Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

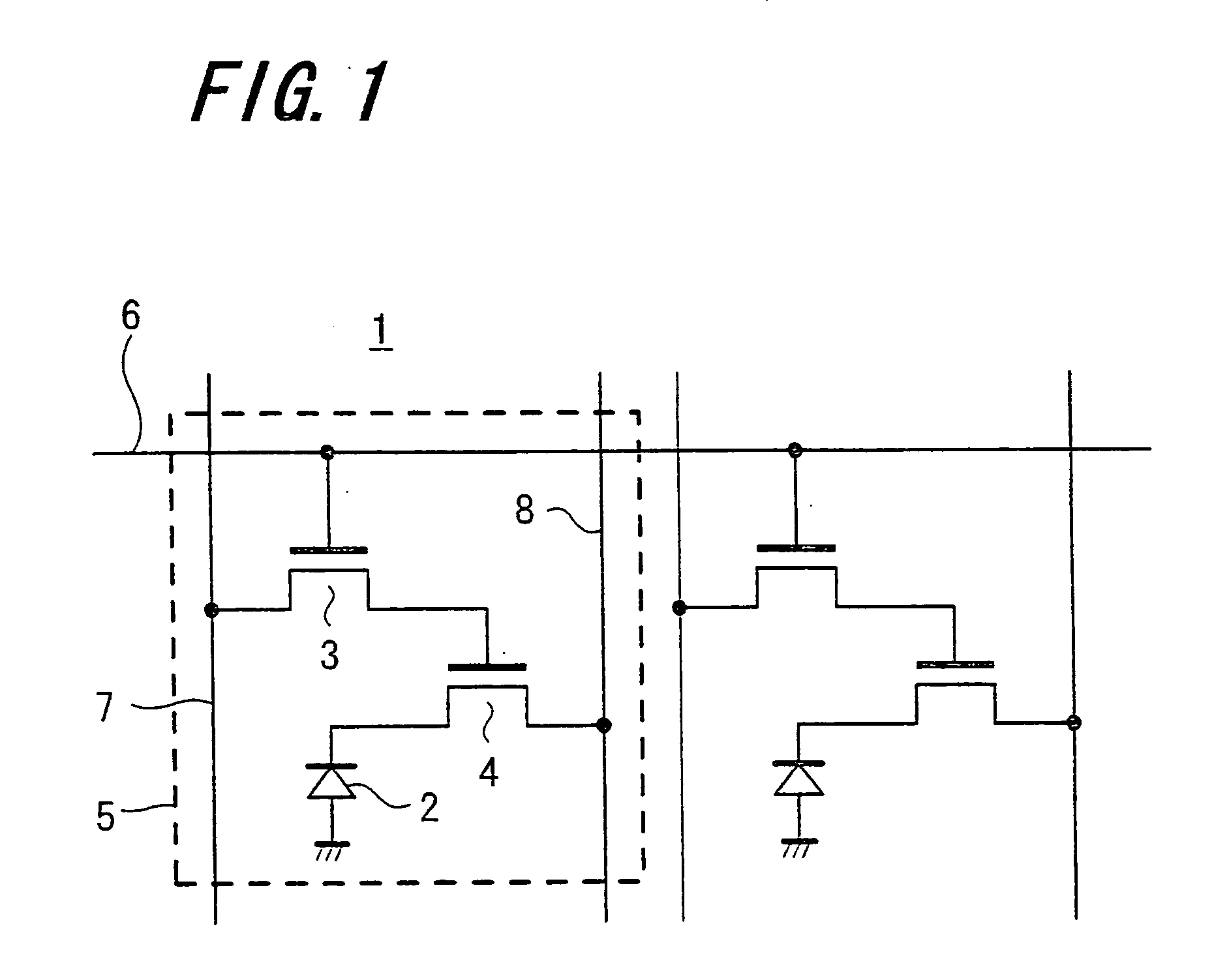

285results about How to "High precision forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

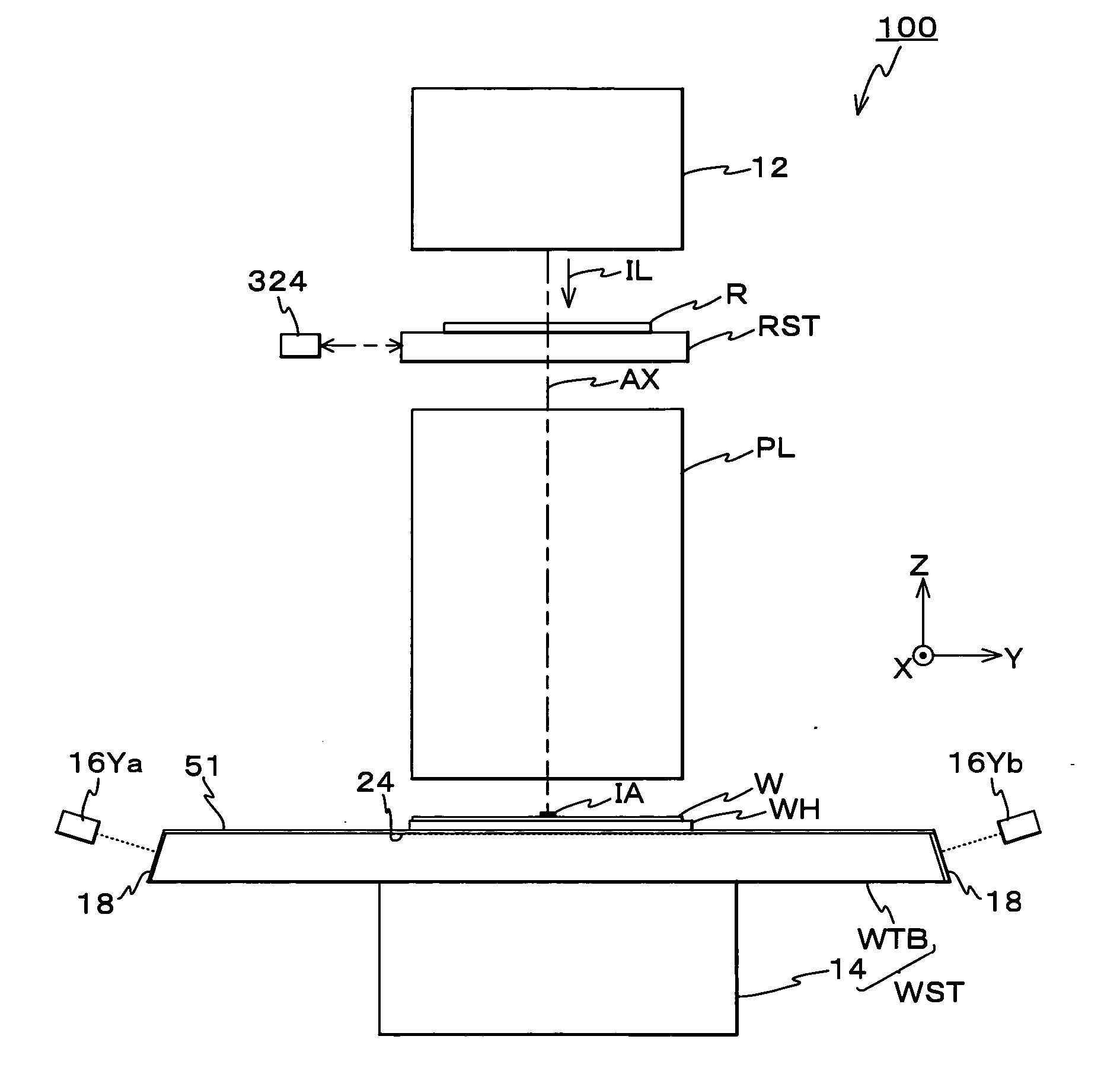

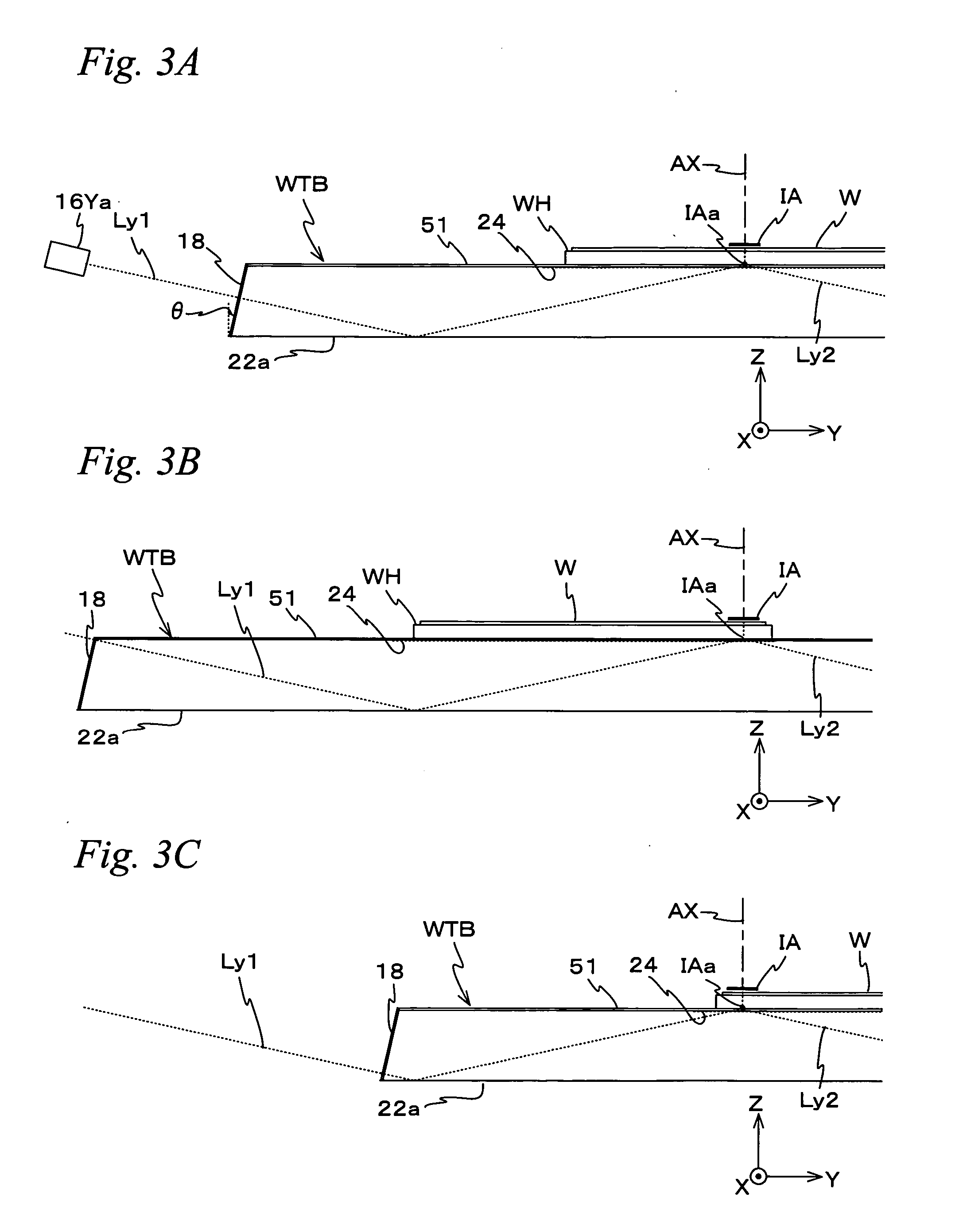

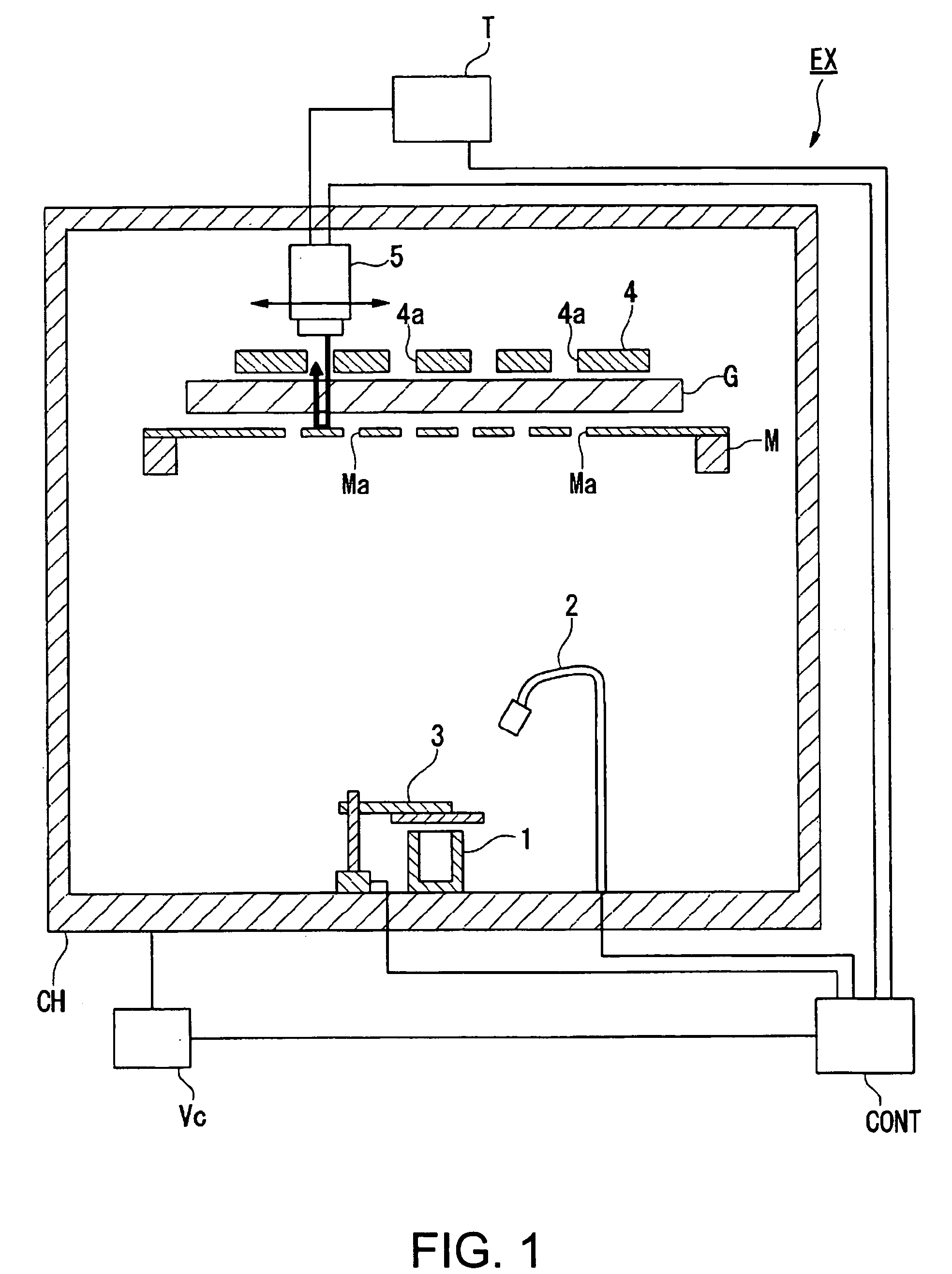

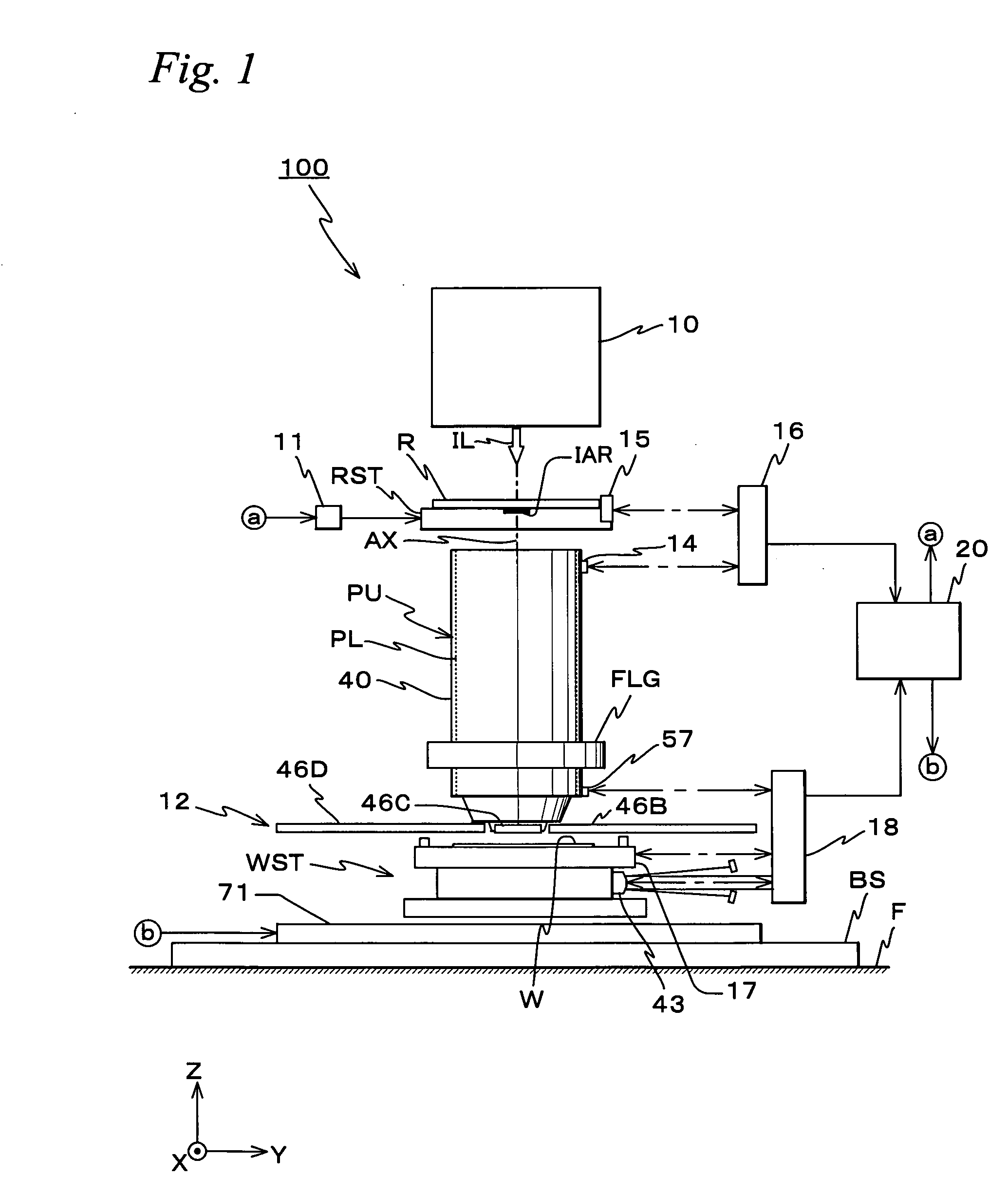

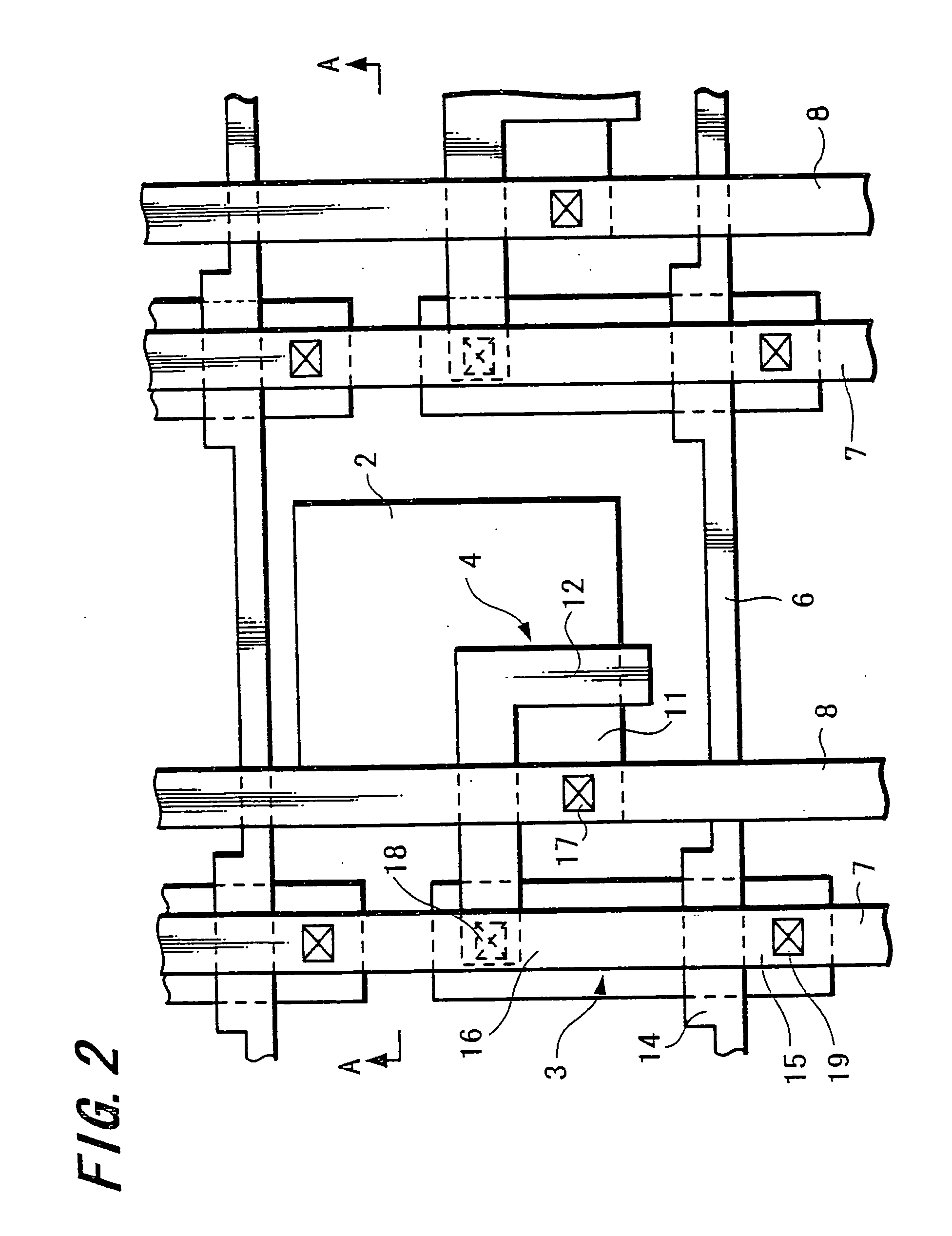

Movable body system, pattern formation apparatus, exposure apparatus and exposure method, and device manufacturing method

InactiveUS20080094594A1Small sizeImprove accuracyPhotomechanical apparatusSemiconductor/solid-state device manufacturingGratingLight beam

A laser beam emitted by an encoder main body enters a wafer table via a PBS from the outside, and reaches a grating at a point that is located right under exposure area, and is diffracted by the grating. Then, by receiving interference light of a first polarized component that has returned from the grating and a second polarized component reflected by the PBS, positional information of the wafer table is measured. Accordingly, because the first polarized component, which has passed through PBS passes through the wafer table until it is synthesized with the second polarized component again, does not proceed through the atmosphere outside, position measurement of the wafer table can be performed with high precision without the measurement beam being affected by the fluctuation of the atmosphere around the wafer table.

