Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

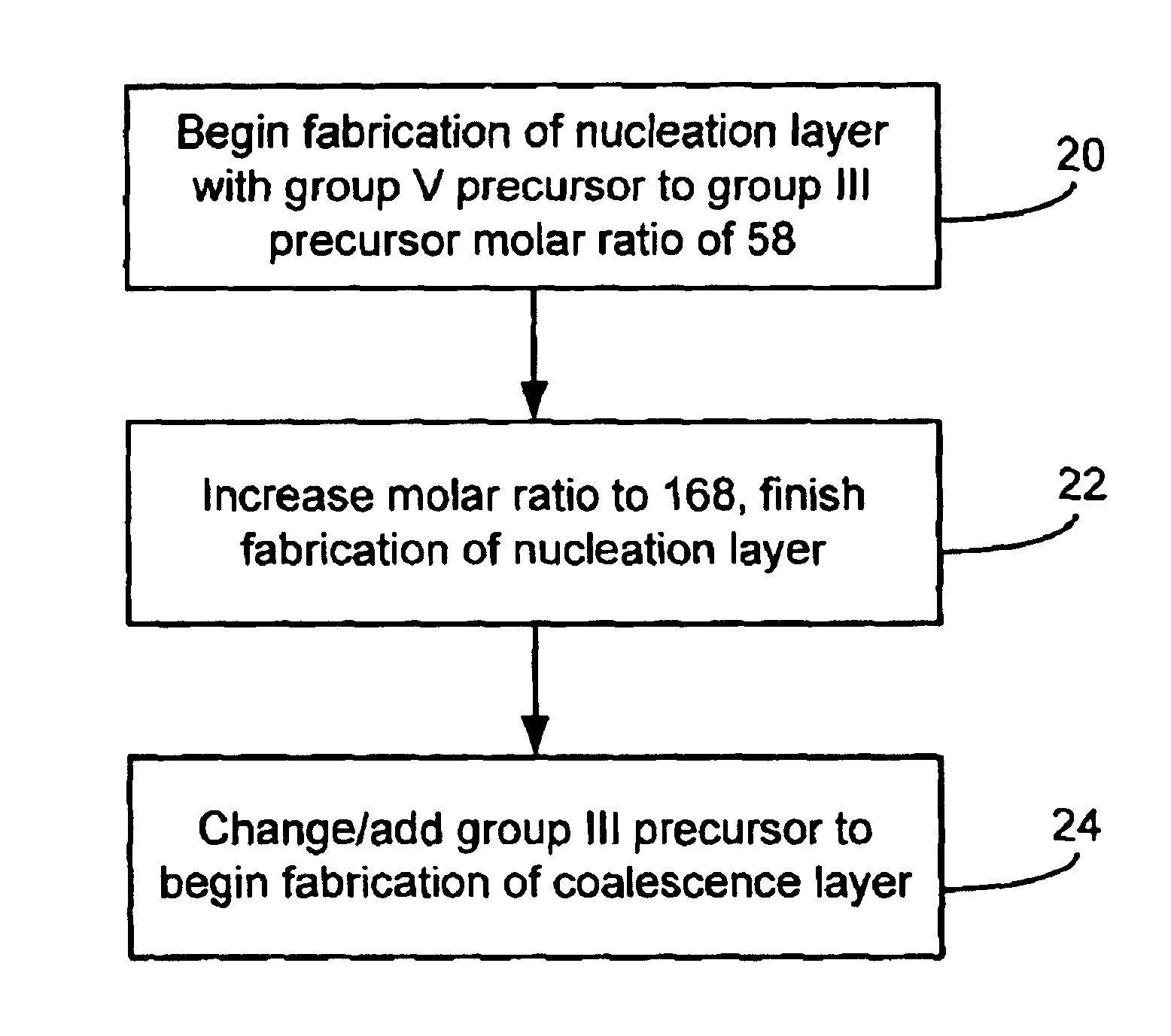

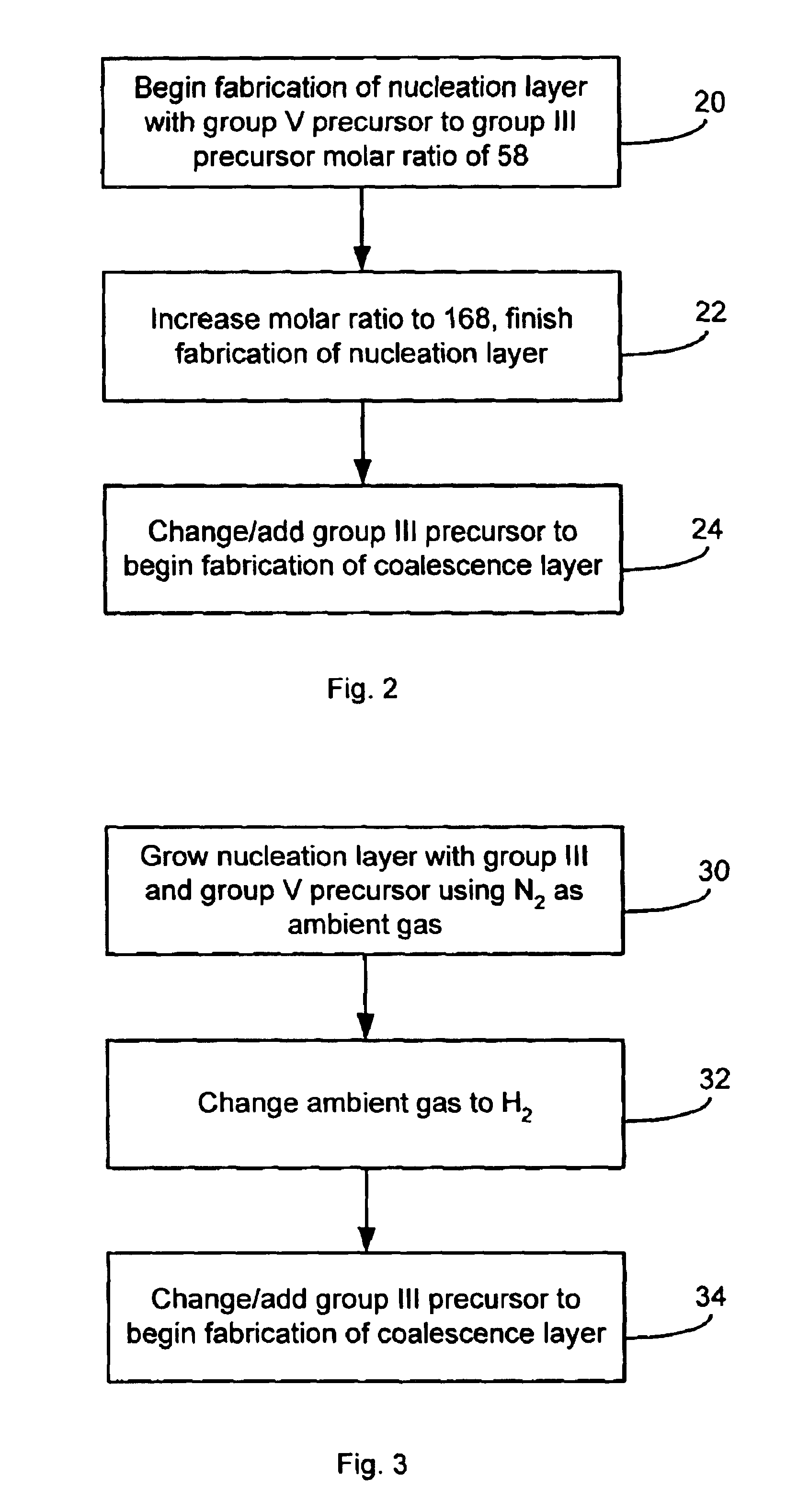

Growth of III-nitride films on mismatched substrates without conventional low temperature nucleation layers

ActiveUS6900067B2ReactionRaise the ratioPolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseNitrogen

A method of forming a light emitting device includes providing a sapphire substrate, growing an Al1−xGaxN first layer by vapor deposition on the substrate at a temperature between about 1000° C. and about 1180° C., and growing a III-nitride second layer overlying the first layer. The first layer may have a thickness between about 500 angstroms and about 5000 angstroms. In some embodiments, reaction between the group V precursor and the substrate is reduced by starting with a low molar ratio of group V precursor to group III precursor, then increasing the ratio during growth of the first layer, or by using nitrogen as an ambient gas.

Owner:LUMILEDS

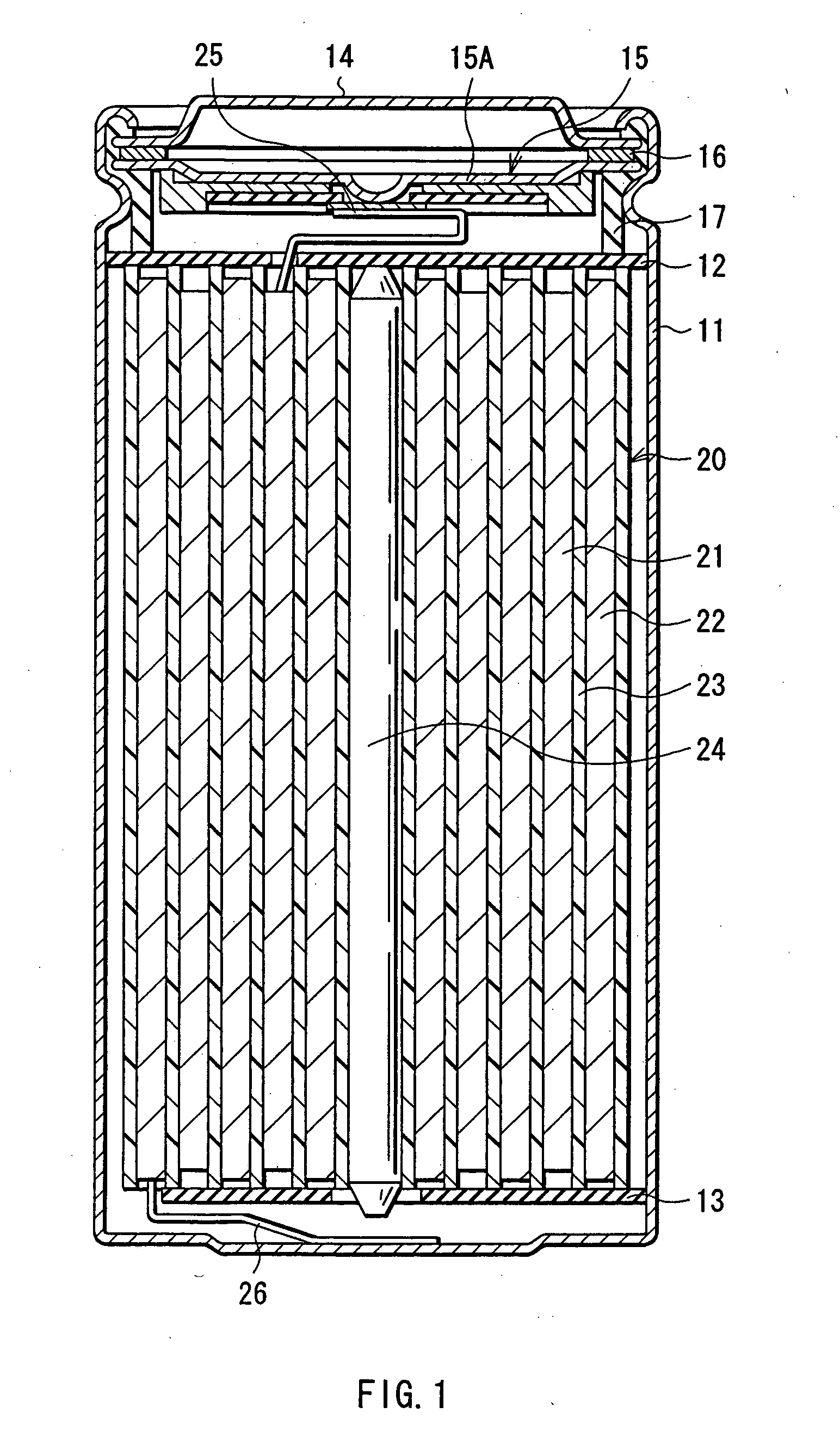

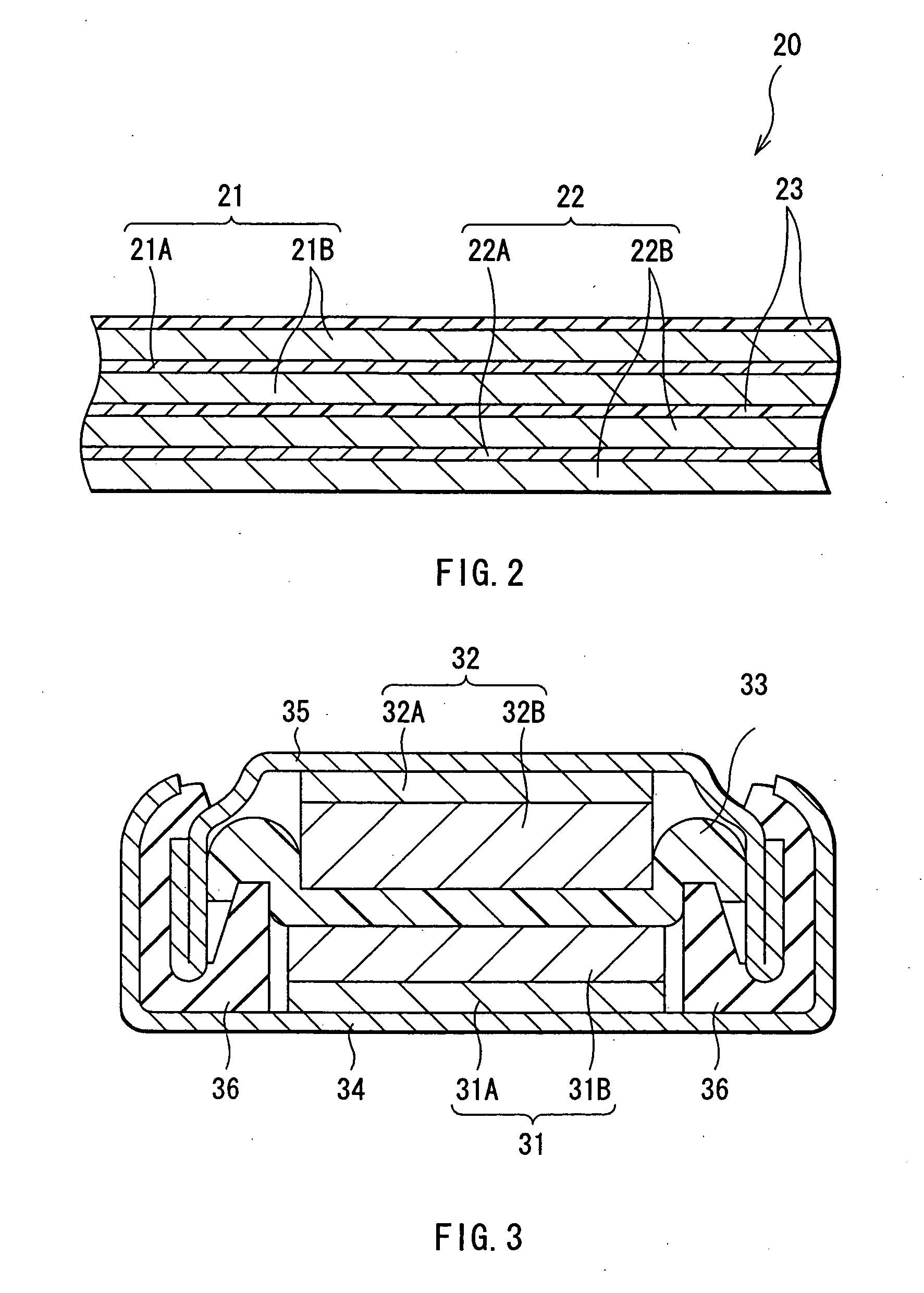

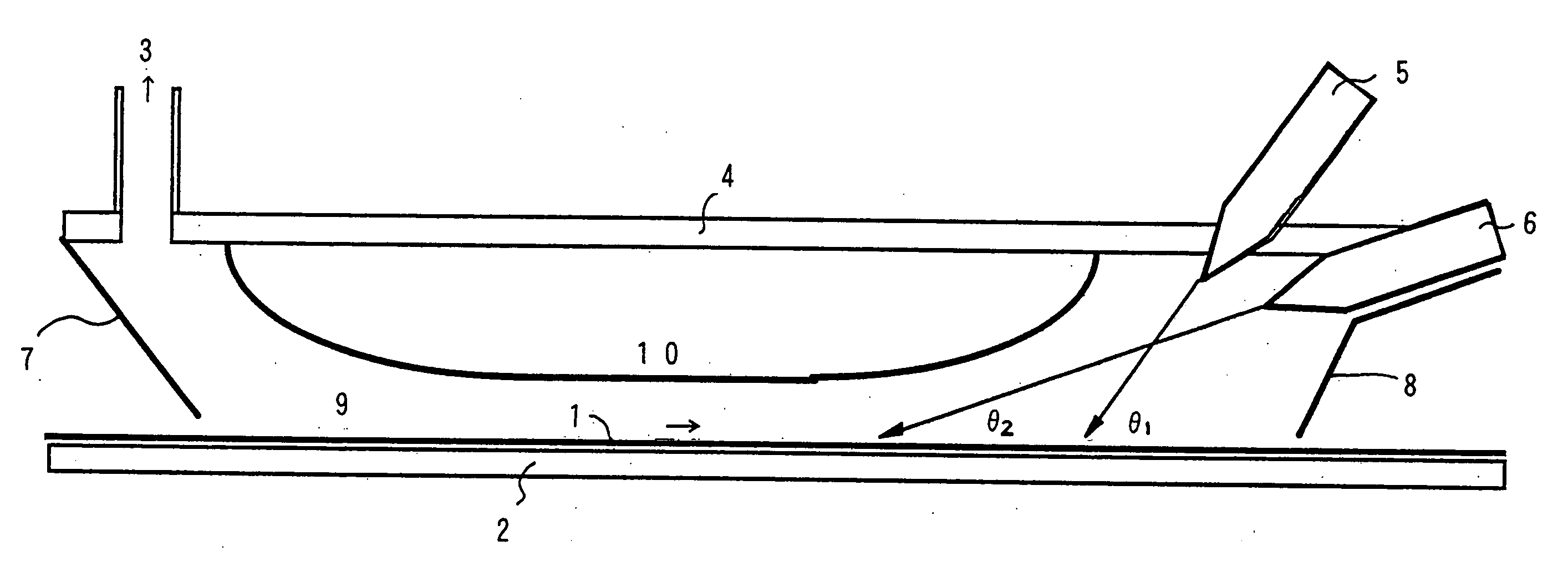

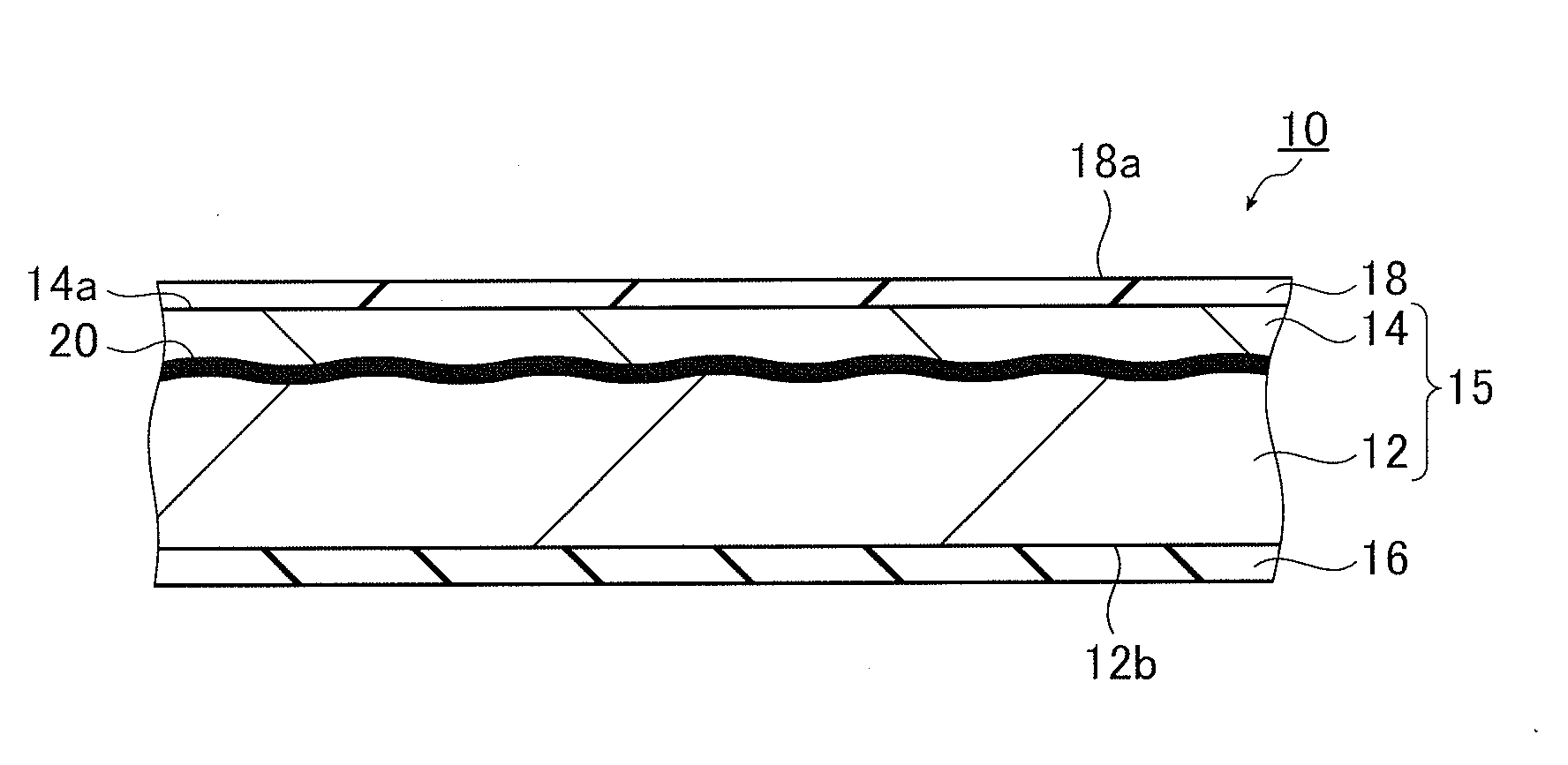

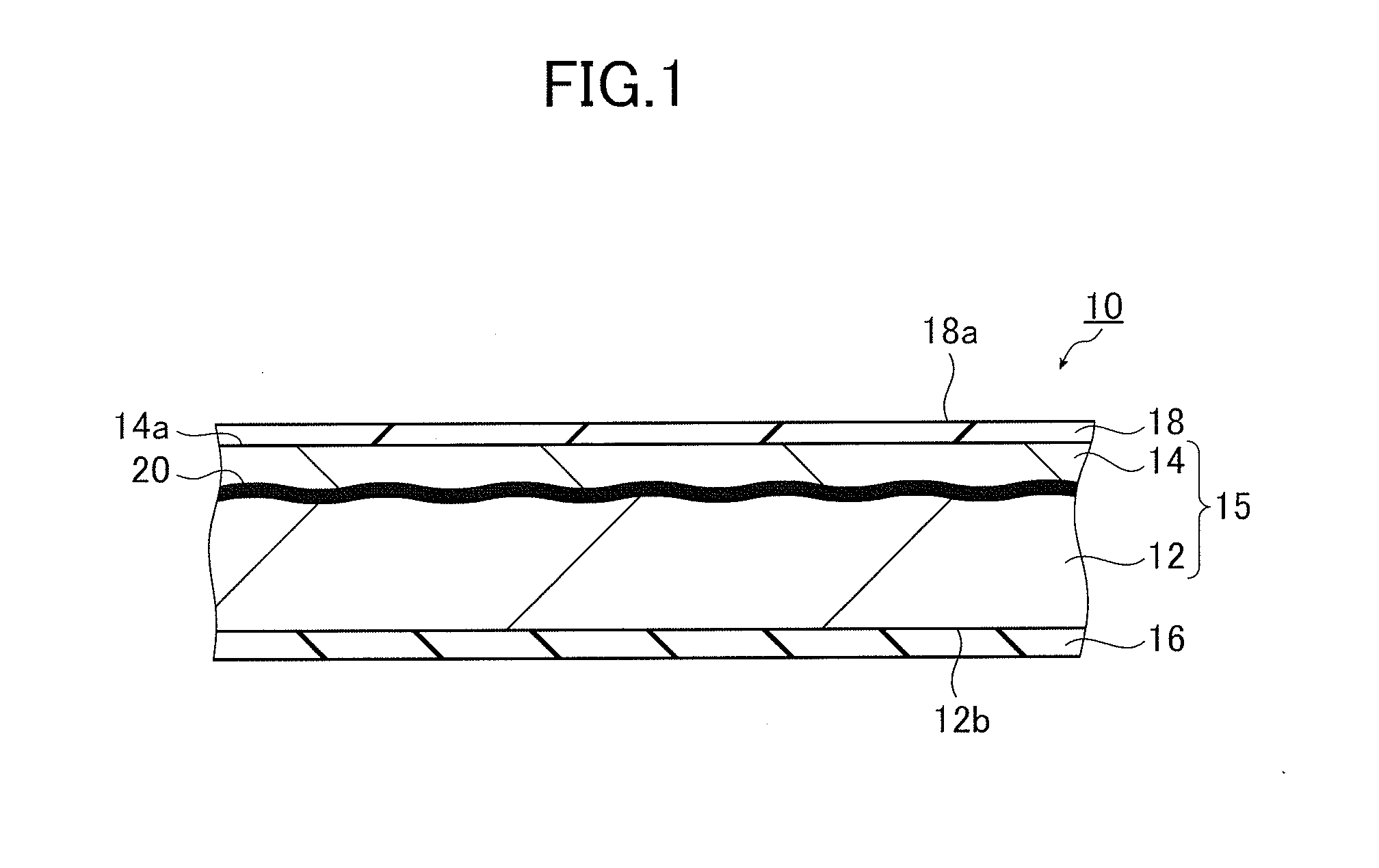

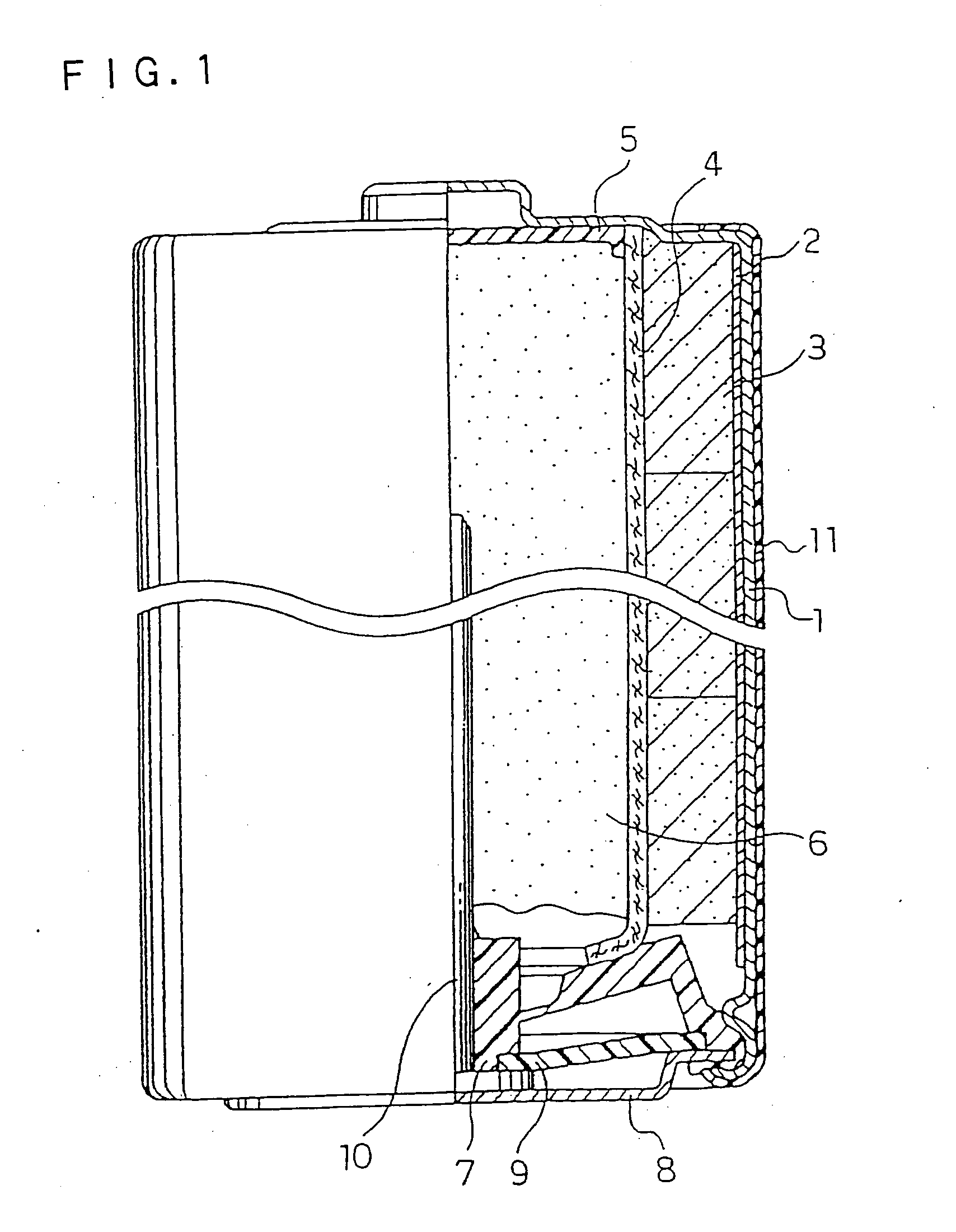

Battery

ActiveUS20050095503A1Large capacityImprove featuresElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesDecompositionAlloy

A battery is provided which has a high capacity and can improve battery characteristics, such as cycle characteristics. The battery includes a spirally wound electrode body, wherein a cathode and an anode are wound with a separator in between. The anode includes, for example, simple substances, alloys, compounds of metal elements or metalloid elements capable of forming an alloy with Li, the like and combinations thereof. An electrolytic solution wherein an electrolyte salt is dissolved in a solvent is impregnated in the separator. For the electrolyte salt, a light metallic salt having B—O bond or P—O bond, such as difluoro[oxalato-O,O′]lithium borate and tetra fluoro[oxalato-O,O′]lithium phosphate, can be used. By forming a stable coating, decomposition reaction of the solvent can be inhibited, and reaction between the anode and the solvent can be prevented.

Owner:SONY CORP +1

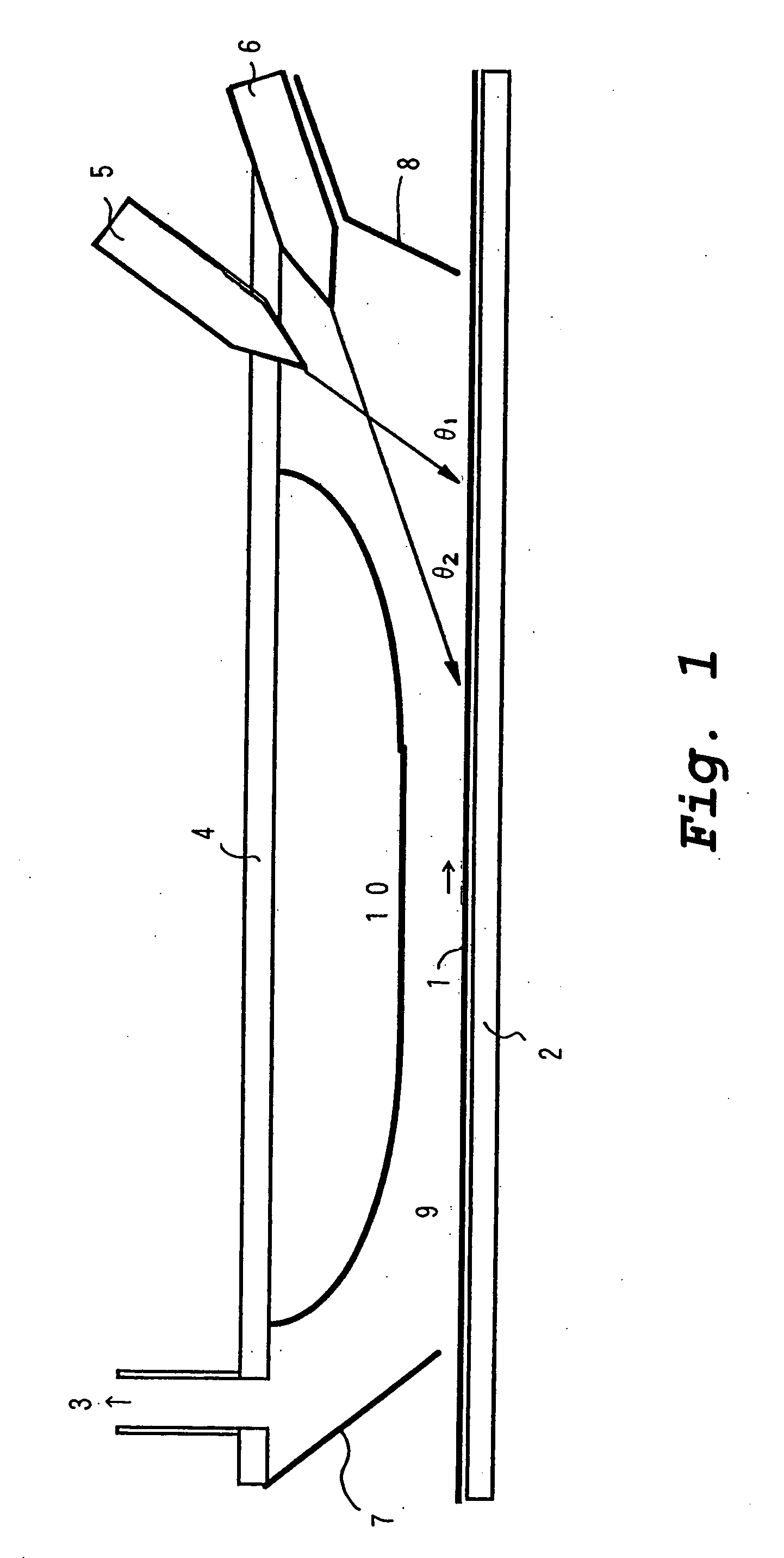

Method for forming metal oxide coating film and vapor deposition apparatus

InactiveUS20070054044A1Avoid reactionEliminate the problemOxide/hydroxide preparationCatalyst activation/preparationGas phaseWater vapor

A photocatalytic composite material having a photocatalytic titanium oxide film on the surface of a substrate is produced by a CVD method in which TiCl4 vapor is reacted with water vapor. The TiCl4 vapor and the water vapor are injected into a vapor deposition chamber (9) through nozzles (5) and (6), respectively, such that the resulting two injected vapor streams meet before reaching the substrate, thereby mixing the two vapors. Within 3 seconds after this mixing, the mixed vapors are brought into contact with a substrate (1) which is moving in one direction. Preferably the TiCl4 vapor is injected in a reverse direction with respect to the direction of movement of the substrate through a multi-orifice nozzle (5), while the water vapor is injected through a slit nozzle (6) disposed at a smaller angle with respect to the substrate.

