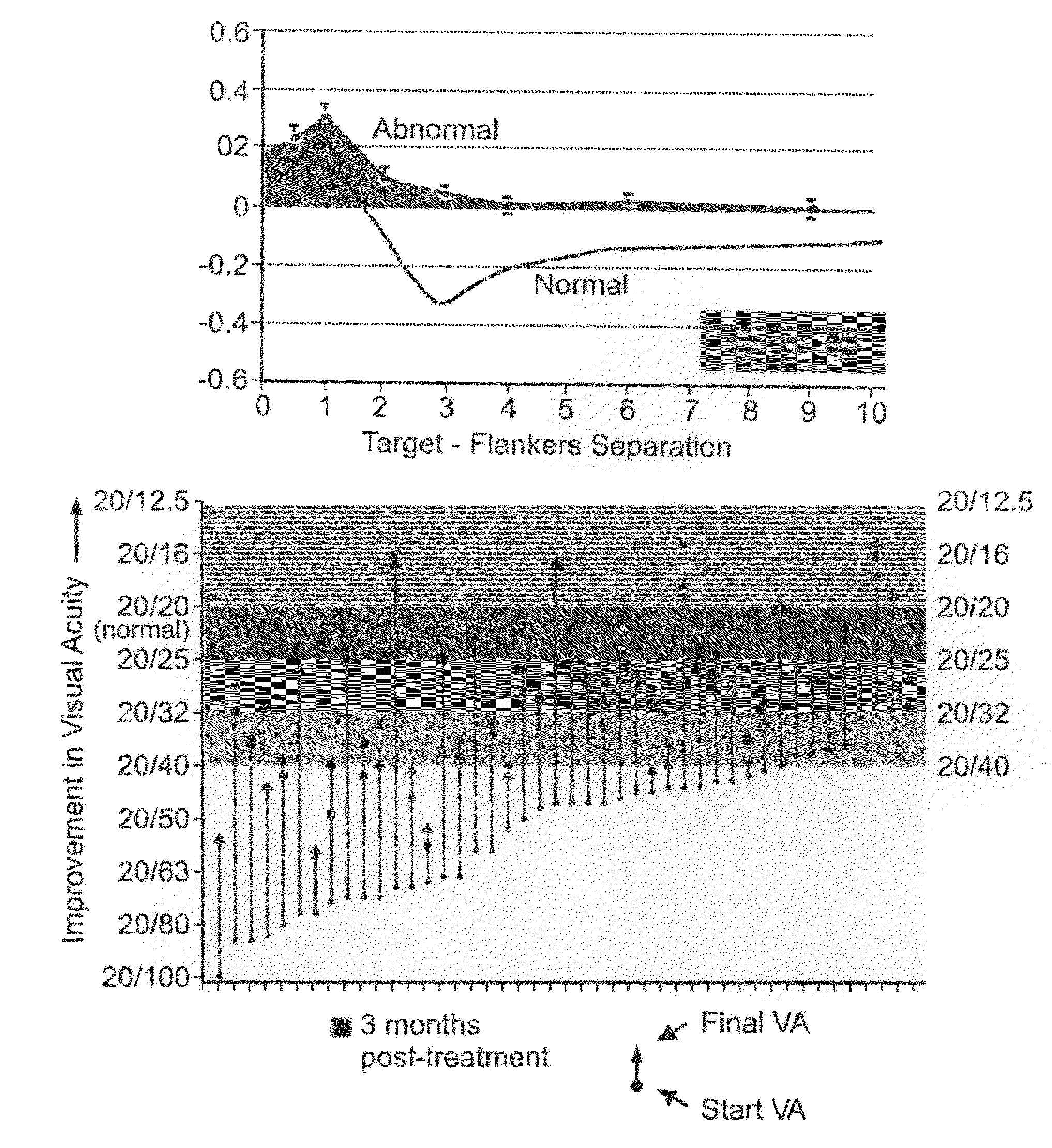

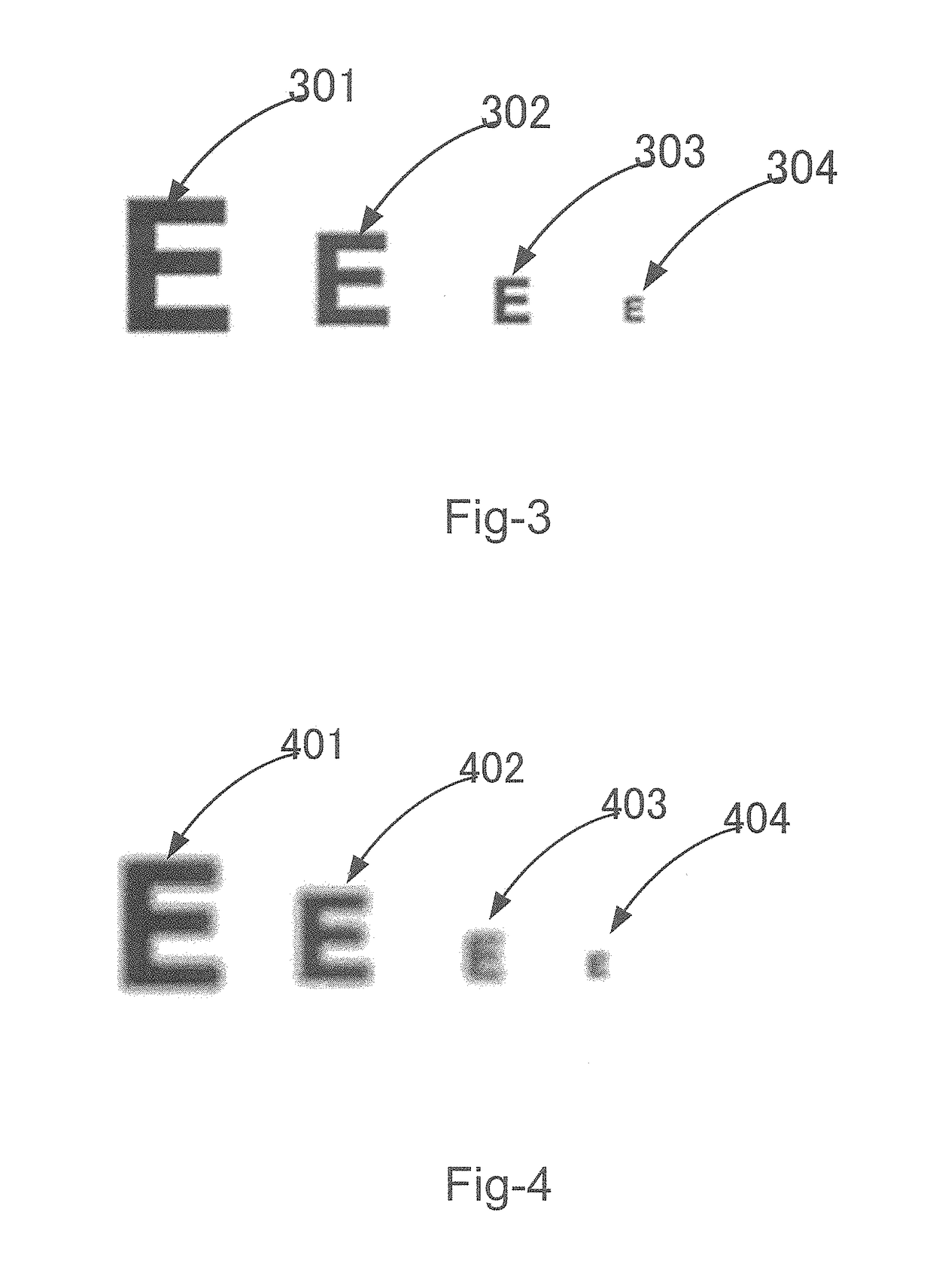

Method and apparatus for improving visual perception

ActiveUS7427138B2Facilitate cognitionImprove abilitiesEye exercisersPhoroptersEyewearVisual perception

A method of improving the visual perception ability of a person by: displaying to the person in at least one evaluation sessions a plurality of images selected to test the visual perception ability of the person with respect to a visual defect, and to elicit responses from the person indicative of the level of the person's visual perception ability with respect thereto; and by utilizing the responses to select another plurality of images designed to treat the person with respect to a detected visual defect; applying training glasses with reduced refraction for the respective eye, and displaying to person another plurality of images in treatment sessions until the visual perception ability of the person has been improved.