Owner:NIKON CORP

Substrate having film pattern and manufacturing method of the same, manufacturing method of semiconductor device, liquid crystal television, and EL television

InactiveUS20050158665A1Low costImprove throughputLiquid surface applicatorsOptical filtersDevice materialEngineering

The invention provides a manufacturing method of a substrate having a film pattern including an insulating film, a semiconductor film, a conductive film and the like by simple steps, and also a manufacturing method of a semiconductor device which is low in cost with high throughput and yield. According to the invention, after forming a first protective film which has low wettability on a substrate, a material which has high wettability is applied or discharged on an outer edge of a first mask pattern, thereby a film pattern and a substrate having the film pattern are formed.

Owner:SEMICON ENERGY LAB CO LTD

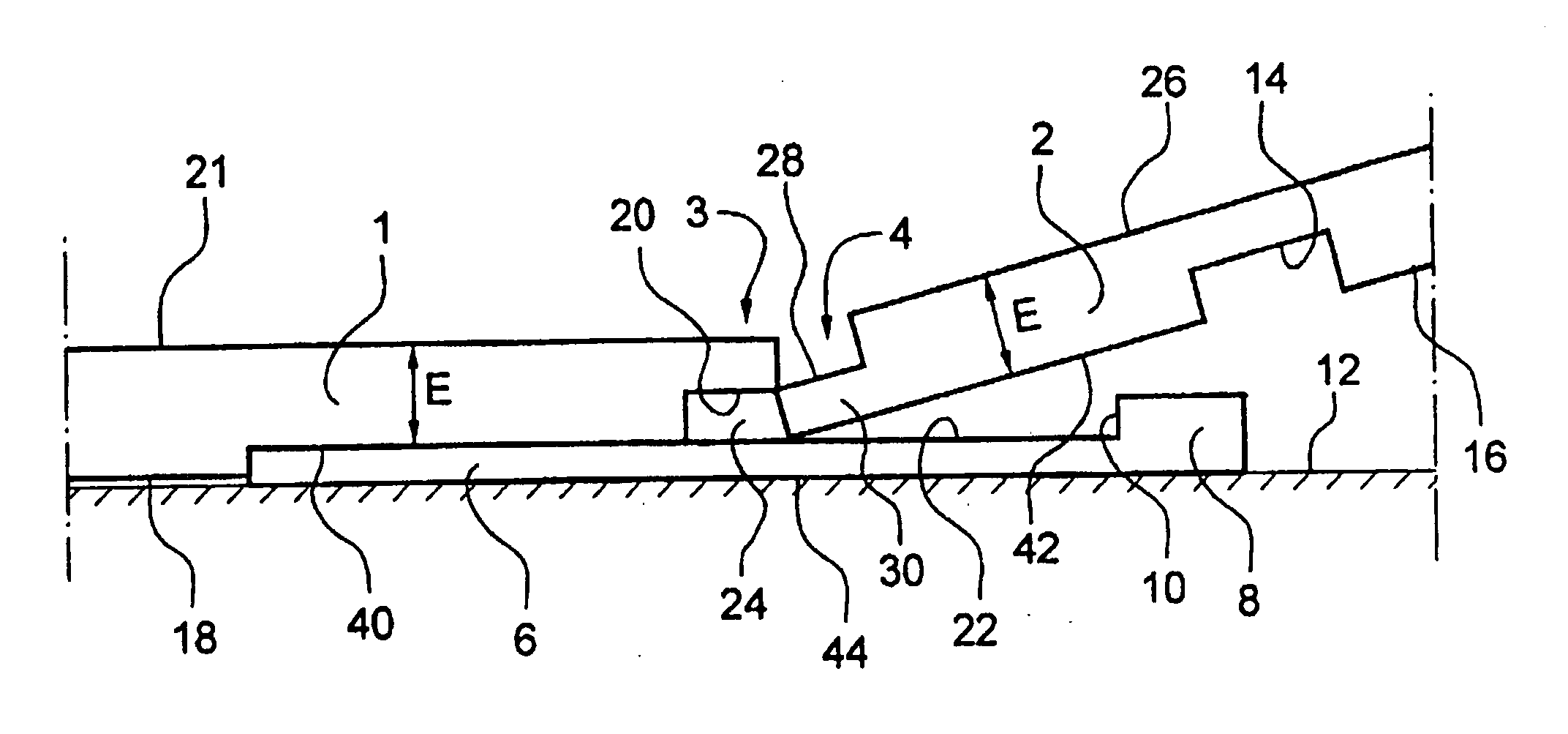

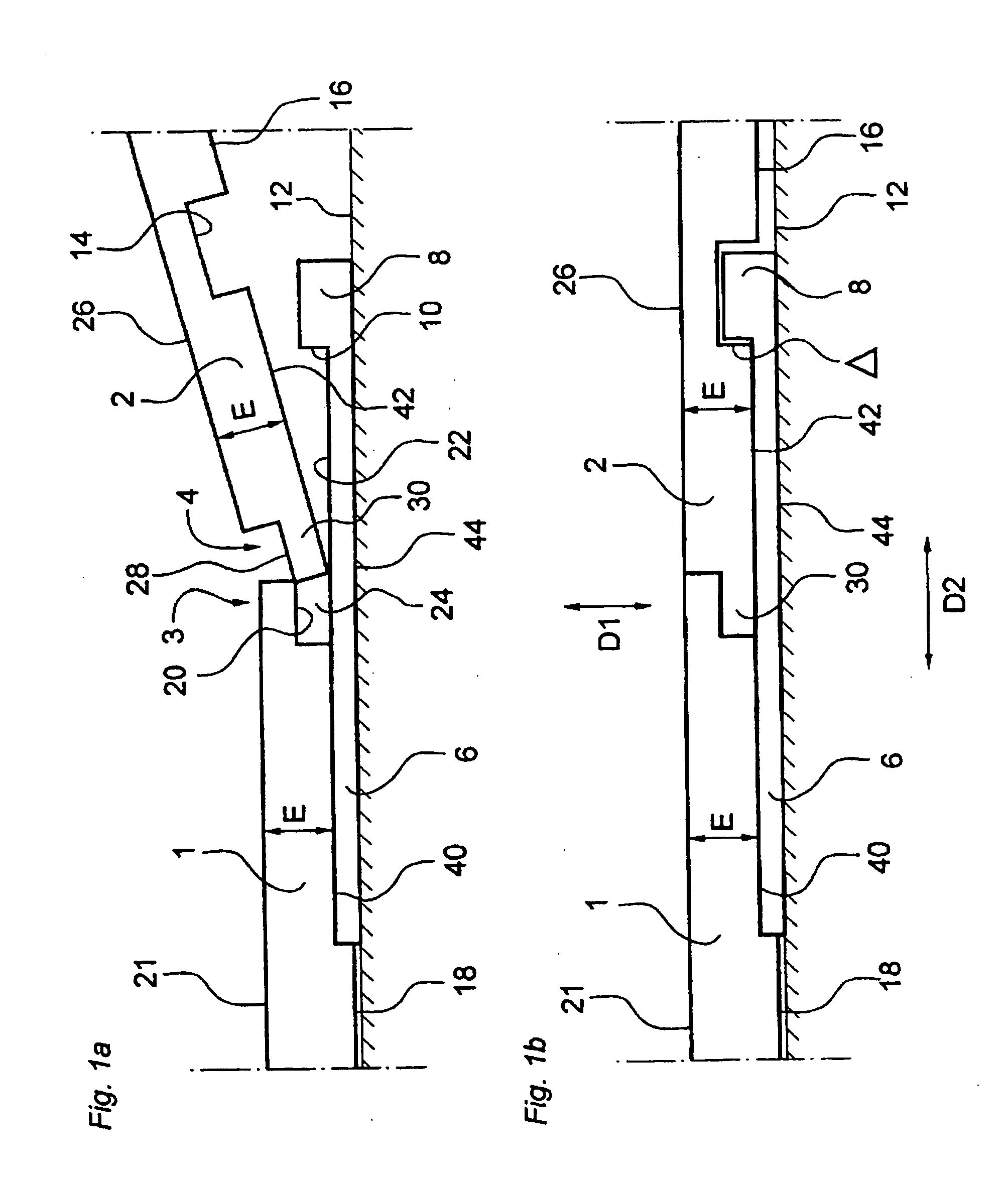

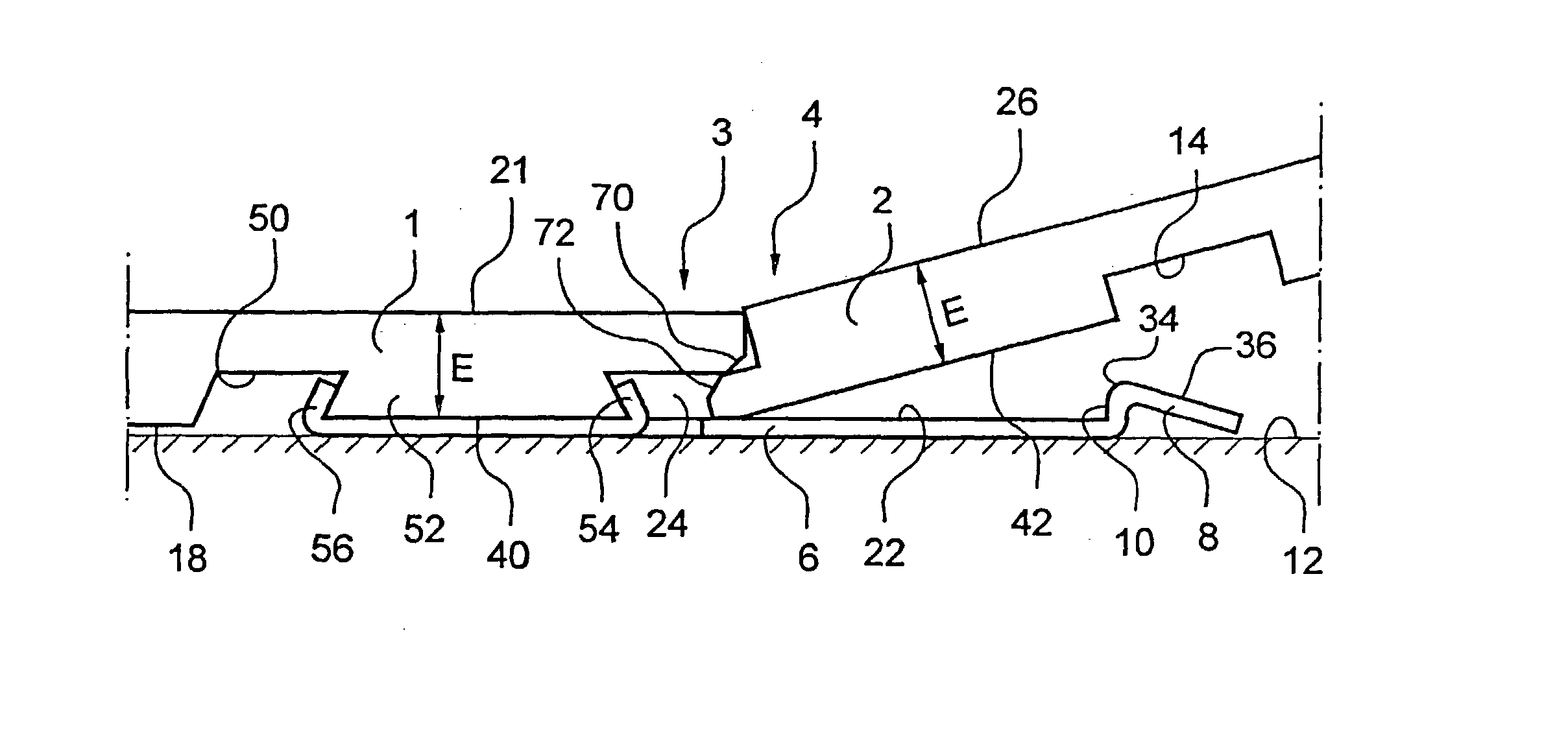

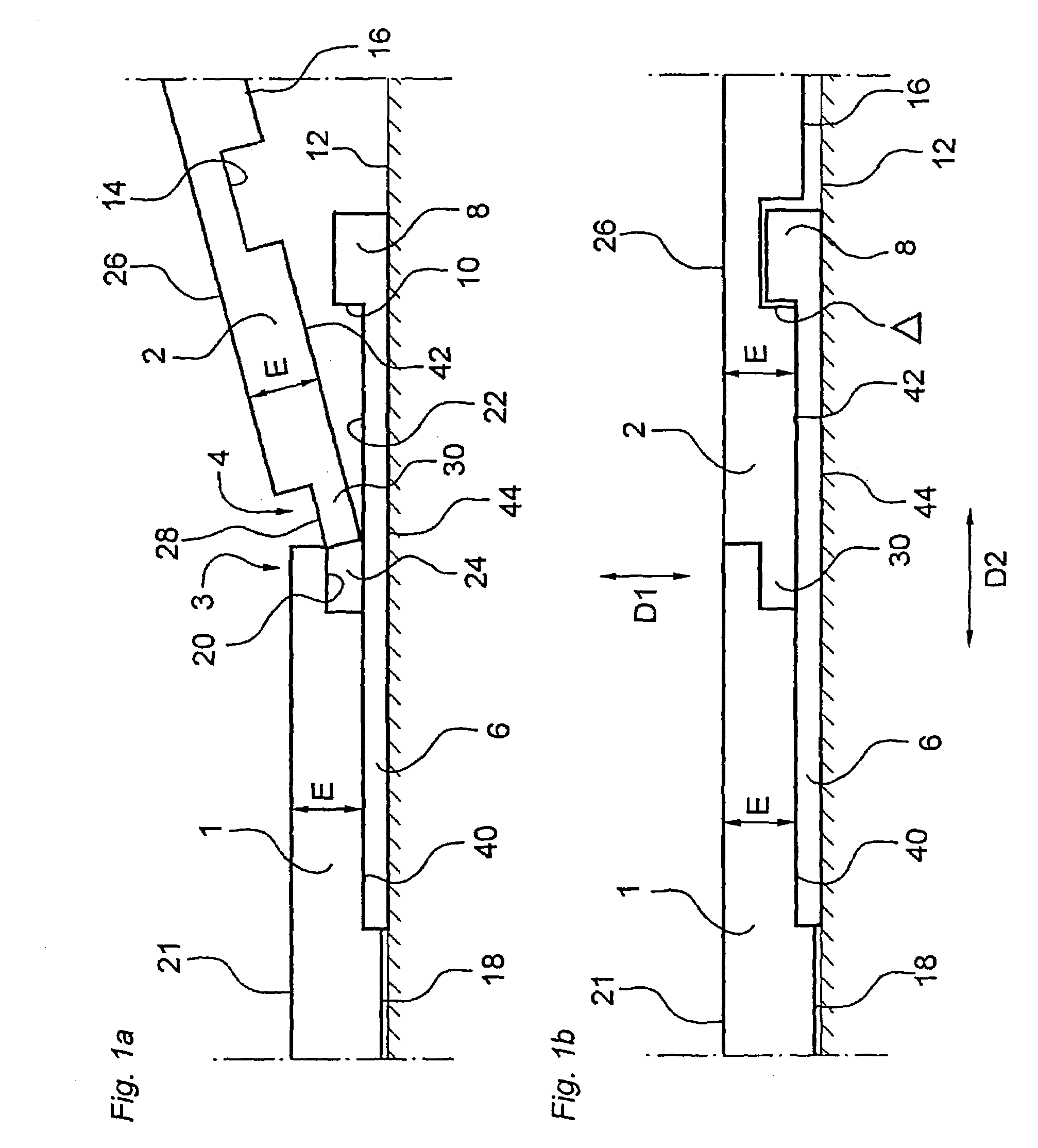

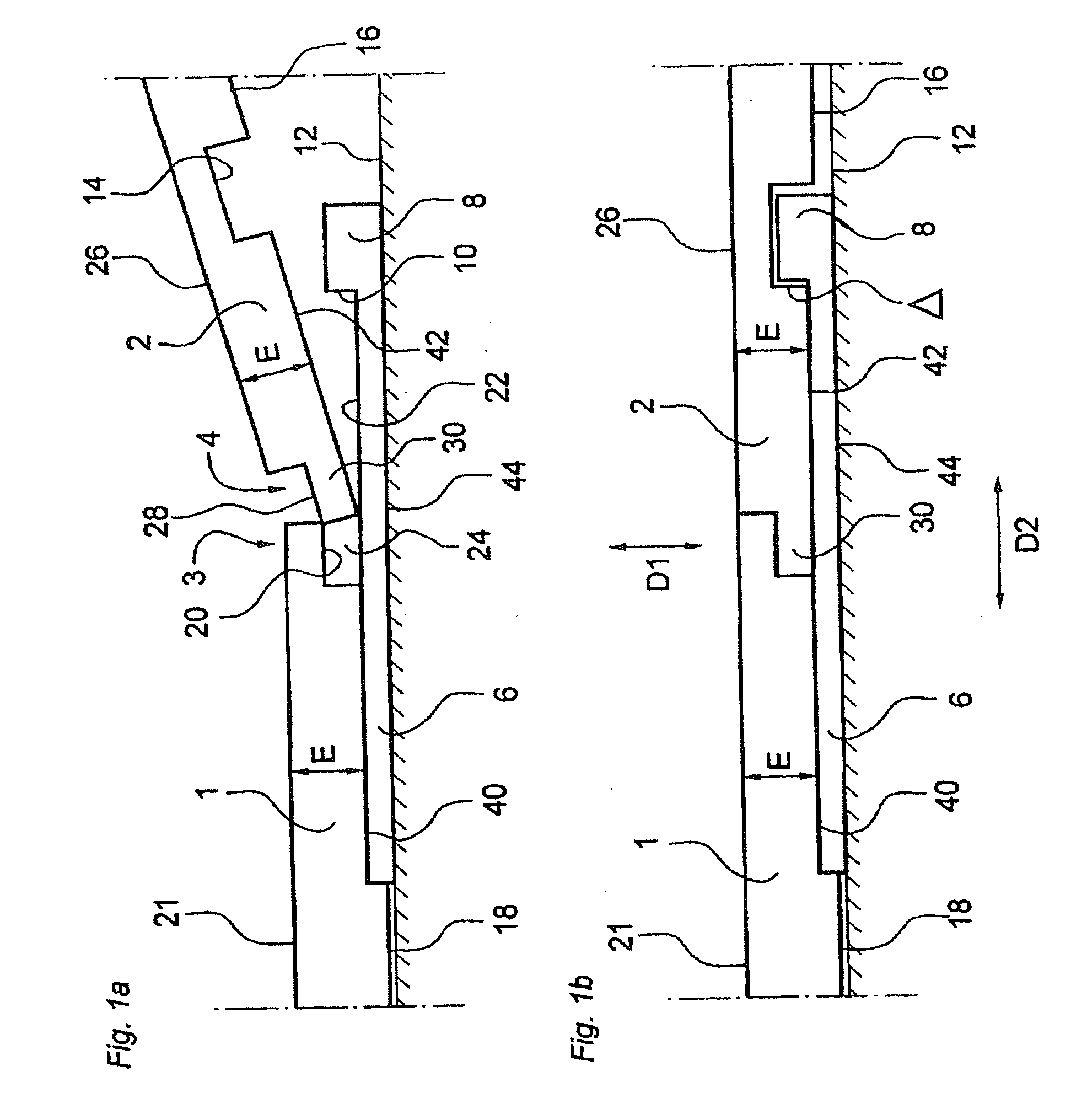

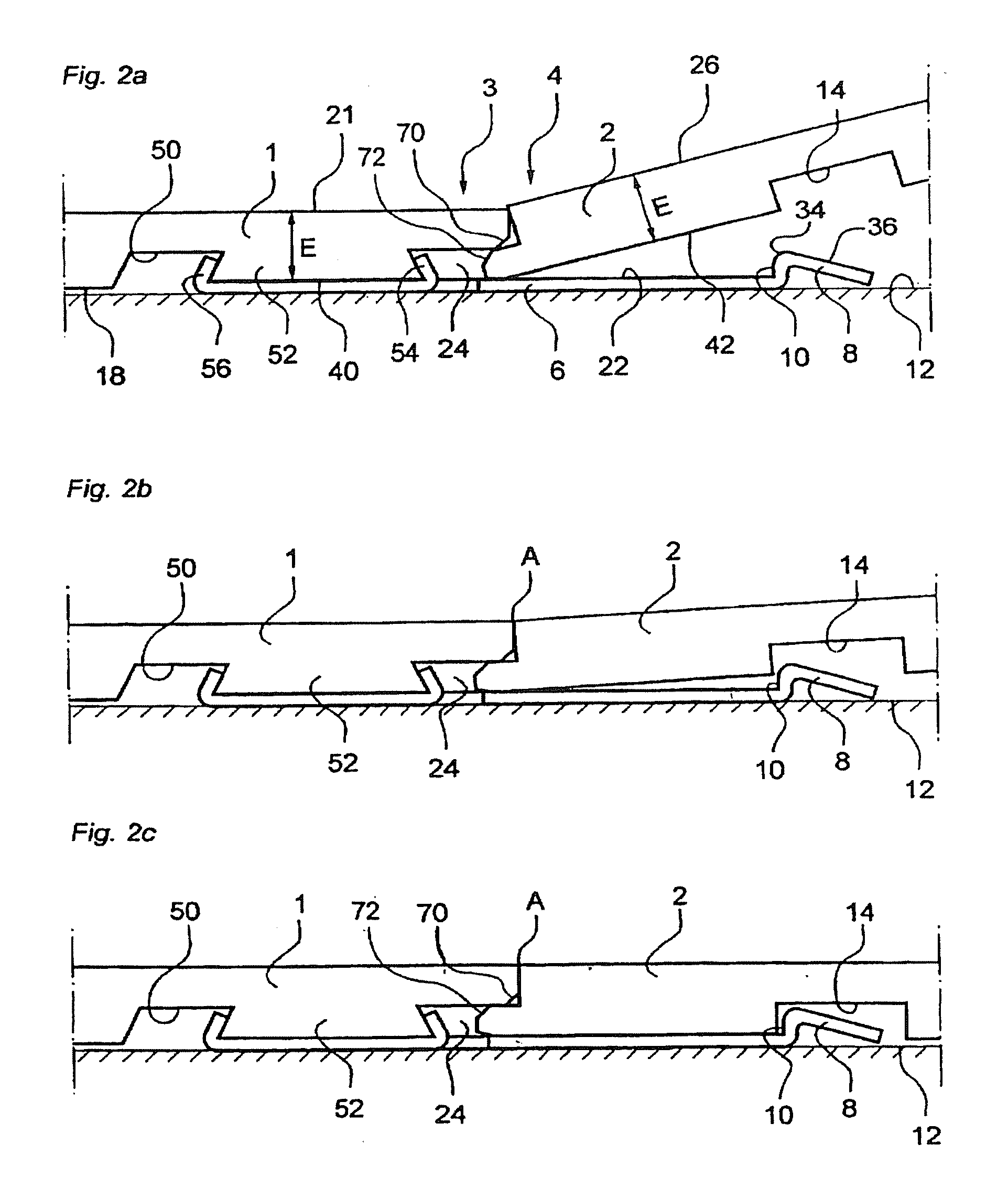

Floor panel with a tongue, groove and a strip

InactiveUS20060283127A1Simpler and cheapImprove accuracyRoof covering using tiles/slatesCovering/liningsDevice formEngineering

Floorboards with substantially planar and parallel upper top sides and lower undersides and panel material located between the upper and lower top sides, and a mechanical locking system for locking a first edge of a first floor board to a second edge of a substantially identical second floor board, the mechanical locking system including a tongue and groove forming a first mechanical connection locking the first and second edges to each other in a first direction at right angles to a principal plane of the floor boards, and a locking device forming a second mechanical connection locking the first and the second edges to each other in a second direction and at right angles to the edges; wherein, when the first edge and the second edge are locked together, there is space in the locking system between the first and the second edges.