Owner:OSAKA TITANIUM TECHNOLOGIES

Negative electrode active particle and method for manufacturing the same

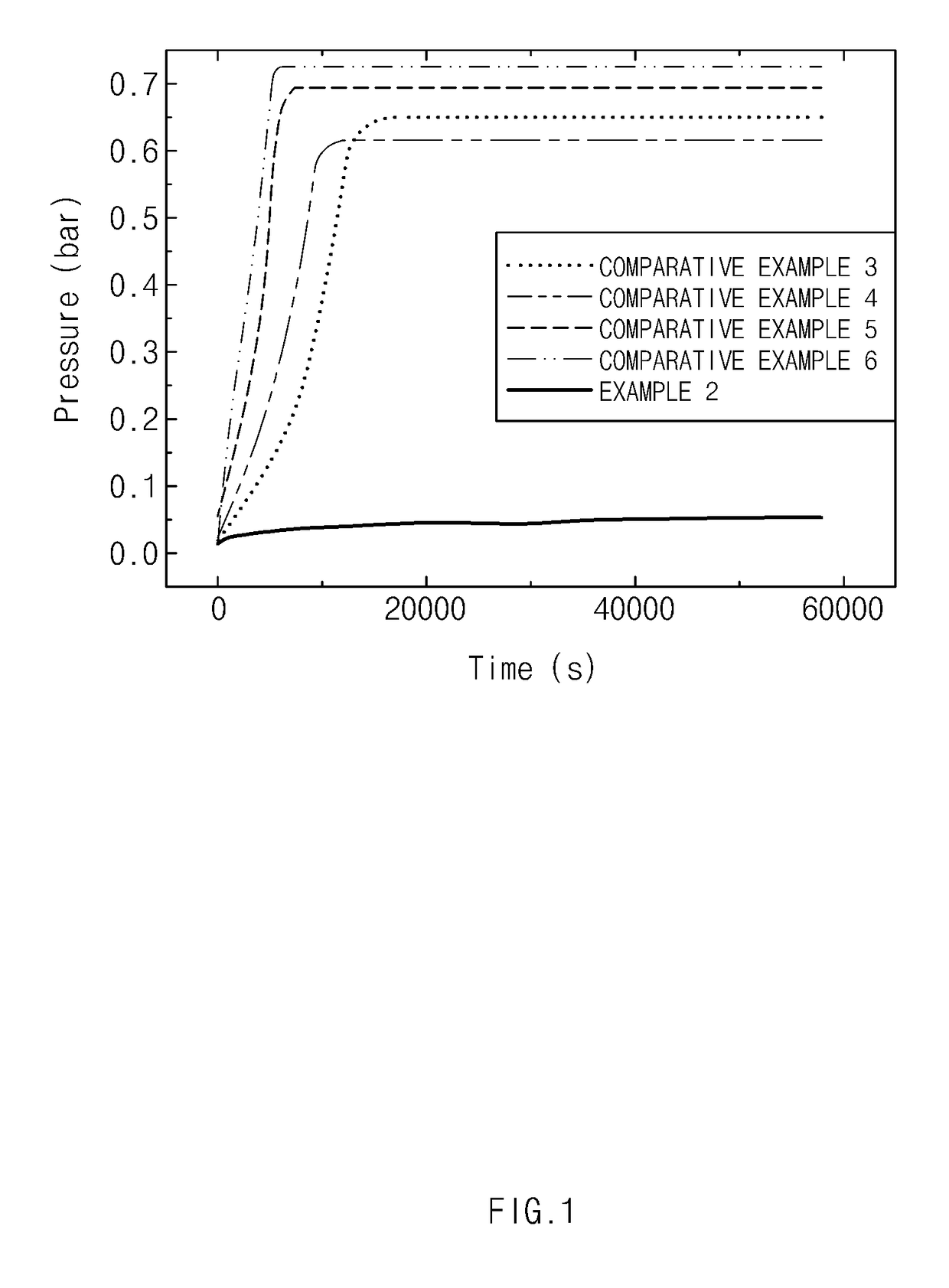

ActiveUS20170117543A1Suppress gas productionImprove stabilityElectrode rolling/calenderingElectrode thermal treatmentActive particlesMaterials science

Owner:LG ENERGY SOLUTION LTD

Factor vii or viia polypeptide variants

The present invention relates to novel polypeptide variants of factor VII (FVII) or factor VIIa (FVIIa) polypeptides, where said variants comprise an amino acid substitution in position 10 and 32 and where said variants further comprise a sugar moiety covalently attached to an introduced in vivo N-glycosylation site located outside the Gla domain. Such polypeptide variants are useful in therapy, in particular for the treatment of a variety of coagulation-related disorders, such as trauma.

Owner:BAYER HEALTHCARE LLC

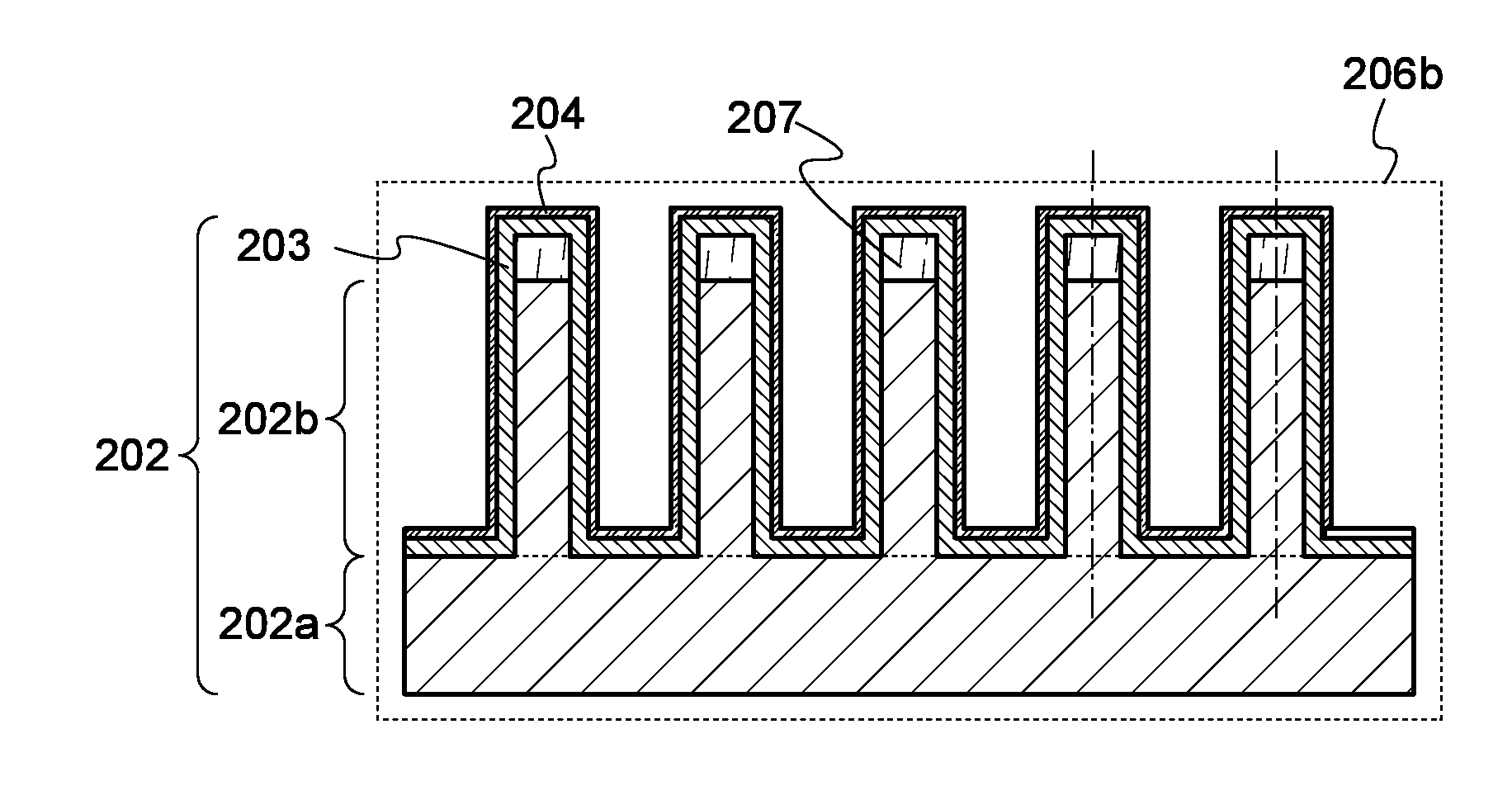

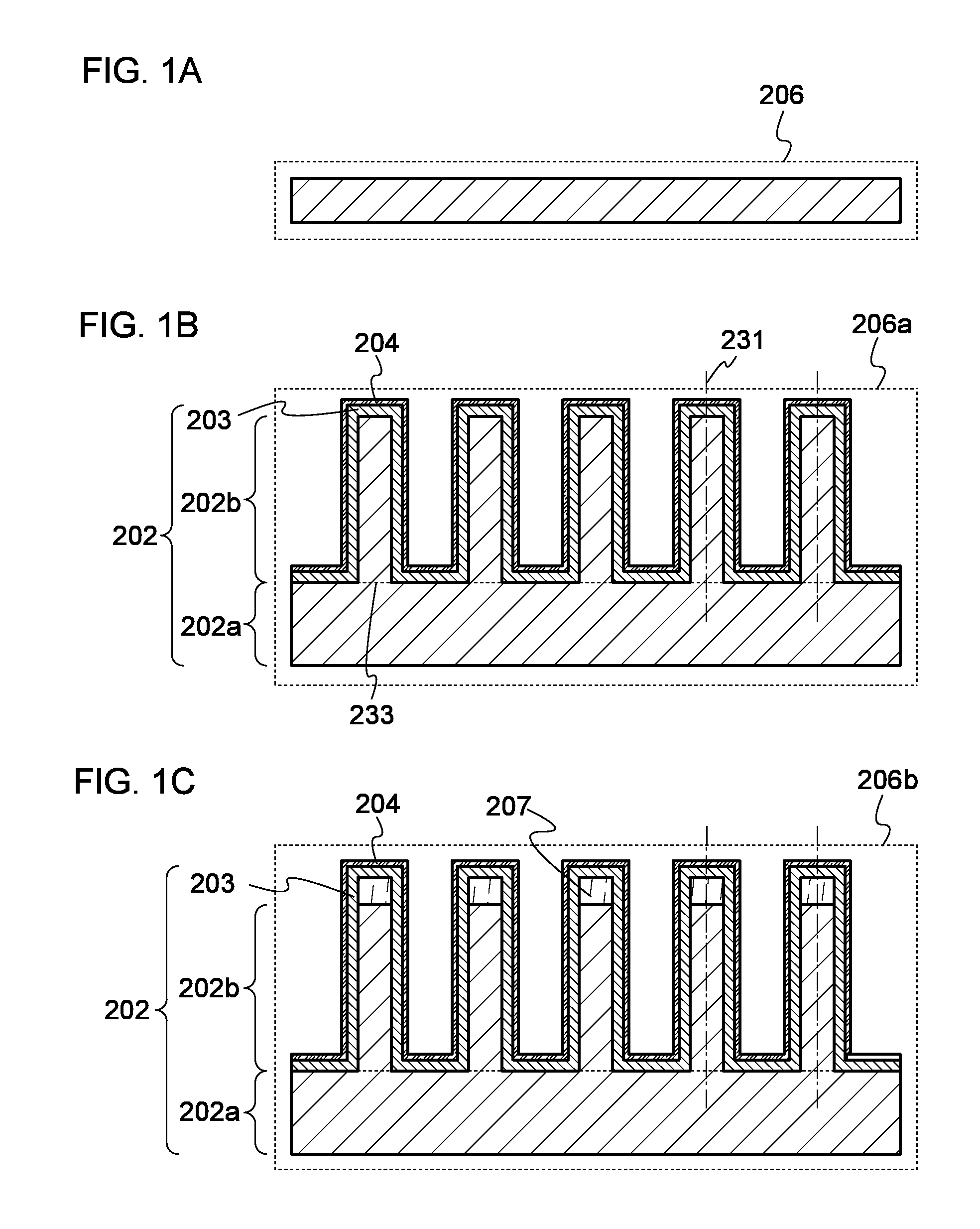

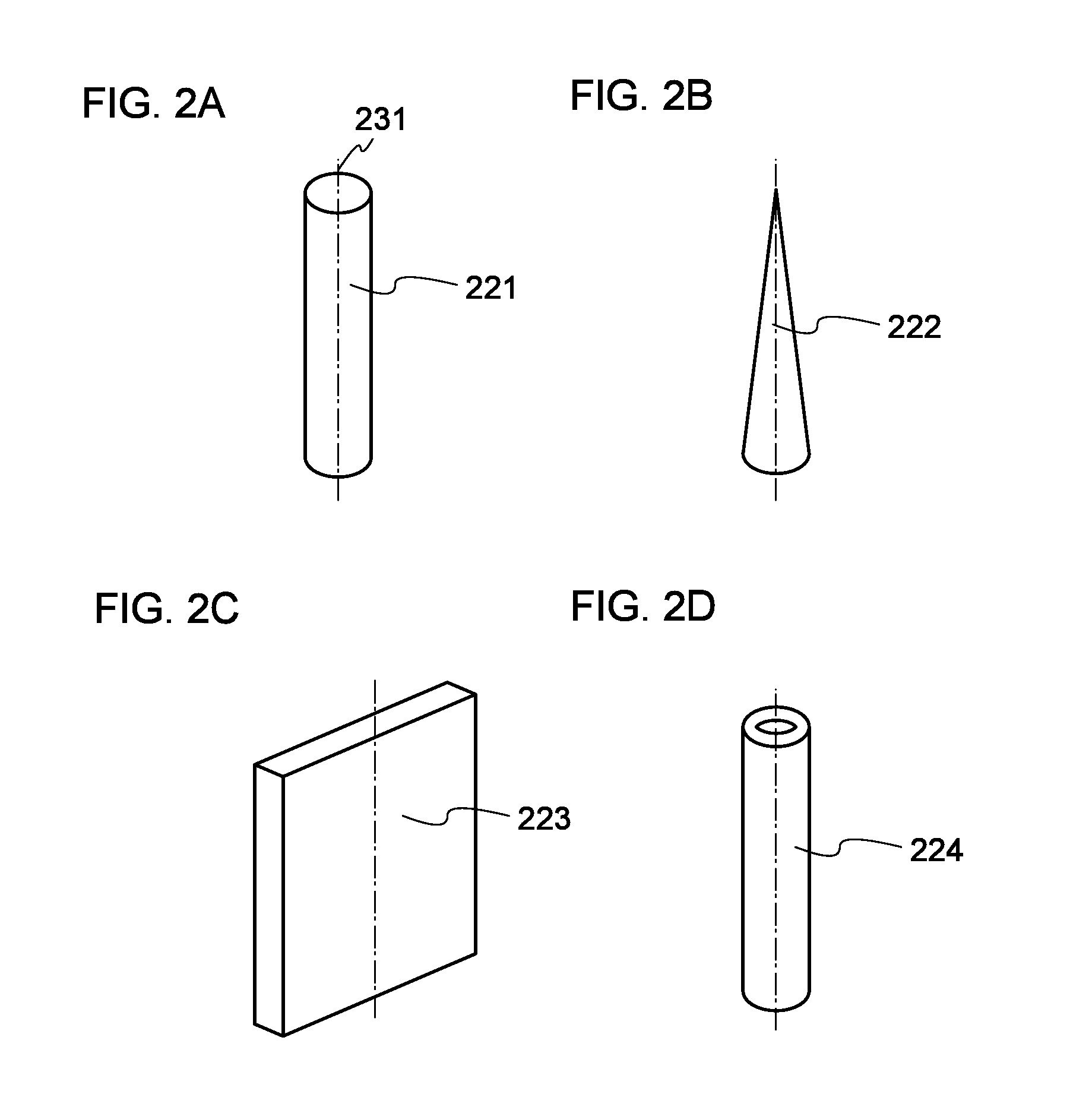

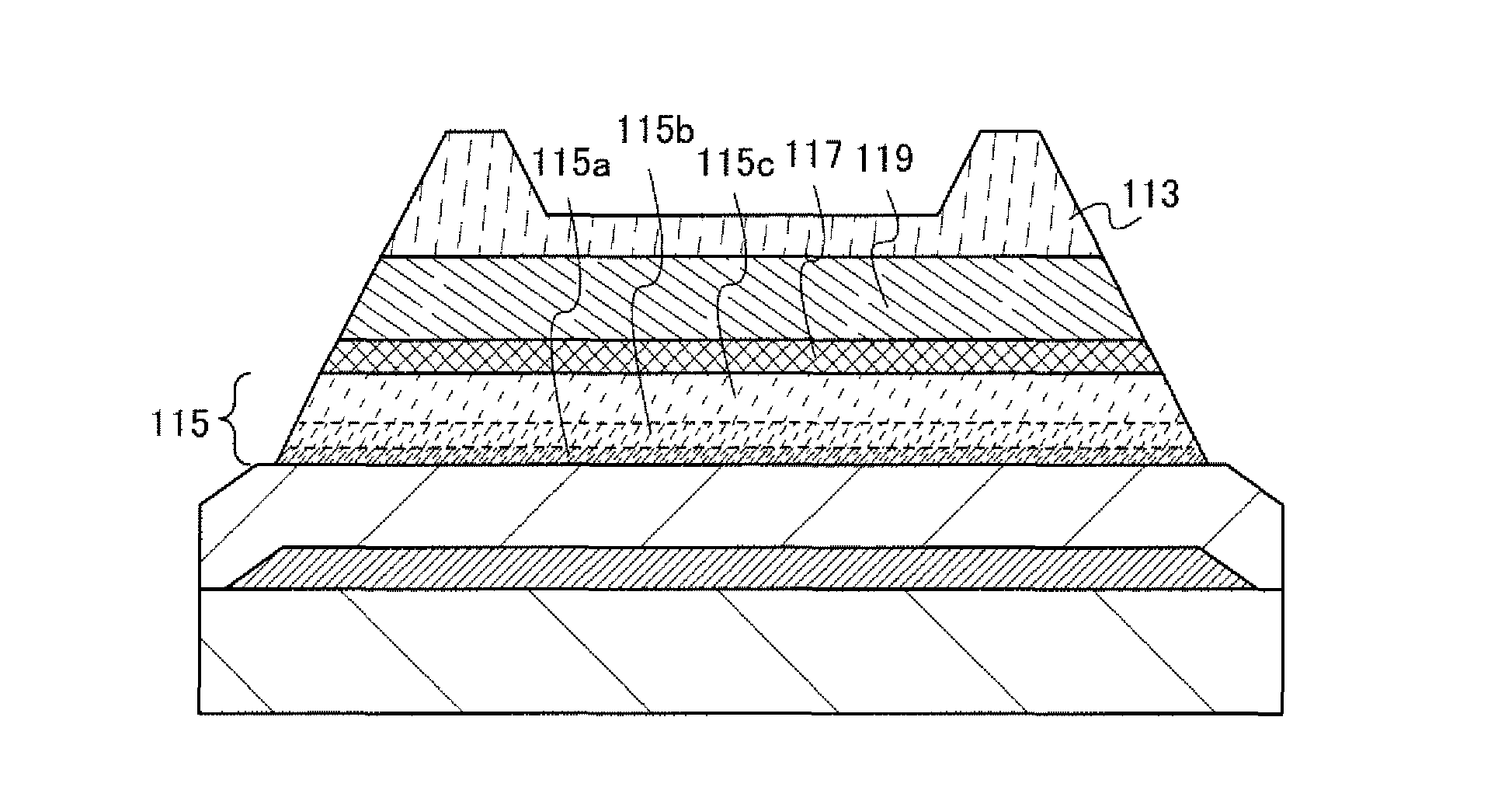

Power storage device

InactiveUS20130071751A1Increase surface areaImprove discharge capacityHybrid capacitor electrodesElectrode carriers/collectorsElectrical batteryEngineering

A power storage device in which charge capacity and discharge capacity are high and deterioration in battery characteristics due to charge / discharge is small is provided. A power storage device in which charge capacity and discharge capacity are high and output characteristics are excellent is provided. A power storage device in which charge capacity and discharge capacity are high and cycle characteristics are excellent is provided. A power storage device includes a negative electrode. The negative electrode includes a current collector, an active material including a plurality of protrusions protruding from the current collector and an outer shell in contact with and attached to surfaces of the plurality of protrusions, and graphene in contact with and attached to the outer shell. Axes of the plurality of protrusions are oriented in the same direction. A common portion may be provided between the current collector and the plurality of protrusions.

Owner:SEMICON ENERGY LAB CO LTD

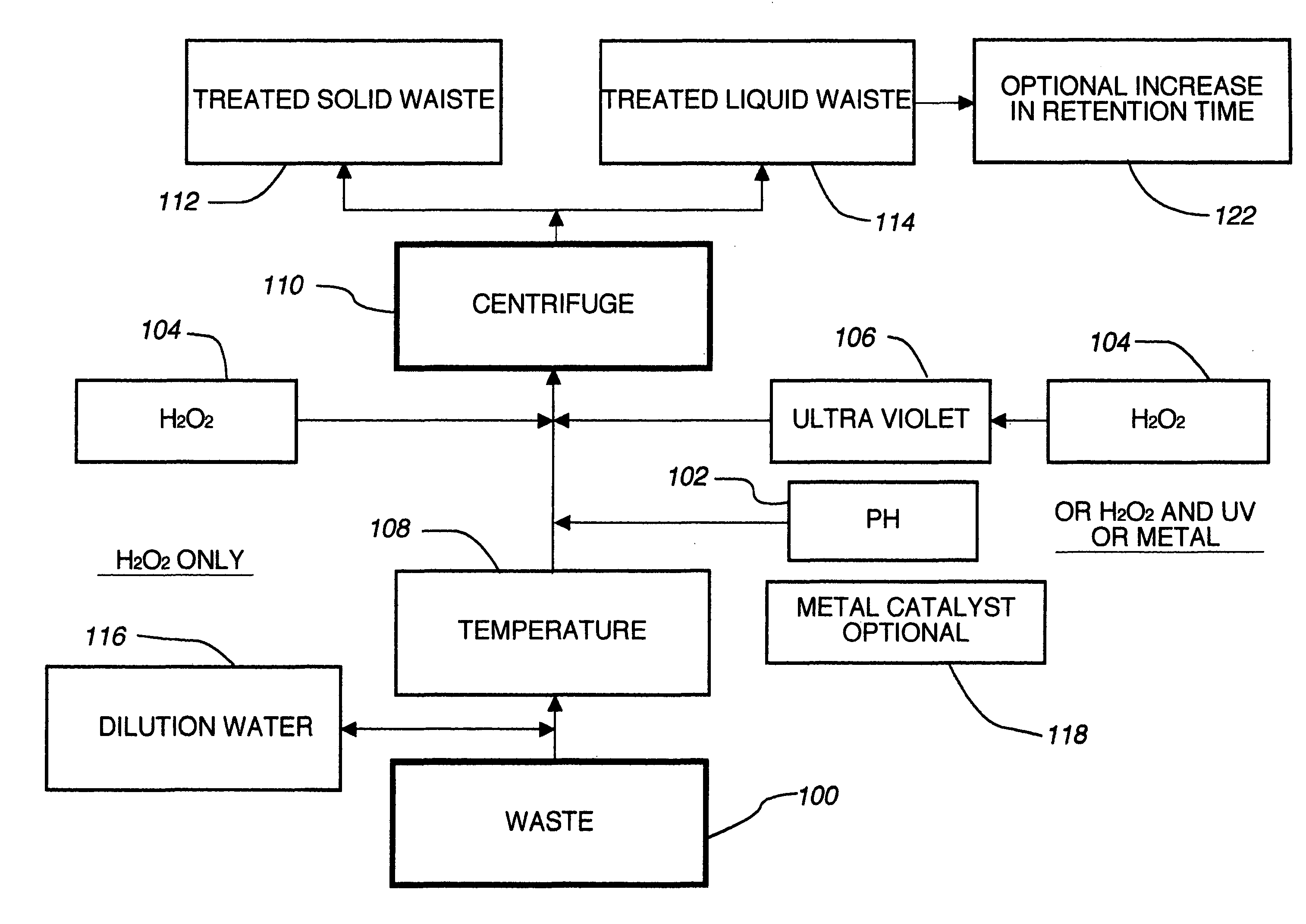

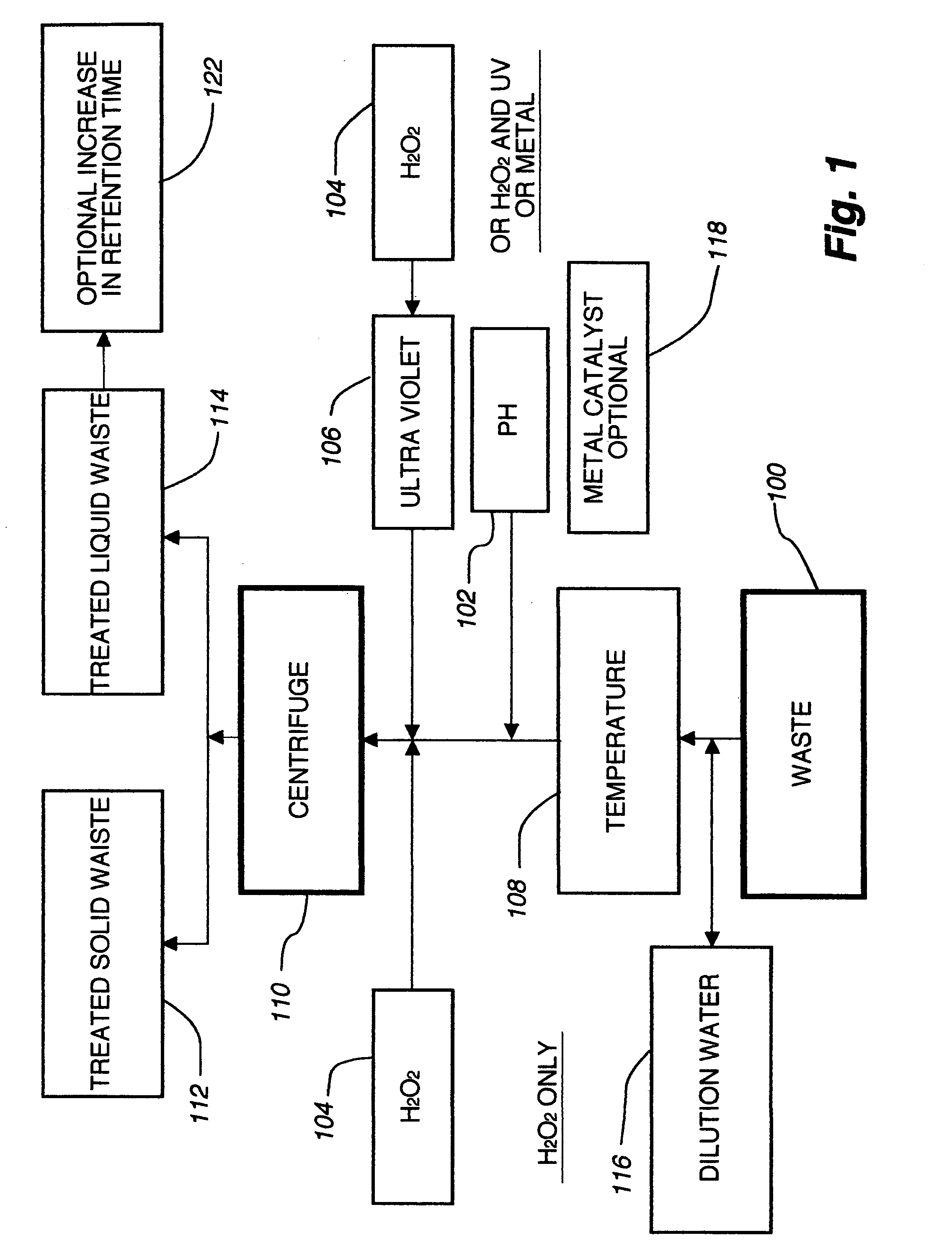

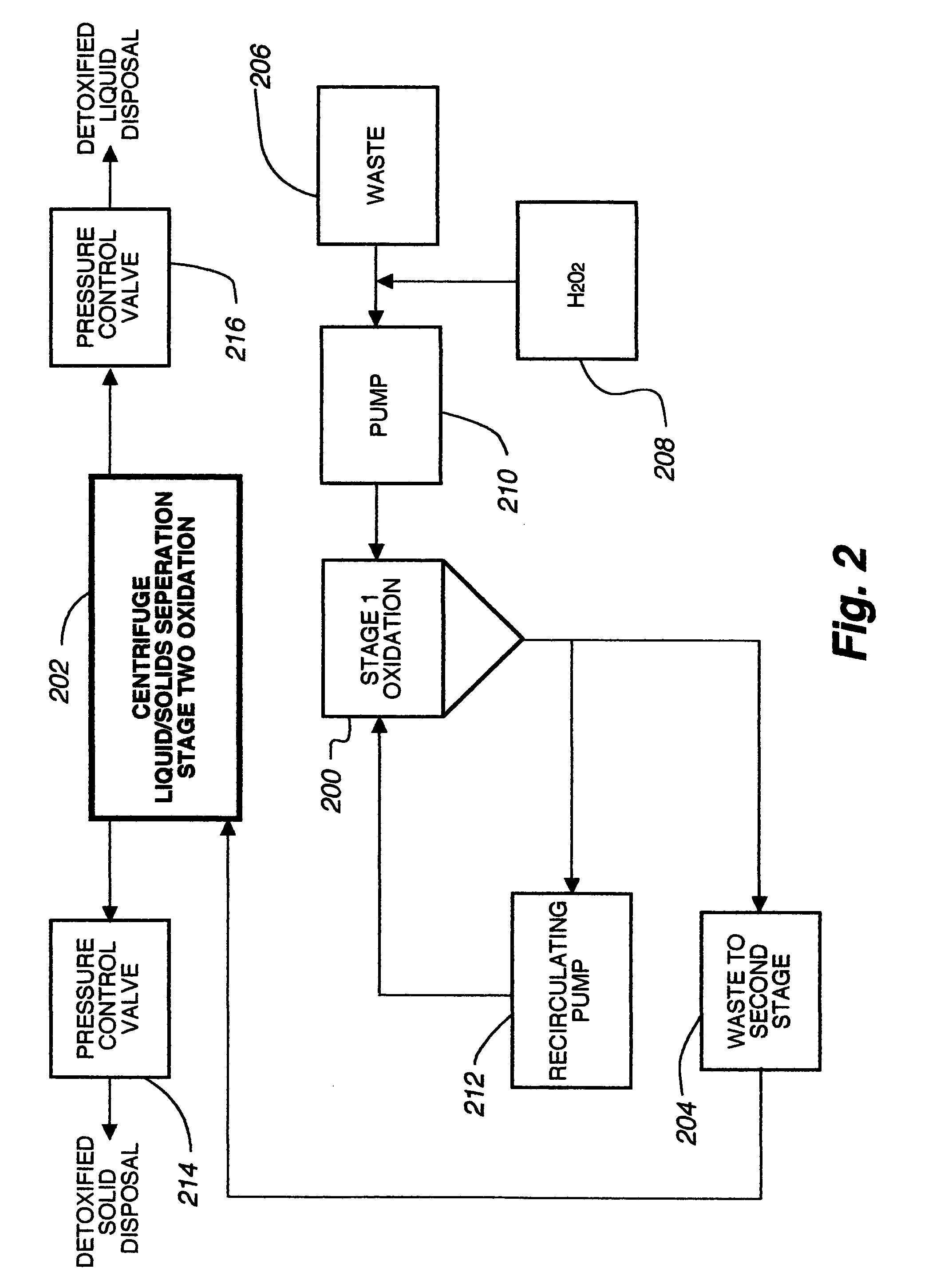

Sub-critical oxidative processes

InactiveUS20050178733A1ReactionImprove responseWater/sewage treatment by centrifugal separationWater treatment parameter controlTime rangeCritical condition

The invention relates to sub-critical processes and systems for accomplishing the same. In one aspect, the process is a sub-critical oxidation process for the destruction of organic and inorganic contaminates within a waste fluid or gas. The sub-critical processes are preferably carried out in a reactor and / or continuous flow centrifuge operating at sub-critical temperature and pressure. The processes and systems provide for destruction of high levels of organic and inorganic contaminates within a contaminate source, which represents a vast improvement over other conventional approaches. The processes and systems also accomplish this superior destruction of contaminates in a much faster time frame, i.e., minutes as compared to hours. Finally, the processes and systems described herein provide a safe and highly economical sub-critical approach as compared to the super-critical conditions, i.e., exceeding high temperatures and pressures, used in most conventional approaches.