Owner:TALSHIR GUY MEDICAL TECH LTD

Method for improving visual perception

ActiveUS20070076168A1Improve visual effectsFacilitate cognitionEye exercisersPhoroptersContrast levelEyewear

A method of improving the visual perception ability of a person with respect to a particular eye condition of one or both eyes, by displaying to the person, in at least one evaluation session of an evaluation phase, a plurality of images selected to test the visual perception ability of the person with respect to at least one visual defect, and to elicit responses from the person indicative of the level of the person's visual perception ability with respect to the at least one visual defect; and by utilizing the responses to select another plurality of images designed to treat the person with respect to a detected visual defect and thereby to improve the visual perception ability of the person with respect to the detected visual defect; and, in a treatment phase, applying training glasses with reduced refraction for the respective eye, and displaying to the person the another plurality of images in at least one treatment session until the visual perception ability of the person has been improved with respect to the detected visual defect. The foregoing operations are performed until the desired “contrast funnel” is achieved, i.e., the desired range of contrast levels expected to be achieved in order to gain optimal visual improvement.

Owner:TALSHIR GUY MEDICAL TECH LTD

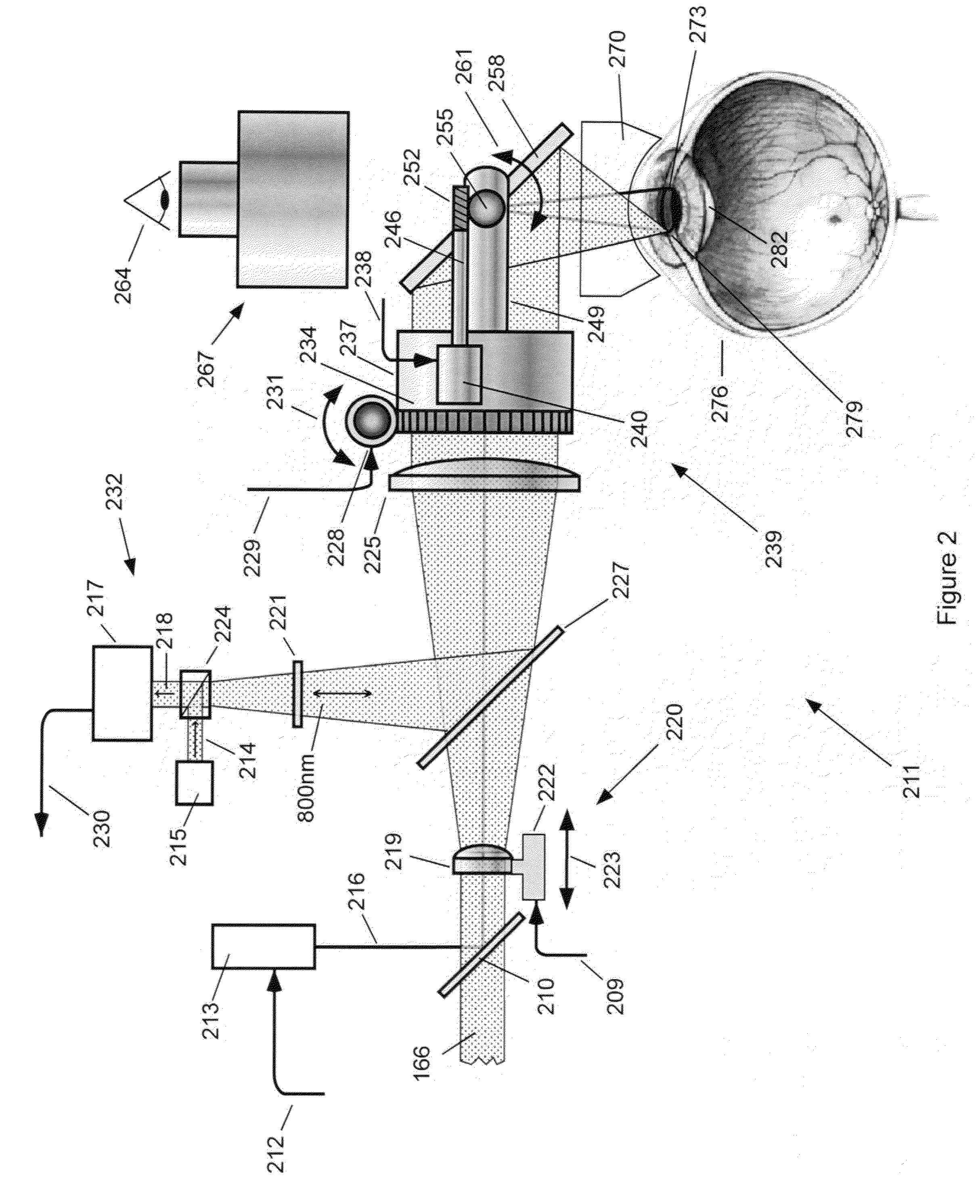

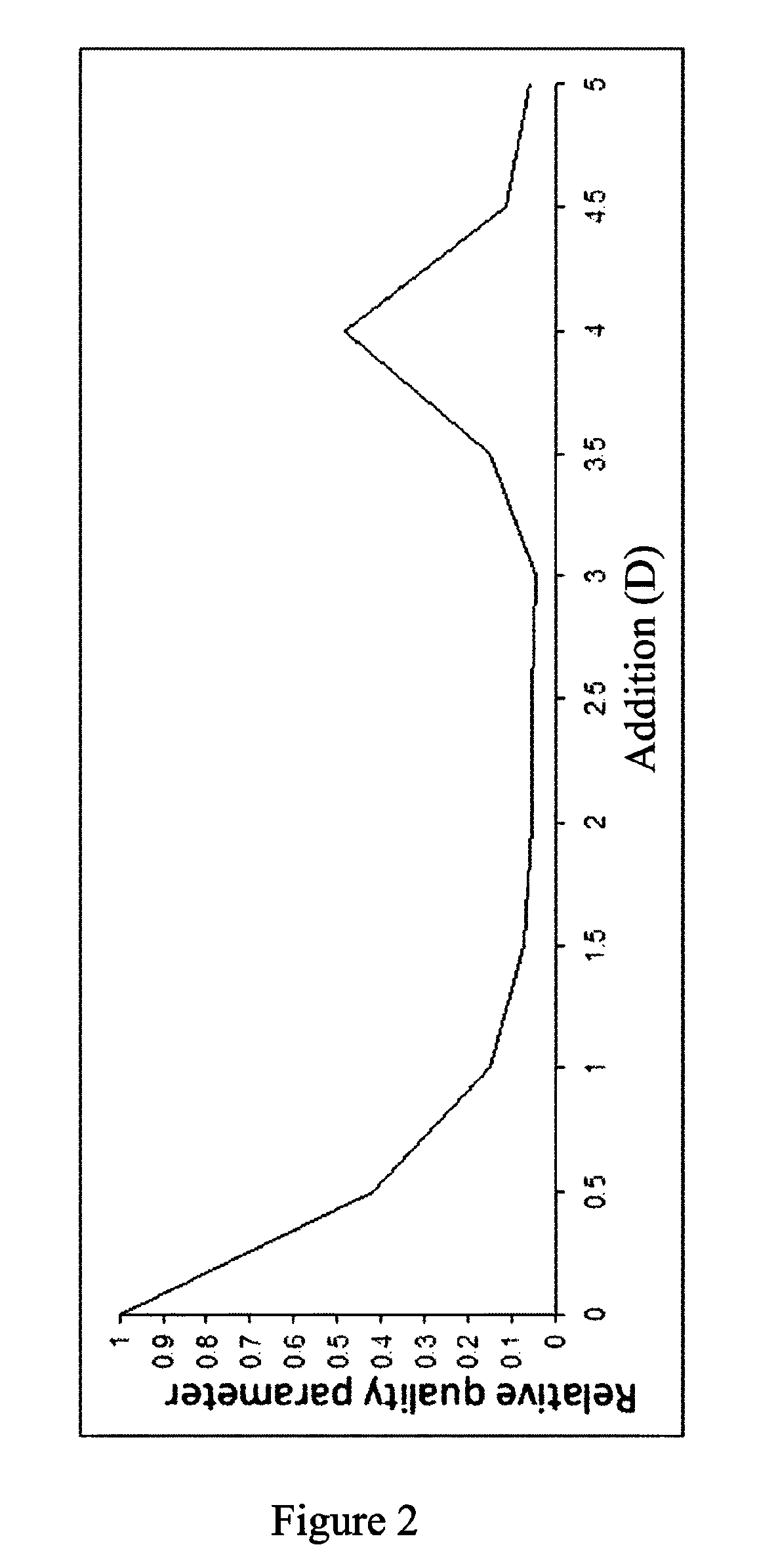