Owner:VÄLINGE INNOVATION AB

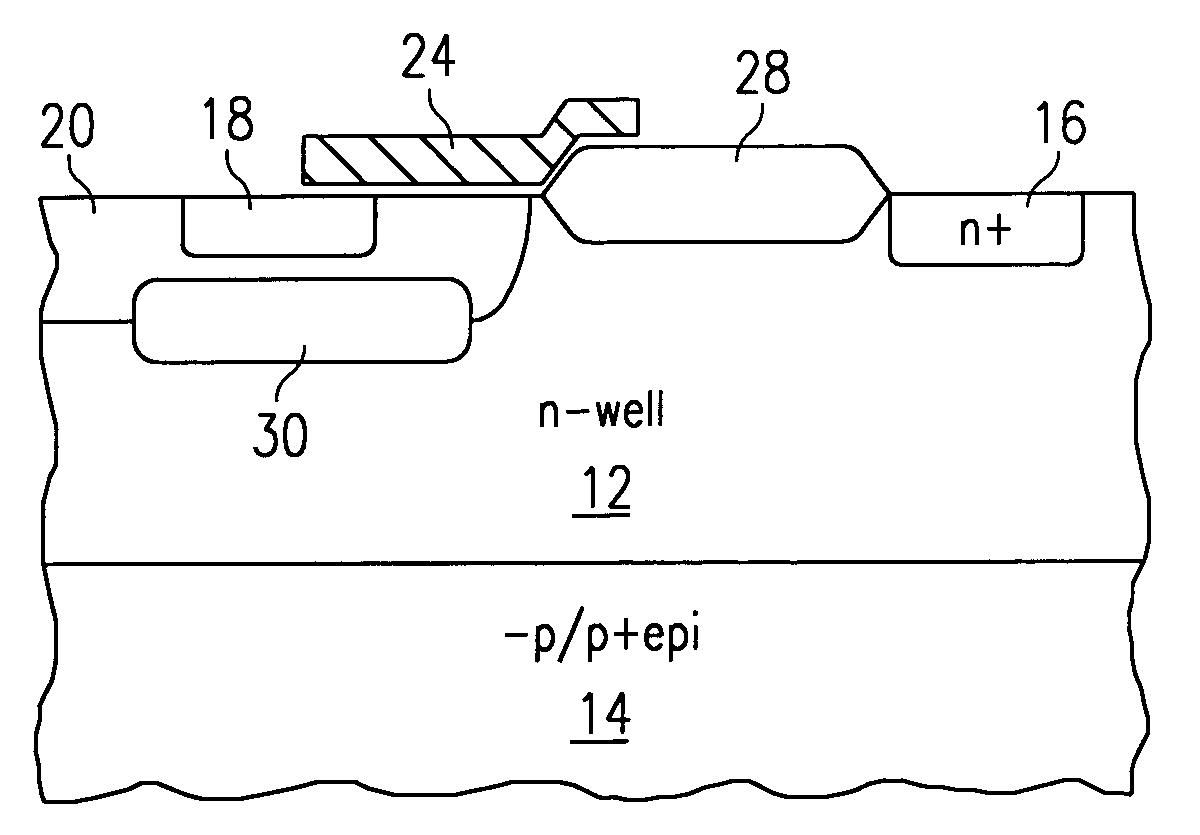

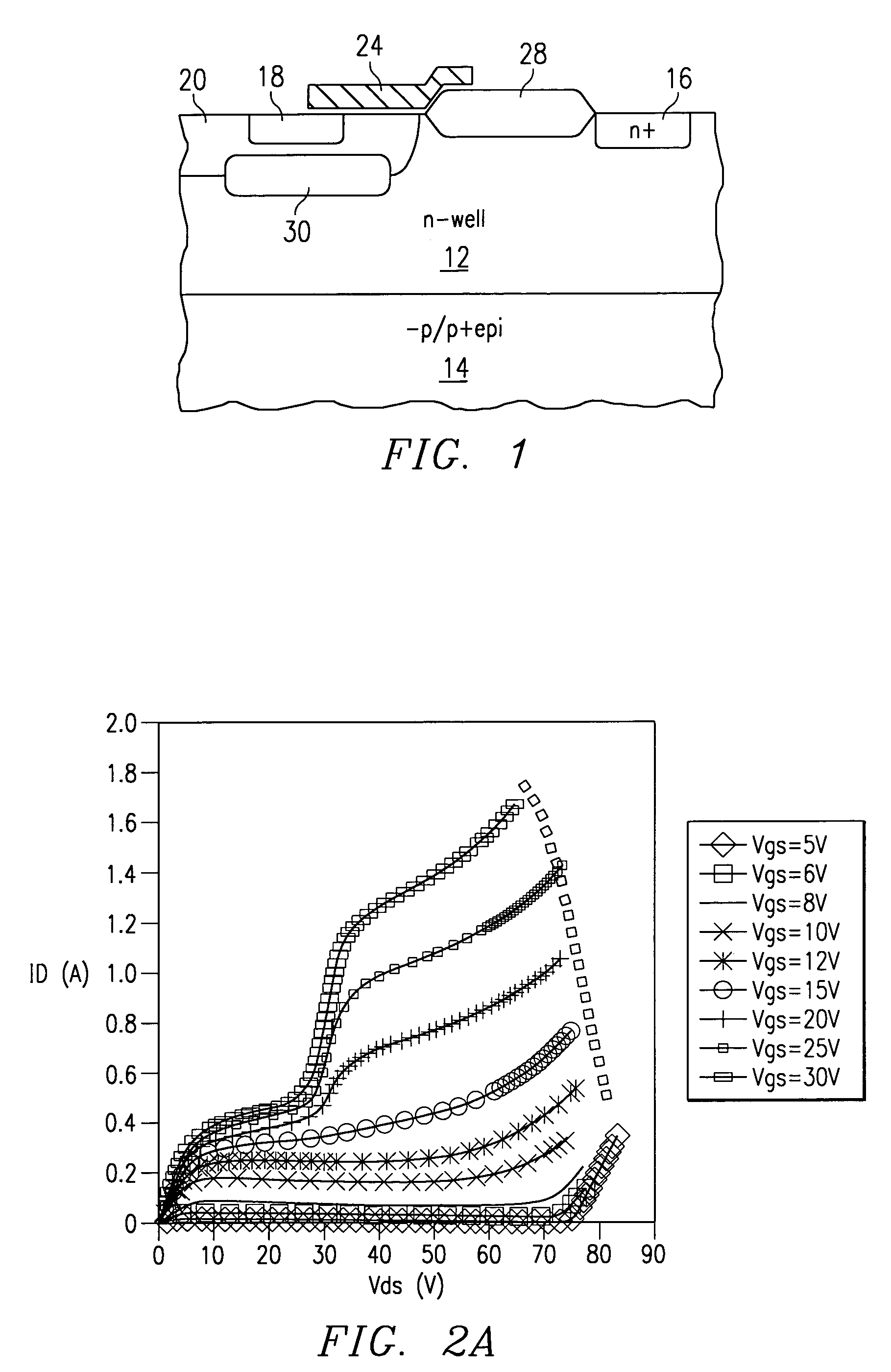

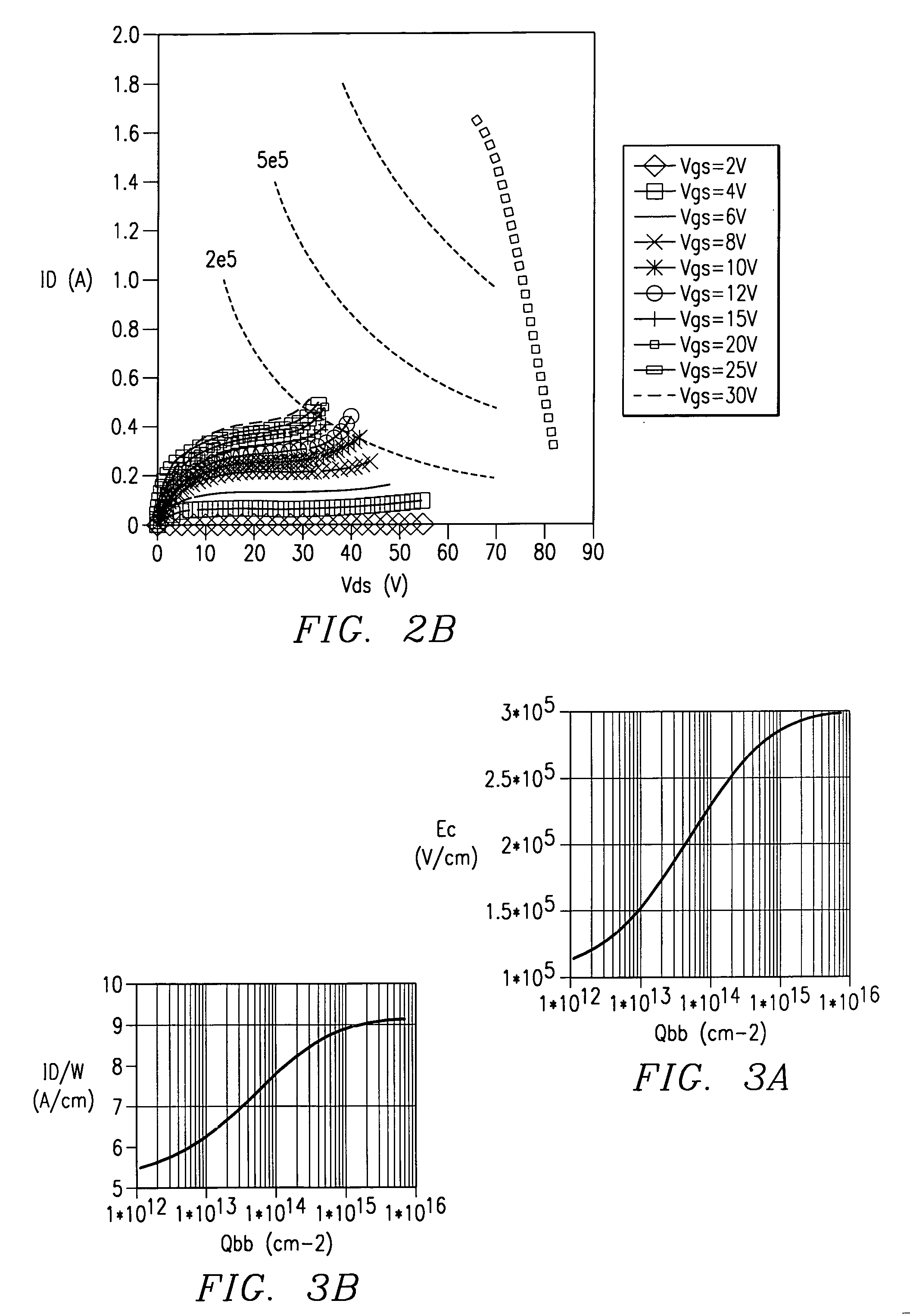

N-channel LDMOS with buried p-type region to prevent parasitic bipolar effects

InactiveUS6958515B2Reduces base resistance and hence base-emitter voltage dropEfficient collectionSemiconductor/solid-state device detailsSolid-state devicesSafe operating areaBody region

An improved n-channel integrated lateral DMOS (10) in which a buried body region (30), beneath and self-aligned to the source (18) and normal body diffusions, provides a low impedance path for holes emitted at the drain region (16). This greatly reduces secondary electron generation, and accordingly reduces the gain of the parasitic PNP bipolar device. The reduced regeneration in turn raises the critical field value, and hence the safe operating area.

Owner:TEXAS INSTR INC

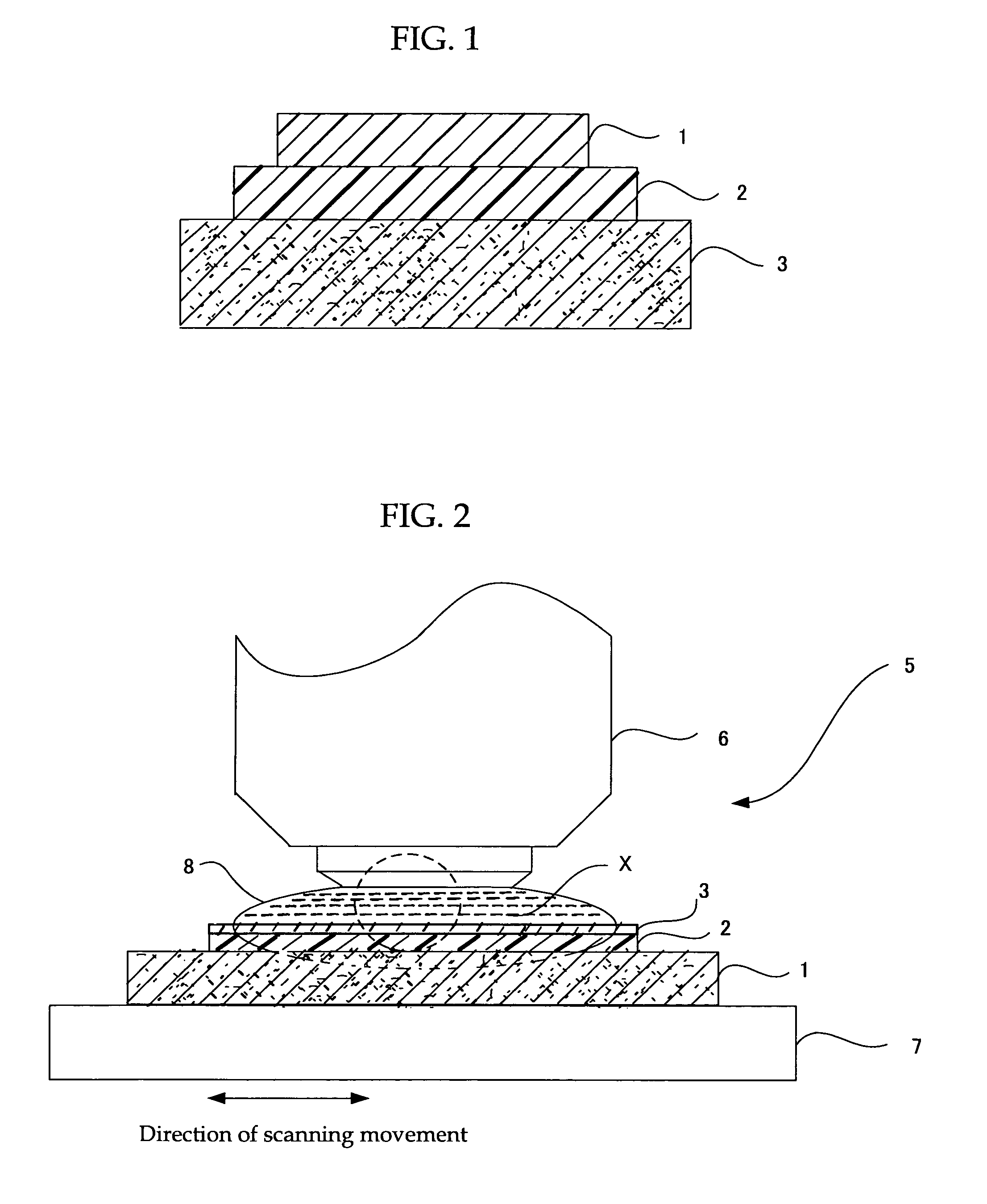

Resist cover film-forming material, process for forming resist pattern, semiconductor device and process for manufacturing the same

InactiveUS7608386B2High light transmittanceResist performance can not be impairedPhotosensitive materialsRadiation applicationsResistEngineering