Owner:CONGER HARRY C +2

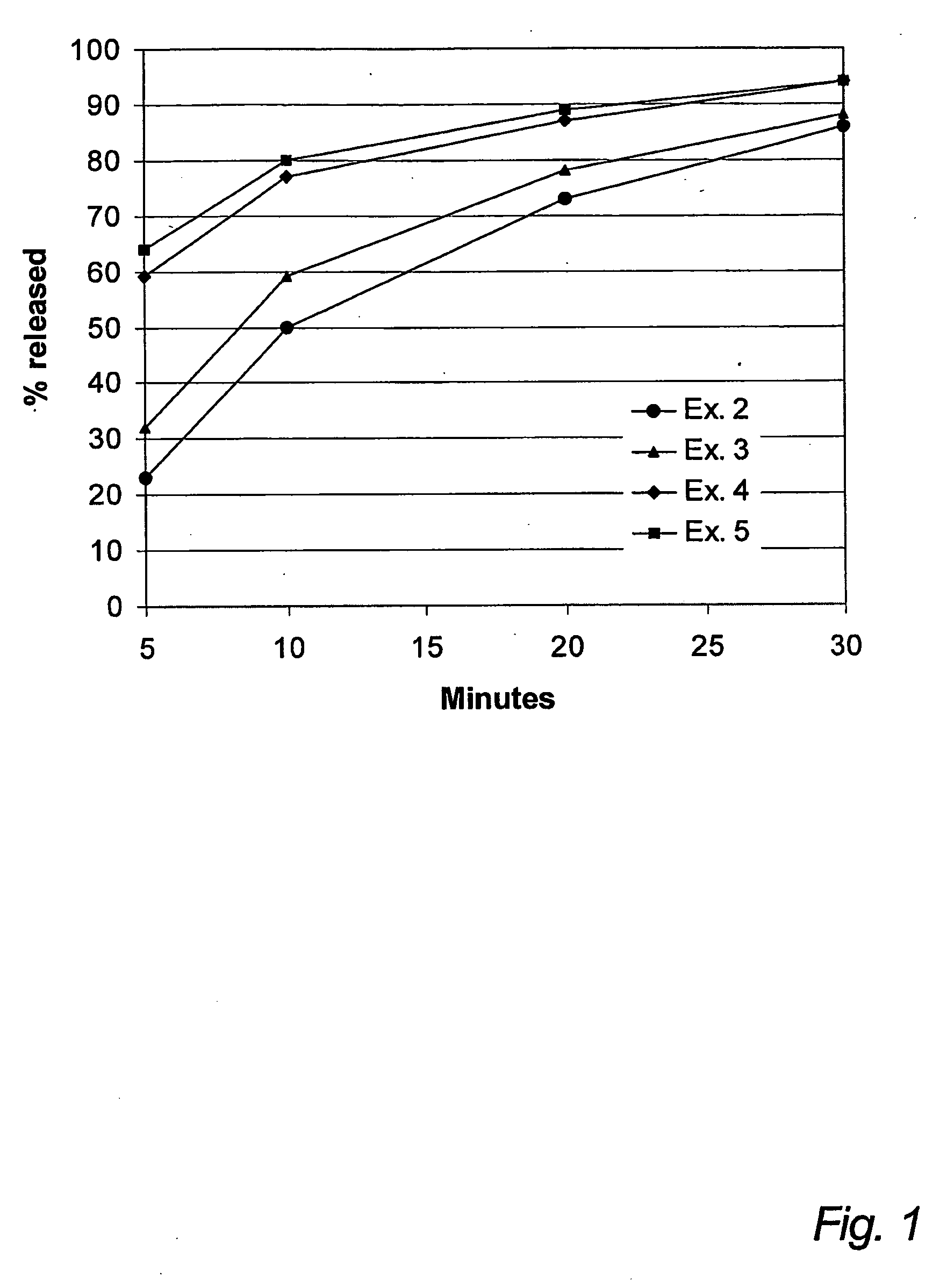

Tobacco alkaloid releasing chewing gum

ActiveUS20090196834A1Improve protectionImprove stabilityBiocideNervous disorderElastomerAdditive ingredient

The invention relates to a tobacco alkaloid releasing chewing gum comprising tobacco alkaloid, gum base, and chewing gum ingredients, said gum base comprising elastomer and resin-compounds constituting an amount in the range of about 2 to 20% by weight of said chewing gum.

Owner:FERTIN PHARMA AS

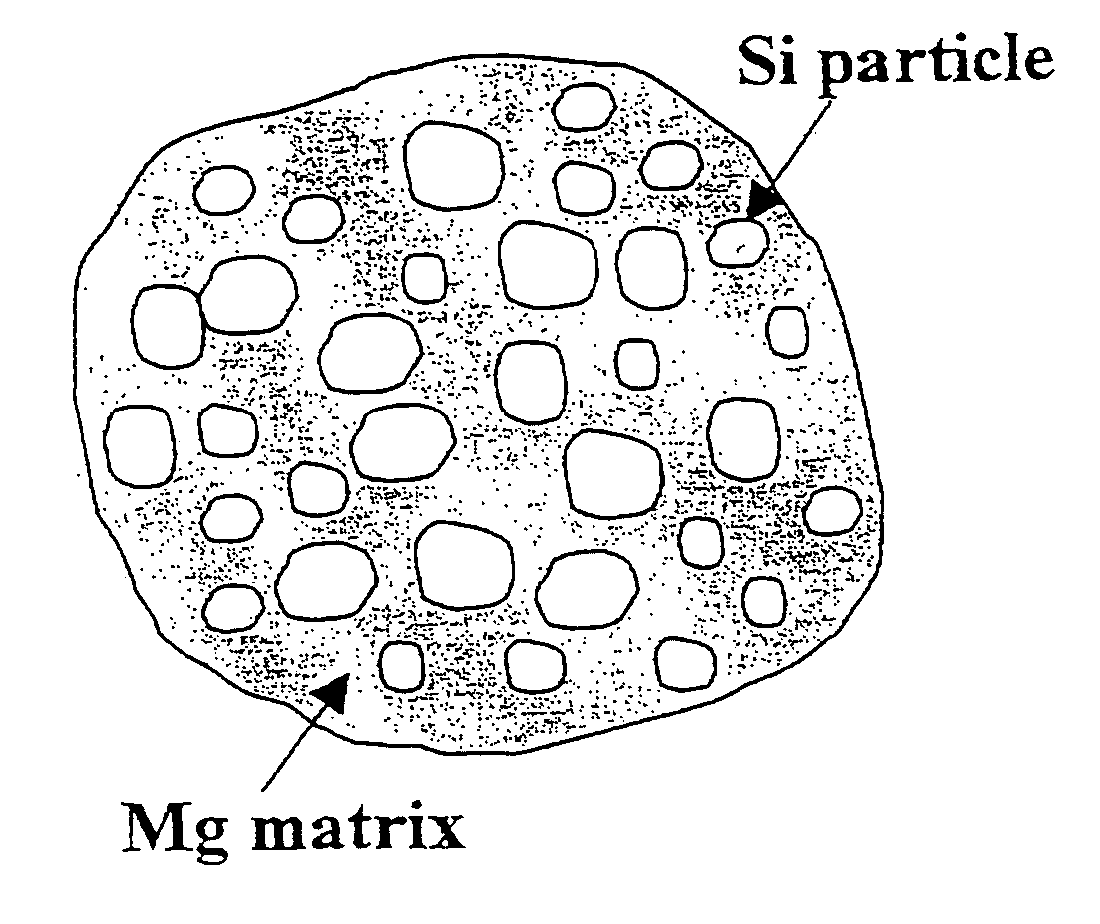

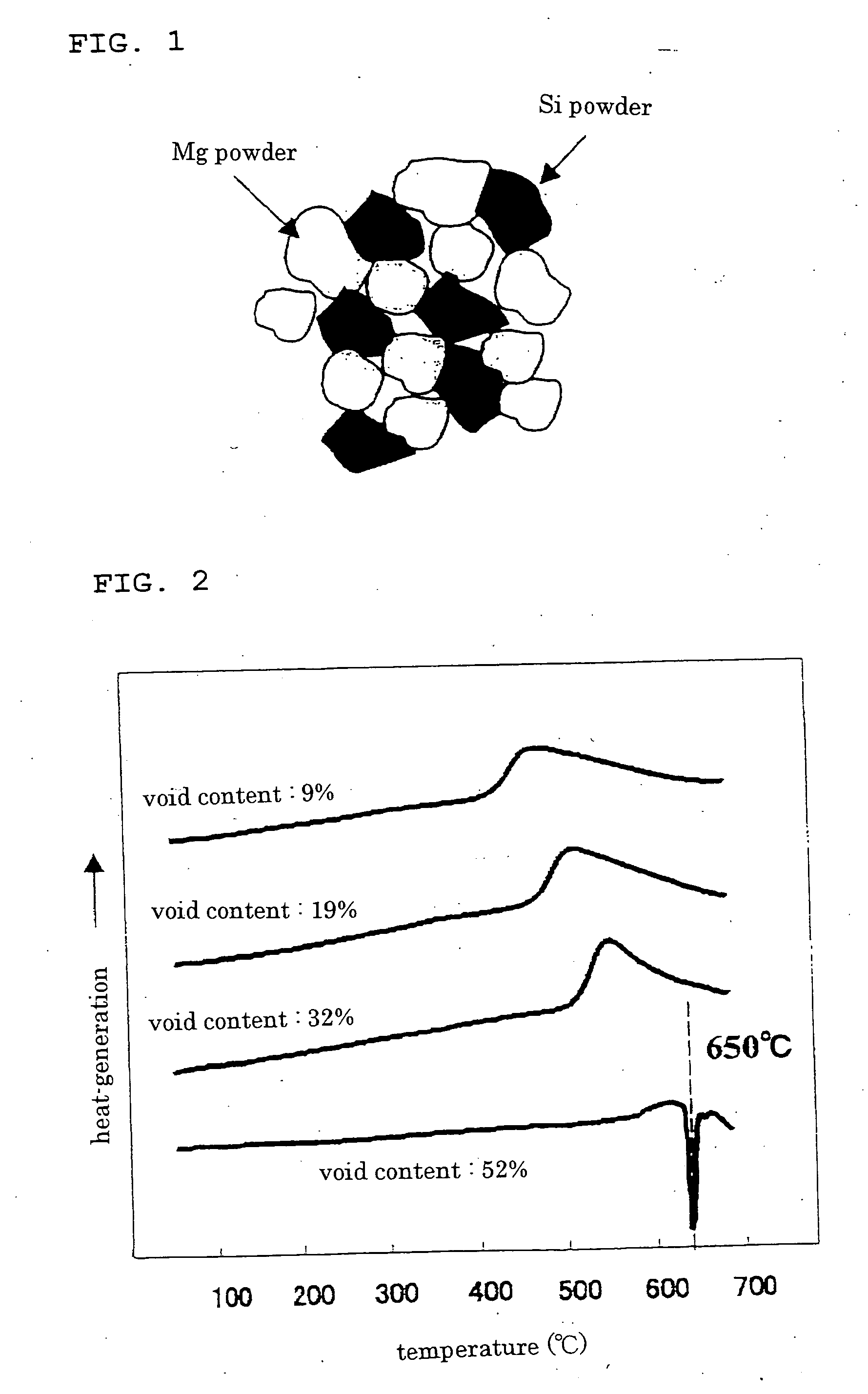

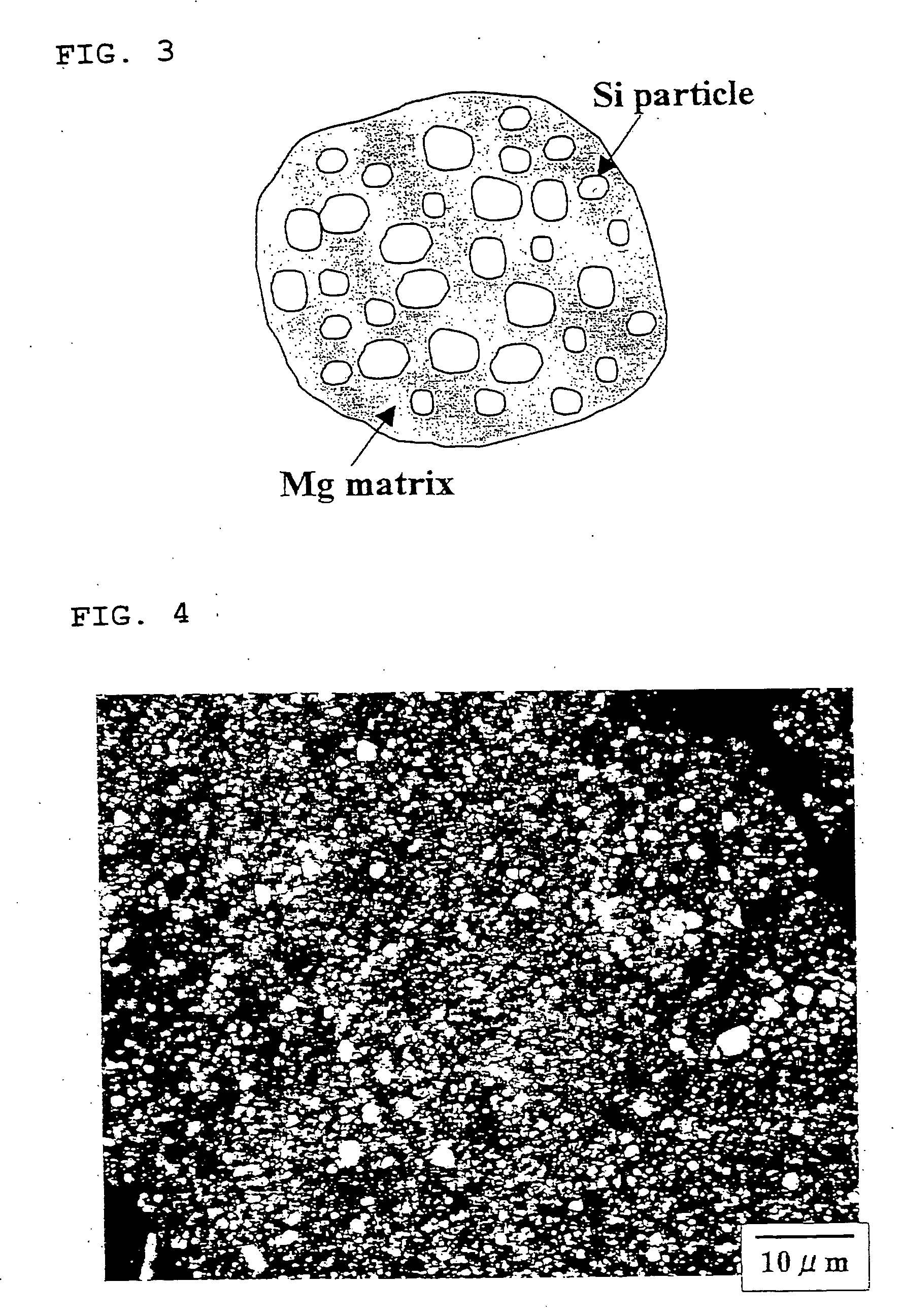

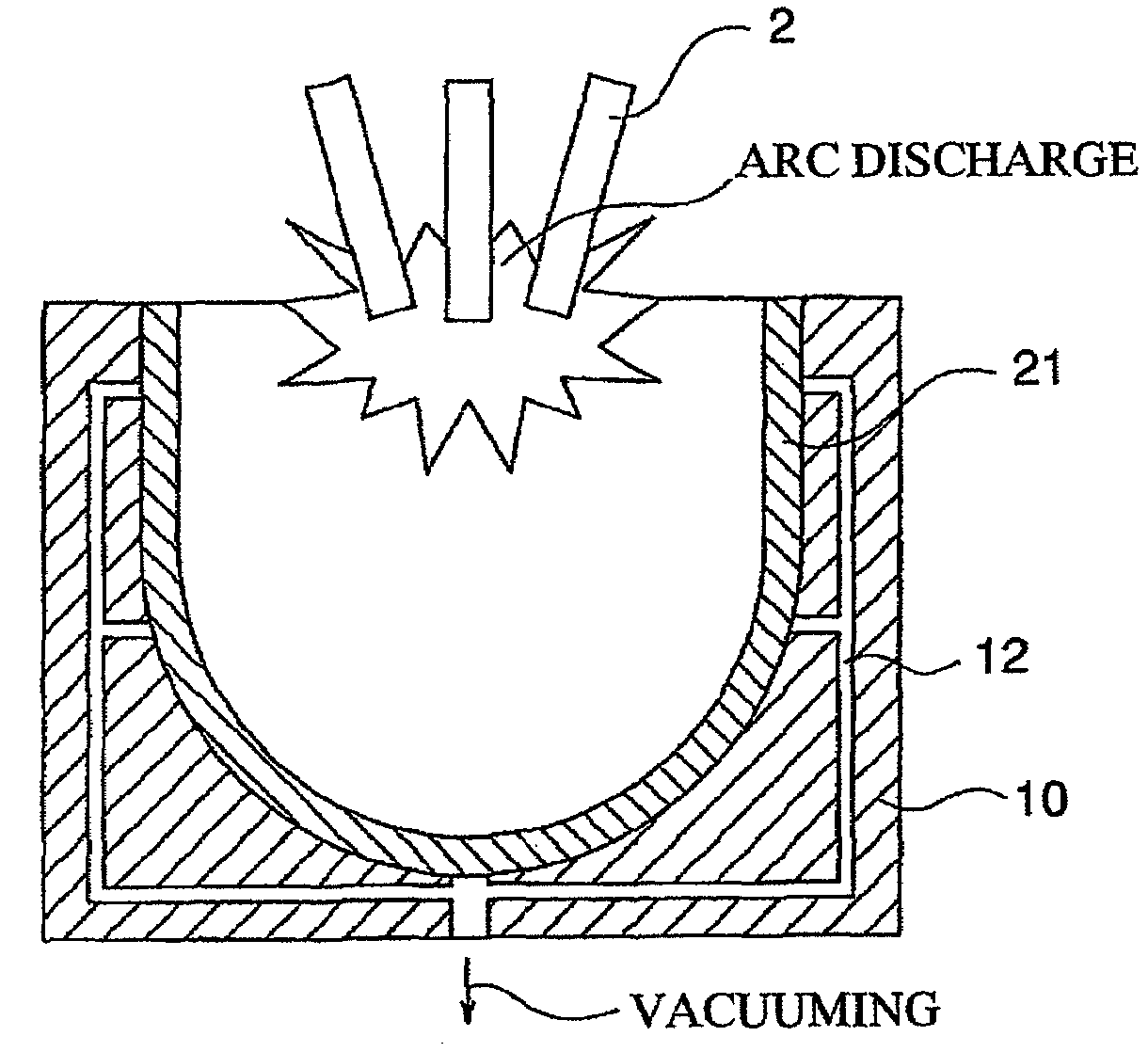

Magnesium base composite material

InactiveUS20050016638A1Improve mechanical propertiesReactionMetal silicidesMagnesium matrix compositeHardness

The present invention provides a magnesium-base composite material capable of suppressing coarse growth of a crystal particle size of a magnesium matrix and Mg2Si particles, thereby providing excellent mechanical properties such as strength and hardness, and a manufacturing method thereof. The manufacturing method includes the steps of: blending matrix powder containing Mg and Si powder to obtain a blended matter; applying a plasticization treatment to the resulting blended matter to form a solid body; heating the solid body to allow Mg and Si to react with each other to form a heat solid body containing Mg2Si; and applying a warm plasticization treatment to the heat solid body. Thus, it is possible to provide a magnesium-base composite material having a tensile strength from not less than 100 MPa to not more than 500 MPa.

Owner:TOUDAITLO LTD

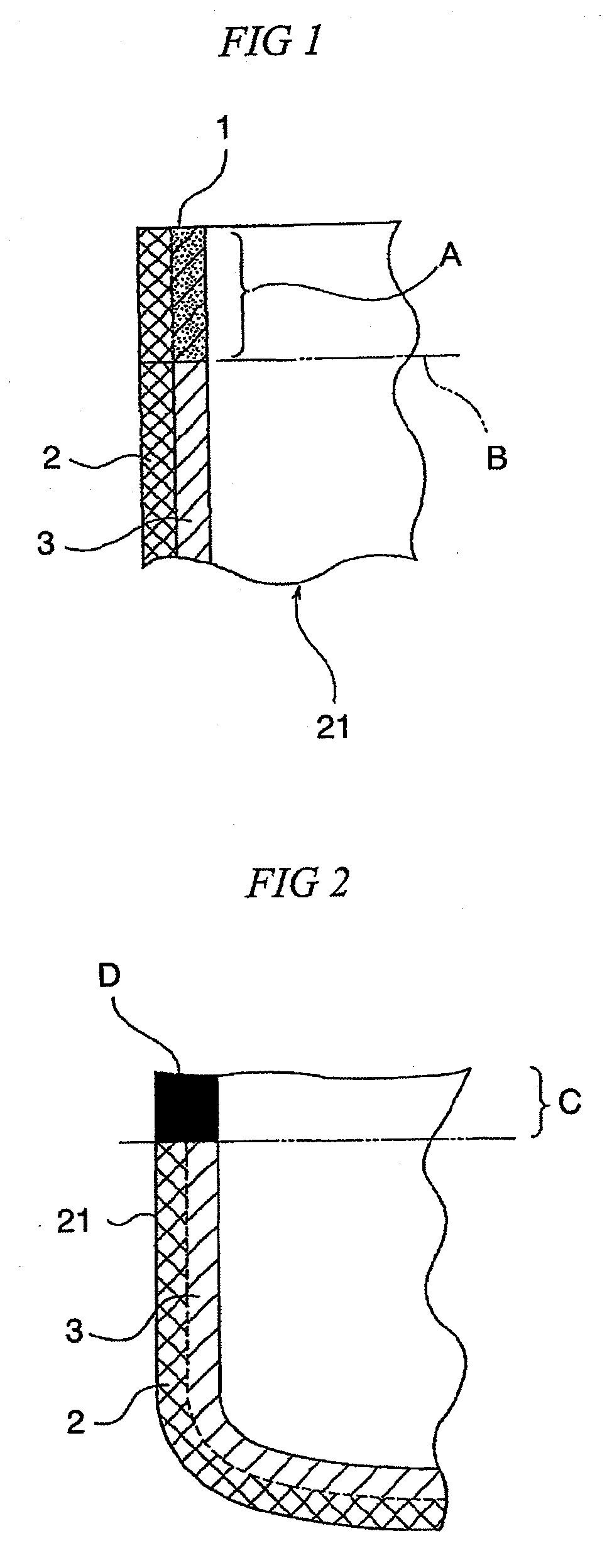

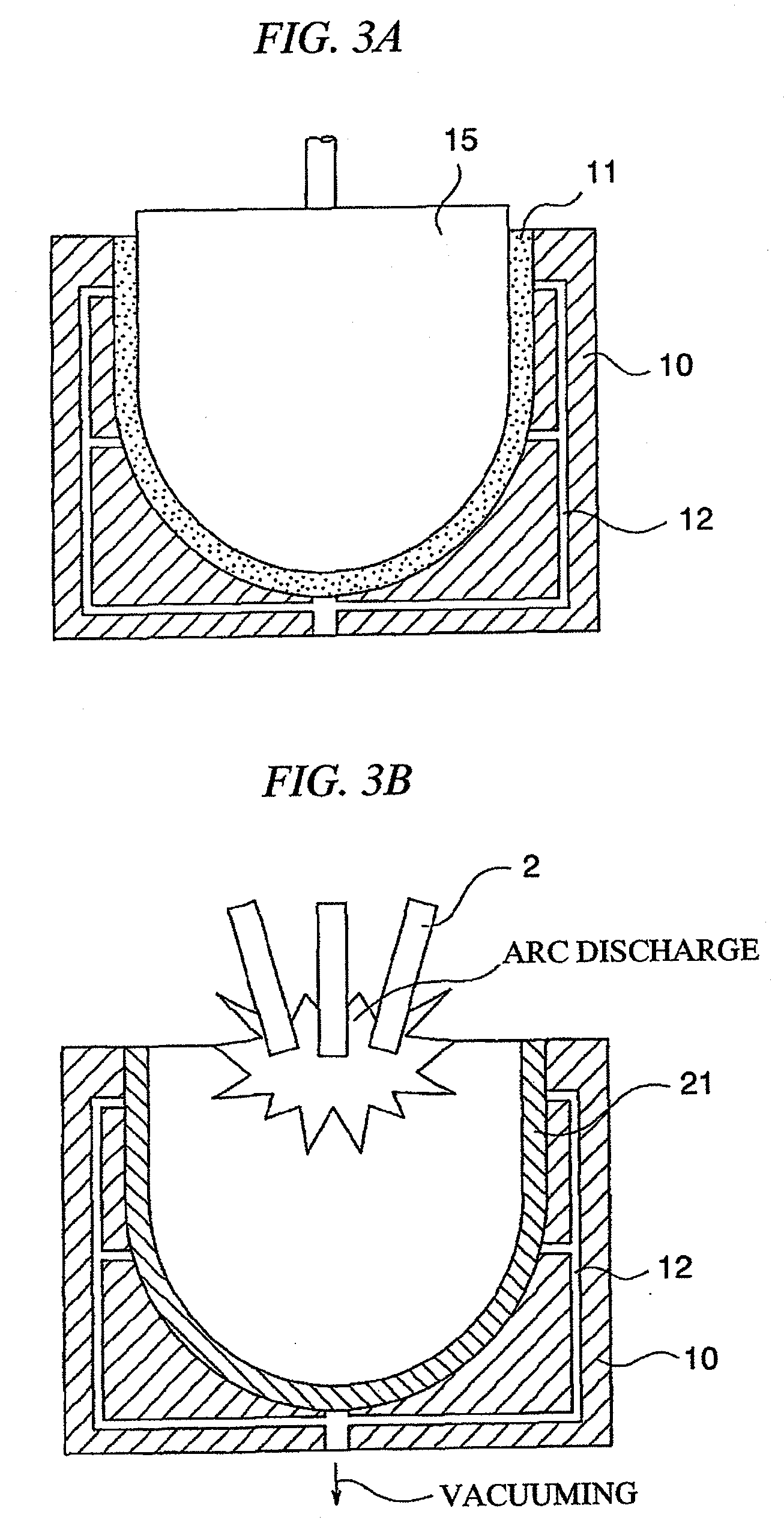

High-purity vitreous silica crucible used for pulling large-diameter single-crystal silicon ingot

ActiveUS20090173276A1High strengthPinhole defectAfter-treatment apparatusPolycrystalline material growthCrucibleCrystal structure

A high-purity vitreous silica crucible which has high strength and is used for pulling a large-diameter single-crystal silicon ingot, includes a double laminated structure constituted by an outer layer composed of amorphous silica glass with a bubble content of 1 to 10% and a purity of 99.99% or higher and an inner layer composed of amorphous silica glass with a bubble content of 0.6% or less and a purity of 99.99% or higher, and in the portion between the upper opening end of the high-purity vitreous silica crucible and the ingot-pulling start line of a silicon melt surface in the step of pulling a single-crystal silicon ingot, a portion corresponding to 40 to 100 volume % from the upper opening end of the crucible is in a crystalline structure free from the crystallization promoter.