System and method for characterizing the optical quality and the pseudo-accommodation range of multifocal means used for correcting visual defects

It is applied to bifocal, multifocal or progressive intraocular lenses or contact lenses, multifocal corneal ablation or other multifocal configurations, comprising means for projecting the image of a point light source on the retina of a patient and an assembly for directly recording the light reflected in said retina after the double passage of the light through the ocular means, integrating a first focus corrector device inserted in the path of the light beam guided towards the retina and a second focus correction device inserted in the light beam reflected from the retina, to be guided towards the mentioned recording means, each of said focus correction devices having independent control means for controlling the operation thereof.

Owner:UNIV POLITECNICA DE CATALUNYA

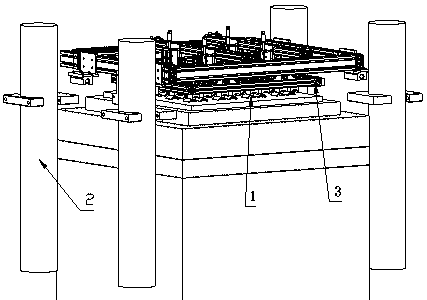

Magnetic material automated production line

PendingCN110289162AEfficient recyclingImprove yieldConveyorsStacking articlesProduction lineScheduling function

The invention relates to a magnetic material automated production line and is in the order of magnetic tile pressing, detecting, conveying, warehouse entry and sintering. The production line is characterized in that a pressing machine 2, a sorting table, a visual defect detecting mechanism 6 used for detecting magnetic tiles 1 on the sorting table, a robot 8 used for taking the magnetic tiles 1, a palletizing platform 9 used for disposing the magnetic tiles 1 and an ID card in a tray, a tray scanner 10 used for scanning the tray ID card information, a conveyor belt 11 used for conveying the tray (the magnetic tile tray, the same below) loaded with the magnetic tiles 1 to a sintering furnace, the sintering furnace 15, a printer system 16, an empty tray return system and a control system having the system scheduling function, wherein the control system includes a server connected with a PC industrial control computer, a tray scanner system, a PLC controller, and a defect identification system and a label printing system connected with the server, motion parts are respectively controlled by PLC, and the control system is used for acquiring and analyzing PLC controller instructions and the induction information and making instructions. The production line is advantaged in that production cost is reduced, production efficiency is improved, product consistency is improved, inspection standards are unified, and the information management level is improved.

Owner:江门市蓬江区联诚达科技发展有限公司

See Through Display enabling the correction of visual deficits

ActiveUS20170322422A1Maximizes transmission of lightImprove the level ofSpectales/gogglesNon-optical adjunctsNight visionSee-through display

A See-Through Display System with the ability to correct visual deficits such as presbyopia, color blindness and poor night vision is disclosed. This invention enables the correction of visual deficits using camera(s), microdisplay (s), controlling circuit(s) with digital grayscale control and see through optics such as free form lens / mirror, half-mirror, diffractive and / or holographic optical element(s).

Owner:IRON CITY MICRO DISPLAY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com