Owner:FUJITSU LTD

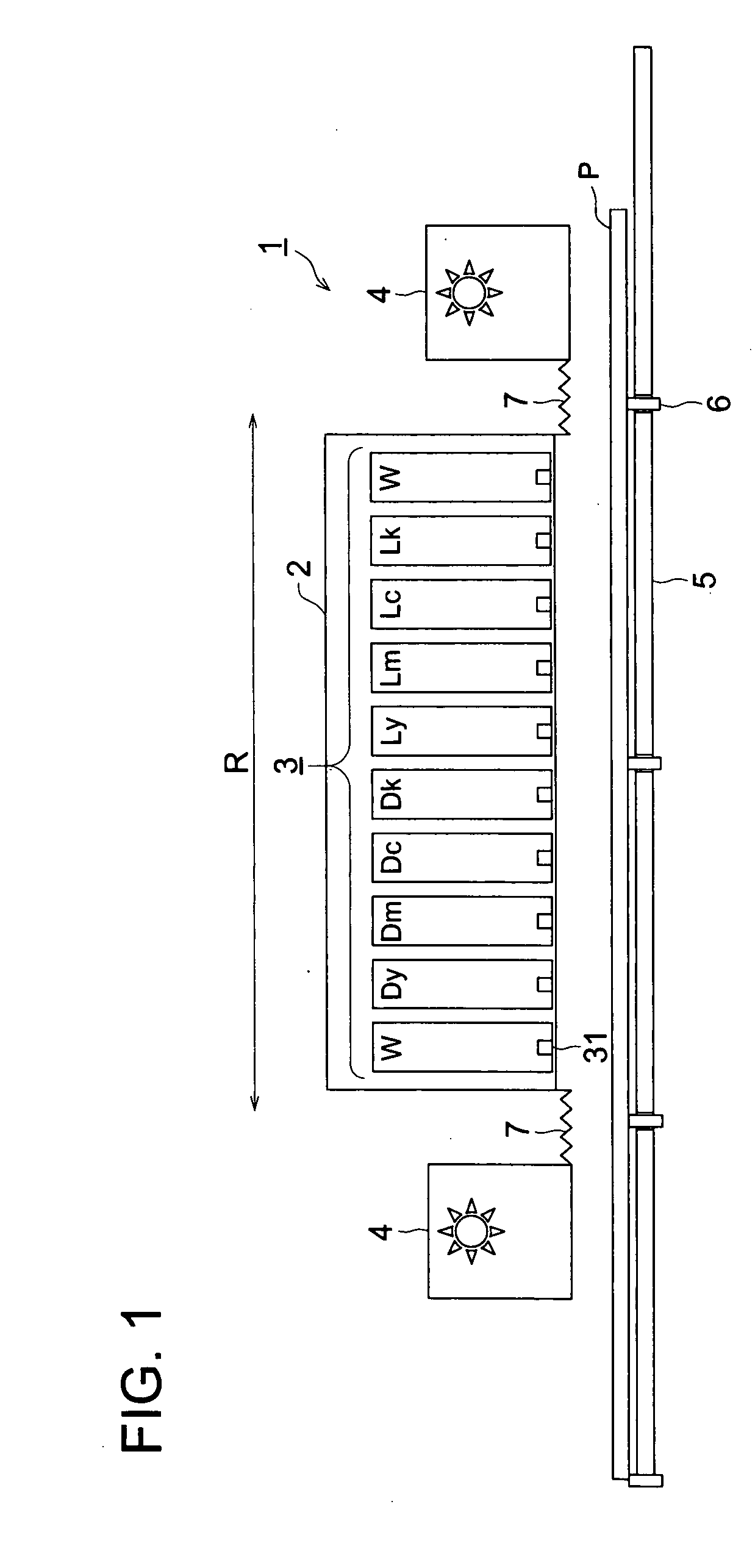

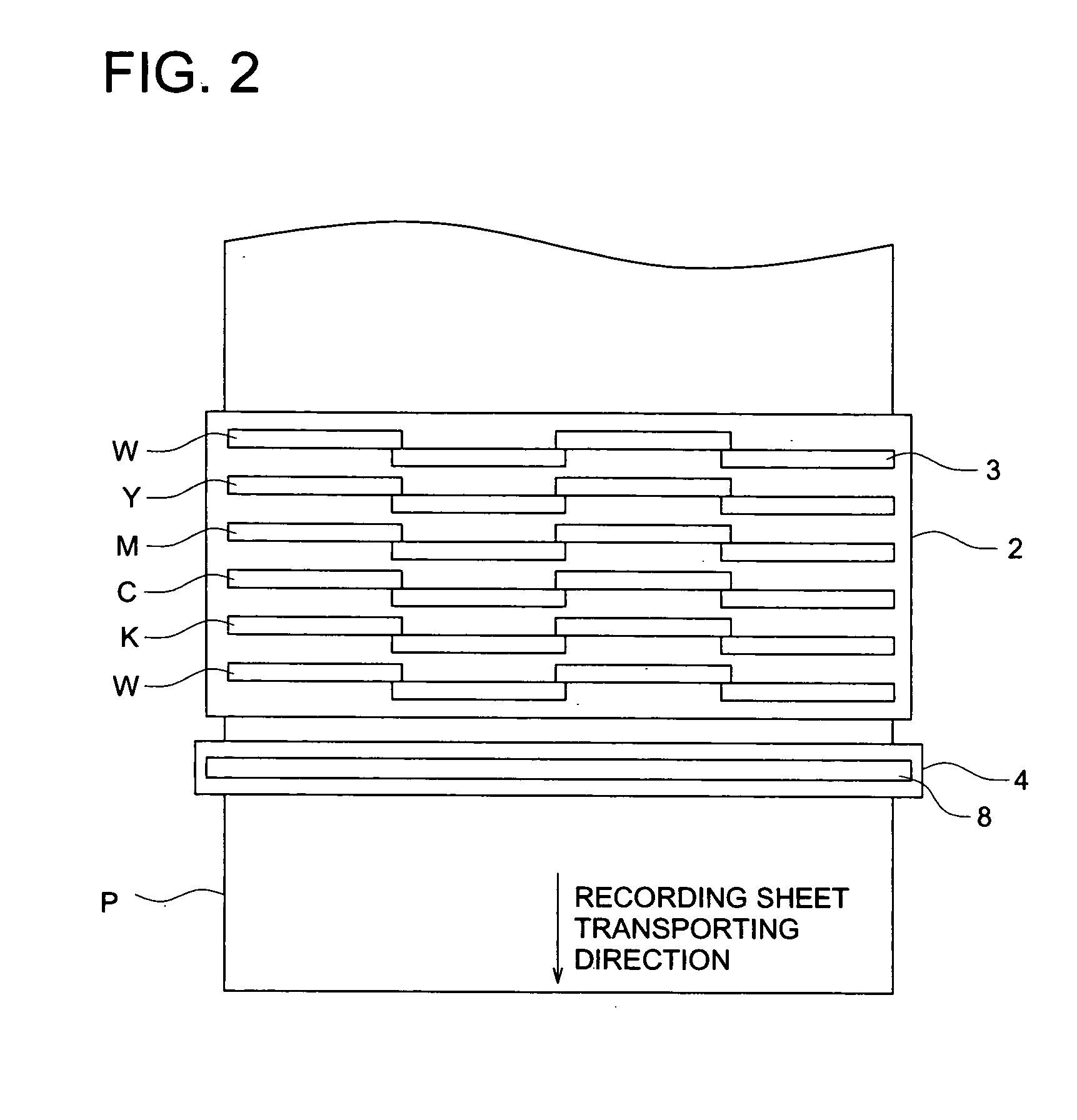

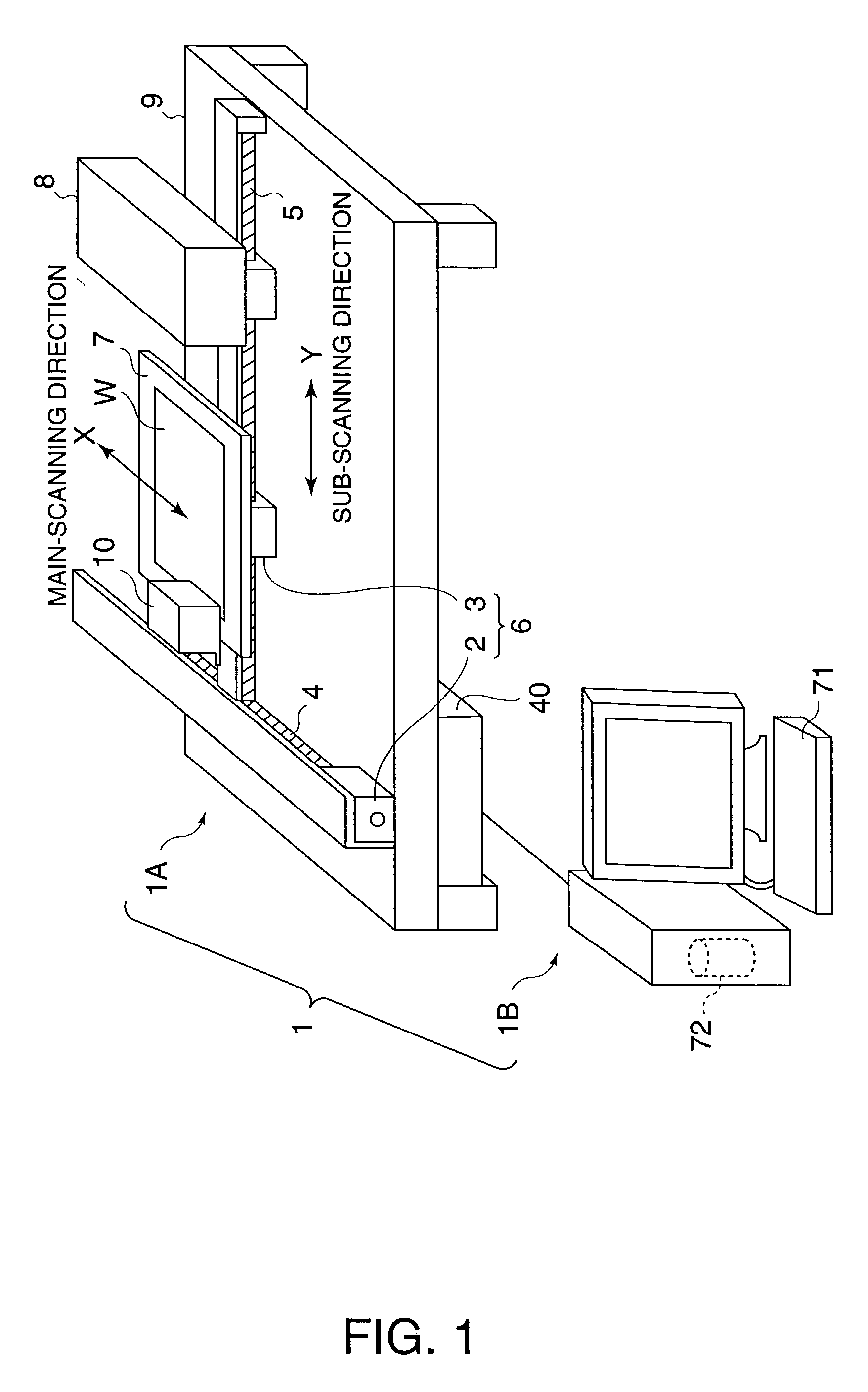

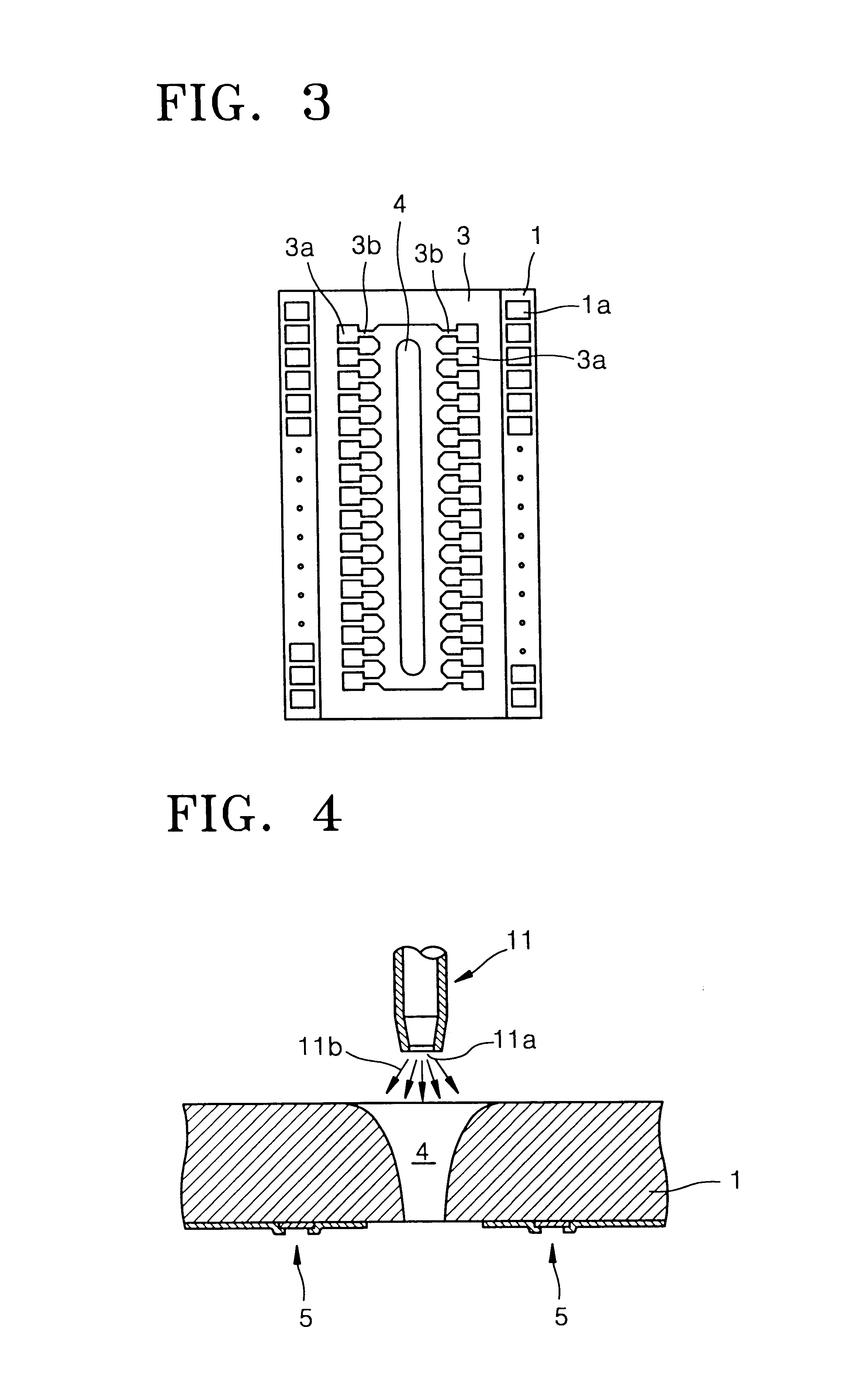

Thin film formation method, thin film formation equipment, method of manufacturing organic electroluminescence device, organic electroluminescence device, and electronic apparatus

InactiveUS20050153472A1Increase productionImprove accuracyMolten spray coatingSemiconductor/solid-state device testing/measurementOptoelectronicsOrganic electroluminescence

A thin film formation method is provided which can carry out various kinds of patterning deposition correctly and with high precision, and a thin film formation equipment. The thin film formation method arranges a mask between a substrate and a material source and forms the material of the material source as a thin film on the substrate. The method further includes: a substrate contacting process to contact the mask and the substrate; a gap measurement process to measure a gap between the mask and the substrate; and a thin film formation process to form the thin film according to the measurement result in the gap measurement process.

Owner:SEIKO EPSON CORP

System for joining building panels

The invention relates to a system for laying and mechanically joining building panels, especially thin, hard, floating floors. Adjacent joint edges of two panels engage each other to provide a first mechanical connection locking the joint edges in a first direction perpendicular to the principal plane of the panels. In each joint, there is further provided a strip which is integrated with one joint edge and which projects behind the other joint edge. The strip has an upwardly protruding locking element engaging in a locking groove in the rear side of the other joint edge to form a second mechanical connection locking the panels in a second direction parallel to the principal plane of the panels and at right angles to the joint. Both the first and the second mechanical connection allow mutual displacement of joined panels in the direction of the joint.