Owner:SUMCO CORP

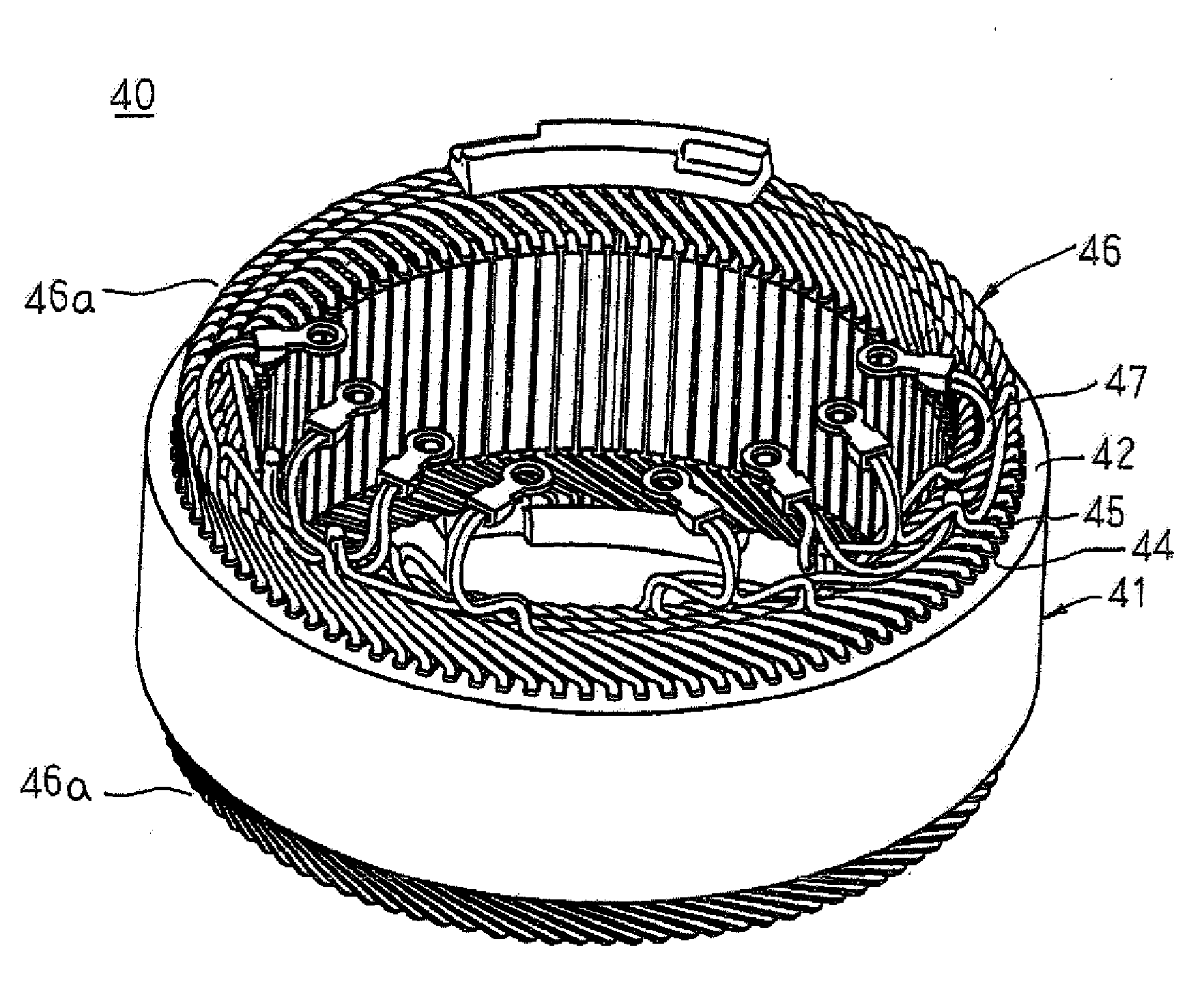

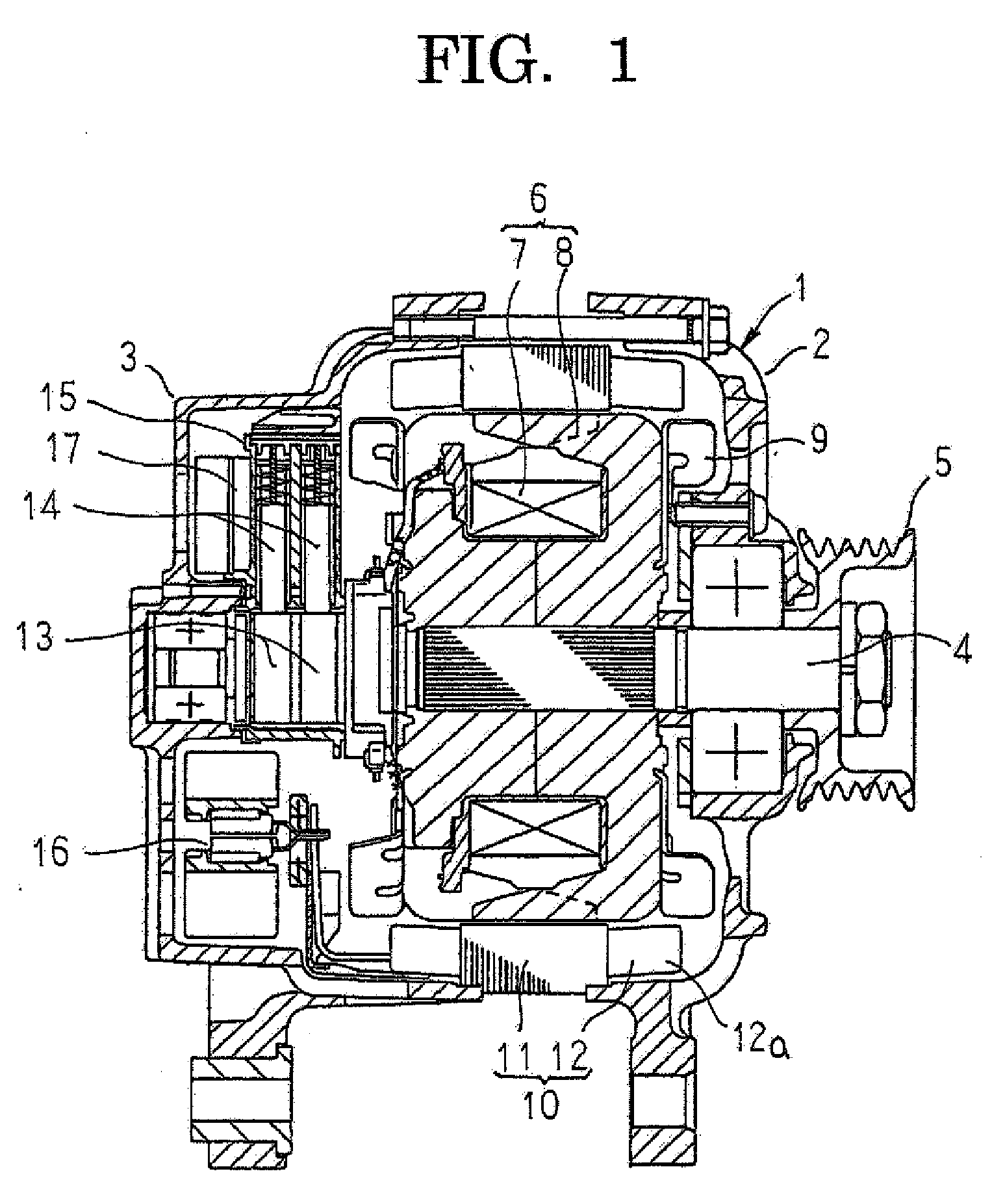

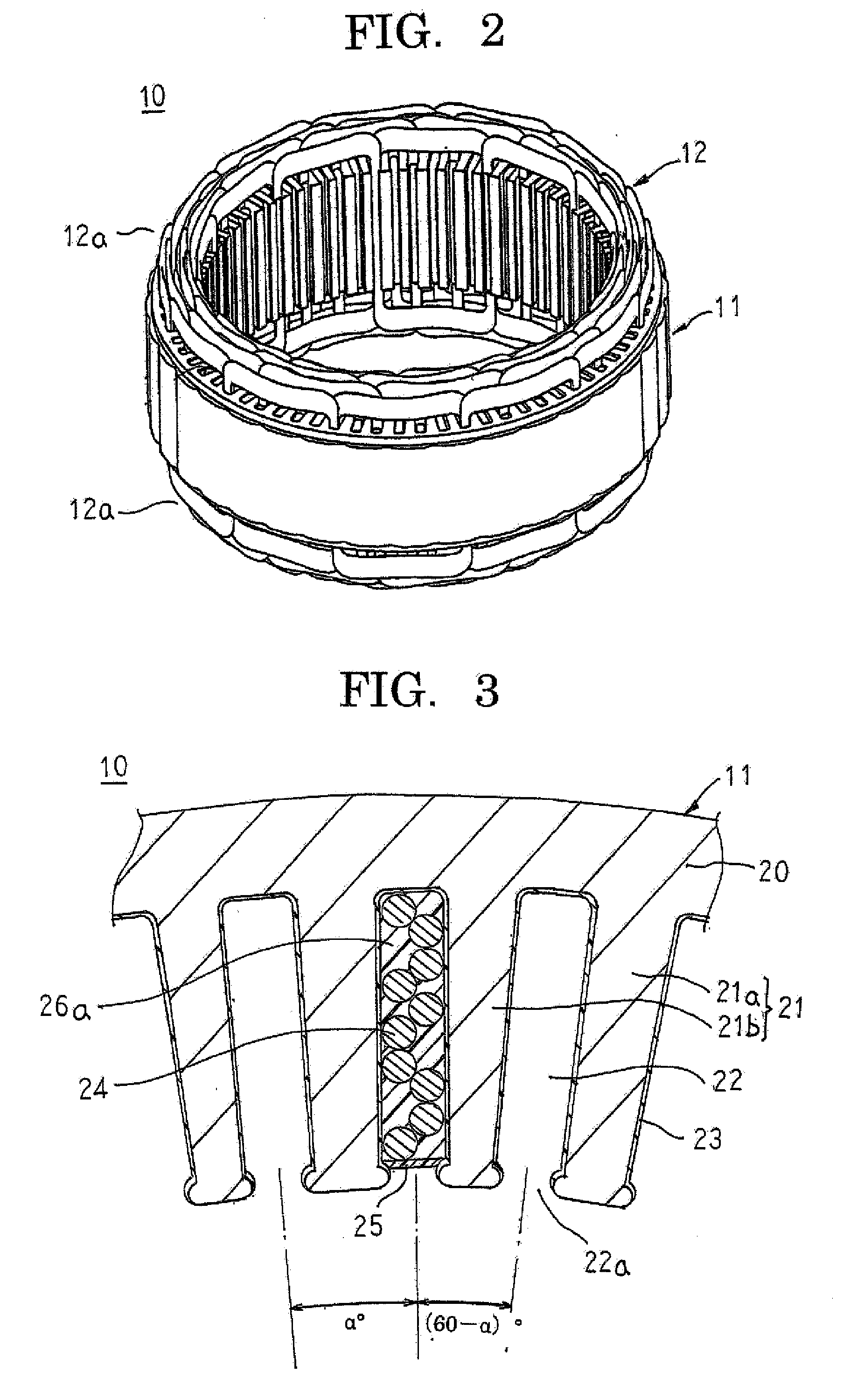

Dynamoelectric coil portion insulating construction

InactiveUS20080246354A1Reduce hardnessImprove heat resistanceWindingsManufacturing dynamo-electric machinesCopper wirePolyamide-imide

A stator coil 24 is installed in a stator core 11, and an insulating resin is impregnated into slot portions 22 and hardened. The stator coil 24 is constituted by enameled wires in which a polyamideimide resin layer has been applied radially outside a copper wire and hardened, and the insulating resin contains as a major component a THEIC-modified polyester resin that has been modified by a fatty acid.

Owner:MITSUBISHI ELECTRIC CORP +1

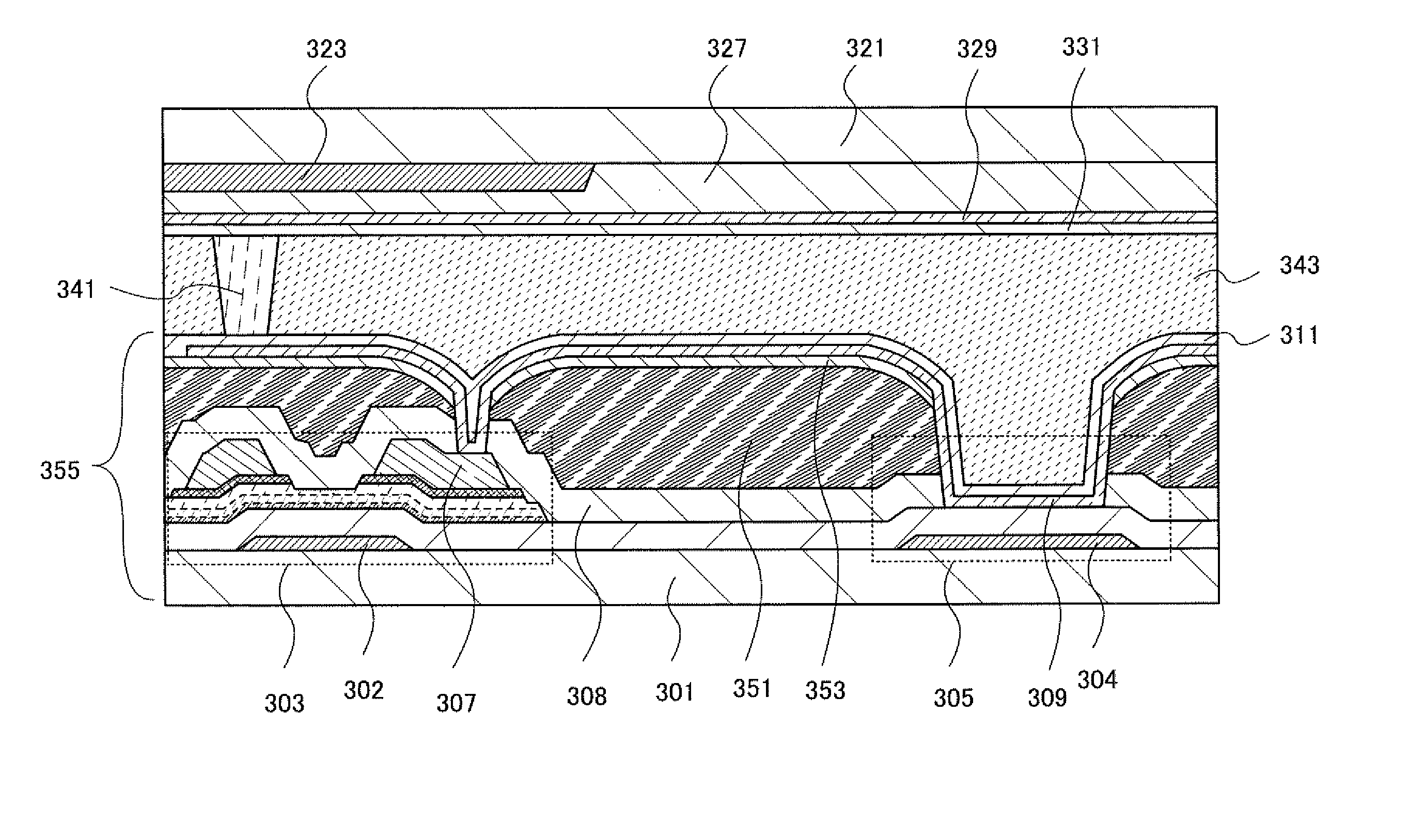

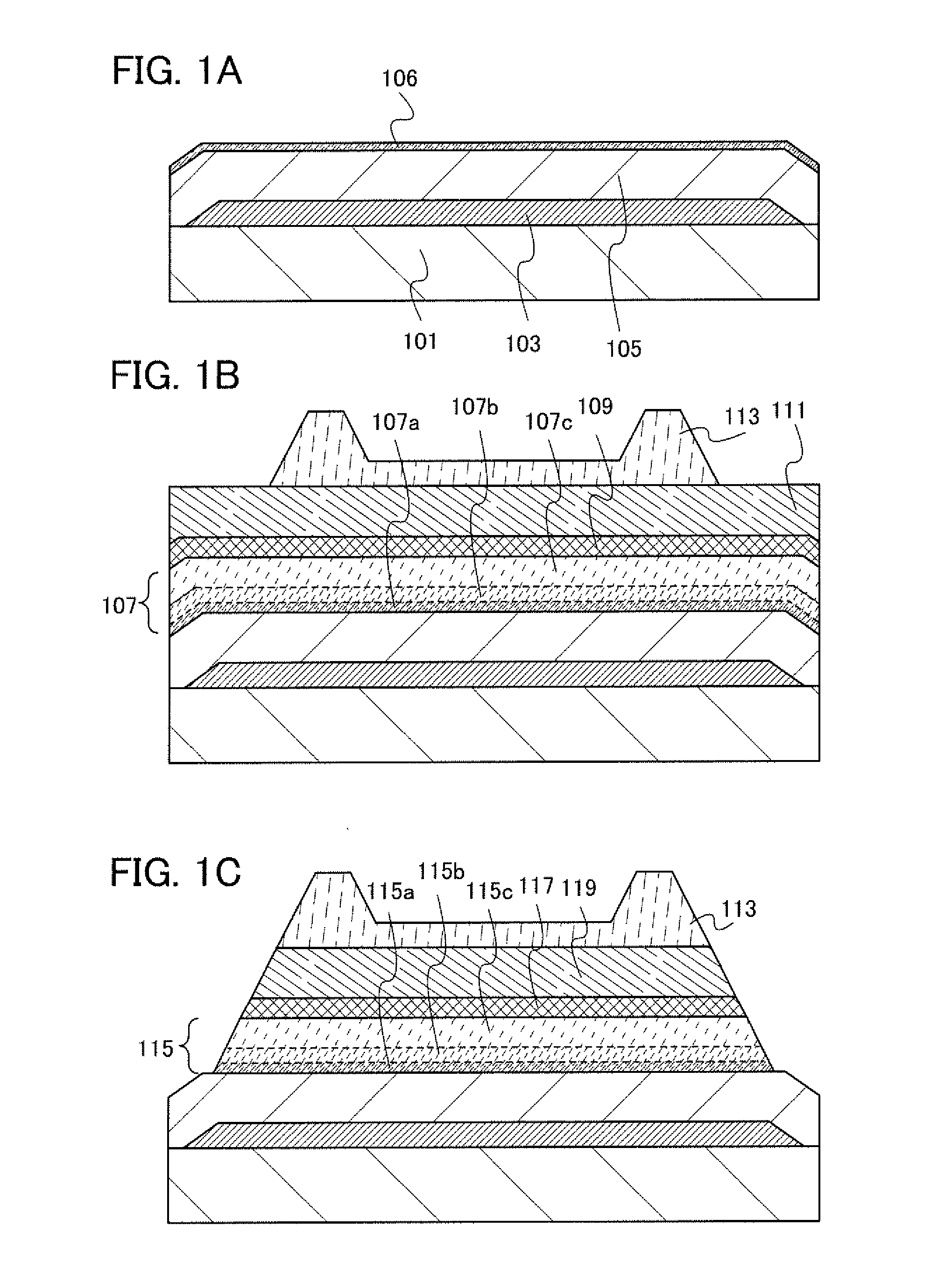

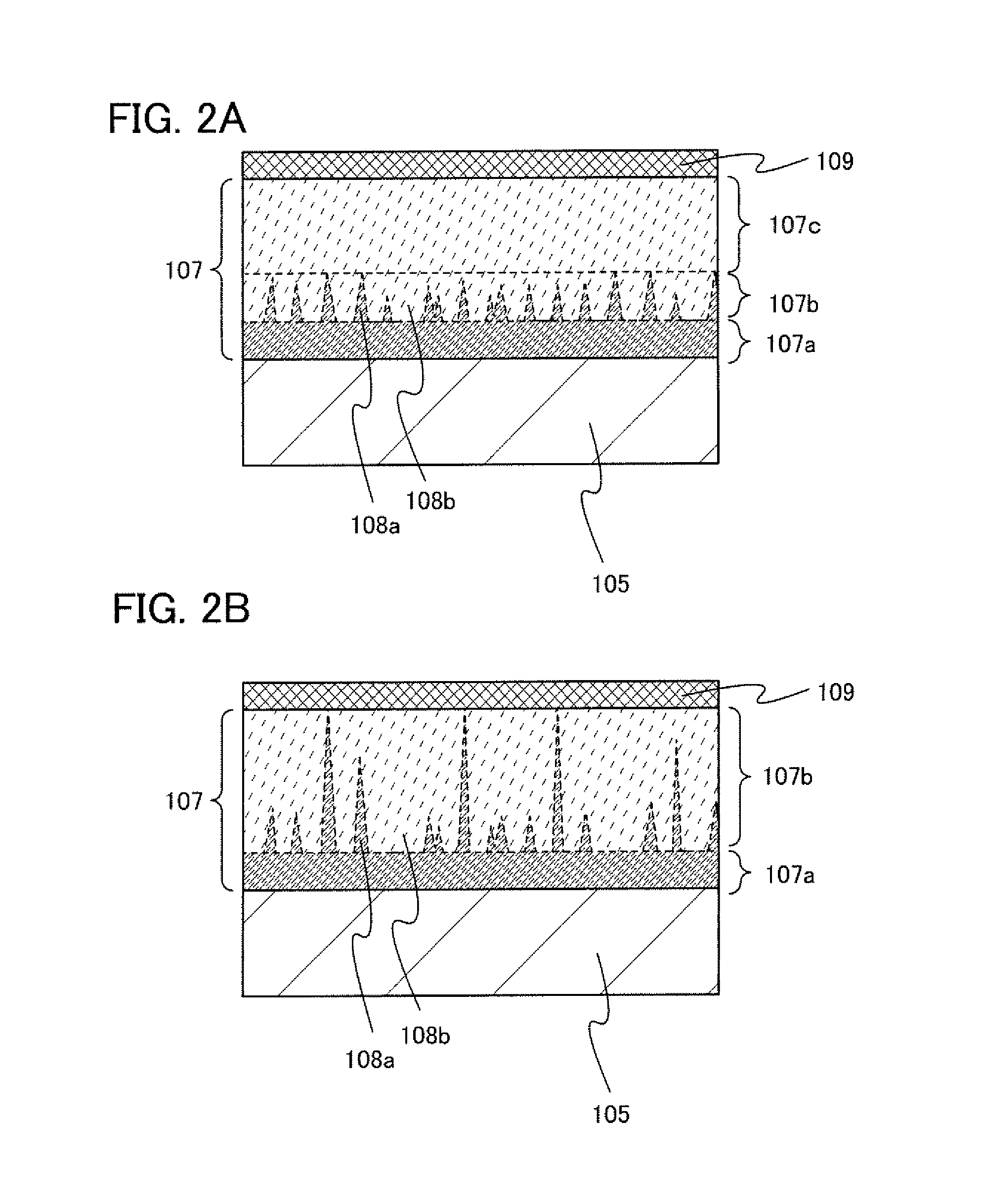

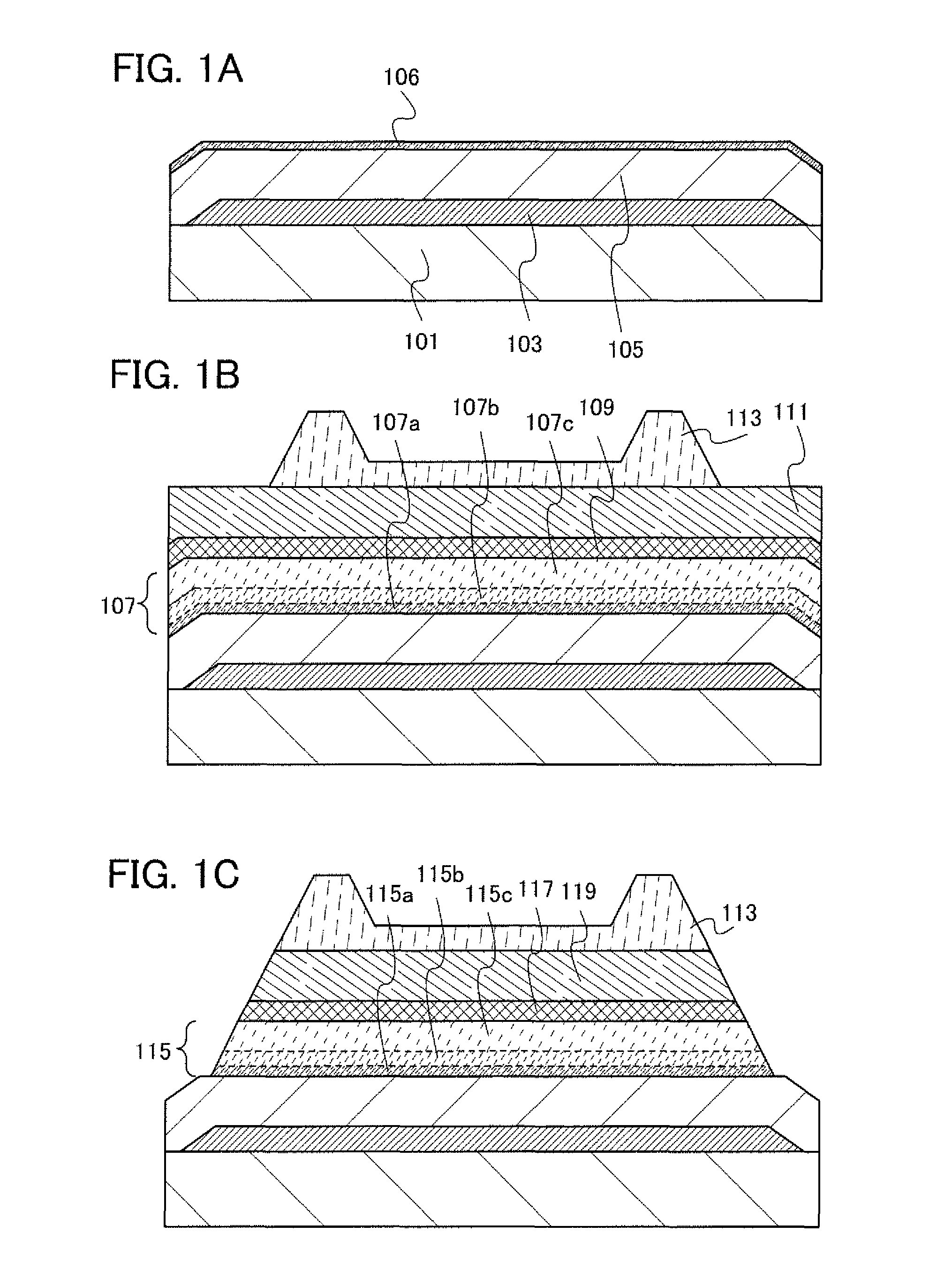

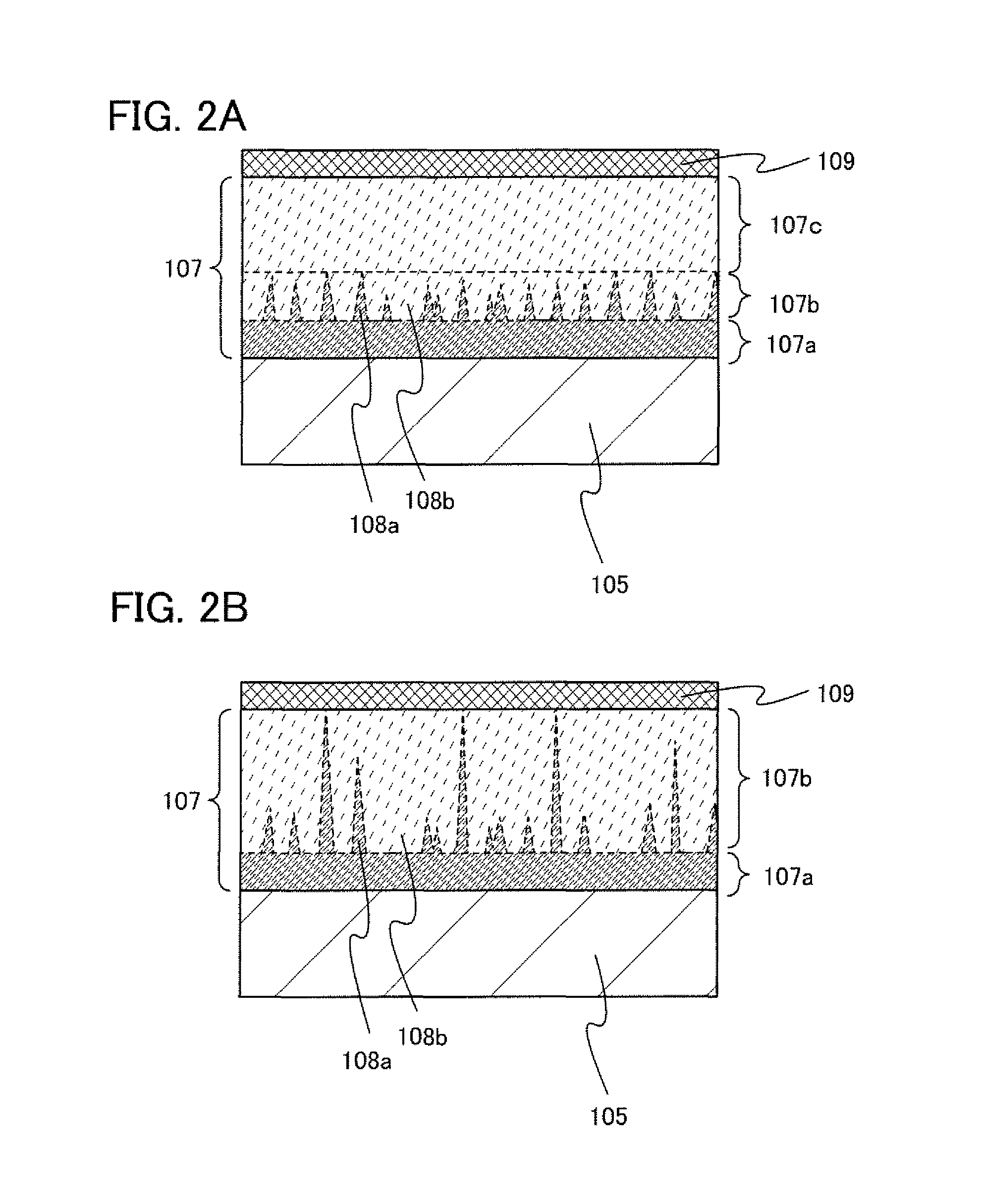

Method for manufacturing thin film transistor

InactiveUS20100124804A1Increase volumeReactionSolid-state devicesSemiconductor/solid-state device manufacturingNoble gasSeed crystal

An object is to provide a method for manufacturing a thin film transistor having favorable electric characteristics, with high productivity. A gate electrode is formed over a substrate and a gate insulating layer is formed over the gate electrode. A first semiconductor layer is formed over the gate insulating layer by generating plasma using a deposition gas containing silicon or germanium, hydrogen, and a rare gas. Next, a second semiconductor layer including an amorphous semiconductor and a microcrystal semiconductor is formed in such a manner that the first semiconductor layer is partially grown as a seed crystal by generating plasma using a deposition gas containing silicon or germanium, hydrogen, and a gas containing nitrogen. Then, a semiconductor layer to which an impurity imparting one conductivity is added is formed and a conductive film is formed. Thus, a thin film transistor is manufactured.

Owner:SEMICON ENERGY LAB CO LTD

Substrate for selenium compound semiconductors, production method of substrate for selenium compound semiconductors, and thin-film solar cell

InactiveUS20110186131A1Avoid corrosionGood insulation characteristic and mechanical strength and flexibilityAnodisationSolid state diffusion coatingSelenium CompoundAlloy

A substrate for selenium compound semiconductor has at least a steel base and an aluminum base. The aluminum base is arranged on one end in a direction of lamination of the steel base and the aluminum base, the steel base is arranged on the other end in the direction. An alloy layer having a thickness of from 0.01 μm to 10 μm is formed between the steel base and the aluminum base. A thermal oxide film having a thickness of 6 nm or more is formed on a surface of the steel base opposite to the aluminum base.