Owner:VÄLINGE INNOVATION AB

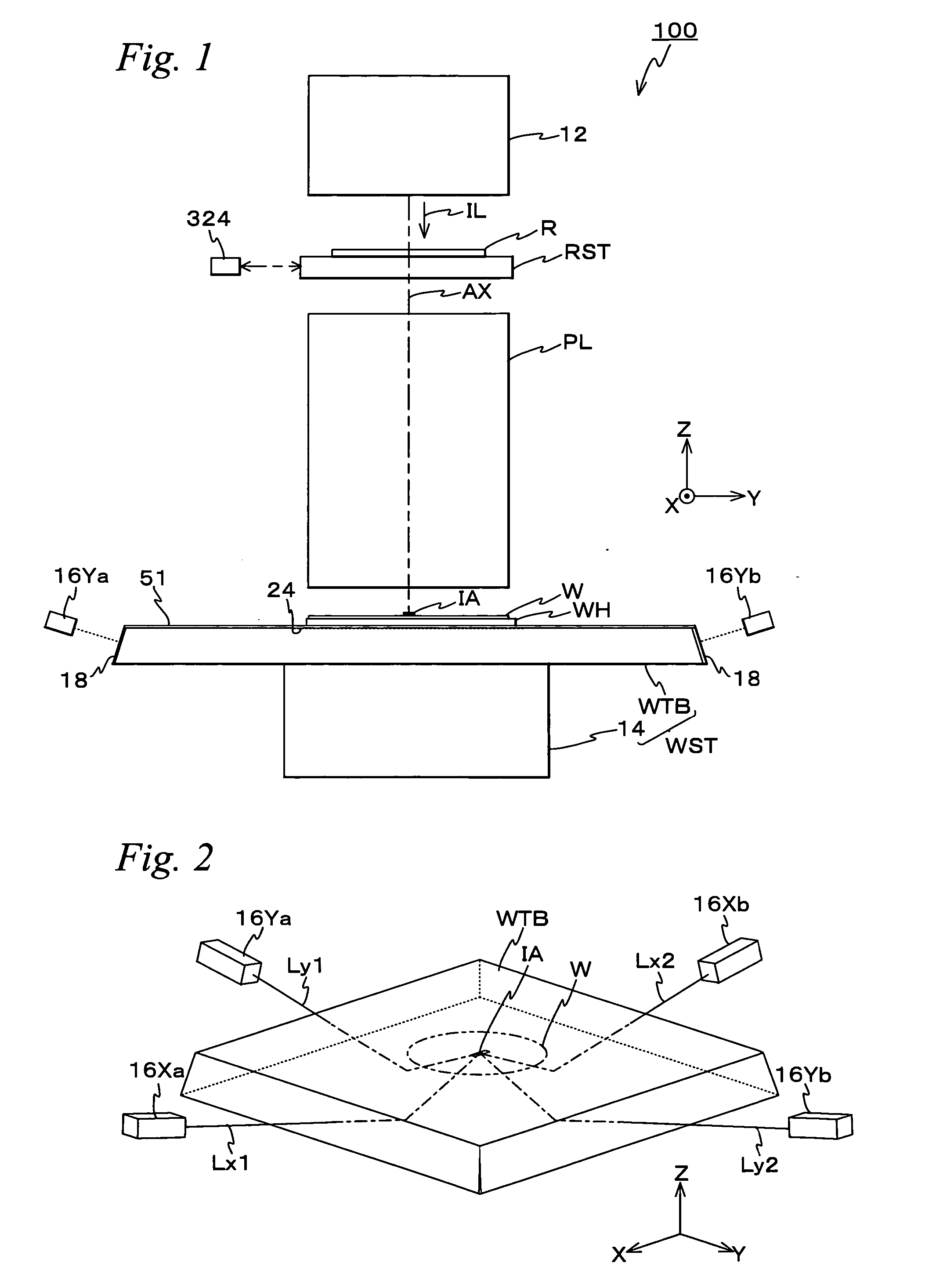

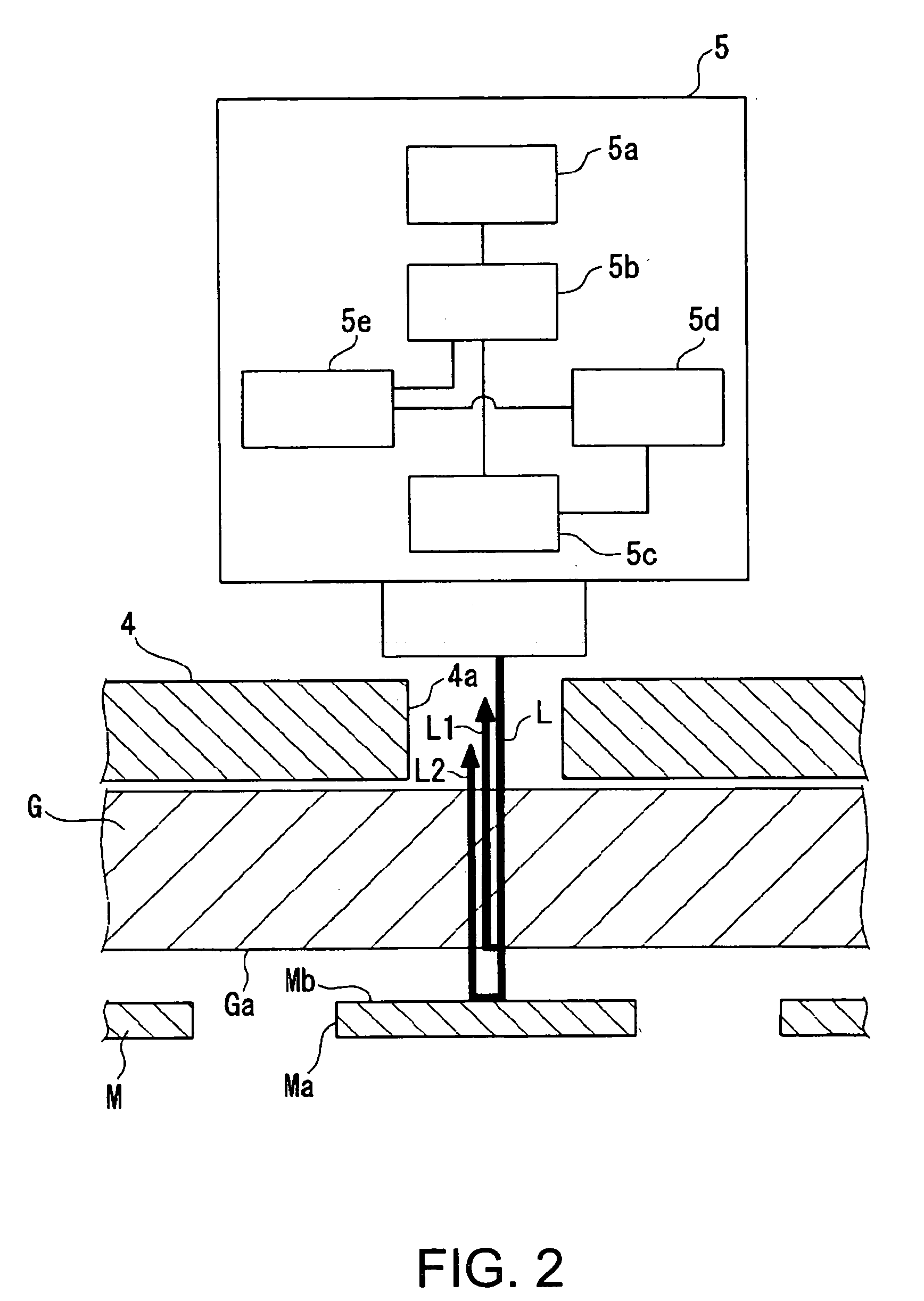

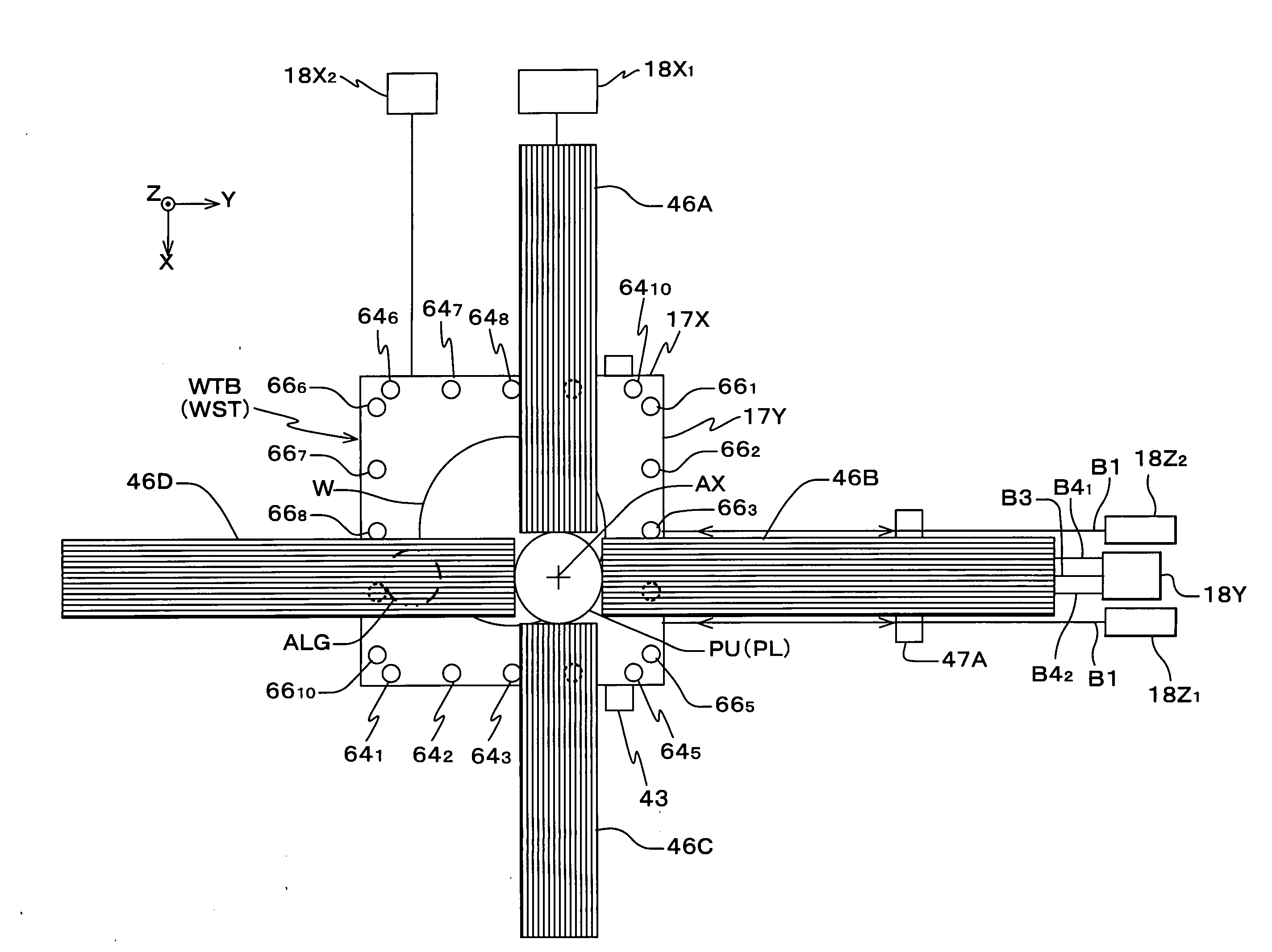

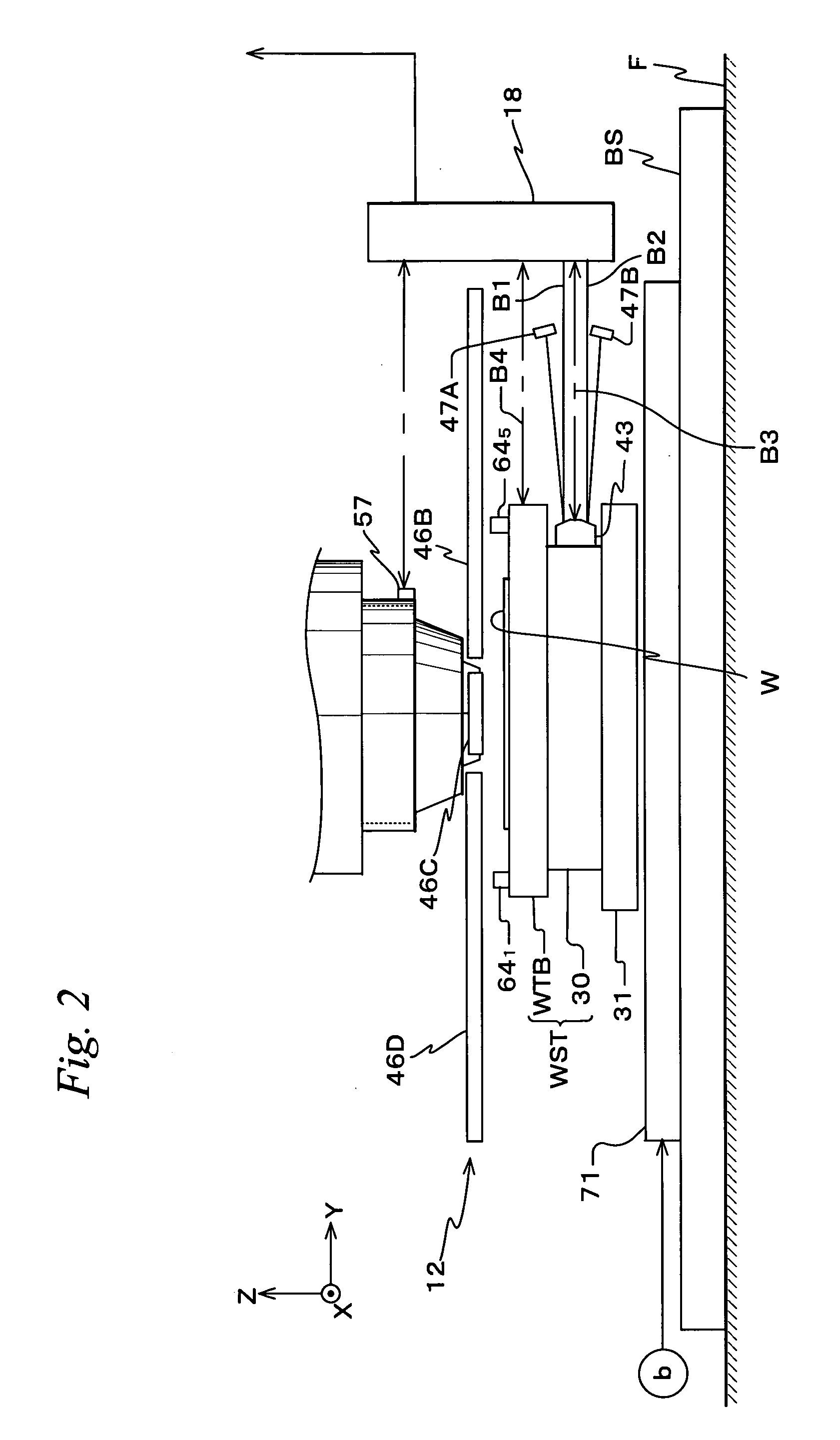

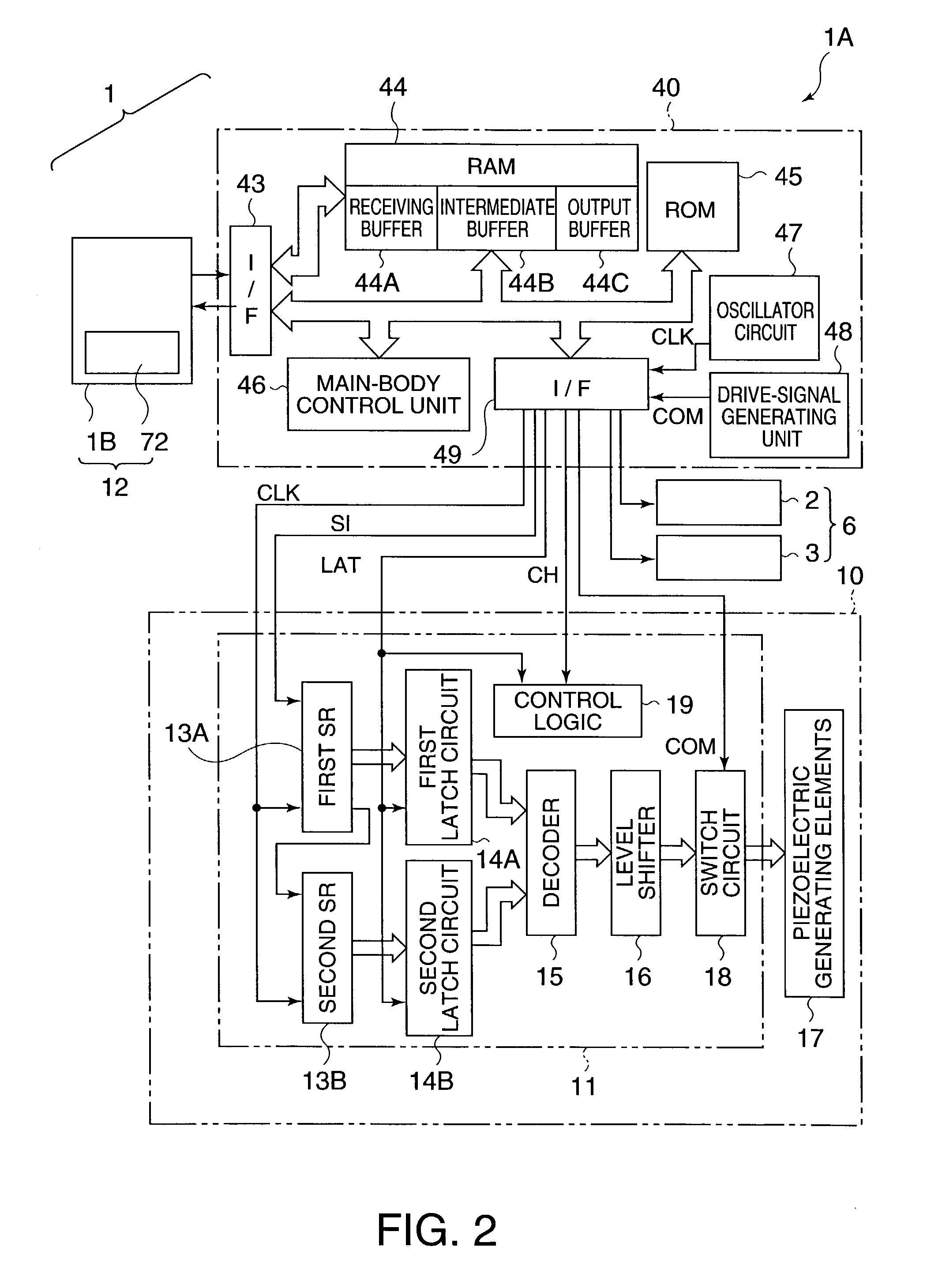

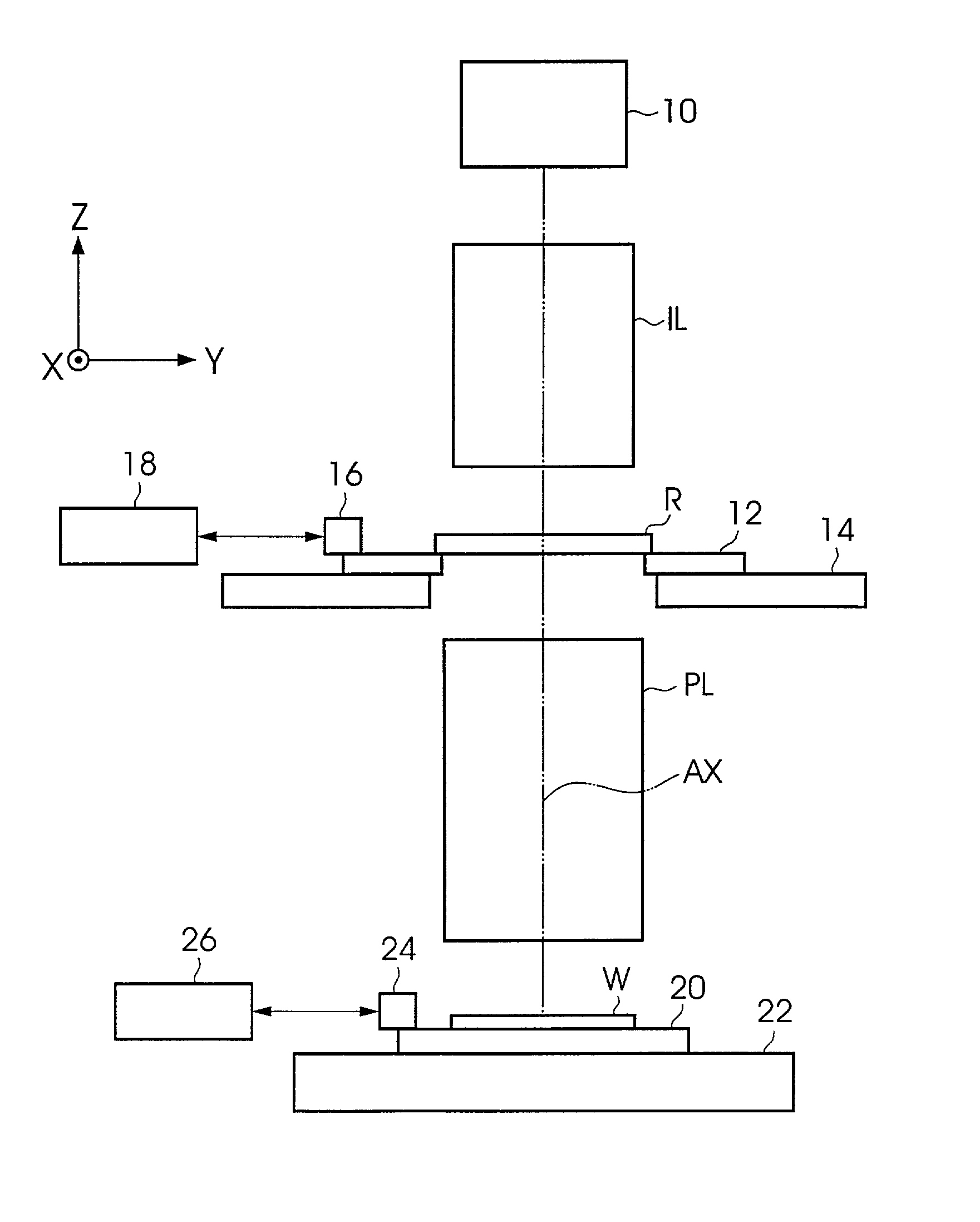

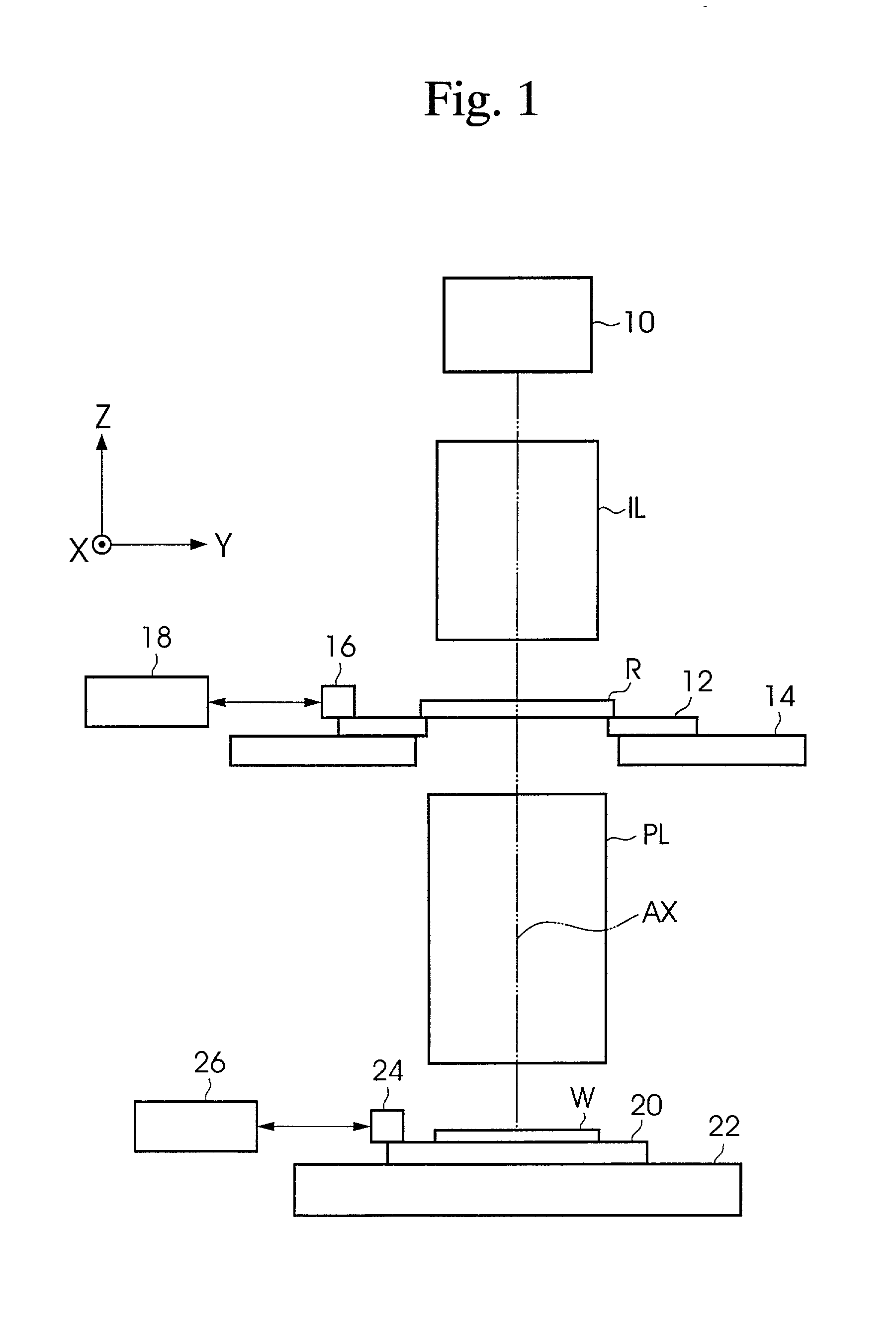

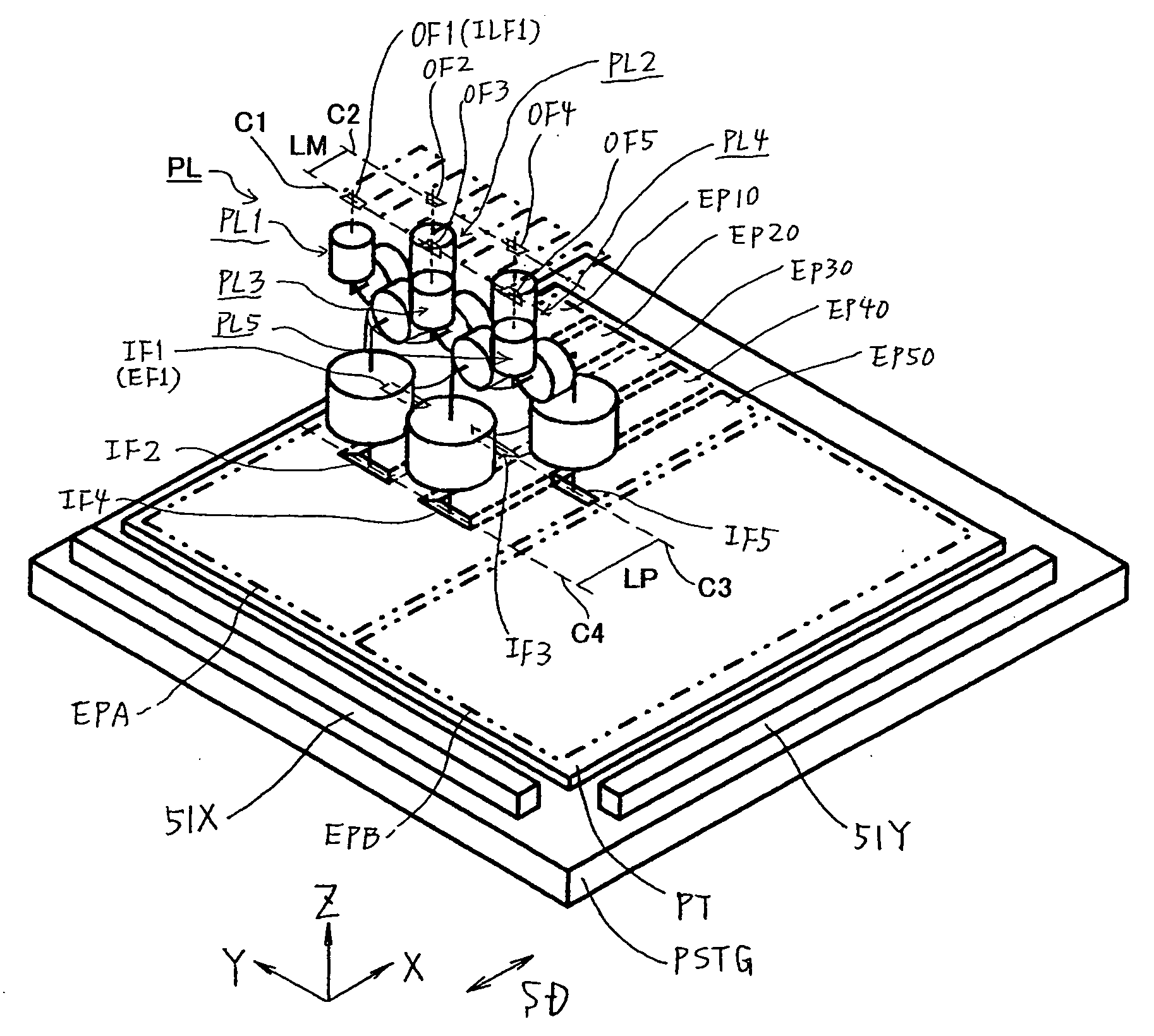

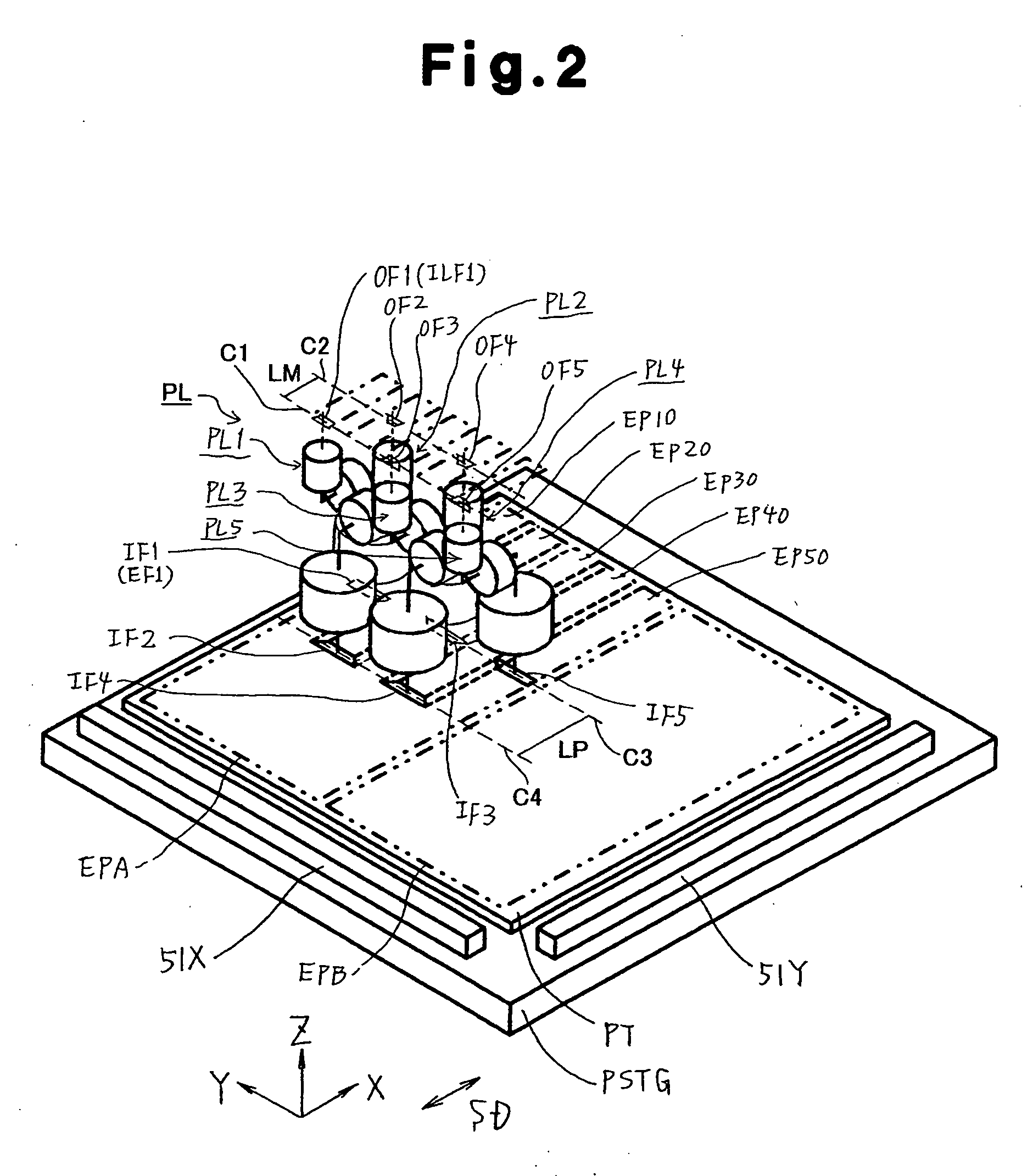

Movable body drive system, pattern formation apparatus, exposure apparatus and exposure method, and device manufacturing method

InactiveUS20090190110A1High-precision exposureImprove accuracyWalking sticksPhotomechanical apparatusGratingEncoder

A stage device is equipped with a first scale which is placed with a Y-axis direction serving as its longitudinal direction and in which a first grating whose periodic direction is in an X-axis direction is formed and a second scale which is placed with the X-axis direction serving as its longitudinal direction and in which a second grating whose periodic direction is orthogonal to the periodic direction of the first grating is formed, the first scale and the second scale being placed on a plane which a wafer stage faces. Further, on the upper surface of the wafer stage, a plurality of X heads placed at different positions in the X-axis direction and a plurality of Y heads placed at different positions in the Y-axis direction are arranged. An encoder system that has these heads measures positional information of the stage within an XY plane, based on an output of the X head facing the first scale and an output of the Y head facing the second scale.

Owner:NIKON CORP

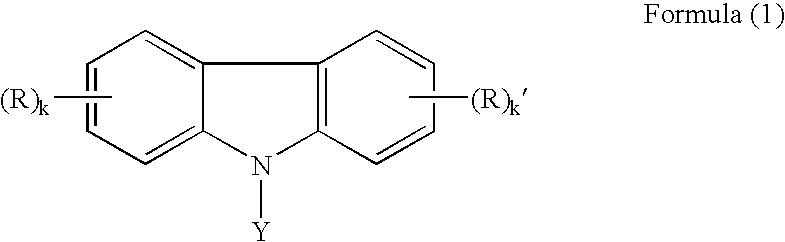

Actinic ray curable ink-jet ink composition, image formation method employing the same, and ink-jet recording apparatus

ActiveUS20050113483A1Stable formImprove accuracyLiquid surface applicatorsOrganic chemistryBenzeneCompound a

Disclosed is an actinic ray curable ink-jet ink composition containing a photopolymerizable compound, a sulfonium salt (compound A) as a photoinitiator, which does not release benzene on actinic ray exposure, and a compound (compound B) as a sensitizing agent selected from the group consisting of (i) a polycyclic aromatic compound having a hydroxyl group, a substituted or unsubstituted aralkyloxy group or a substituted or unsubstituted alkoxy group, (ii) a carbazole derivative, and (iii) a thioxanthone derivative.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