Owner:FUJIFILM CORP

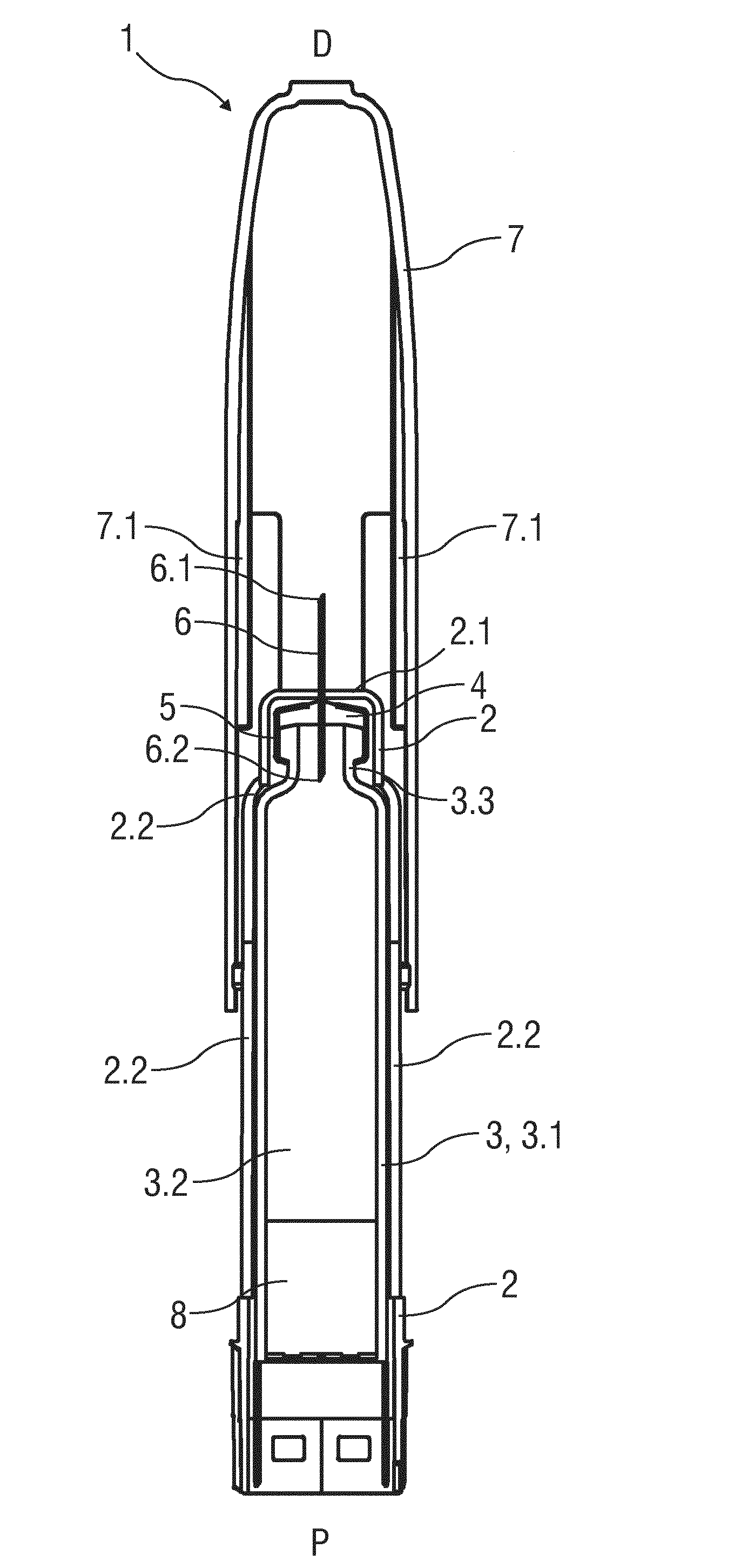

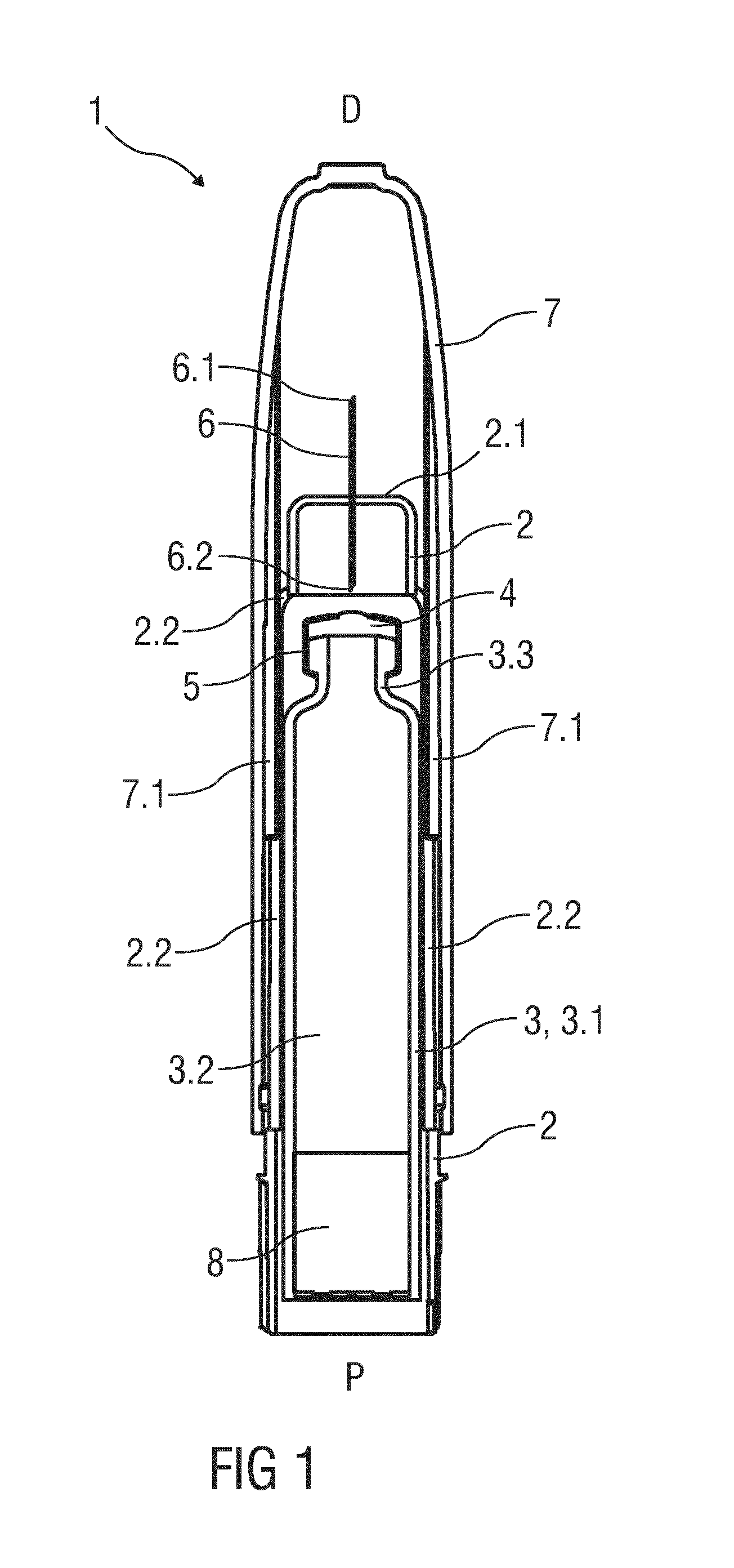

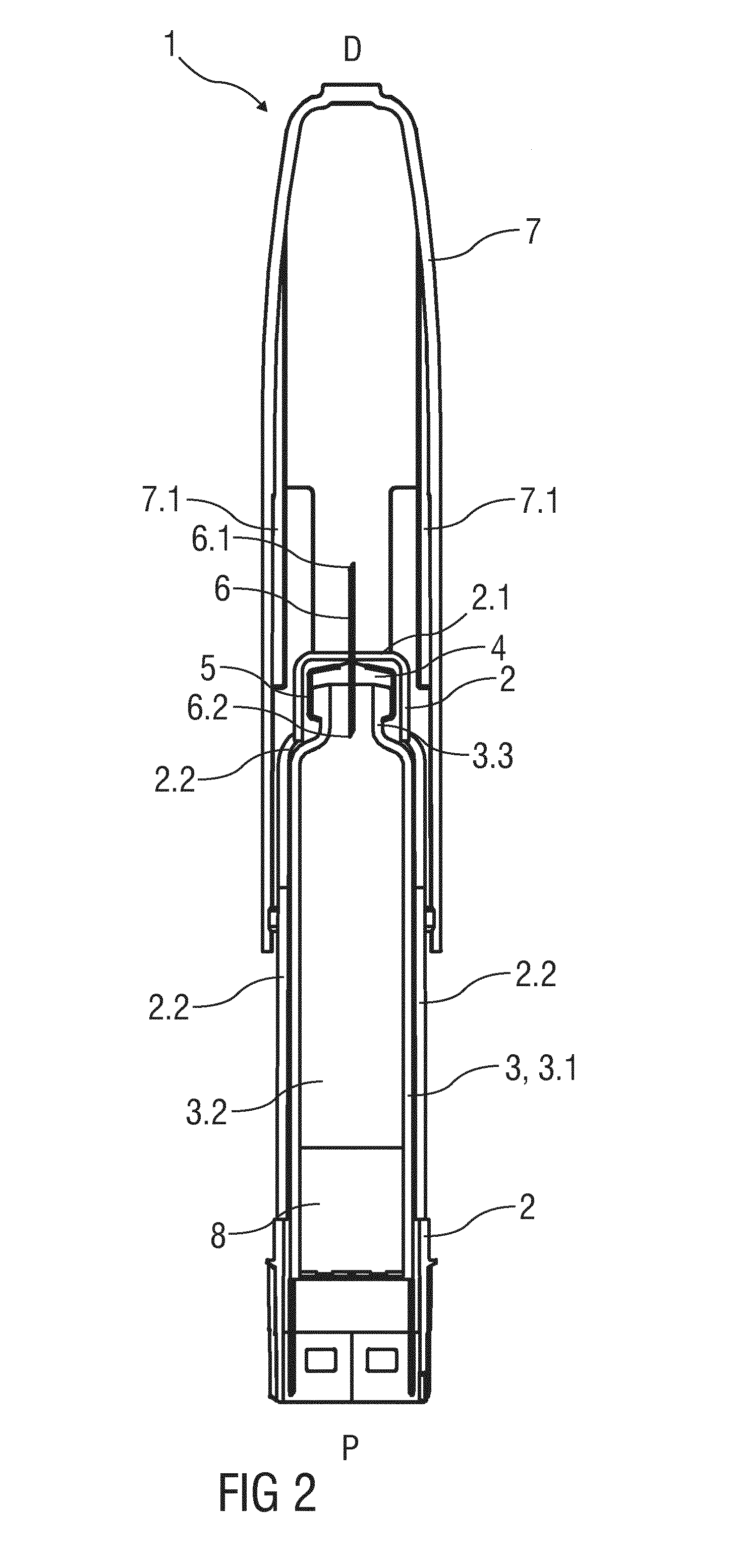

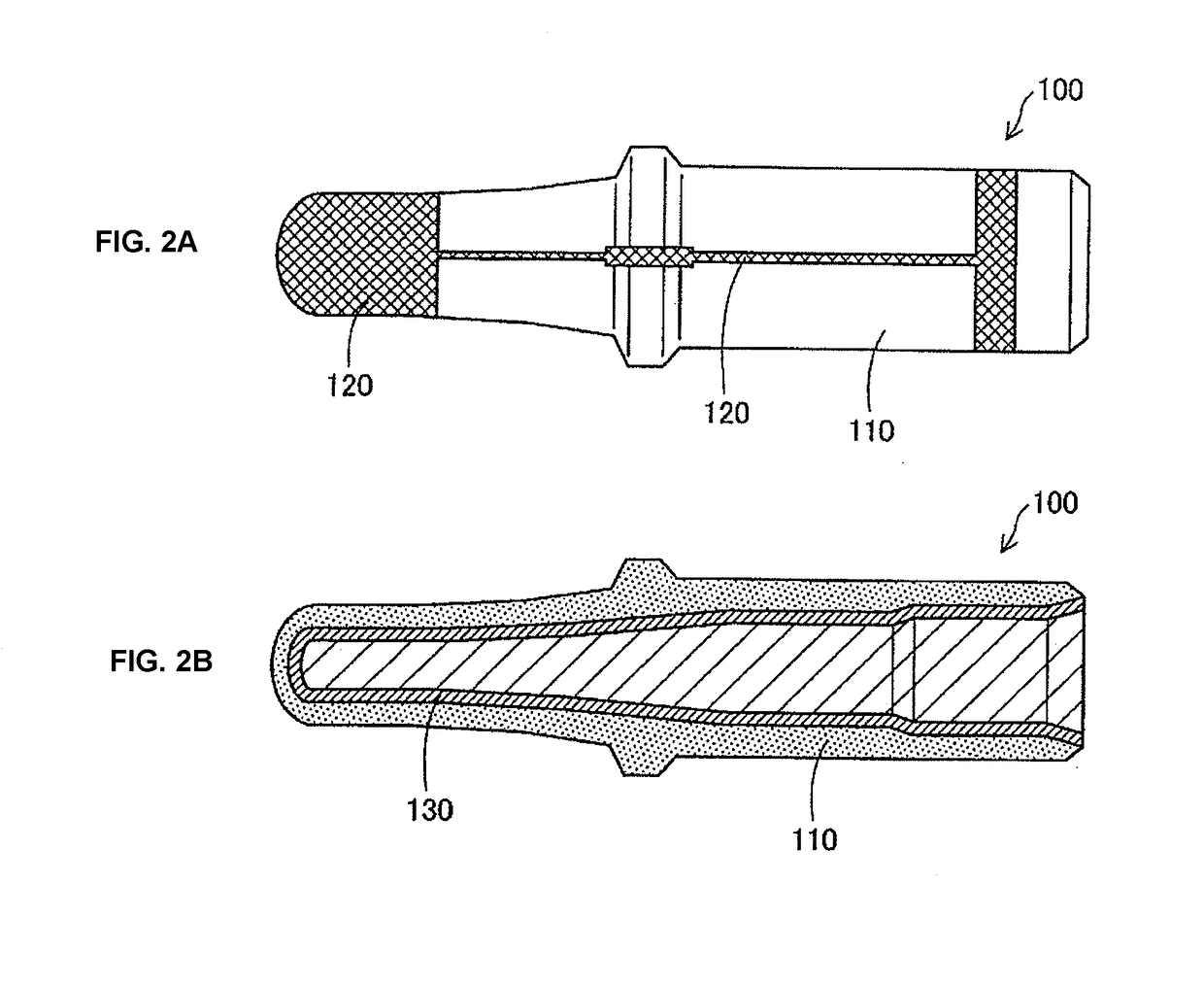

Injection device

ActiveUS20160220763A1ReactionAvoid reactionAmpoule syringesInfusion needlesSurgeryIntensive care medicine

Described is an injection device (1) for administering a drug, the injection device (1) comprising a cartridge holder (2) adapted to receive a drug cartridge (3), a hollow injection needle (6) having a proximal tip (6.2) adapted to pierce a septum (4) of the cartridge (3) so as to establish a fluid communication between the cartridge (3) and the needle (6),and a cap (7) arrangeable over the cartridge holder (2) in a manner to cover the needle (6). In an initial state the cartridge (3) is arranged within the cartridge holder (2) with the septum (4) axially spaced from the proximal tip (6.2) of the needle (6). The cap (7) is adapted to move the needle (6) relative to the septum (4) for piercing it on movement of the cap (7) relative to the cartridge holder (2).

Owner:SANOFI AVENTIS DEUT GMBH

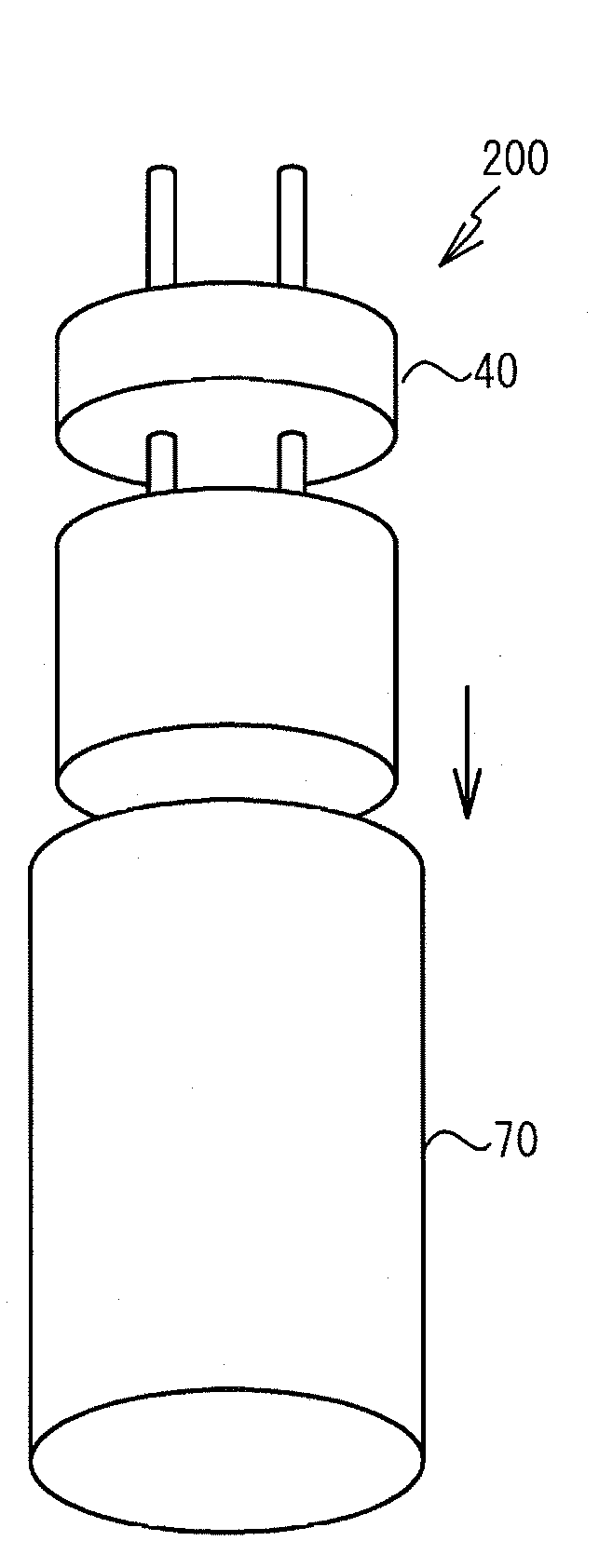

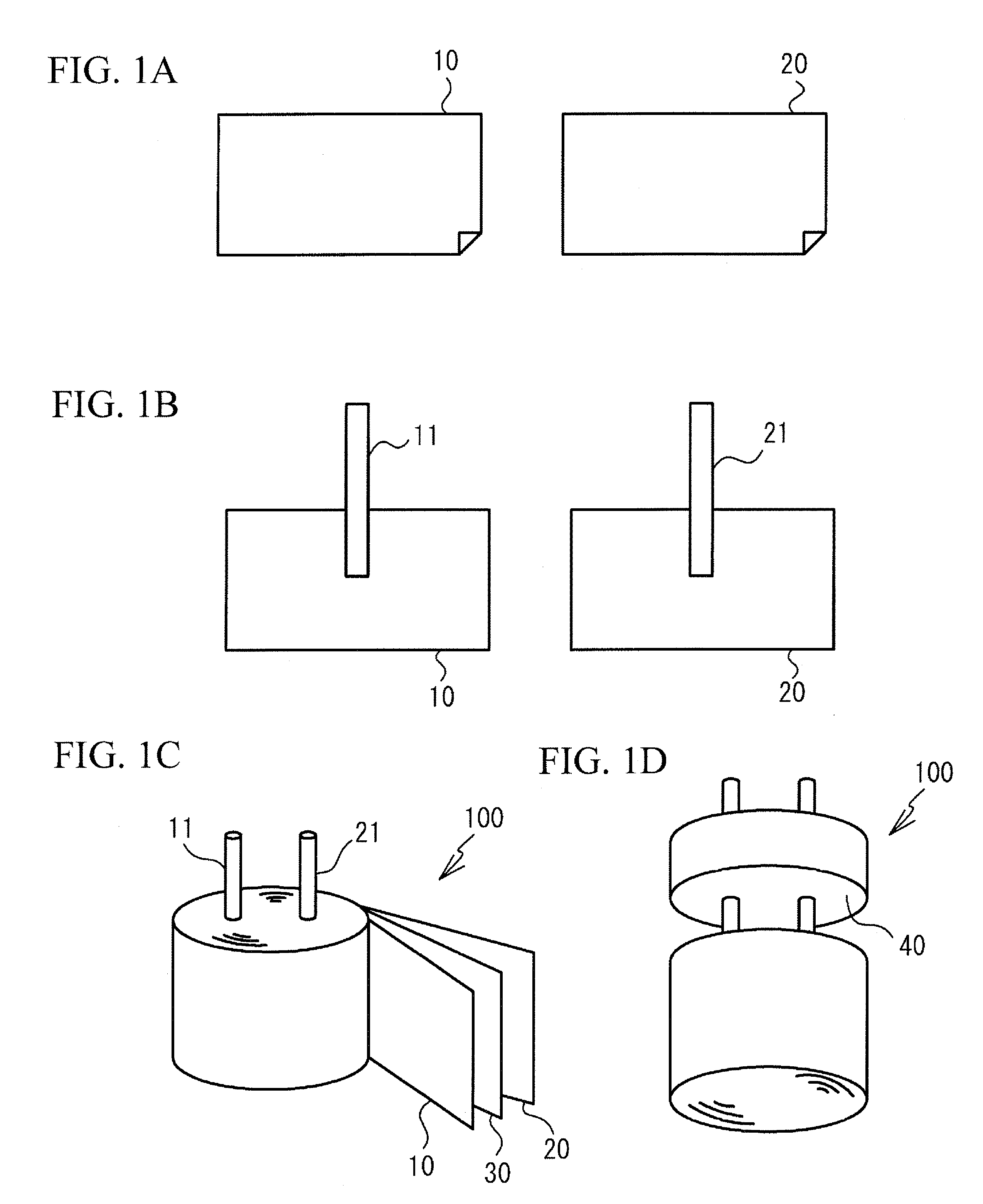

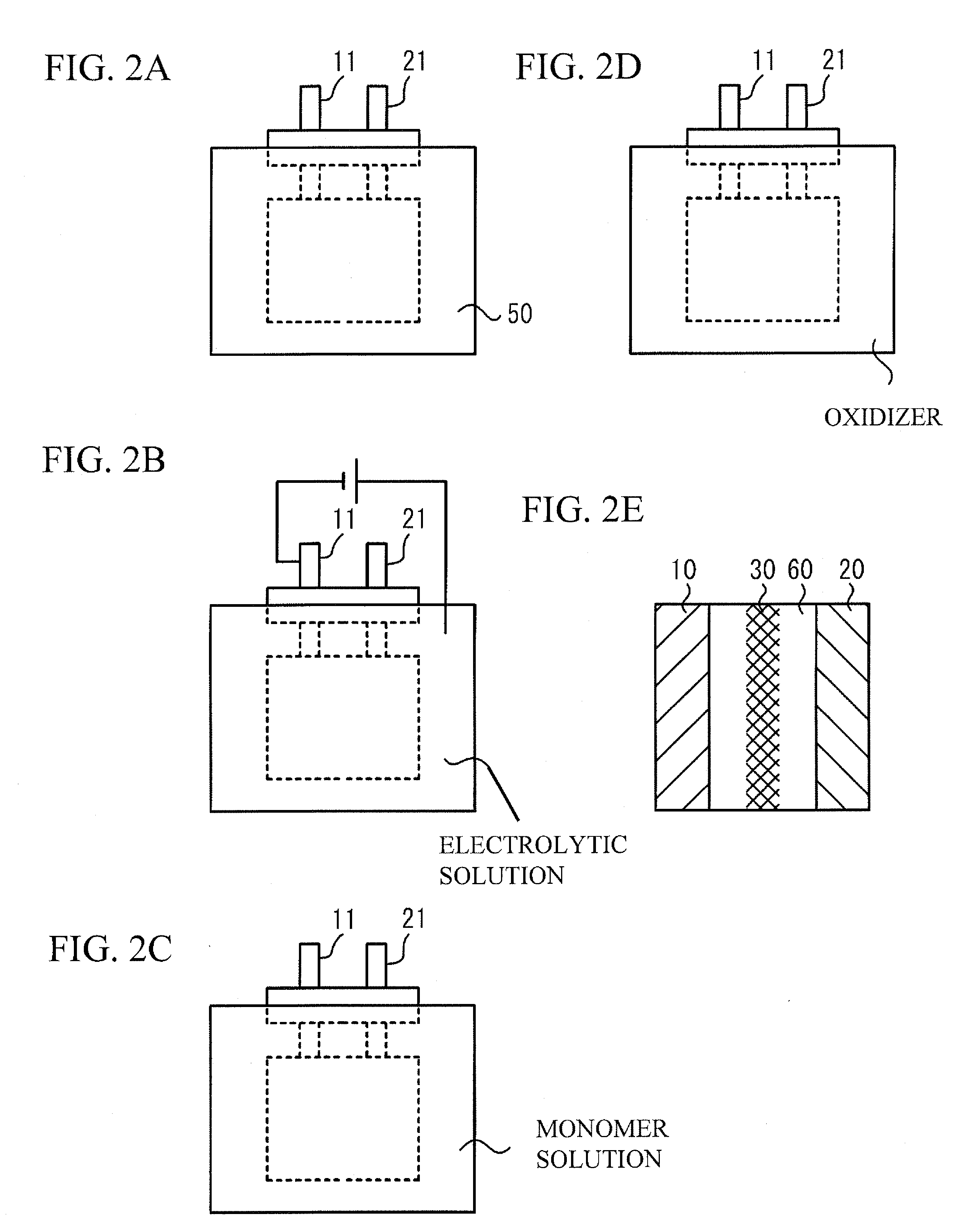

Solid electrolytic capacitor and method of manufacturing the same

InactiveUS7948740B2Swelling caused by a reflow heat is restrainedSwelling caused by reflow heat is restrainedClosuresSolid electrolytic capacitorsElectrolysisOptoelectronics

A method of manufacturing a solid electrolytic capacitor includes: rolling an anode foil, a cathode foil and a separator together, the separator being a mixed fiber composed of a chemical fiber and a natural fiber and being between the anode foil and the cathode foil; degrading and removing the natural fiber with enzyme; and forming an electrolytic layer composed of solid polymer between the anode foil and the cathode foil after degrading and removing the natural fiber.

Owner:NICHICON CORP

Non-aqueous electrolyte secondary battery and method for producing the same

ActiveUS20110223469A1Increase battery capacityImprove featuresFinal product manufacturePrimary cellsLutetiumPhosphate

A positive electrode active material with least part of a surface coated with a surface treatment layer composed of a phosphate compound. The phosphate compound contains at least one element selected from the group consisting of neodymium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, and lutetium.