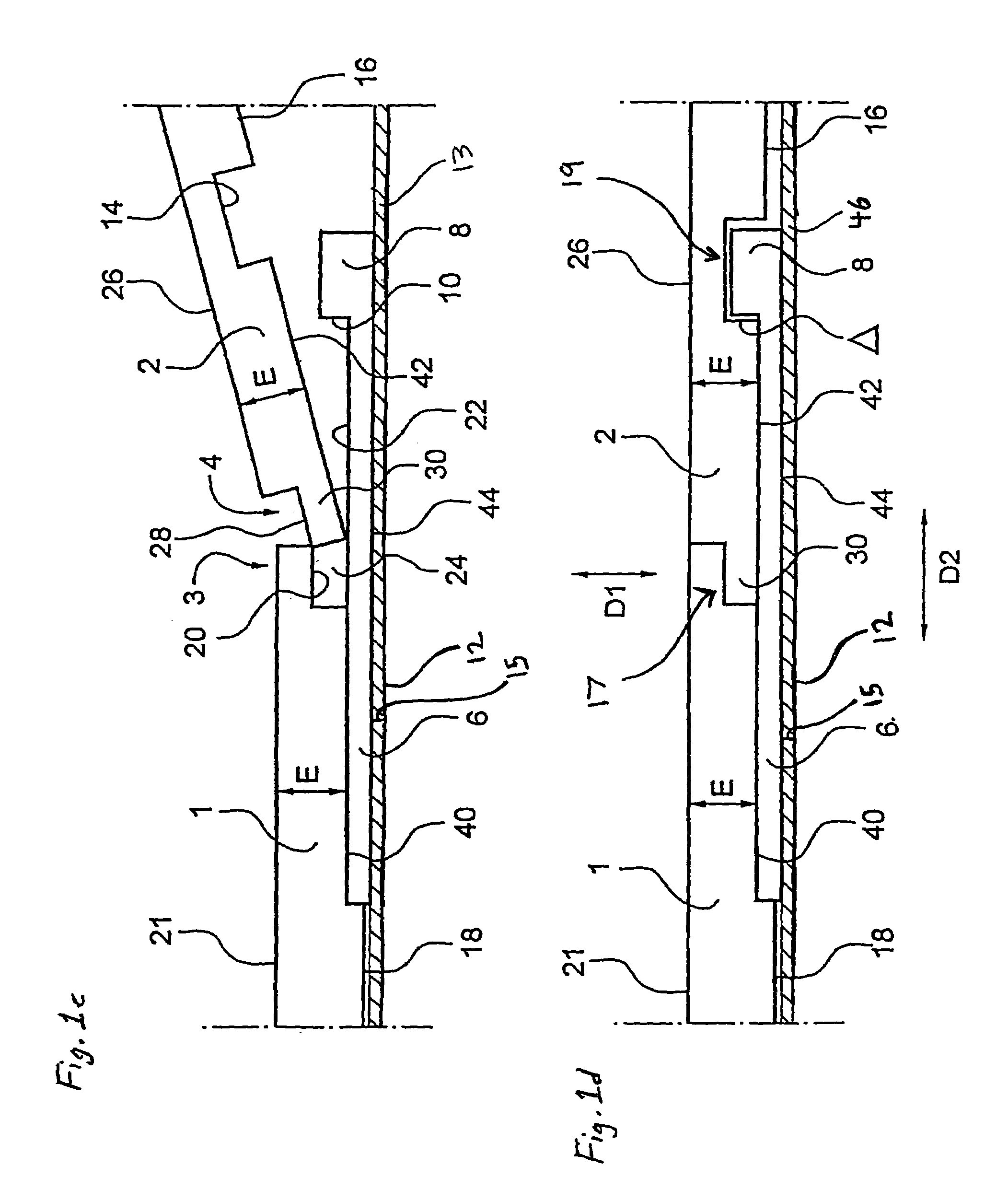

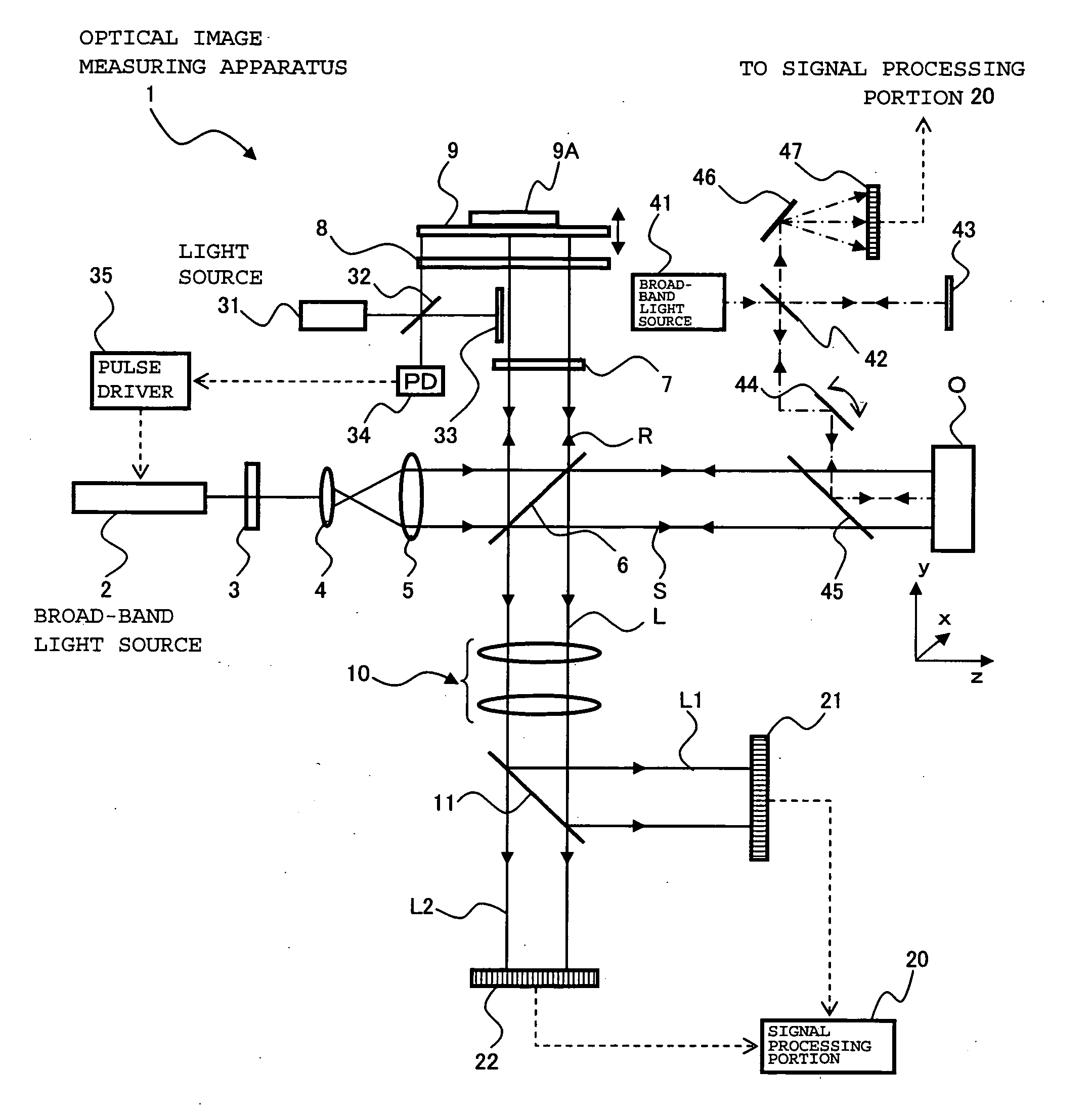

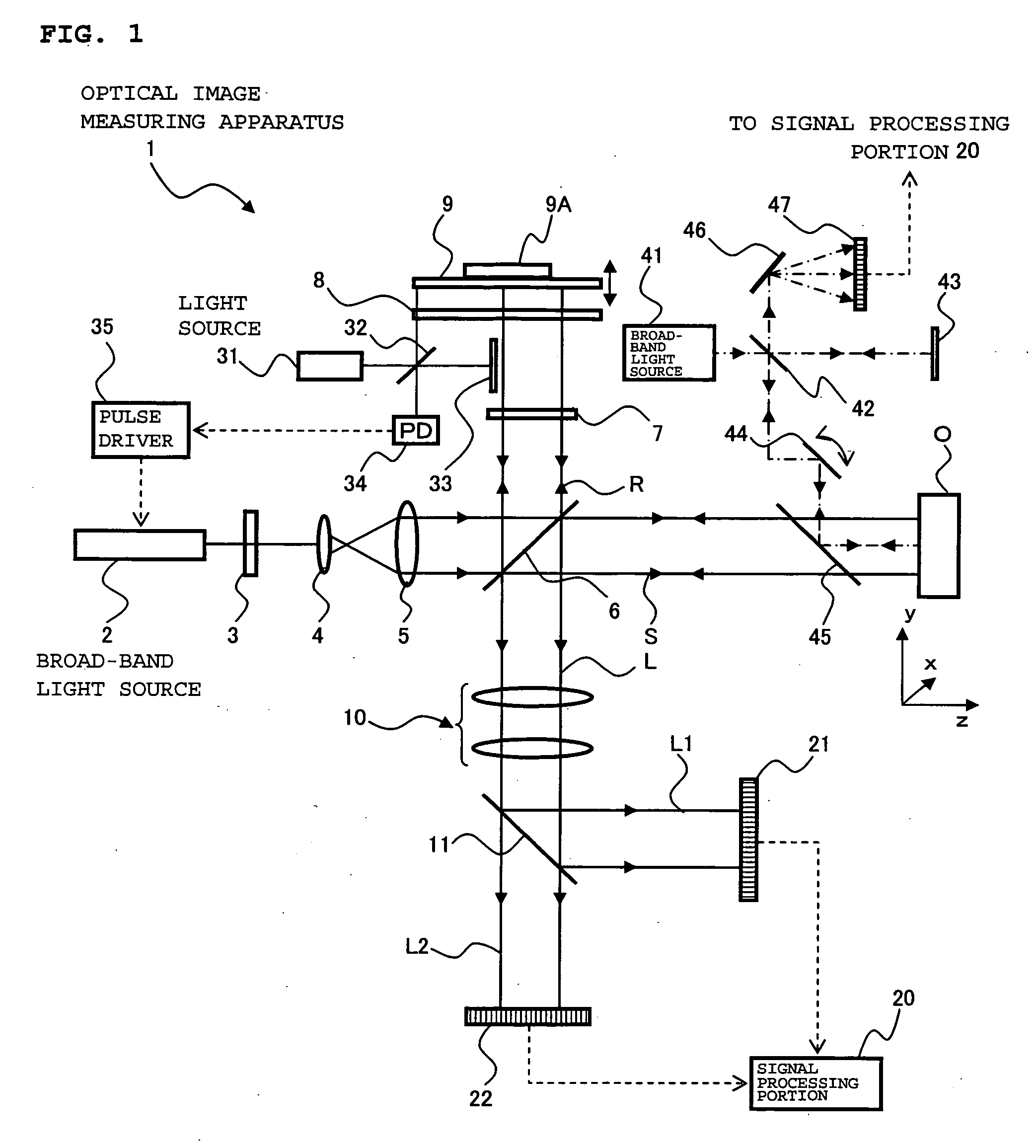

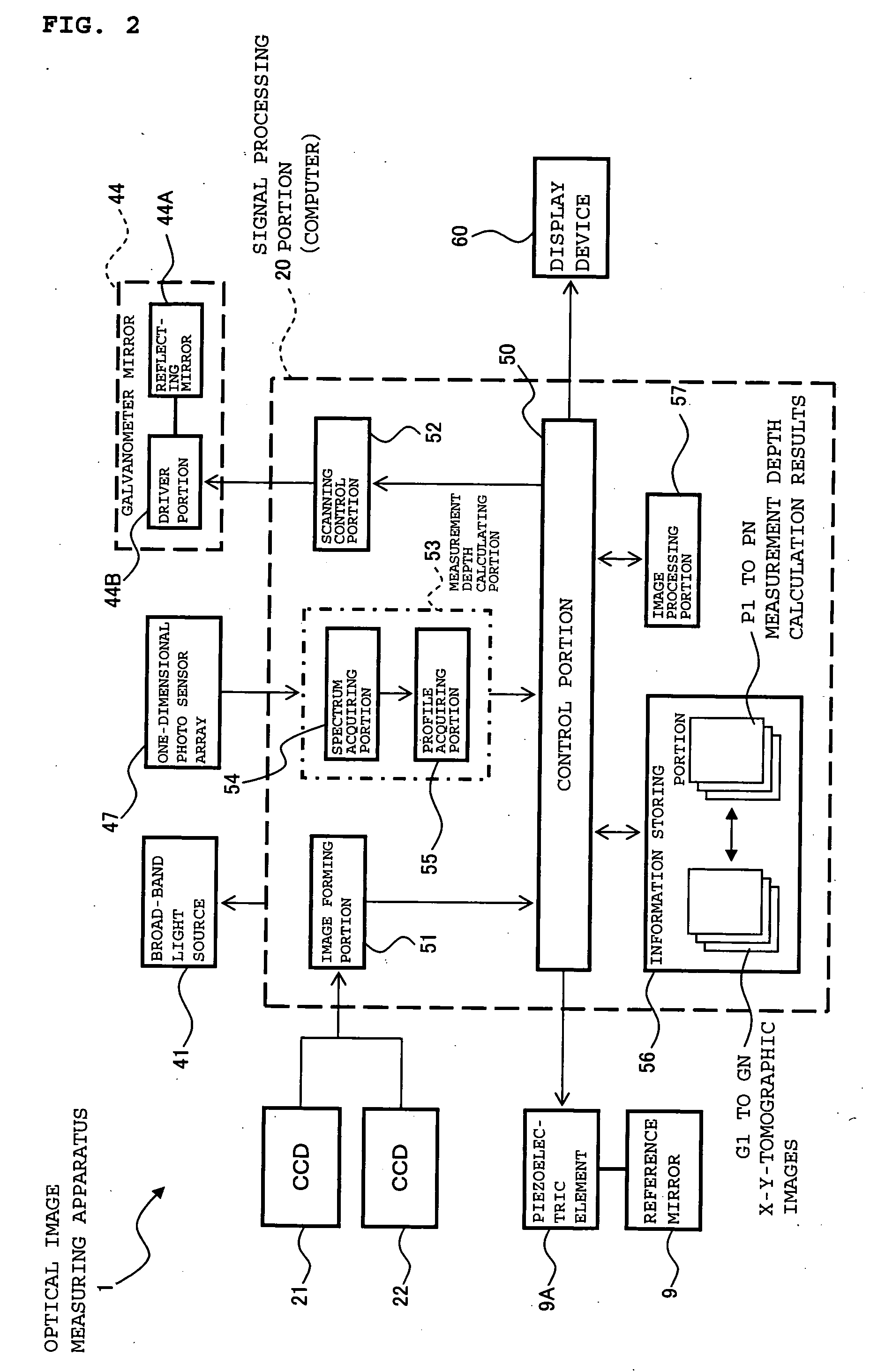

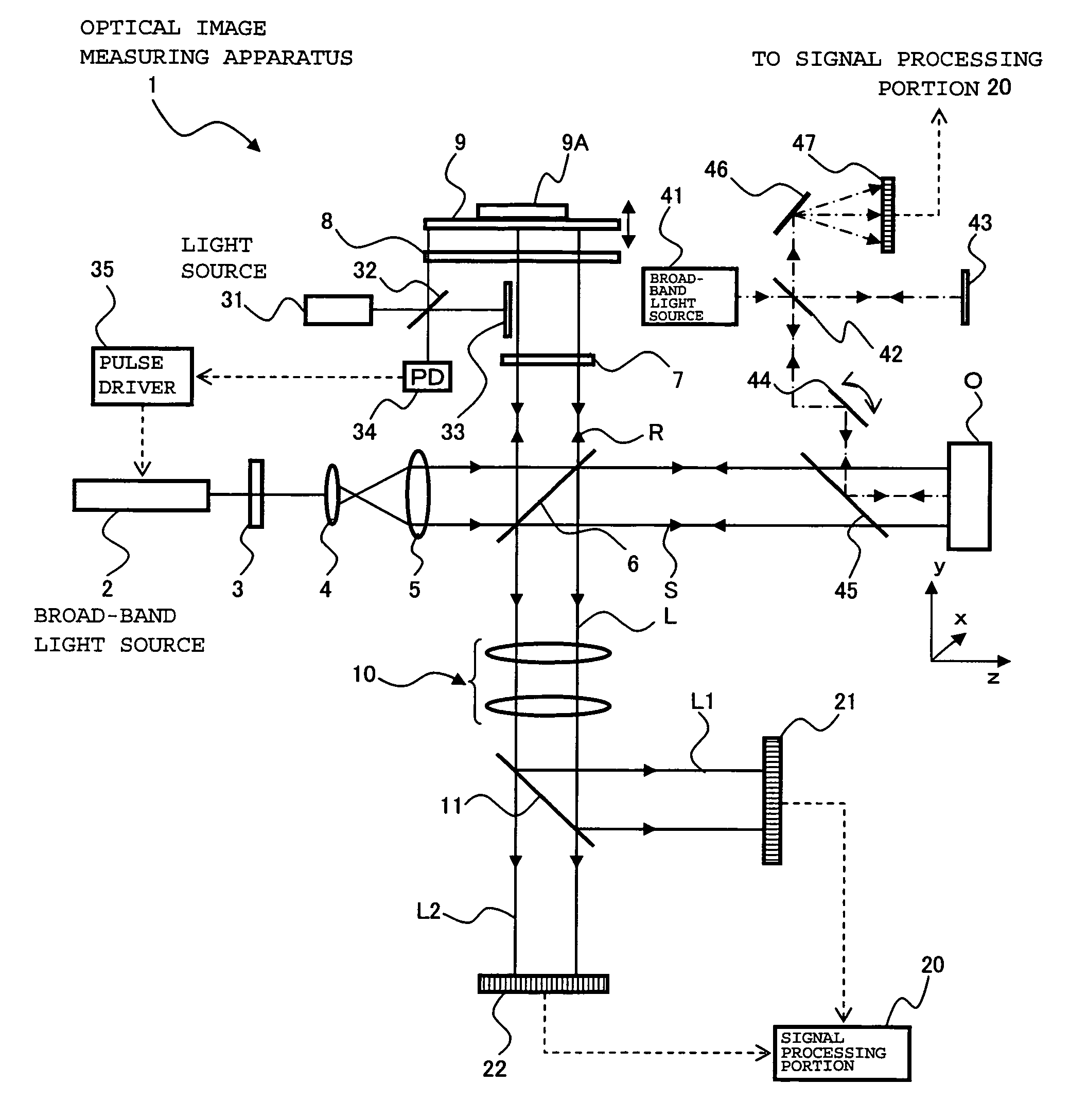

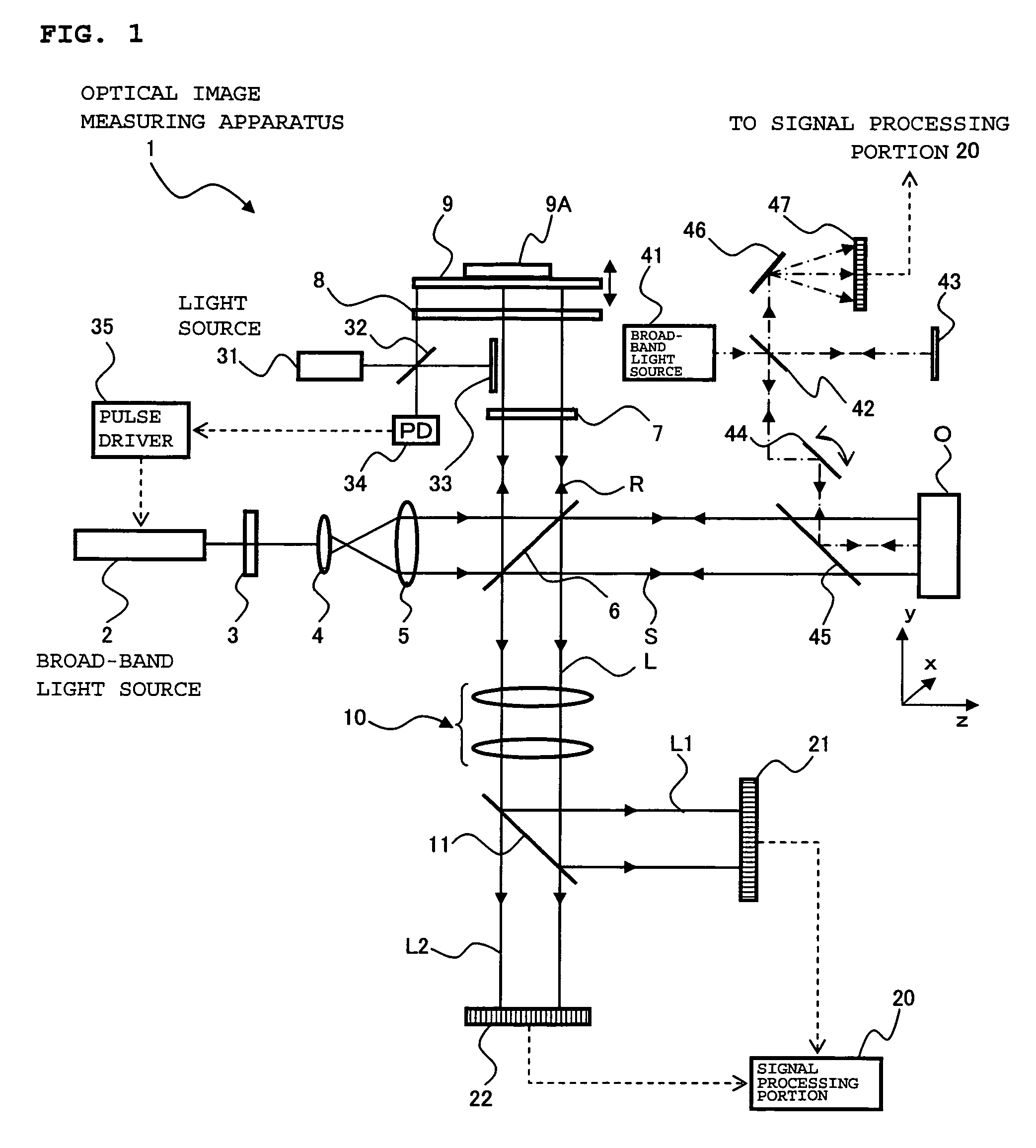

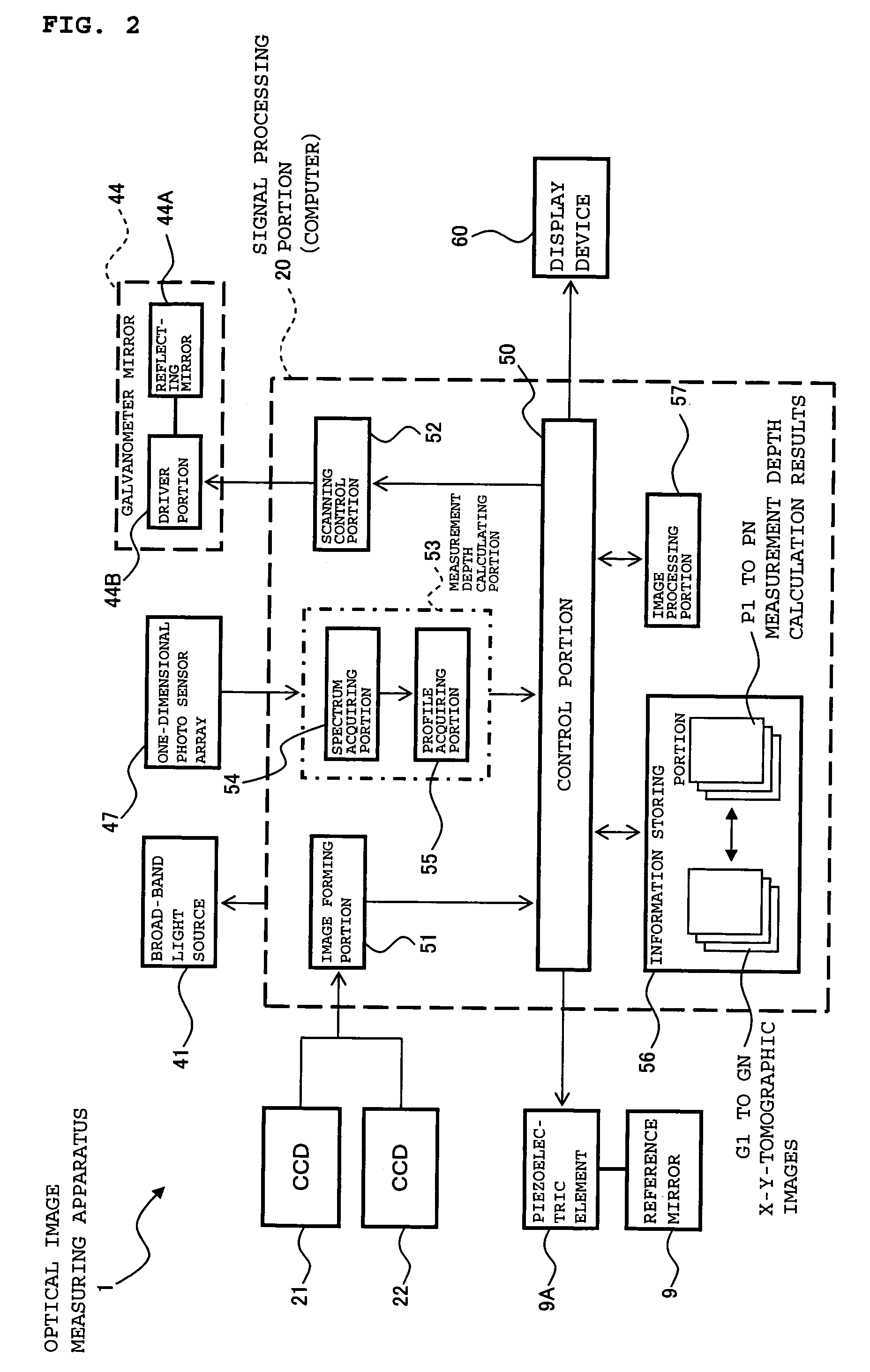

Optical image measuring apparatus and optical image measuring method

InactiveUS20060077395A1Improve accuracyHigh precision formingInterferometersUsing optical meansOptoelectronicsSignal light

Provided is an optical image measuring apparatus forming a three-dimensional image based on tomographic images of an object, acquired at various depths even when the object moves during measurement. Including a half mirror (6) for dividing a light beam signal light (S) and reference light (R), a frequency shifter (8), a reference mirror (9) and a piezoelectric element (9A) used to change an optical path length of the reference light (R), CCDs (21, 22) for receiving interference light beams (L) resulting from interference light produced by superimposing the signal light (S) and the reference light (R) on each other by the half mirror (6) and outputting detection signals, an image forming portion for forming tomographic images based on the detection signals, a measurement depth calculating means (53), and an image processing portion (57). Forming a three-dimensional image or the like based on the arranged tomographic images.