Owner:PANASONIC ENERGY CO LTD

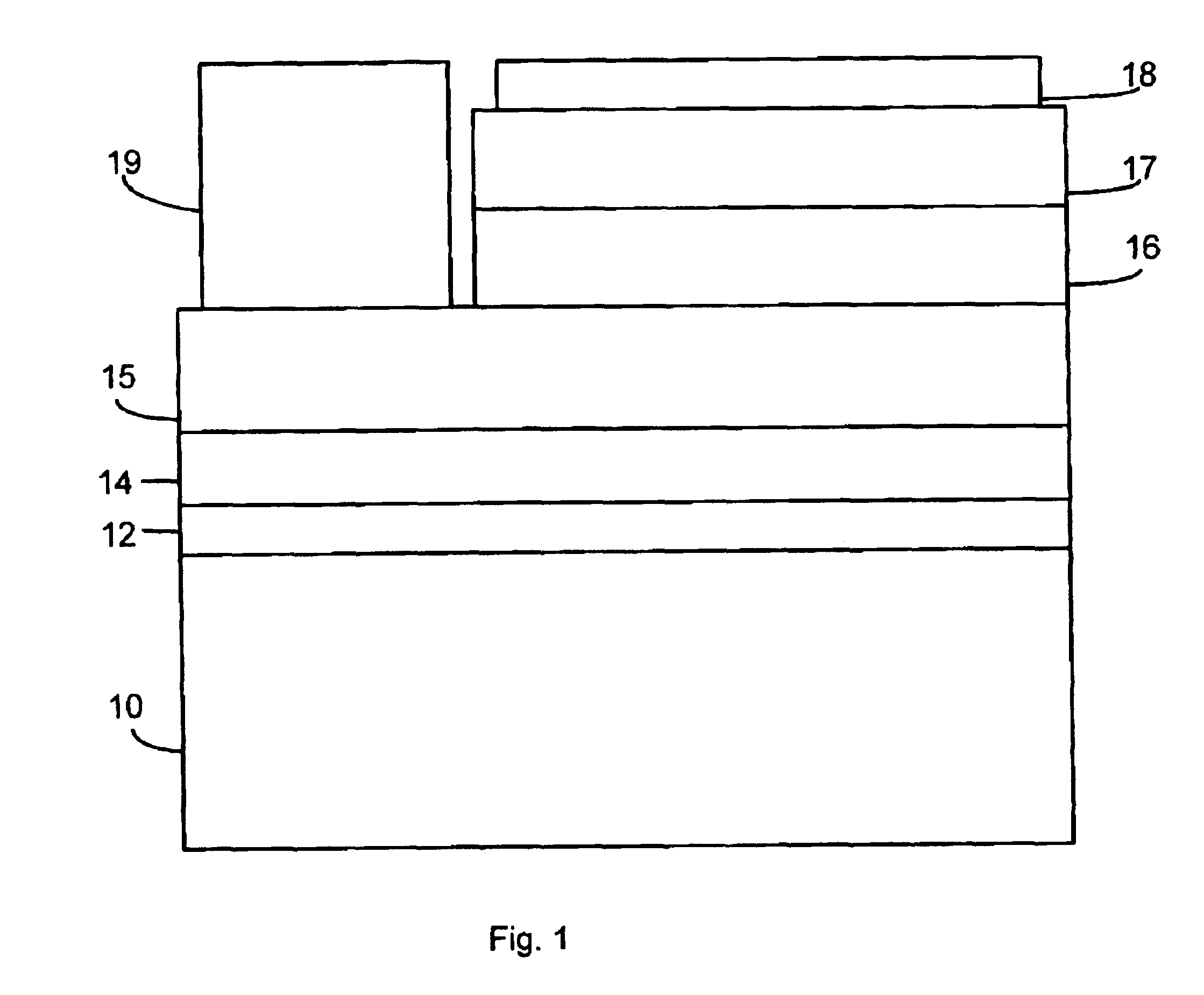

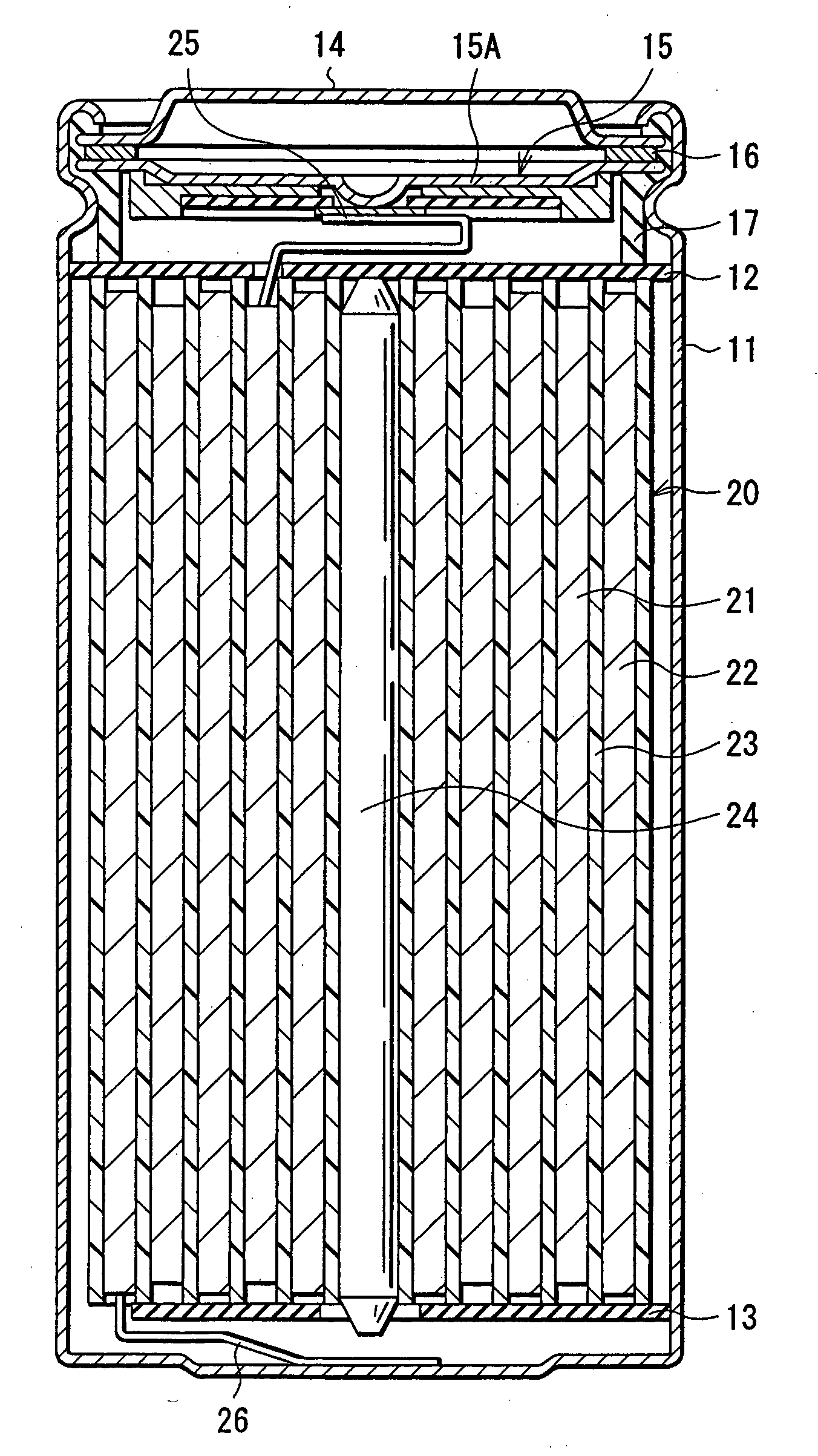

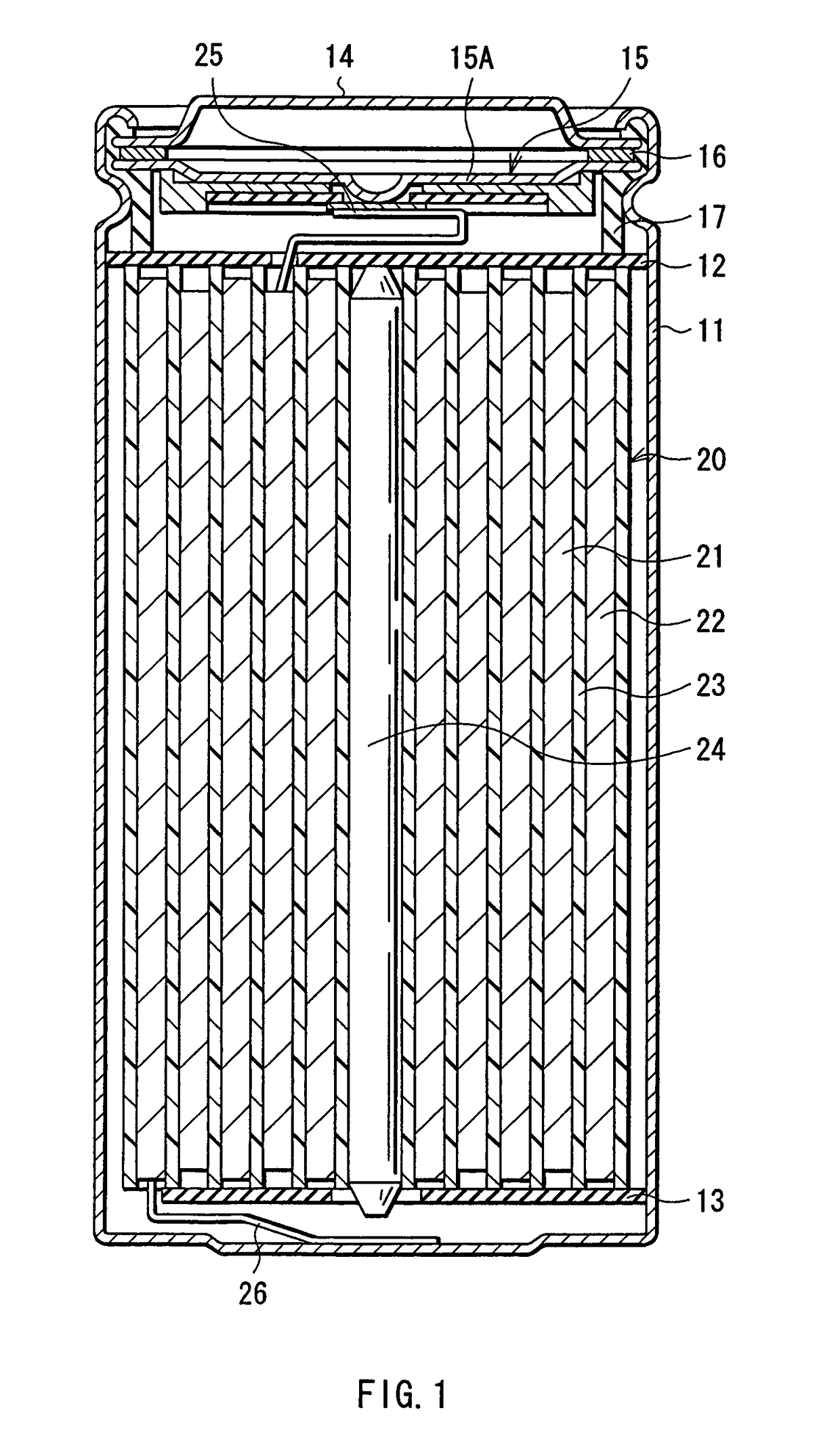

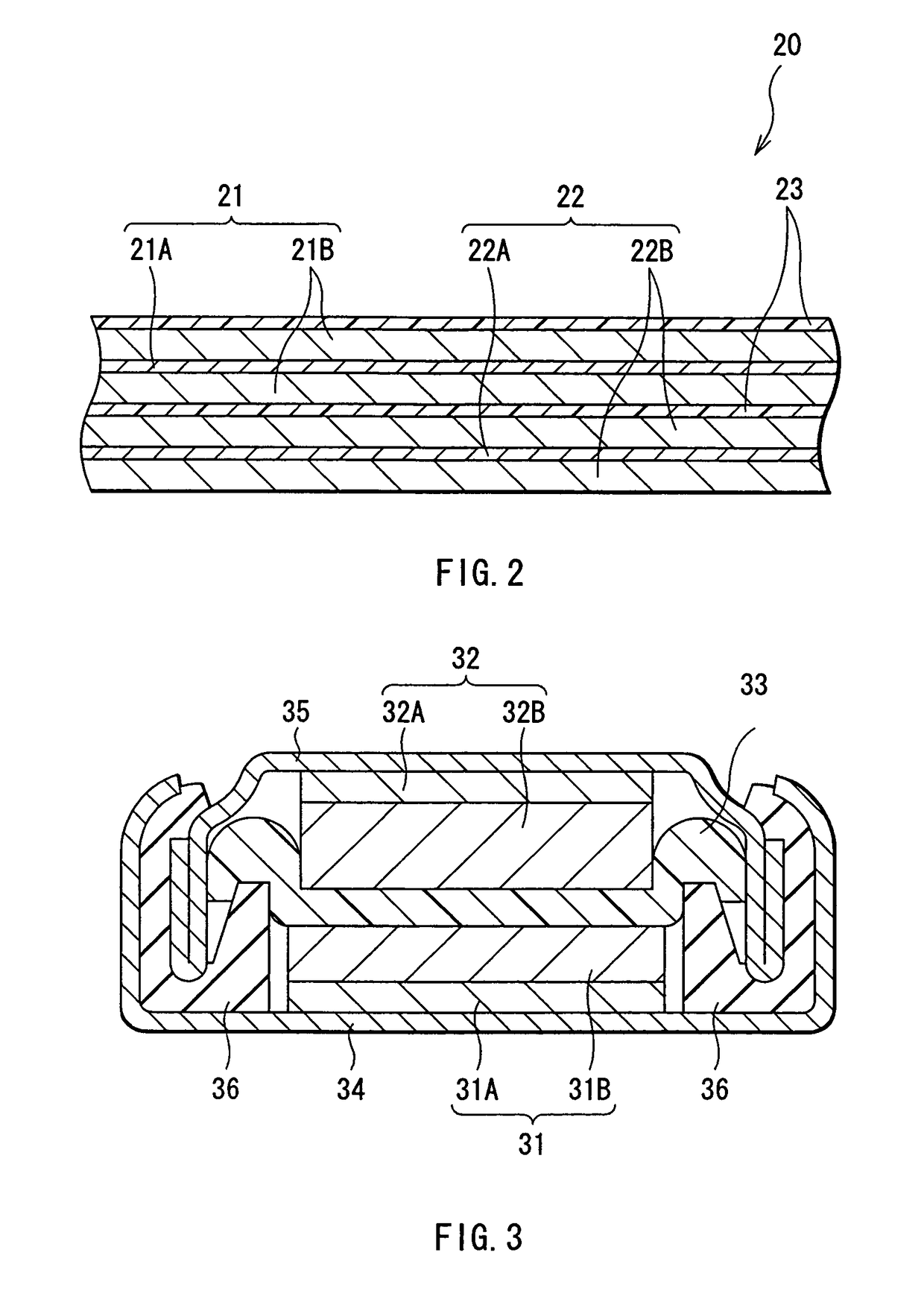

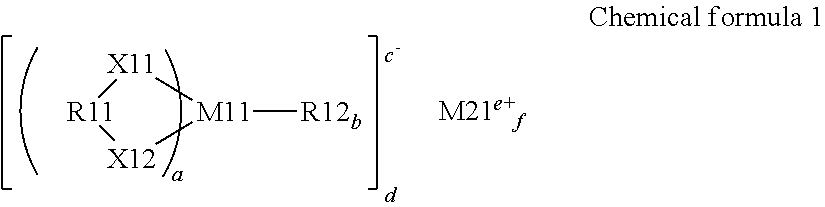

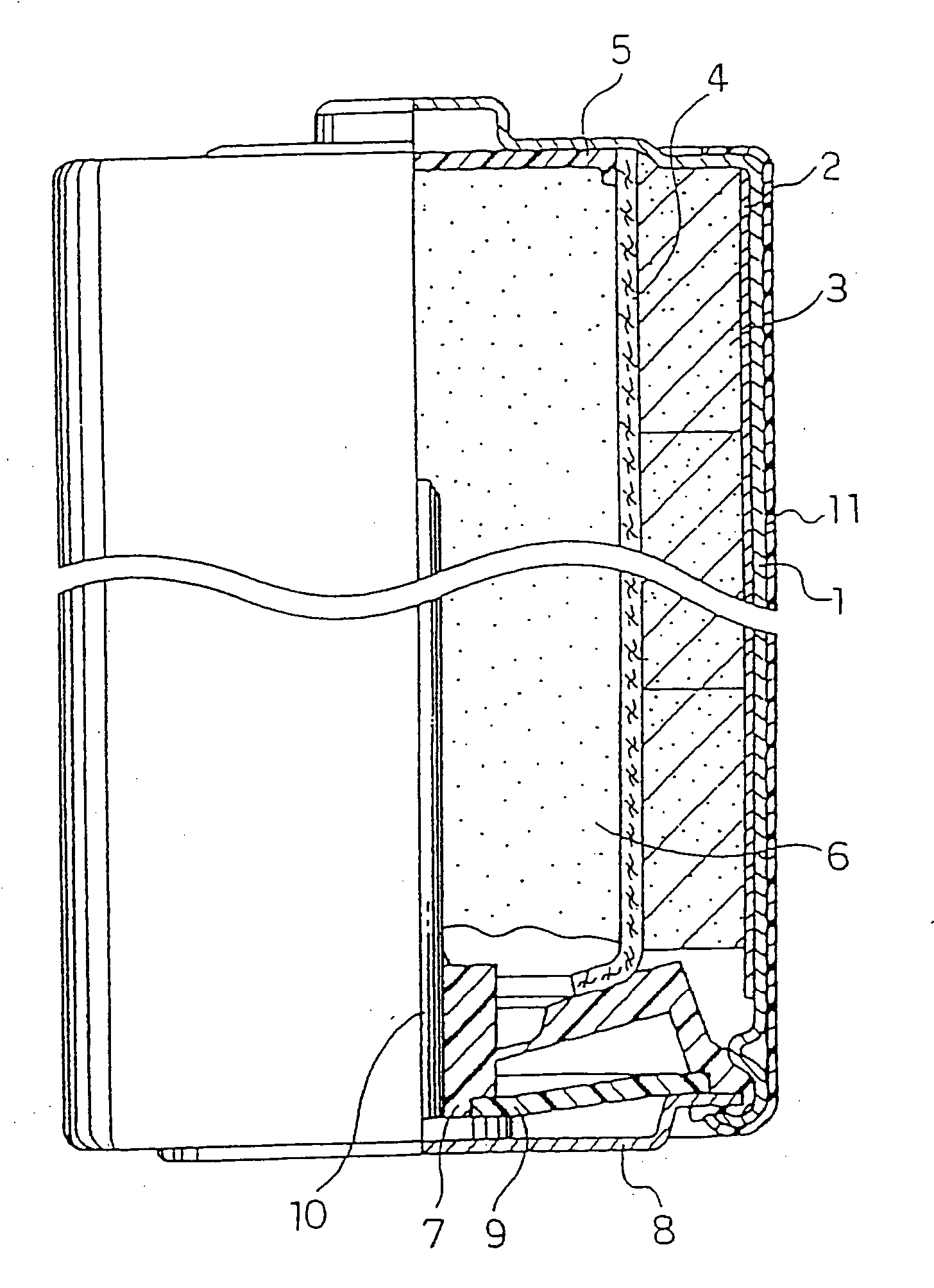

Battery

ActiveUS7906237B2Large capacityImprove featuresElectrode carriers/collectorsLi-accumulatorsDecompositionAlloy

A battery is provided which has a high capacity and can improve battery characteristics, such as cycle characteristics. The battery includes a spirally wound electrode body, wherein a cathode and an anode are wound with a separator in between. The anode includes, for example, simple substances, alloys, compounds of metal elements or metalloid elements capable of forming an alloy with Li, the like and combinations thereof. An electrolytic solution wherein an electrolyte salt is dissolved in a solvent is impregnated in the separator. For the electrolyte salt, a light metallic salt having B—O bond or P—O bond, such as difluoro[oxalato-O,O′]lithium borate and tetra fluoro[oxalato-O,O′]lithium phosphate, can be used. By forming a stable coating, decomposition reaction of the solvent can be inhibited, and reaction between the anode and the solvent can be prevented.

Owner:SONY CORP +1

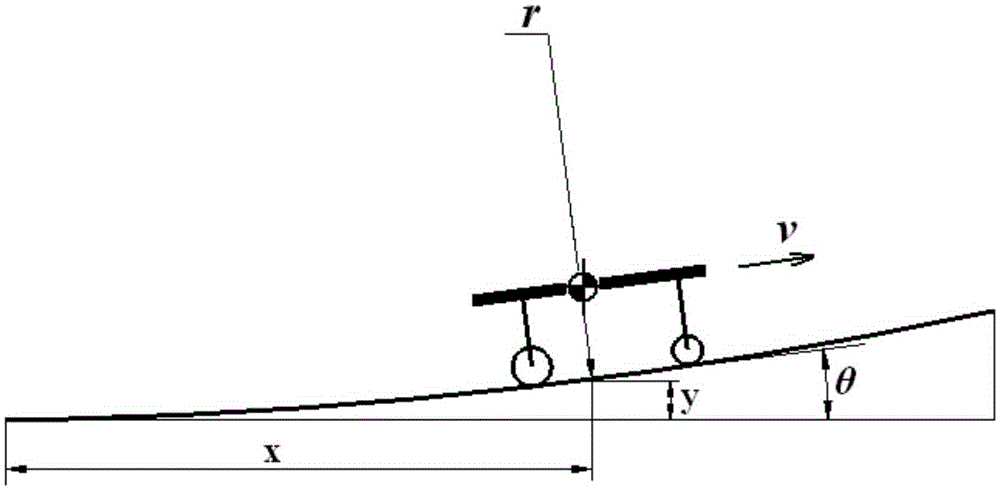

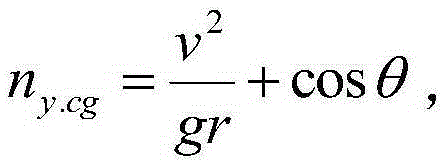

Gravity-center normal overload calculation method for ski-jump takeoff of aircraft

InactiveCN105389438AExact solutionImprove fitGeometric CADSpecial data processing applicationsGravity centerStrength design

The present invention relates to the field of aircraft structure strength design, and particularly relates to a gravity-center normal overload calculation method for ski-jump takeoff of an aircraft, so as to solve the problem of an inaccurate calculation result of the existing gravity-center normal overload calculation method. The gravity-center normal overload calculation method for ski-jump takeoff of an aircraft comprises the following steps: calculating the curvature radius of an oblique board of an aircraft carrier by using a predetermined formula; and according to formulas involving the gravitational acceleration, a takeoff roll speed of the aircraft, and a tangential angle of the oblique board of the aircraft carrier, calculating the gravity-center normal overload for ski-jump takeoff of the aircraft. According to the gravity-center normal overload calculation method for ski-jump takeoff of an aircraft, normal overload can be figured out more accurately, so that the calculation result matches the actual takeoff load better, thereby more truly reflecting a deck reaction force borne by a landing gear of the aircraft.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

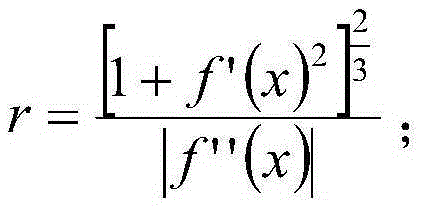

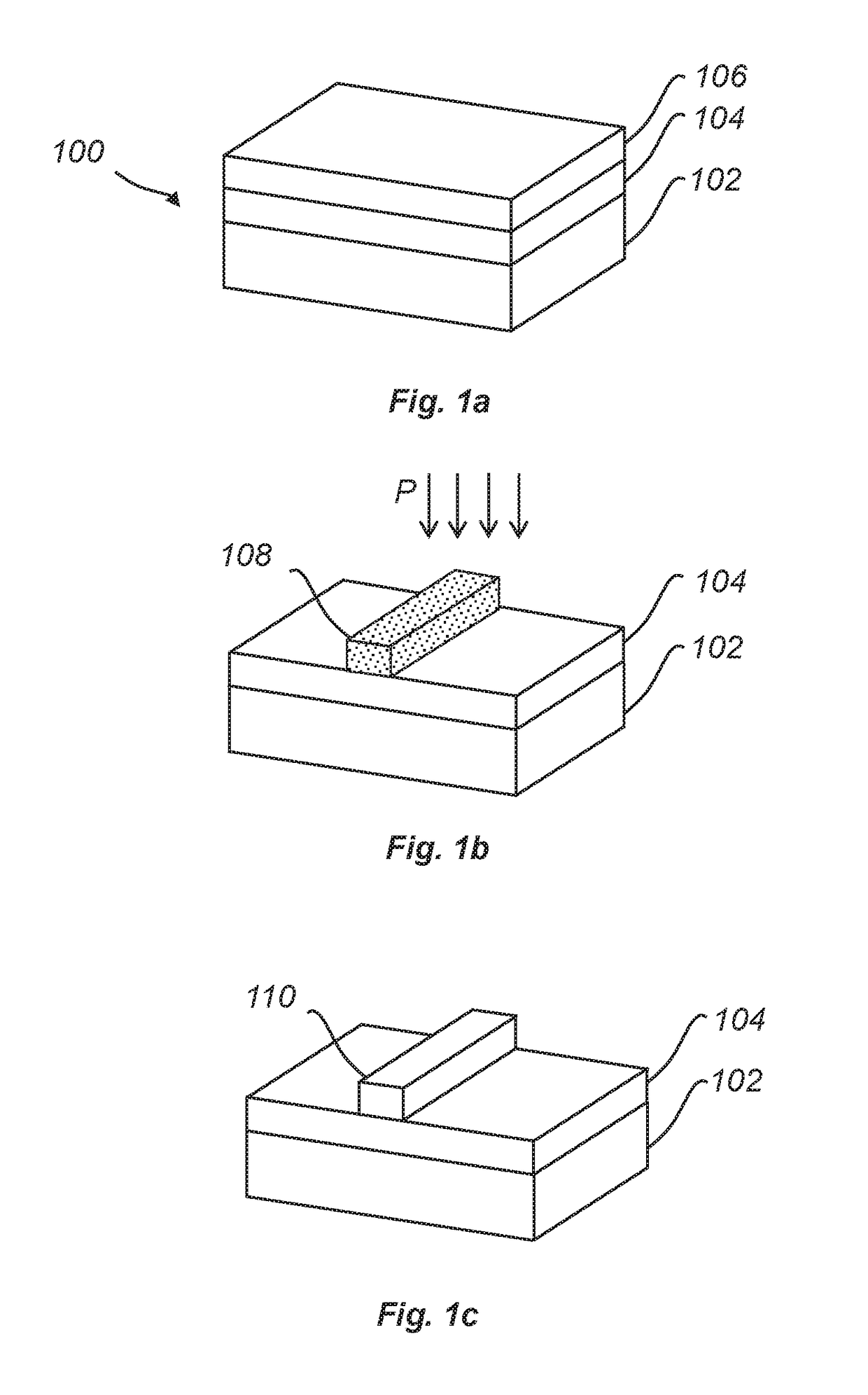

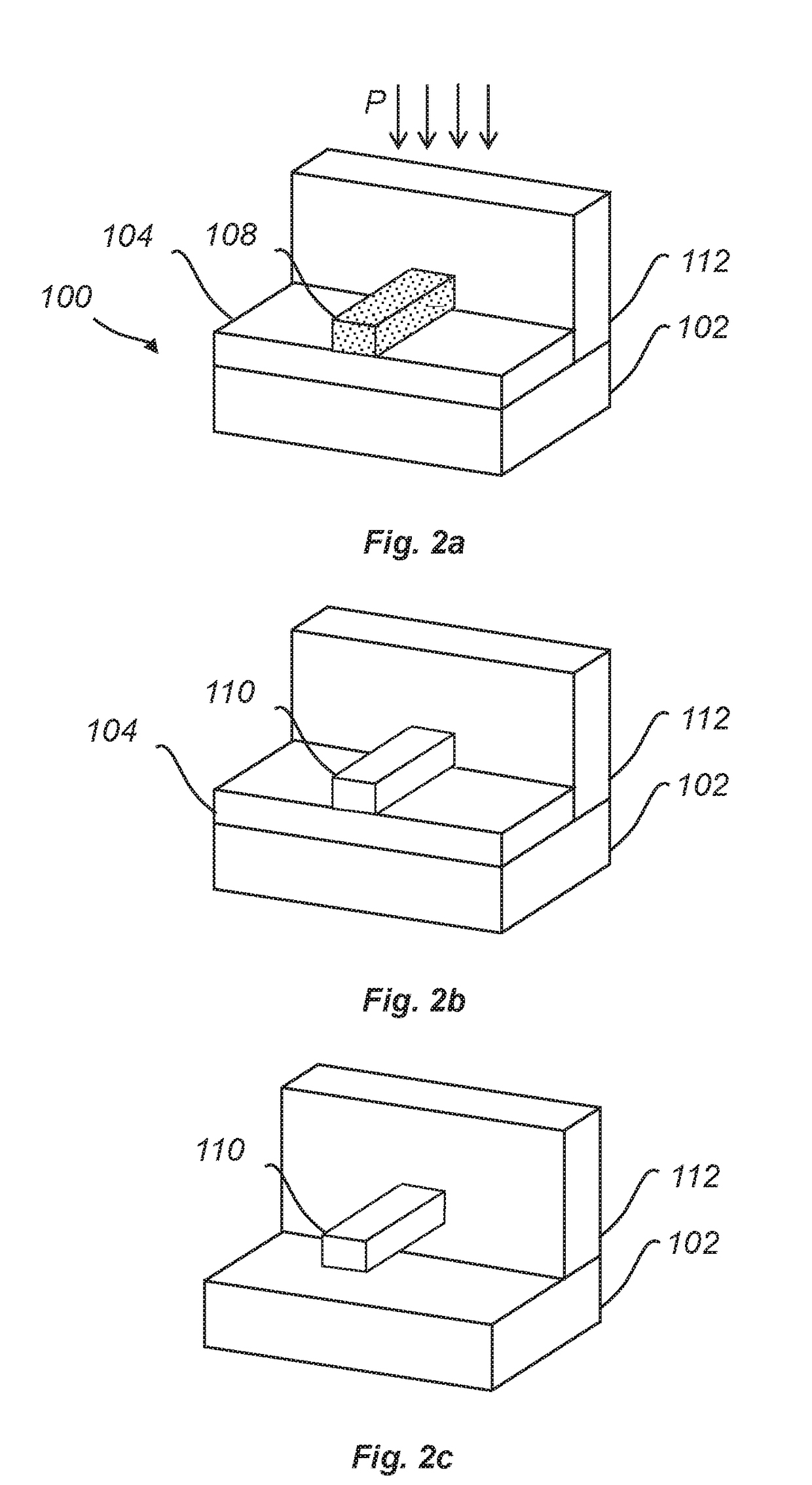

Method of Forming a Feature of a Target Material on a Substrate

ActiveUS20170178905A1Avoid reactionAccurate and reliable processSemiconductor/solid-state device manufacturingDeposition processMaterial selection

A method is provided for forming a feature of a target material on a substrate. The method including:forming a feature of a sacrificial material on the substrate; andforming the feature of the target material by a deposition process during which the feature of the sacrificial material is removed from the substrate by forming a volatile reaction product with a precursor of the deposition process, wherein the sacrificial material is replaced by the target material and the target material is selectively deposited on surface portions of the substrate, which portions were covered by the feature of the sacrificial material, to form the feature of the target material.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

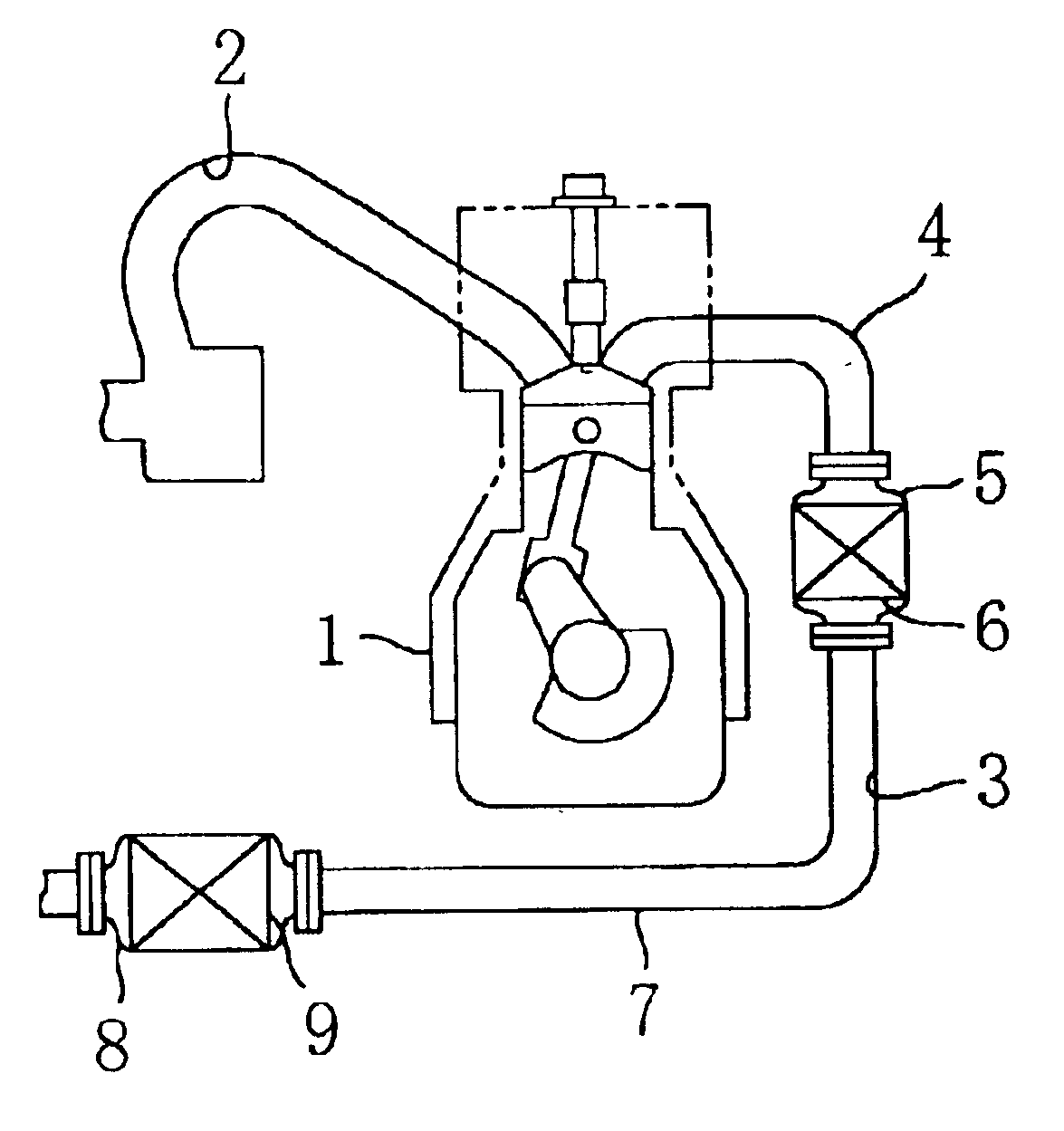

Oxidation catalyst

InactiveUS6927191B2Inhibit productionWide rangeOrganic chemistryMolecular sieve catalystsAlloyMaterials science

An inside layer including zeolite and an outside layer including alumina and Pd are formed in a layered shape on a carrier, and Ag and Bi are simultaneously allowed to be carried on the inside and outside layers through impregnation. Thus, production of an alloy through a reaction between Pd and Ag can be suppressed by Bi.

Owner:MAZDA MOTOR CORP

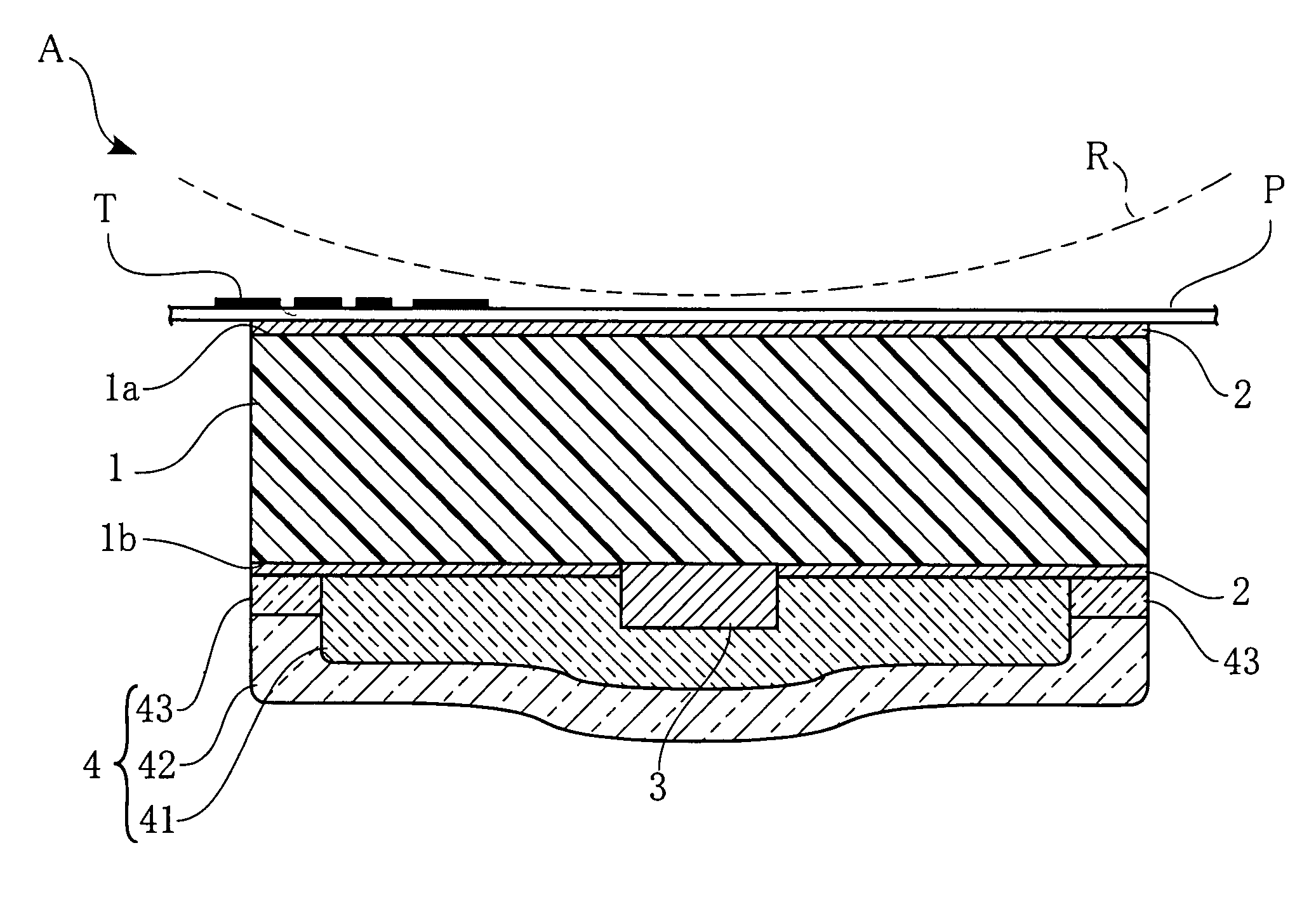

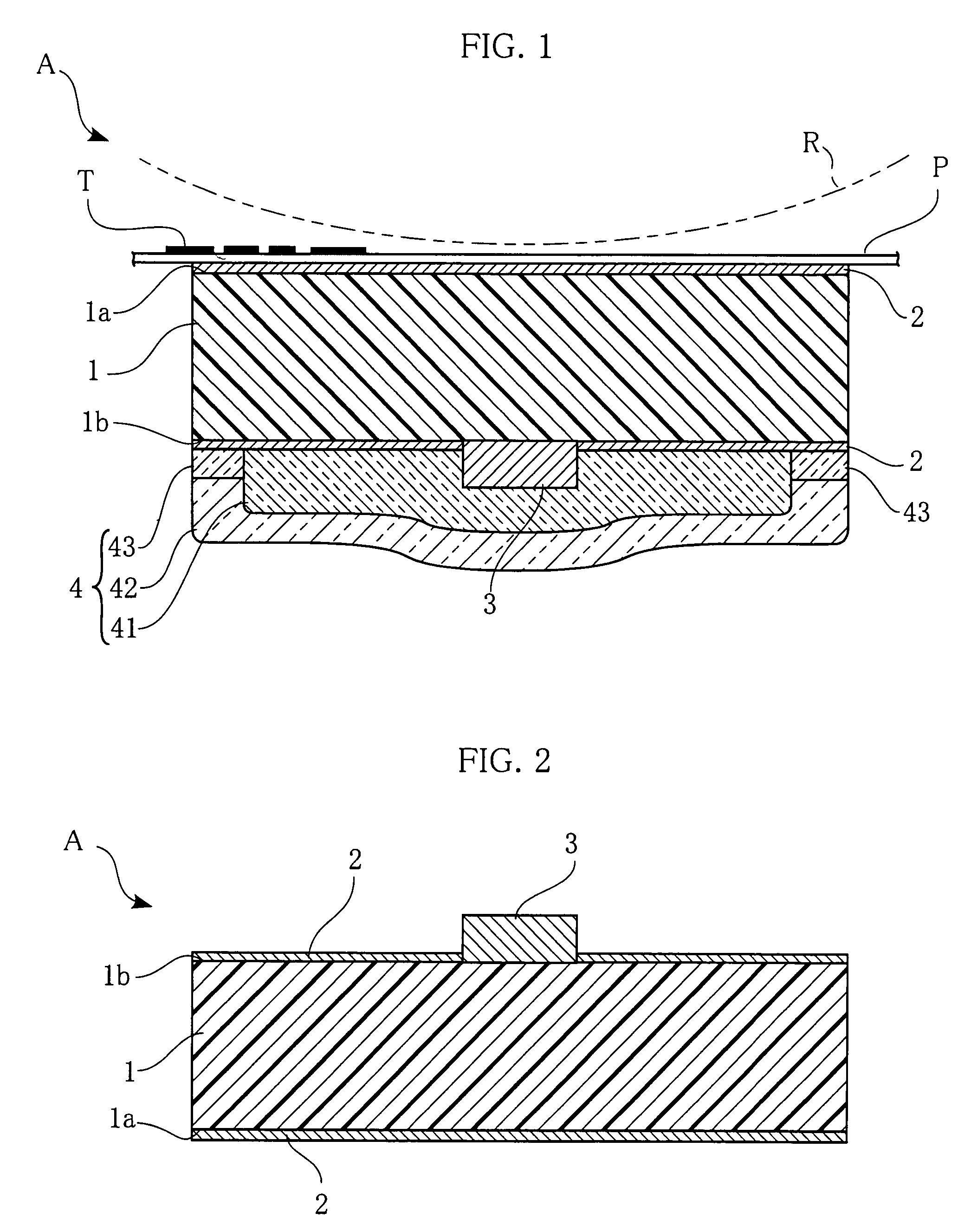

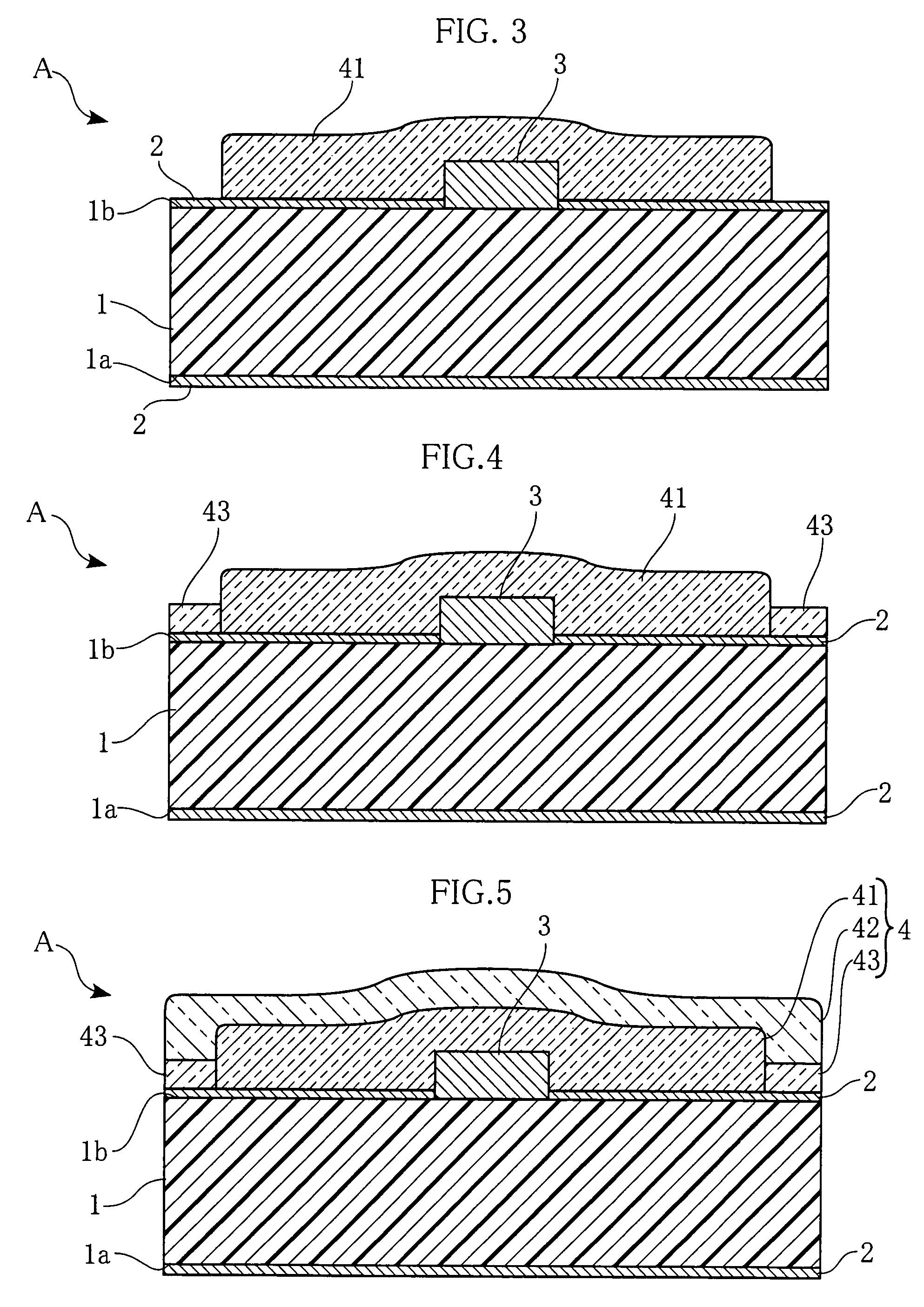

Analyzing tool being reduced in distance of diffusion of reagent and method for manufacture thereof

InactiveUS20070053790A1Shorten analysis timeAccurate analysisAnalysis using chemical indicatorsLaboratory glasswaresDiffusionAnalysis tools

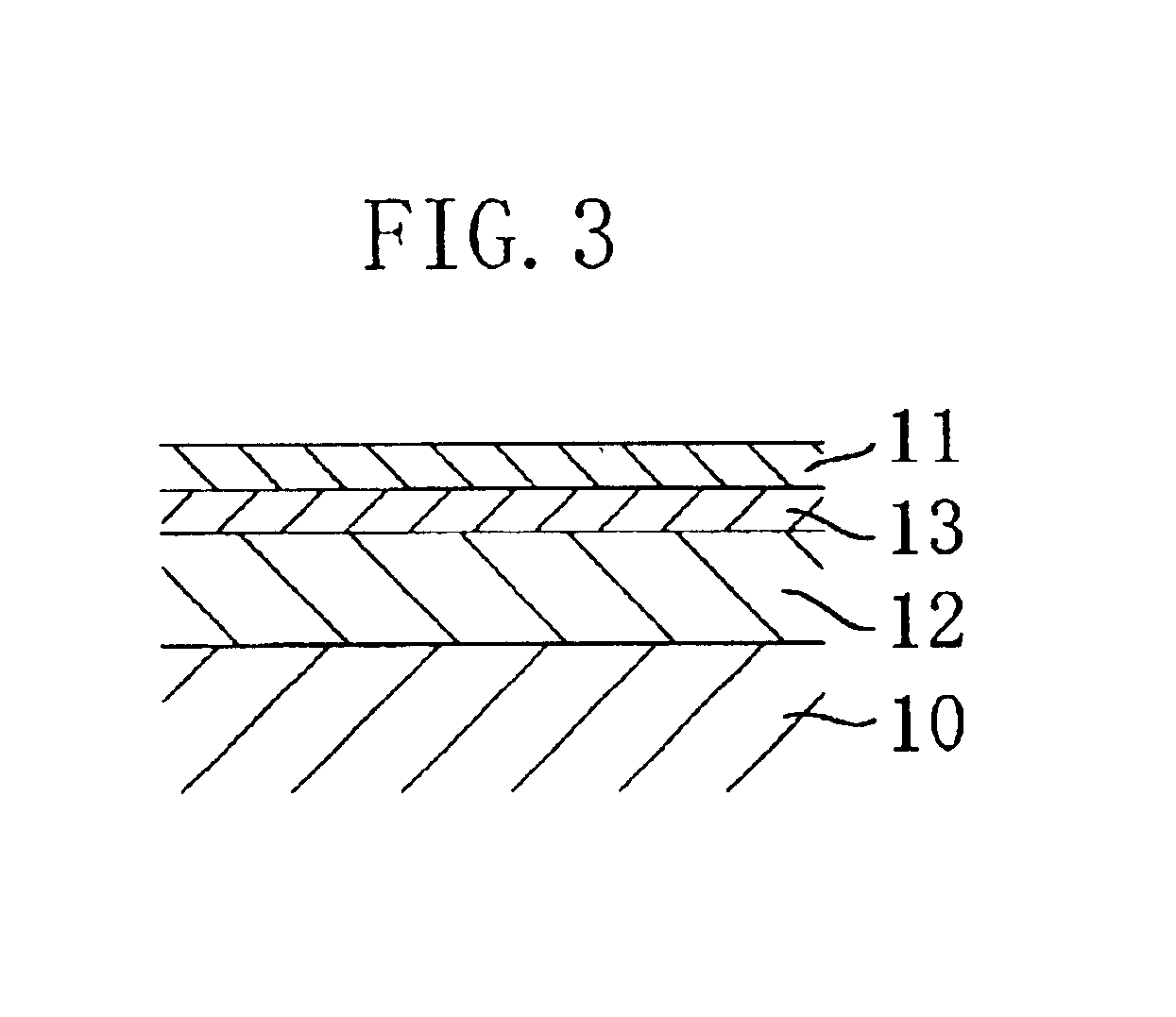

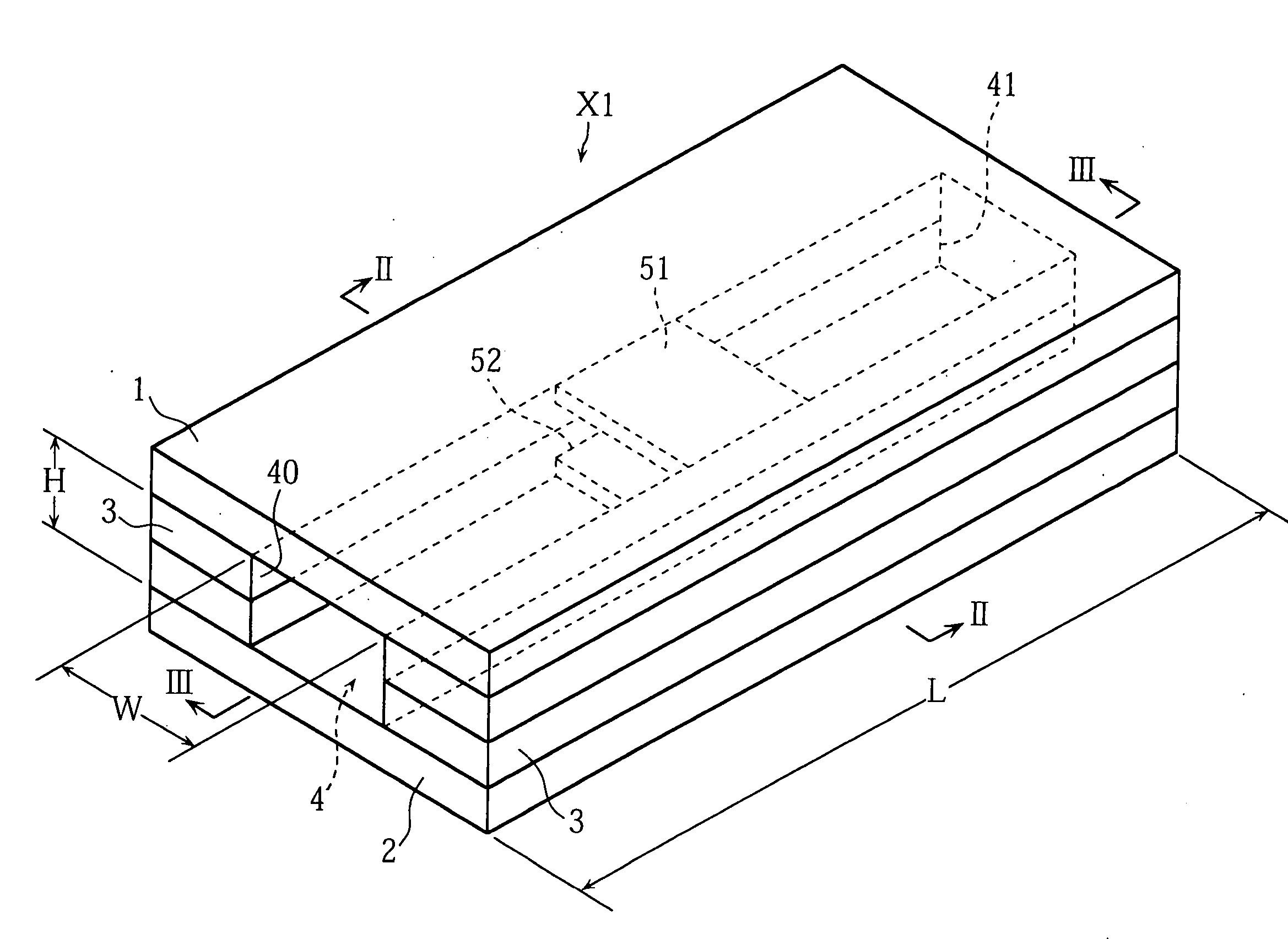

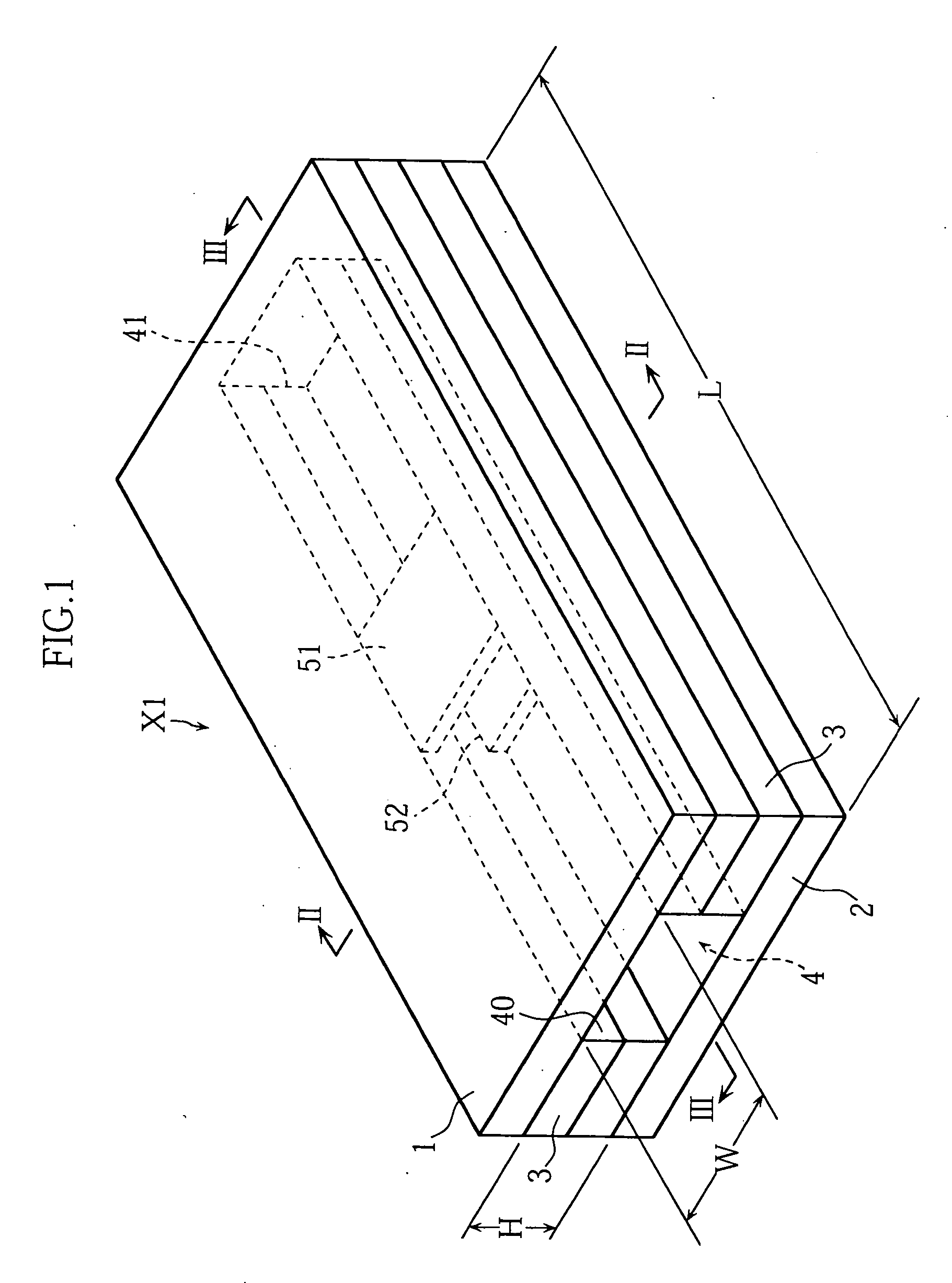

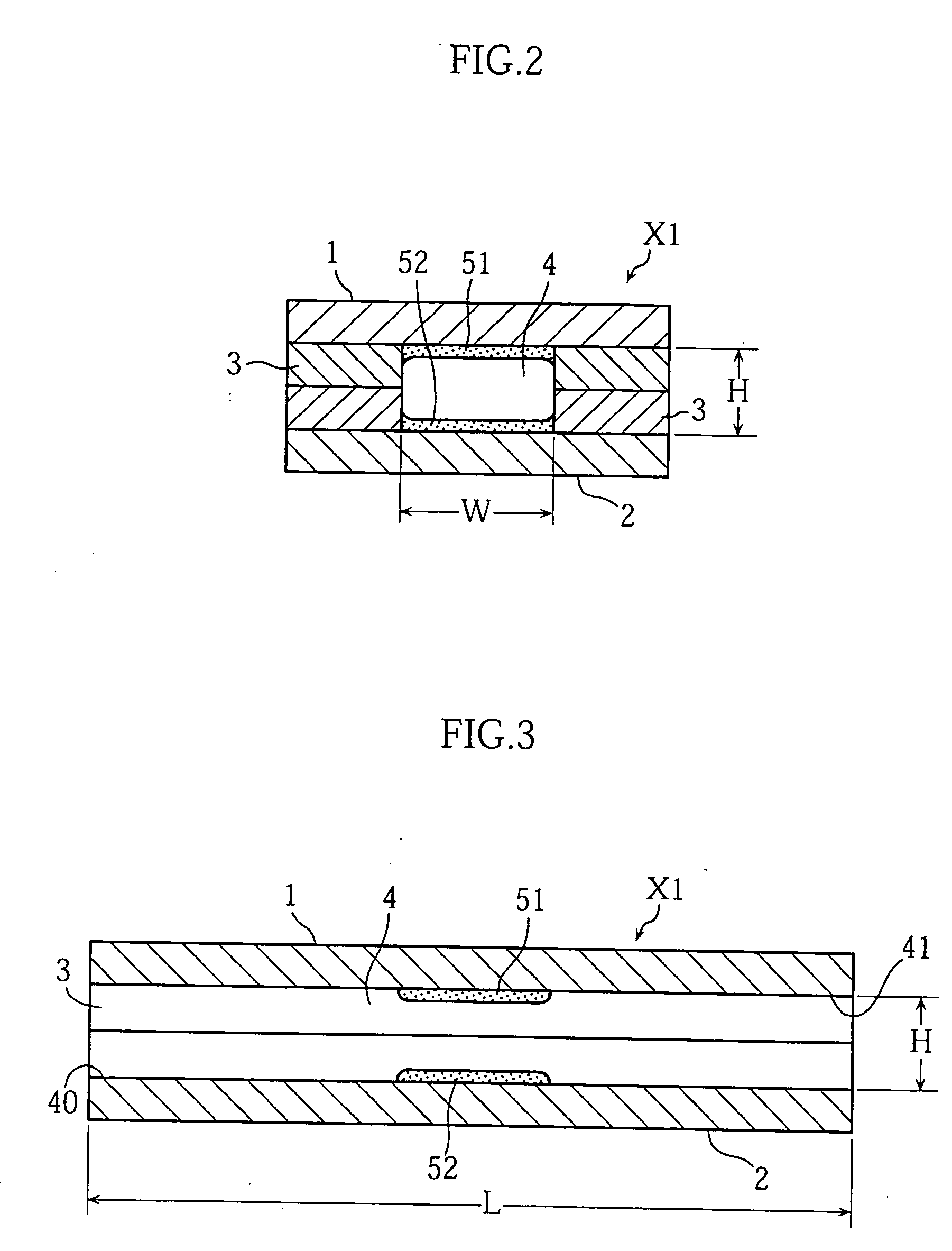

The present invention relates to an analyzing tool (X1) including a reaction space (4) for allowing a particular component contained in a sample and a reagent to react with each other, and a reagent portion (51, 52) which is arranged in the reaction space (4) and which dissolves when the sample is supplied to the reaction space (4). The reagent portion (51, 52) includes a first part (51) and a second part (52) facing each other at a defining surface defining the reaction space (4).

Owner:ARKRAY INC

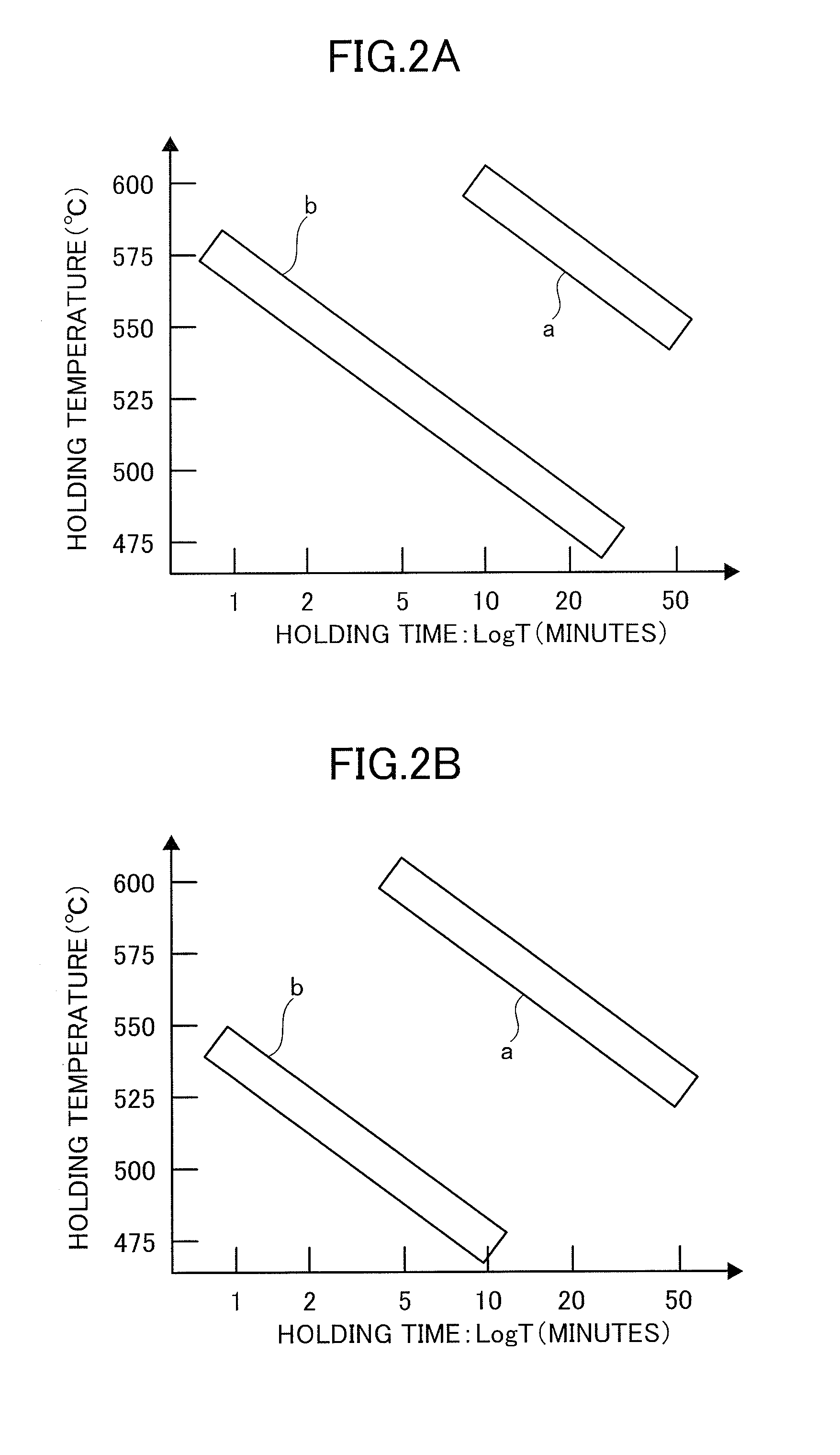

Heating unit and method of making the same

InactiveUS7928347B2Improve pressure resistanceShort timeSemiconductor/solid-state device detailsSolid-state devicesCrystallization temperatureEngineering

A heating unit includes an AlN substrate having a main surface on which an elongated heat-generating resistor is provided. A protection layer is formed on the main surface of the substrate for the heat-generating resistor. The protection layer includes a first cover layer covering the heat-generating resistor and a second cover layer covering the first cover layer. The first cover layer is made of crystallized or semi-crystallized glass having a higher crystallization temperature by at least 50° C. than the softening point of the glass. The second cover layer is made of non-crystalline glass.

Owner:ROHM CO LTD

Alkaline Battery

InactiveUS20080070114A1Easy to compressImprove electronic conductivityAlkaline accumulatorsAlkaline accumulator electrodesGraphiteMetallic Nickel

An alkaline battery including a positive electrode, a negative electrode and an alkaline electrolyte, wherein the positive electrode includes a positive electrode material mixture including nickel oxyhydroxide, electrolytic manganese dioxide and expanded graphite, the expanded graphite has an average particle diameter on a volume basis of 5 to 25 μm, a BET specific surface area of 4 to 10 m2 / g, and a bulk specific gravity (apparent density) measured by a static method of 0.03 to 0.10 g / cm3, the nickel oxyhydroxide has an average nickel valence of not less than 3.05, and a content of the expanded graphite in a total amount of the nickel oxyhydroxide, the electrolytic manganese dioxide and the expanded graphite that are included in the positive electrode material mixture of 3 to 15 wt %.

Owner:PANASONIC CORP

Method for manufacturing thin film transistor

InactiveUS8569120B2Improve mobilityHigh currentSolid-state devicesSemiconductor/solid-state device manufacturingNoble gasImpurity

An object is to provide a method for manufacturing a thin film transistor having favorable electric characteristics, with high productivity. A gate electrode is formed over a substrate and a gate insulating layer is formed over the gate electrode. A first semiconductor layer is formed over the gate insulating layer by generating plasma using a deposition gas containing silicon or germanium, hydrogen, and a rare gas. Next, a second semiconductor layer including an amorphous semiconductor and a microcrystal semiconductor is formed in such a manner that the first semiconductor layer is partially grown as a seed crystal by generating plasma using a deposition gas containing silicon or germanium, hydrogen, and a gas containing nitrogen. Then, a semiconductor layer to which an impurity imparting one conductivity is added is formed and a conductive film is formed. Thus, a thin film transistor is manufactured.

Owner:SEMICON ENERGY LAB CO LTD

High-purity vitreous silica crucible used for pulling large-diameter single-crystal silicon ingot

ActiveUS8888915B2High strengthPinhole defectAfter-treatment apparatusPolycrystalline material growthCrucibleCrystal structure

A high-purity vitreous silica crucible which has high strength and is used for pulling a large-diameter single-crystal silicon ingot, includes a double laminated structure constituted by an outer layer composed of amorphous silica glass with a bubble content of 1 to 10% and a purity of 99.99% or higher and an inner layer composed of amorphous silica glass with a bubble content of 0.6% or less and a purity of 99.99% or higher, and in the portion between the upper opening end of the high-purity vitreous silica crucible and the ingot-pulling start line of a silicon melt surface in the step of pulling a single-crystal silicon ingot, a portion corresponding to 40 to 100 volume % from the upper opening end of the crucible is in a crystalline structure free from the crystallization promoter.

Owner:SUMCO CORP

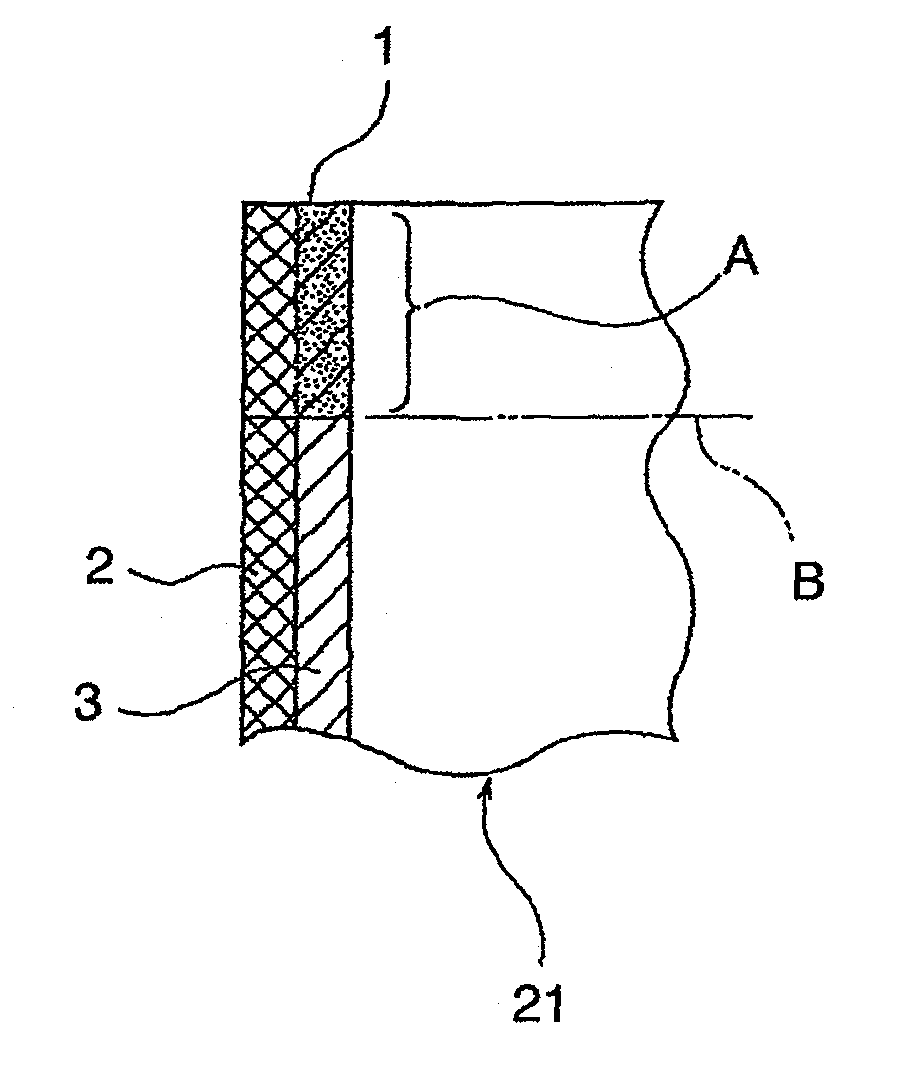

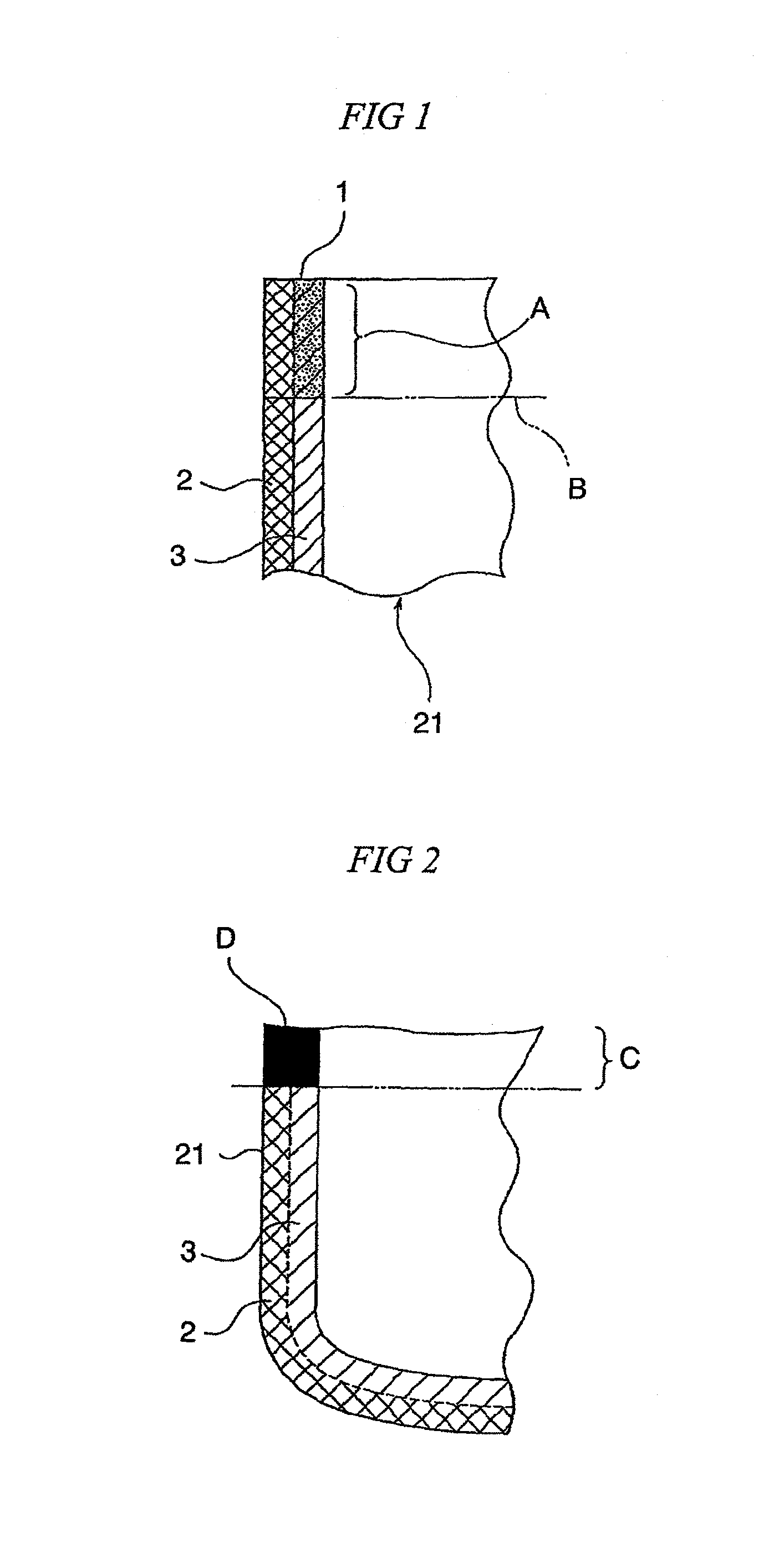

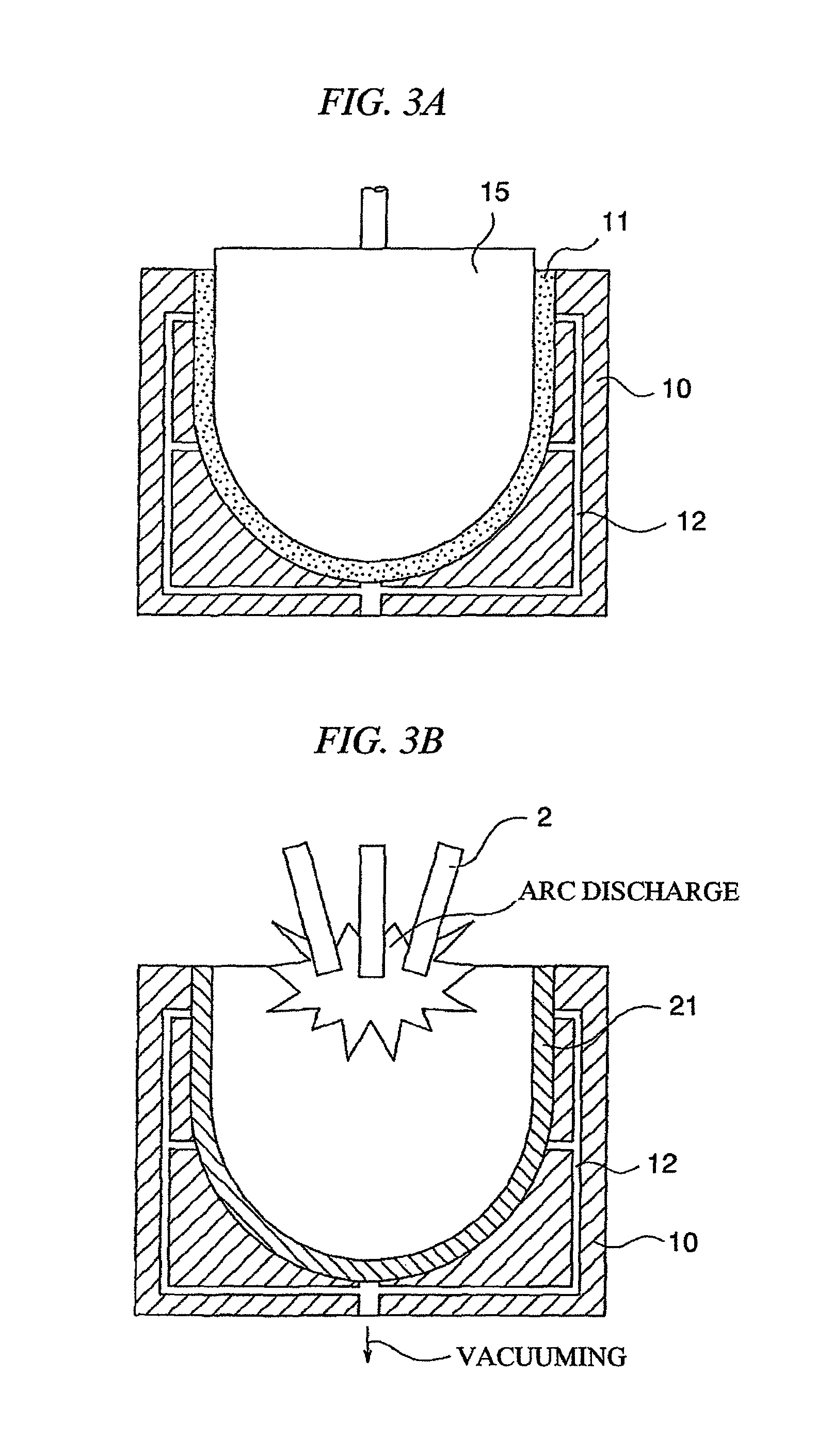

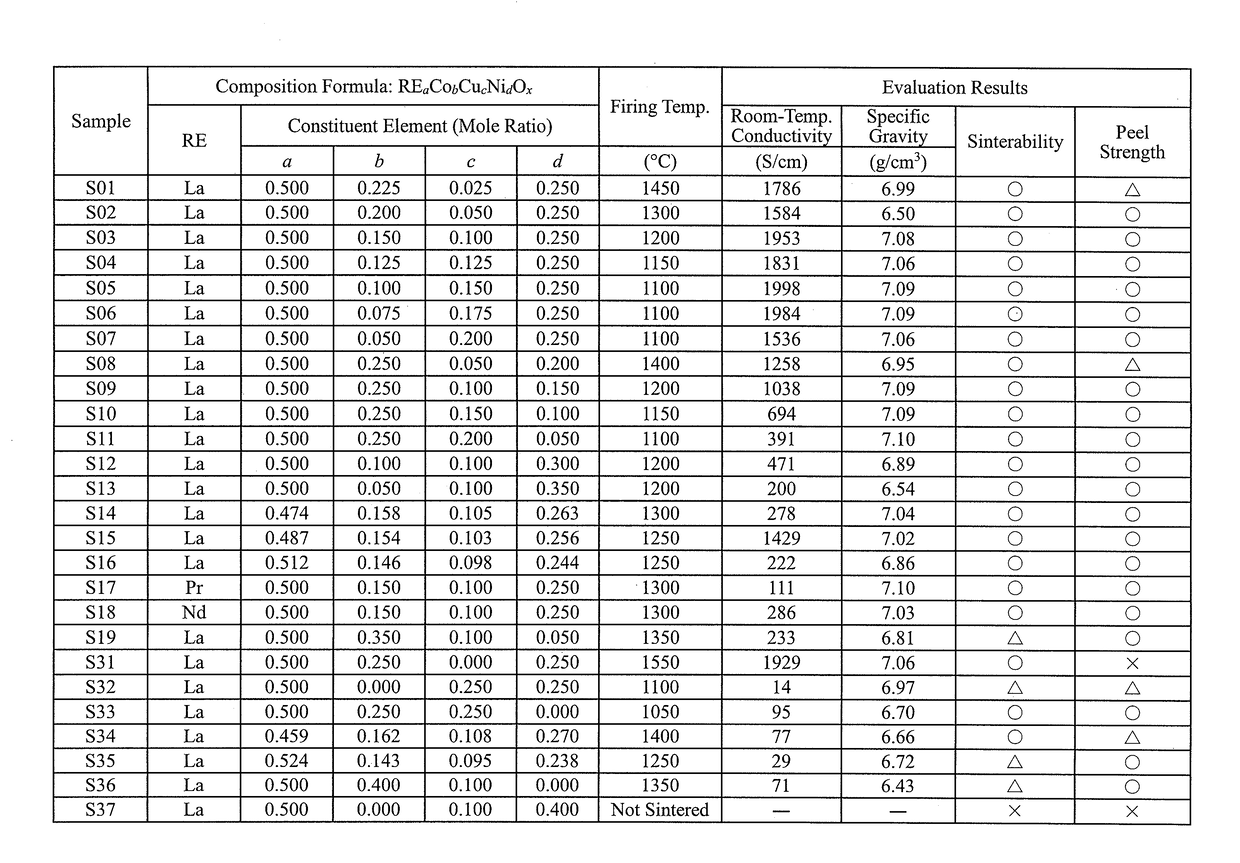

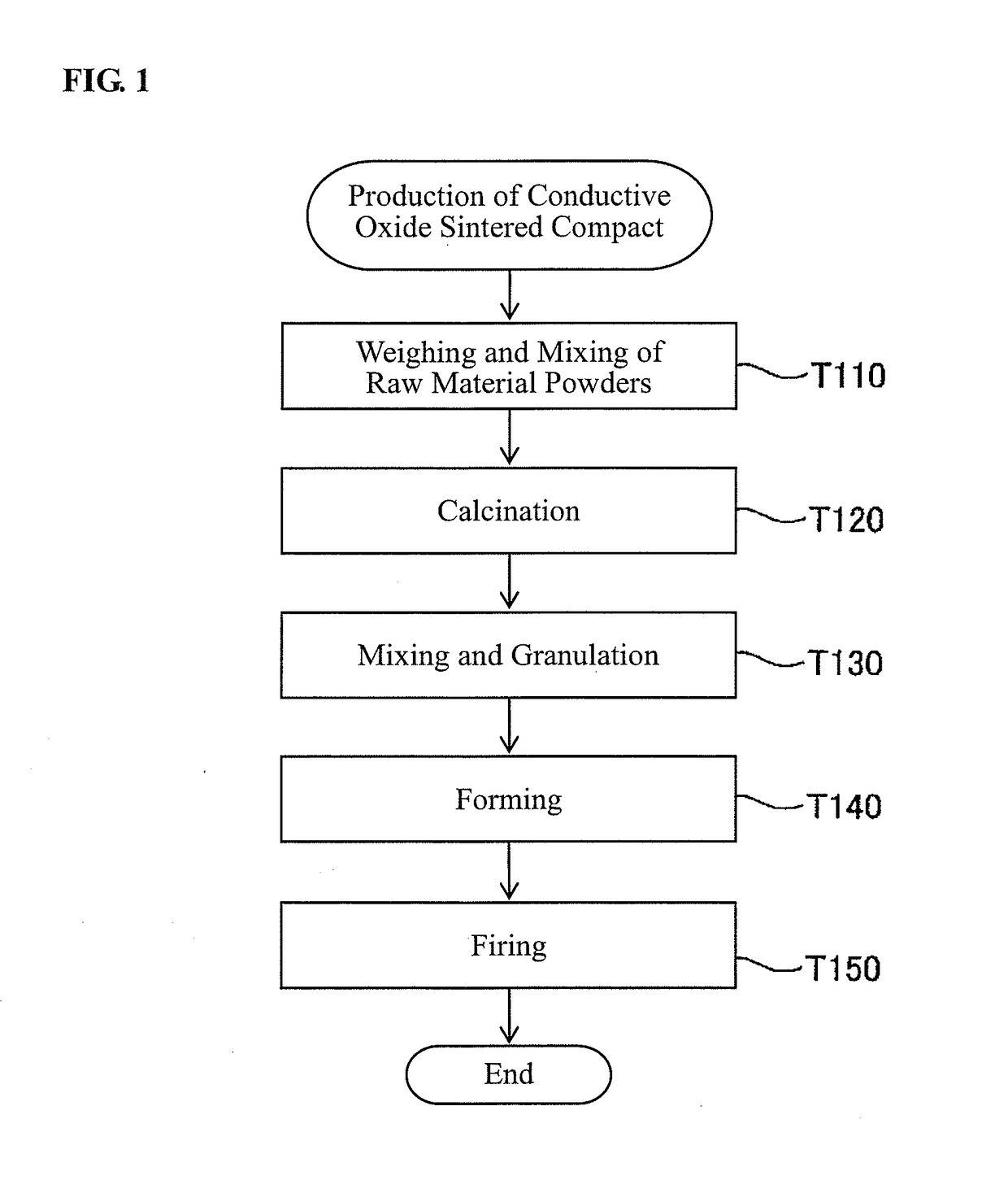

Electrically conductive oxide sintered compact, member for electrical conduction, gas sensor, piezoelectric element, and method for producing piezoelectric element

ActiveUS20180330843A1Impair it propertySuppress occurrenceMaterial analysis using sonic/ultrasonic/infrasonic wavesMaterial analysis by electric/magnetic meansRare-earth elementElectrically conductive

Owner:NGK SPARK PLUG CO LTD

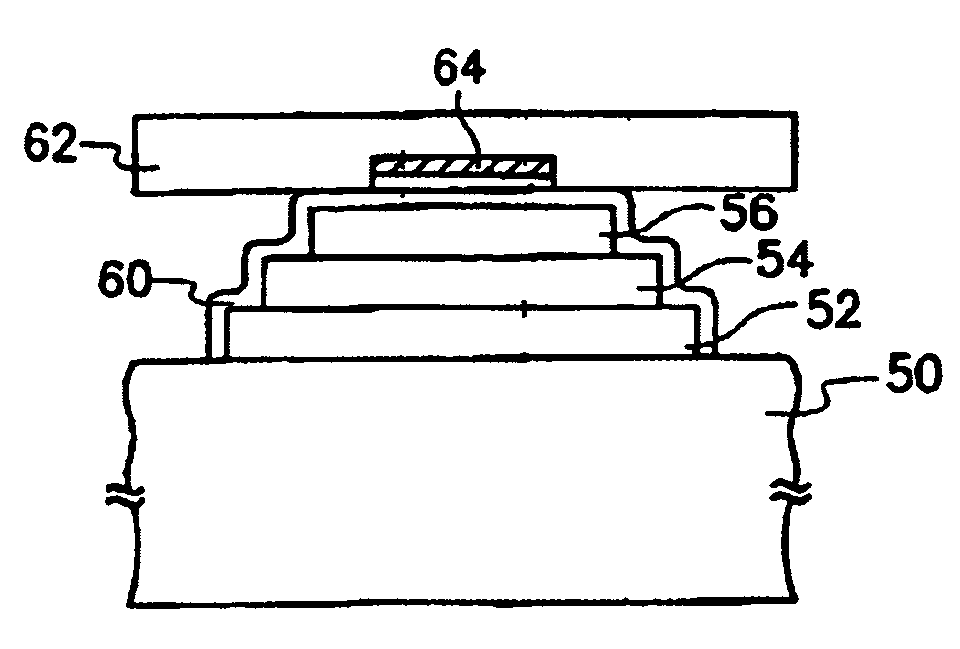

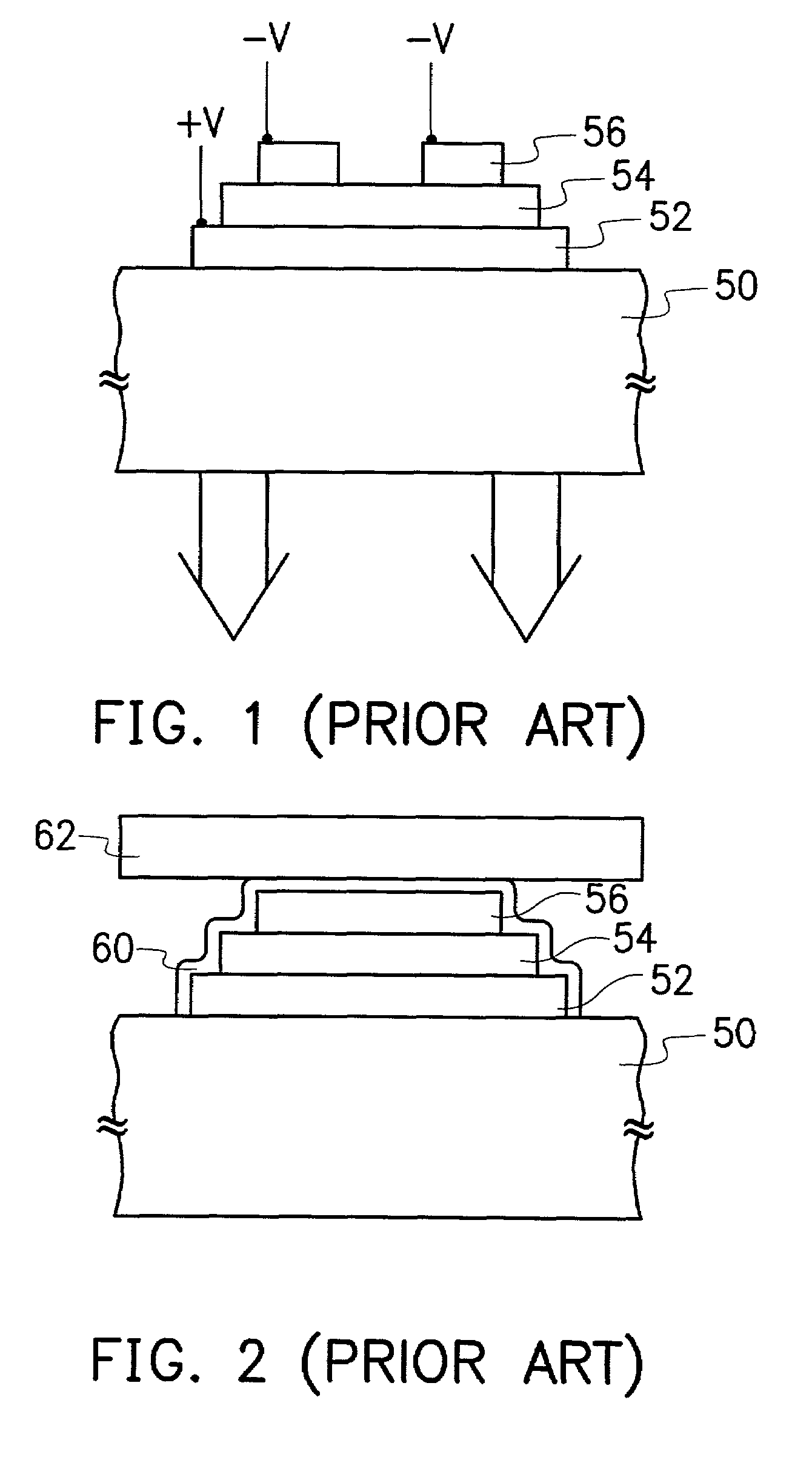

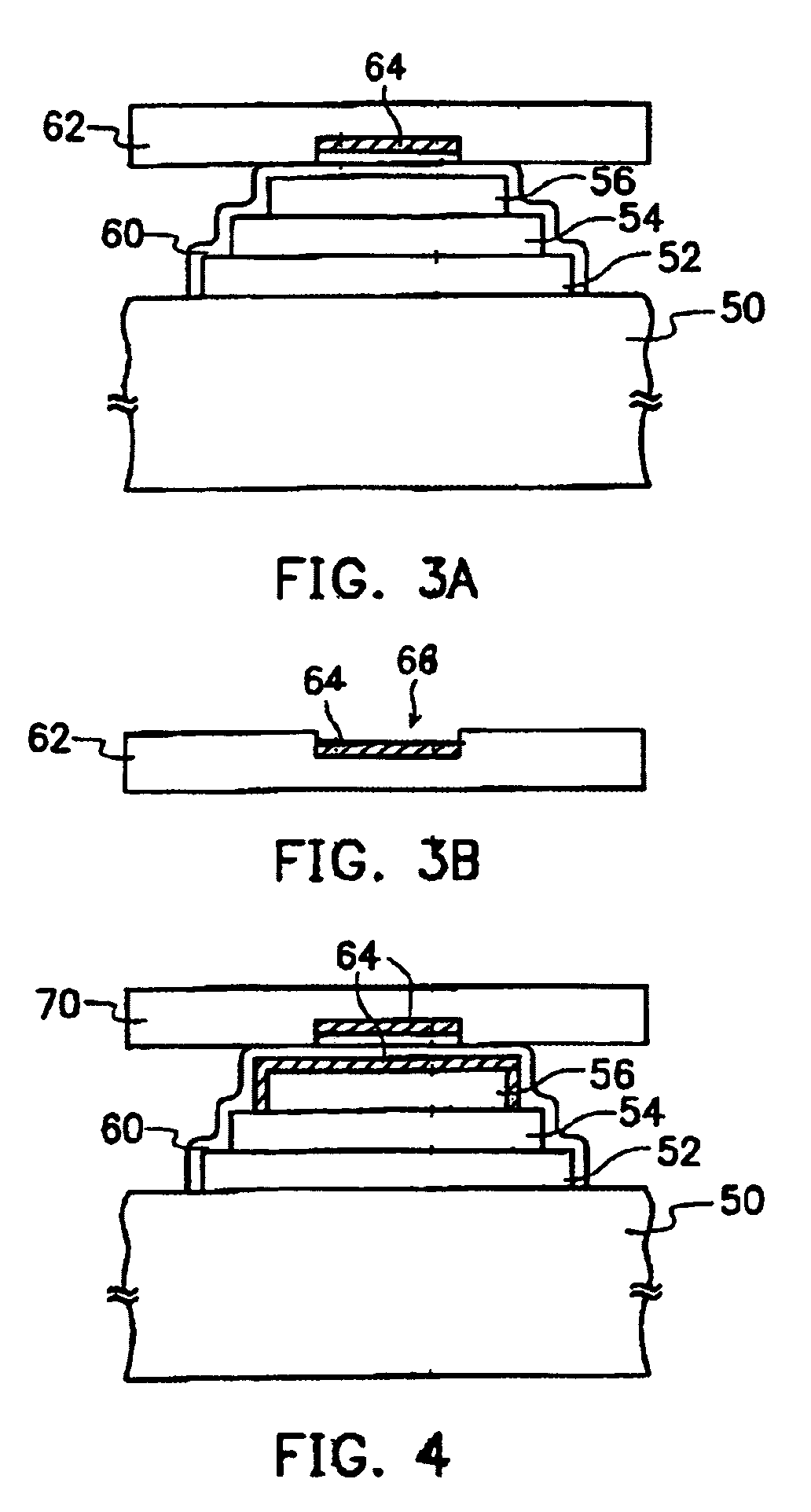

Method for forming a thin film light emitting device

InactiveUS6984546B2Small increase in lifetime of deviceReduce the possibilityLayered productsElectroluminescent light sourcesEvaporationSealant

A method is to form a thin film light emitting device. The method includes providing a transparent substrate. A transparent anode layer, a light emitting layer, a metal cathode layer are sequentially formed on the transparent substrate. A sealant layer is formed to at least cover the light emitting layer and the metal cathode layer. A covering layer having a covering surface is provided. An evaporation process is performed to form an active absorption layer on the covering surface of the covering layer. The covering surface of the covering layer covers on a portion of the sealant layer above the metal cathode layer. The covering layer can have a recess region that is to be formed the active absorption layer thereon. Alternatively, the active absorption layer can be evaporated before the sealant is formed. Moreover, the active absorption layer can be replaced with an insulating layer.

Owner:DELTA OPTOELECTRONICS

Non-aqueous electrolyte secondary battery and method for producing the same

ActiveUS9331337B2Increase battery capacityImprove featuresFinal product manufacturePrimary cellsLutetiumPhosphate

A positive electrode active material with least part of a surface coated with a surface treatment layer composed of a phosphate compound. The phosphate compound contains at least one element selected from the group consisting of neodymium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, and lutetium.

Owner:PANASONIC ENERGY CO LTD

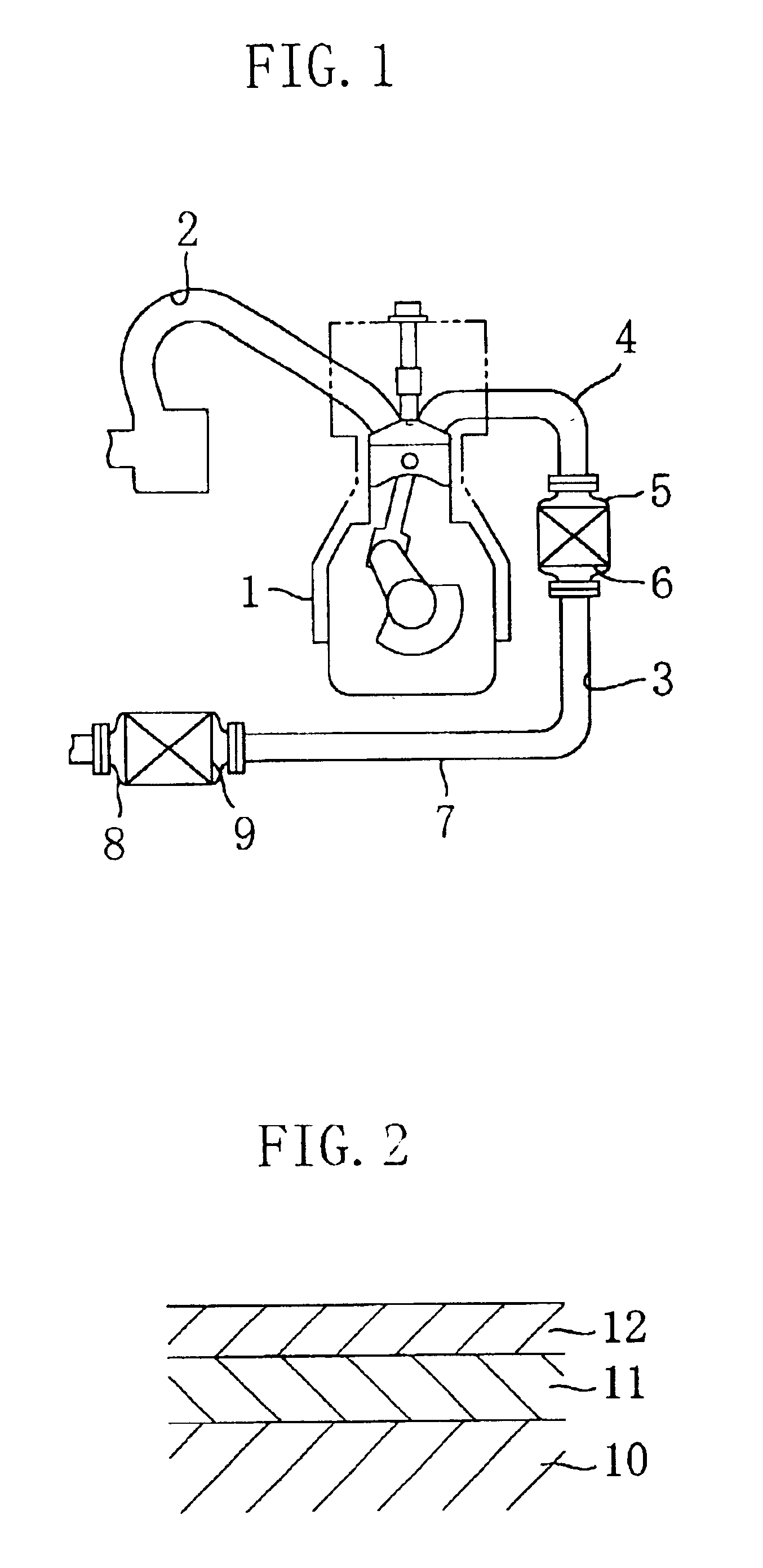

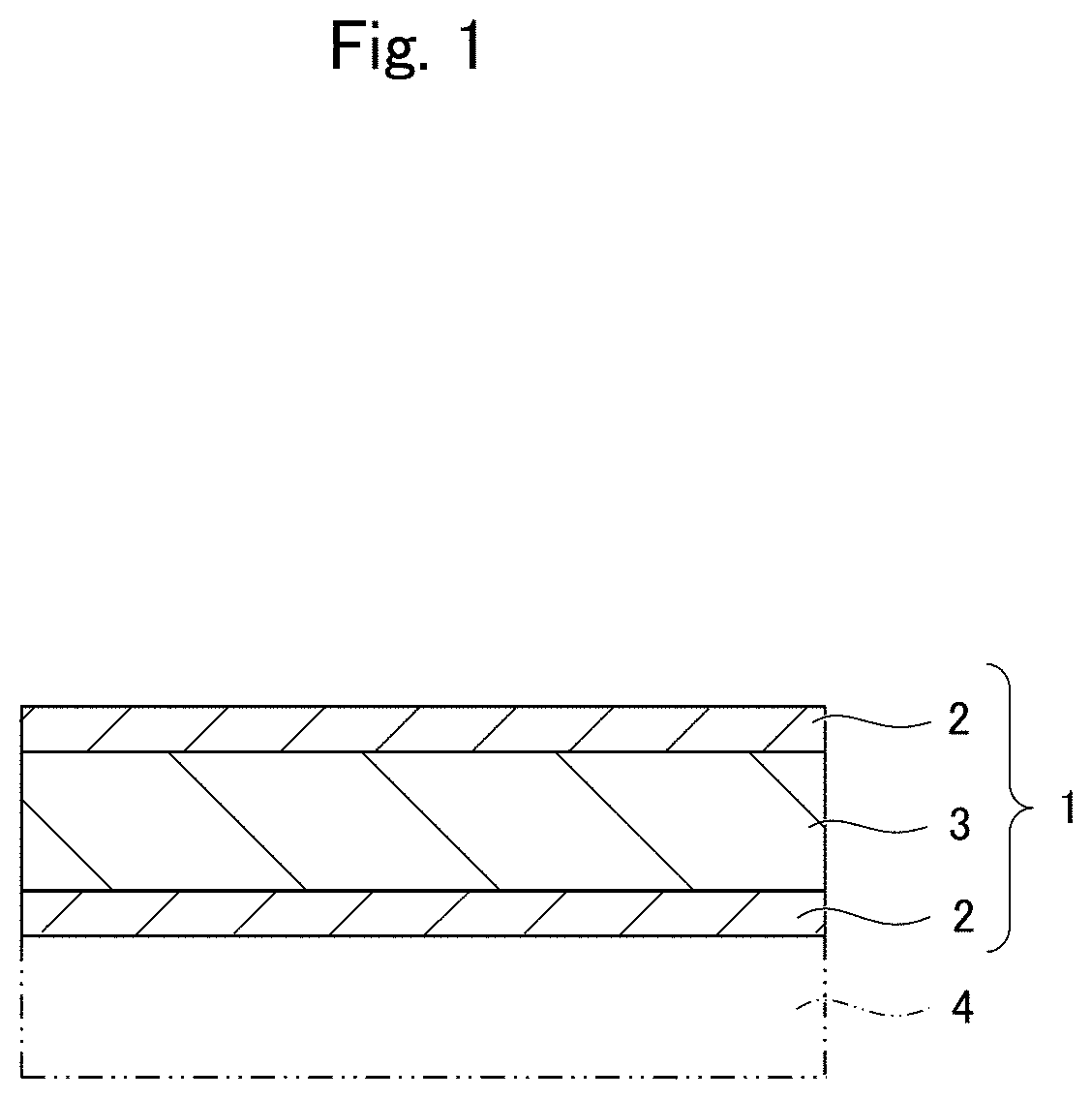

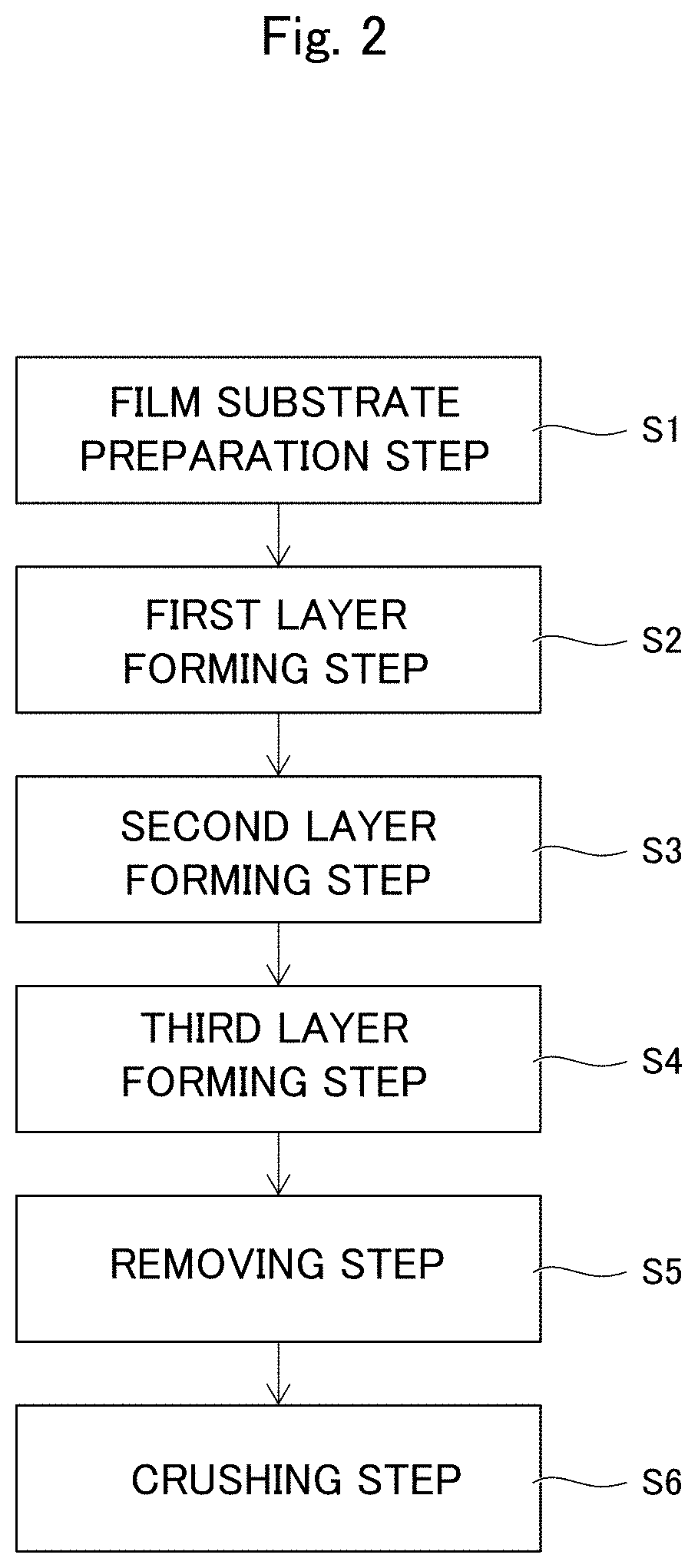

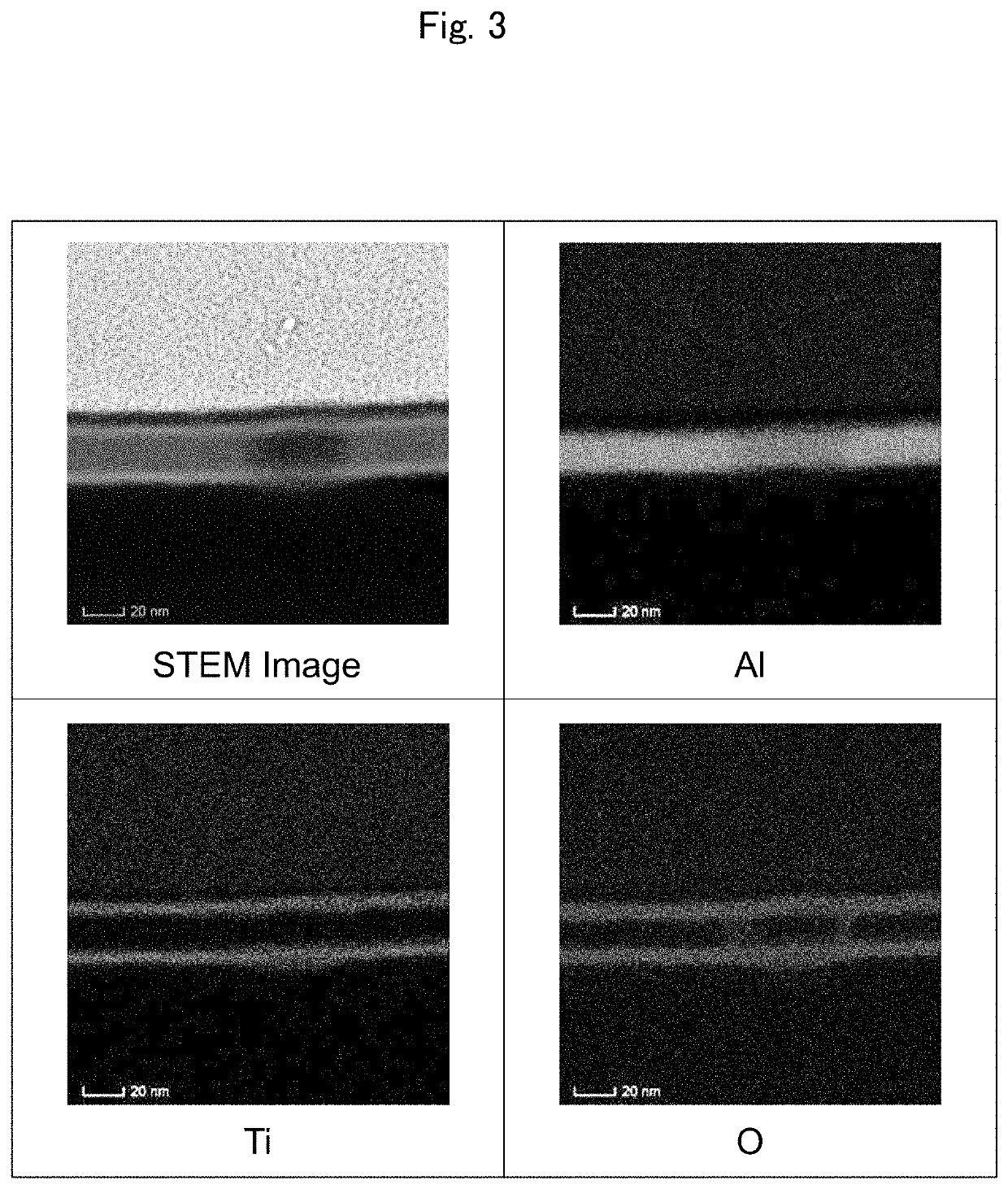

Luster pigment and method for producing the same

InactiveUS20200148887A1Inhibitory responseReactionCoatingsPigment physical treatmentPhotopigmentTitanium

A method for producing a luster pigment containing a plurality of scaly pigment particles that is capable of suppressing reactions between an aluminum layer as a core layer of each pigment particle and water, even when the luster pigment is exposed to atmosphere containing oxygen or water. The method includes forming a first layer on a surface of a film substrate through deposition of titanium as material, forming a second layer on a surface of the first layer through deposition of aluminum as material, and forming a third layer on a surface of the second layer through deposition of titanium as material, so as to form a stack including the first layer, second layer, and third layer stacked in sequence on the surface of the film substrate, and removing the stack from the film substrate and crushing the removed stack, so as to produce the plurality of scaly pigment particles.

Owner:TOYOTA JIDOSHA KK +1

Water-based inkjet ink and method for producing printed matter

InactiveUS20200172746A1Good storage stabilityProducing a printed matterDuplicating/marking methodsInksPolymer scienceOrganic chemistry

Provided is a water-based inkjet ink, comprising: a fluorine resin; a wetting agent; a pigment; a curing agent; and a water-based solvent, wherein the fluorine resin has a hydroxyl value of 10 to 30 mg KOH / g, and wherein the wetting agent does not comprise a hydroxy group.

Owner:SEIREN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com