Owner:KK TOPCON

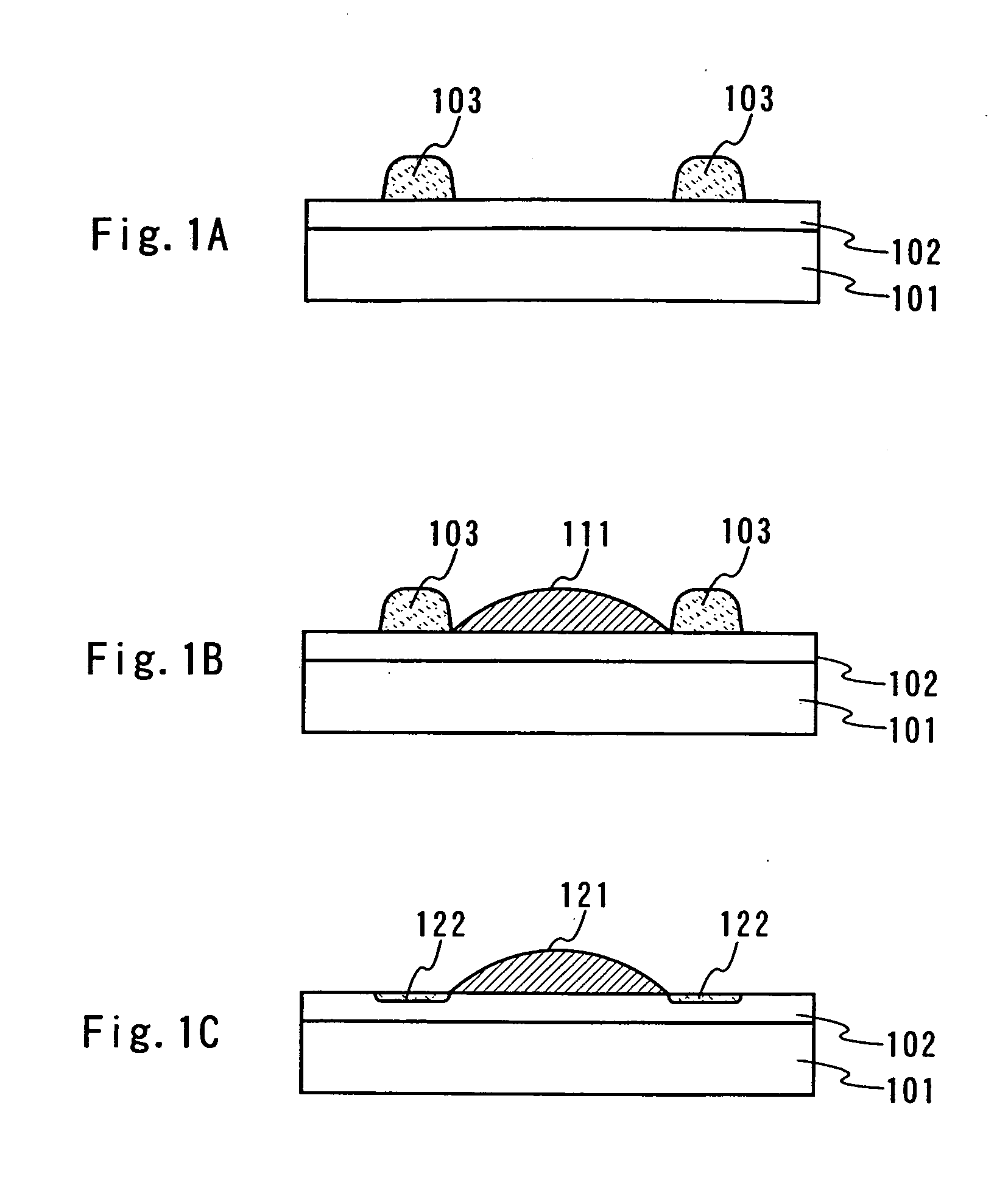

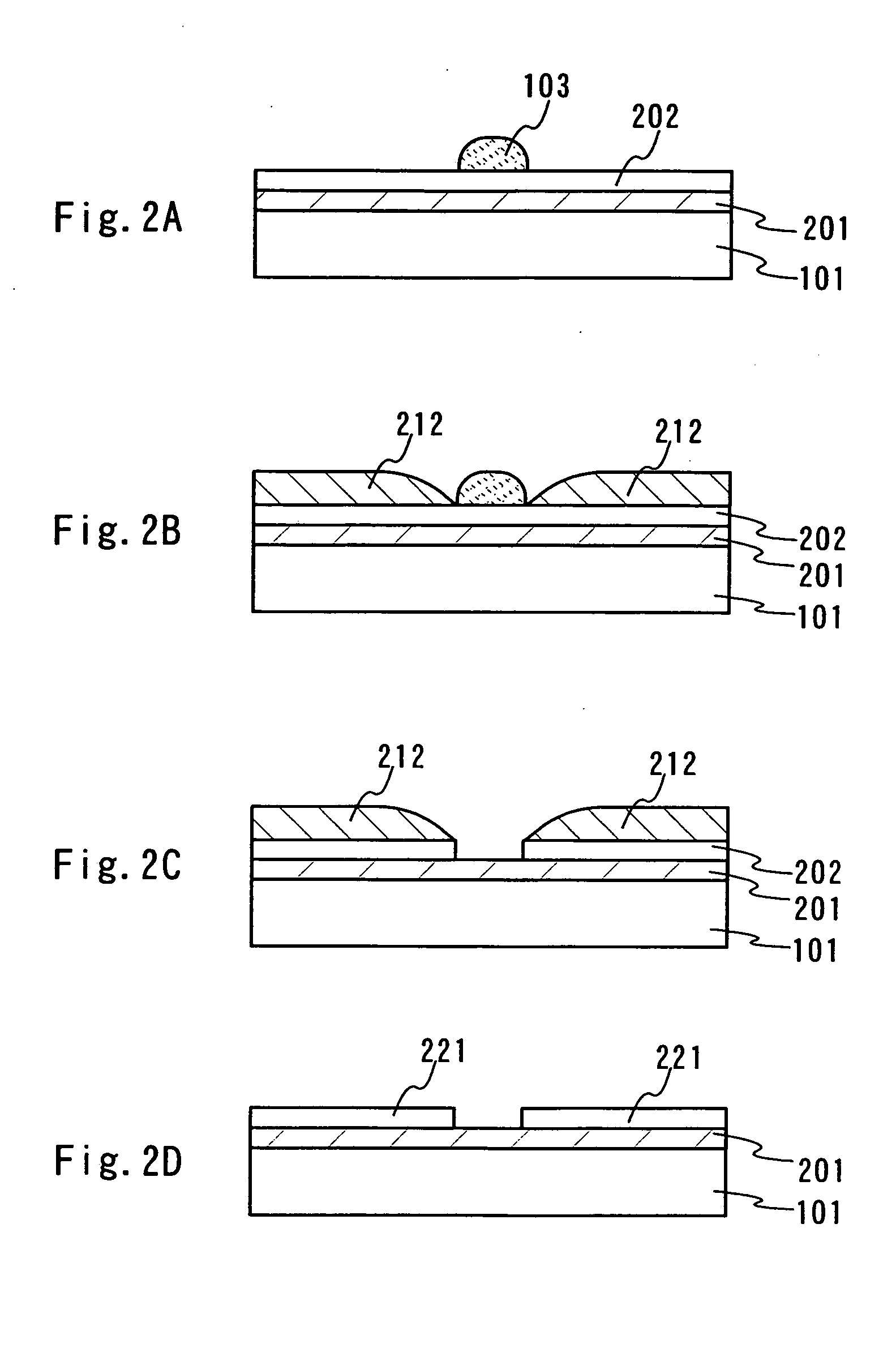

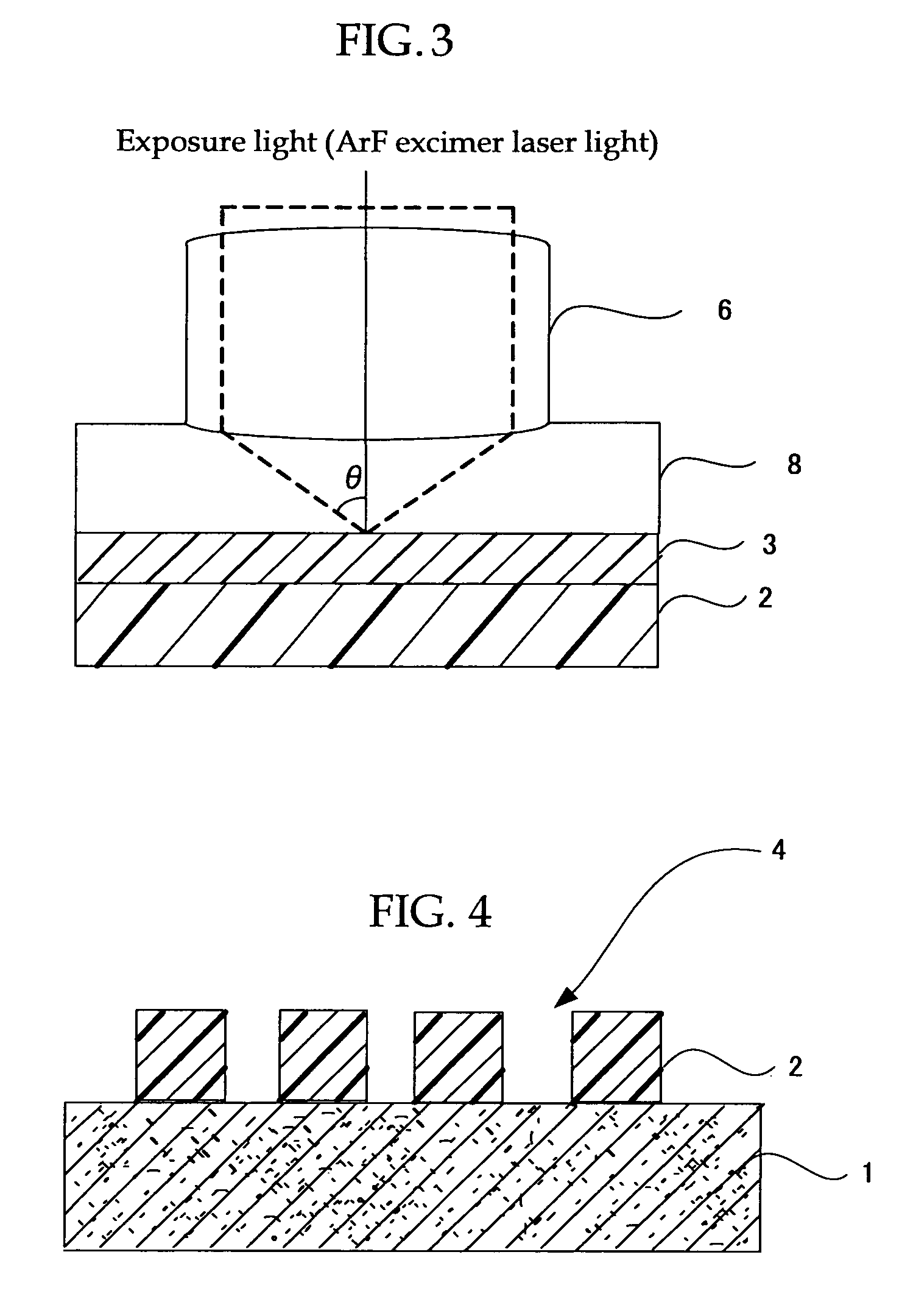

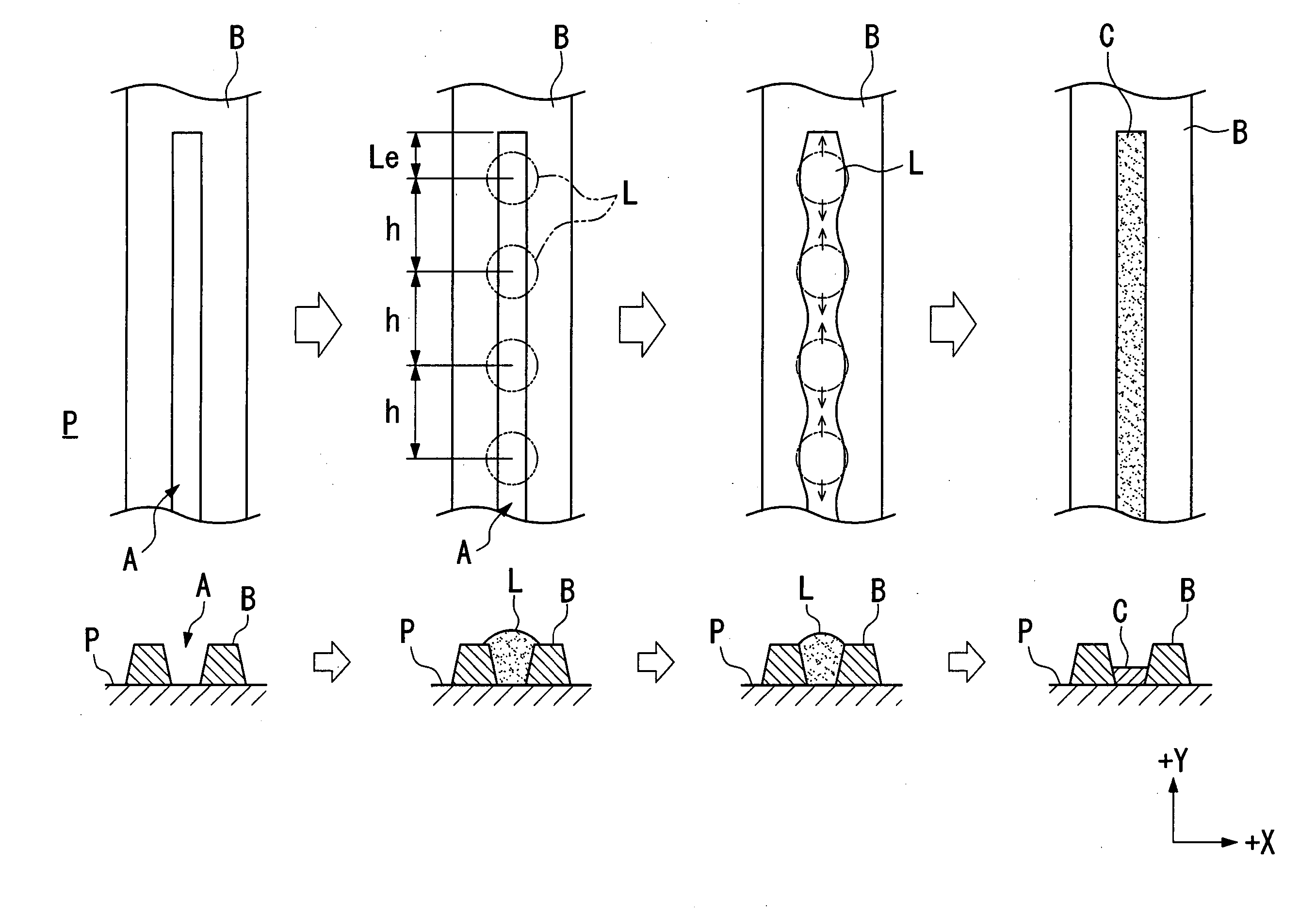

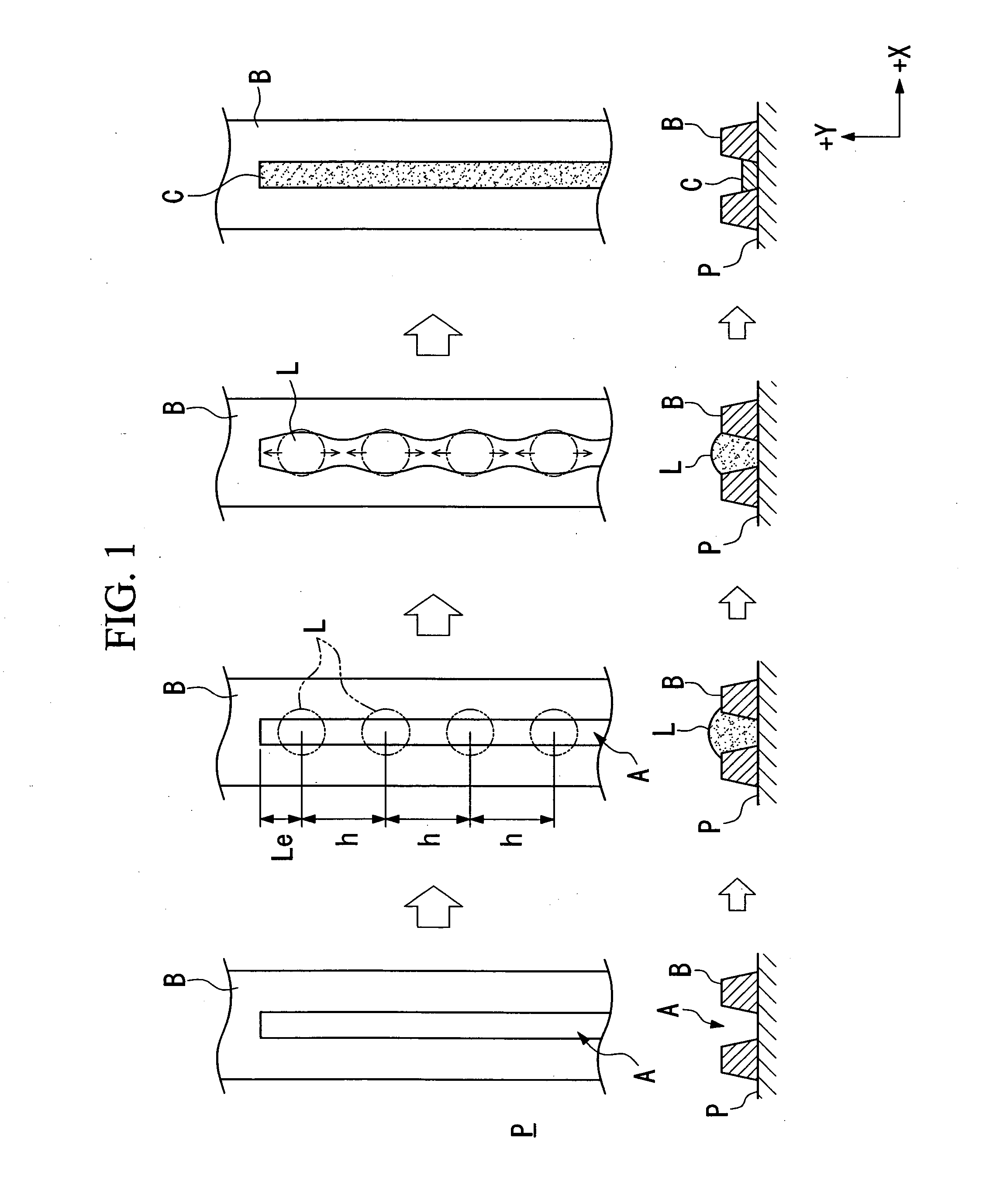

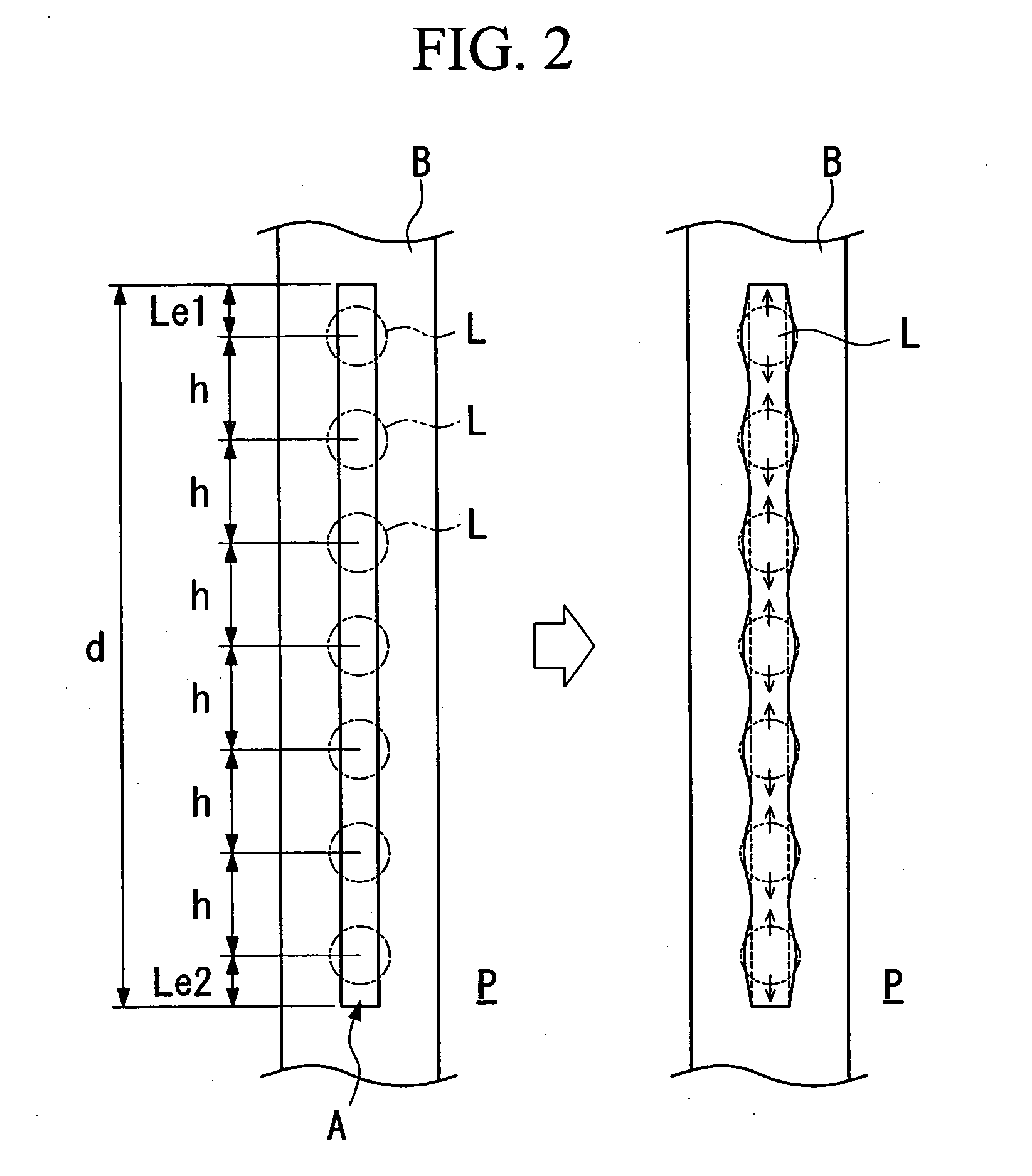

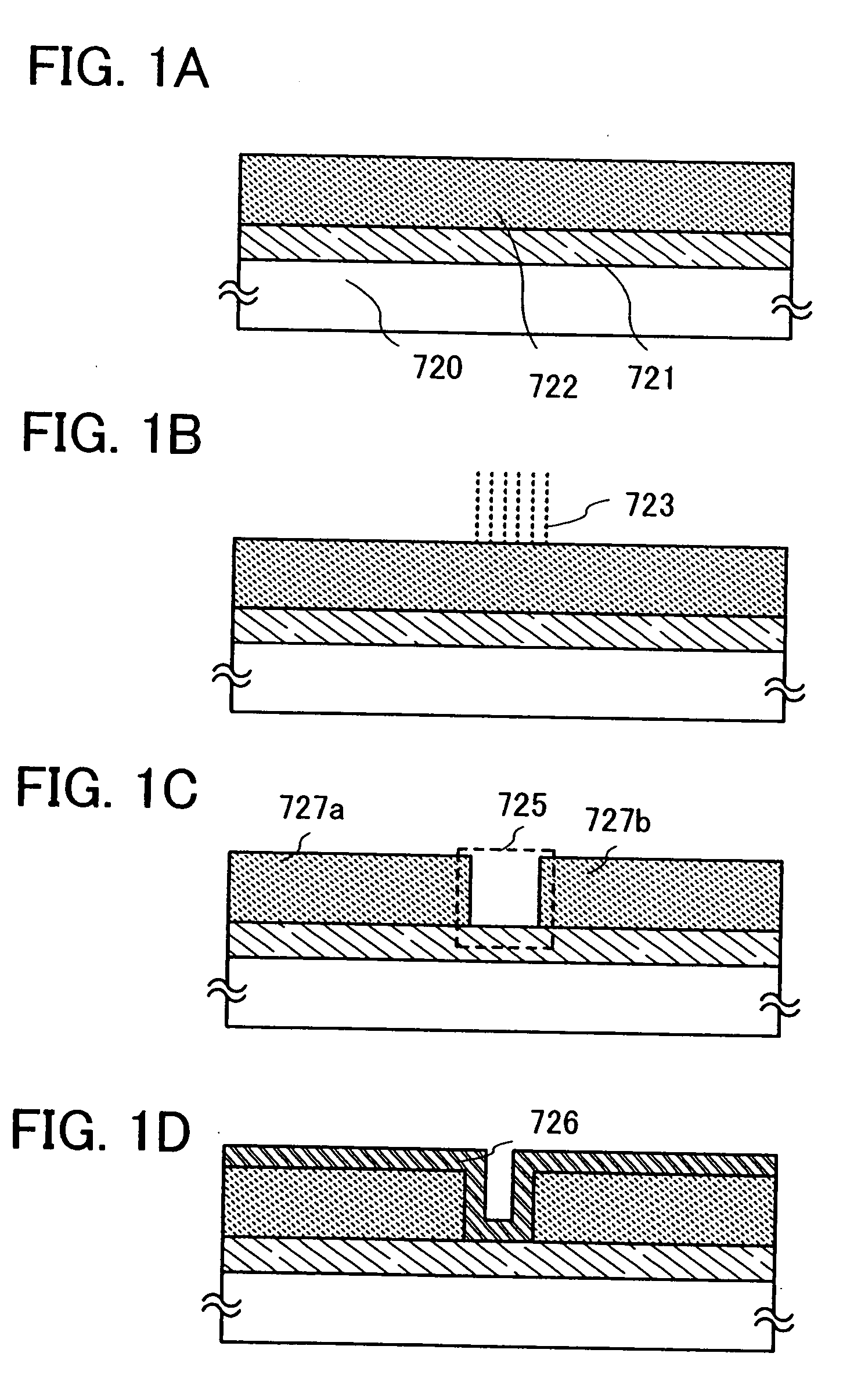

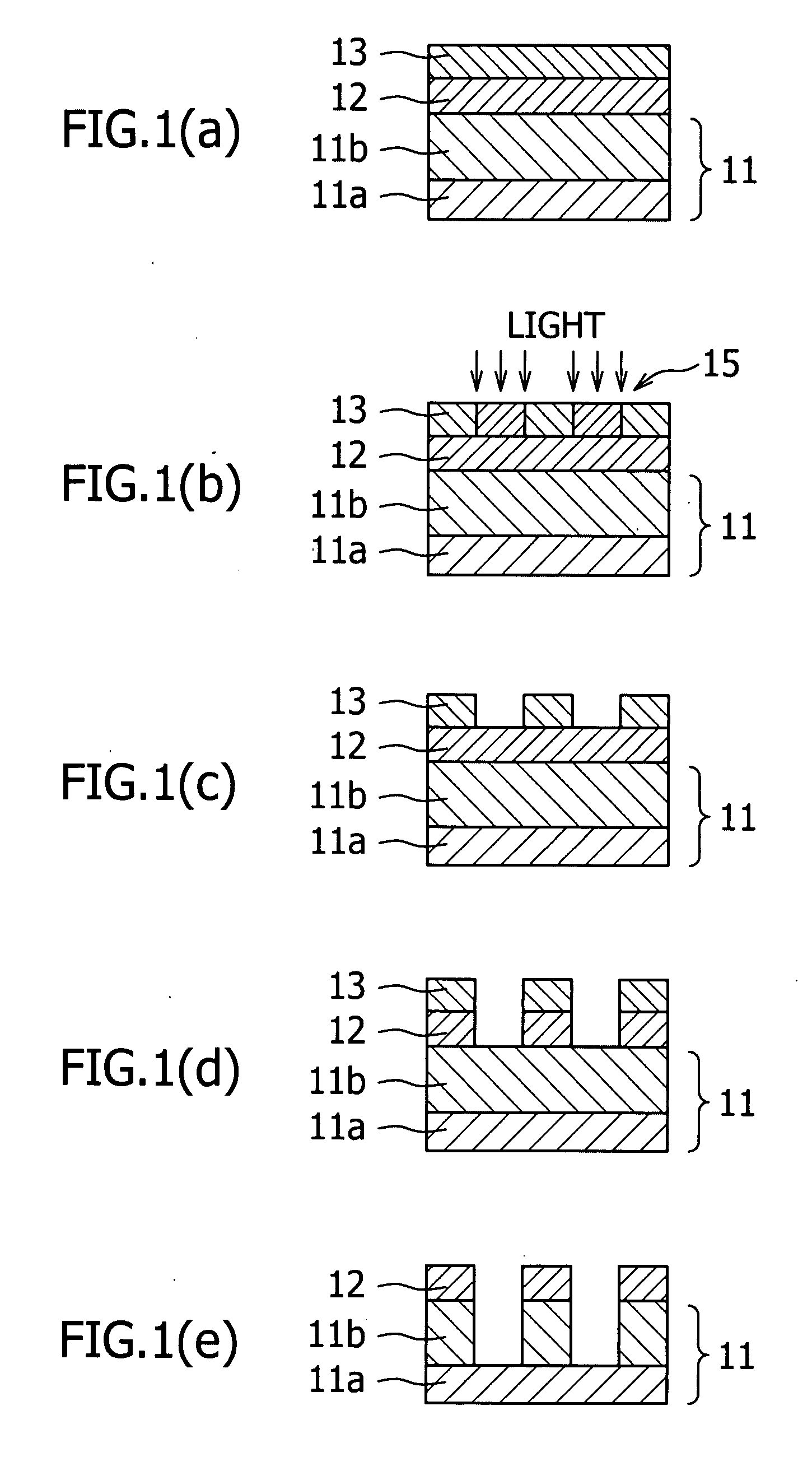

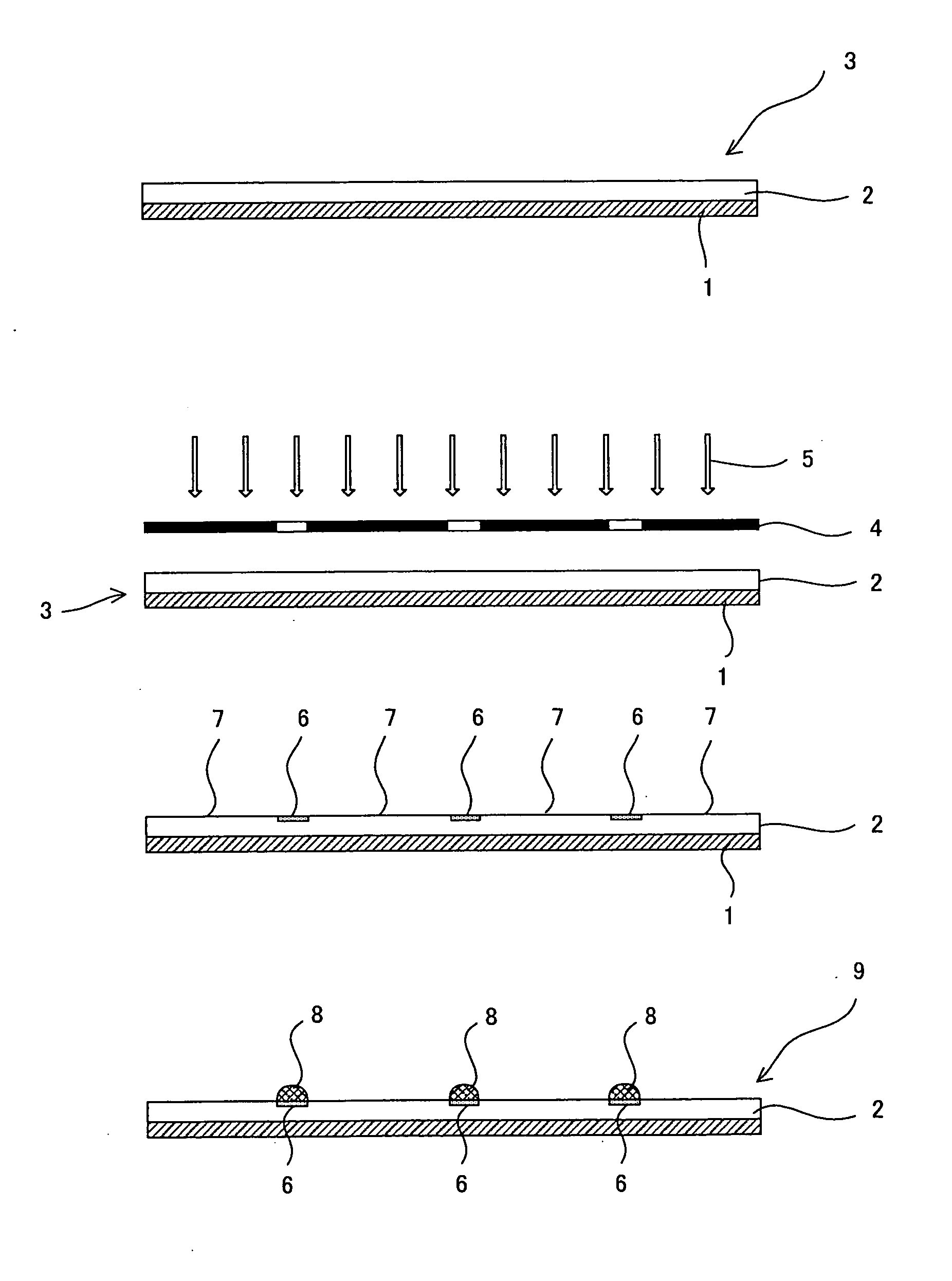

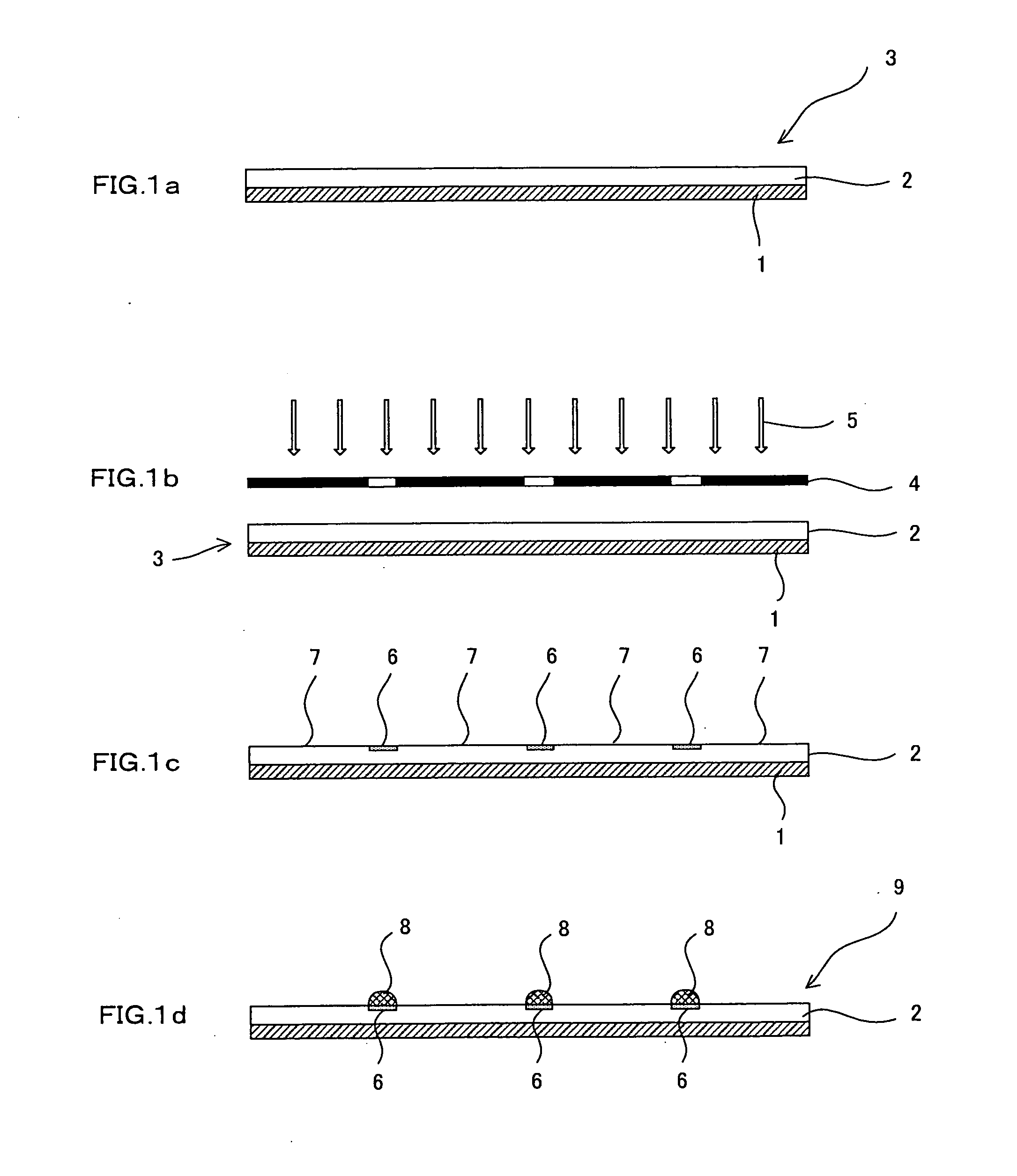

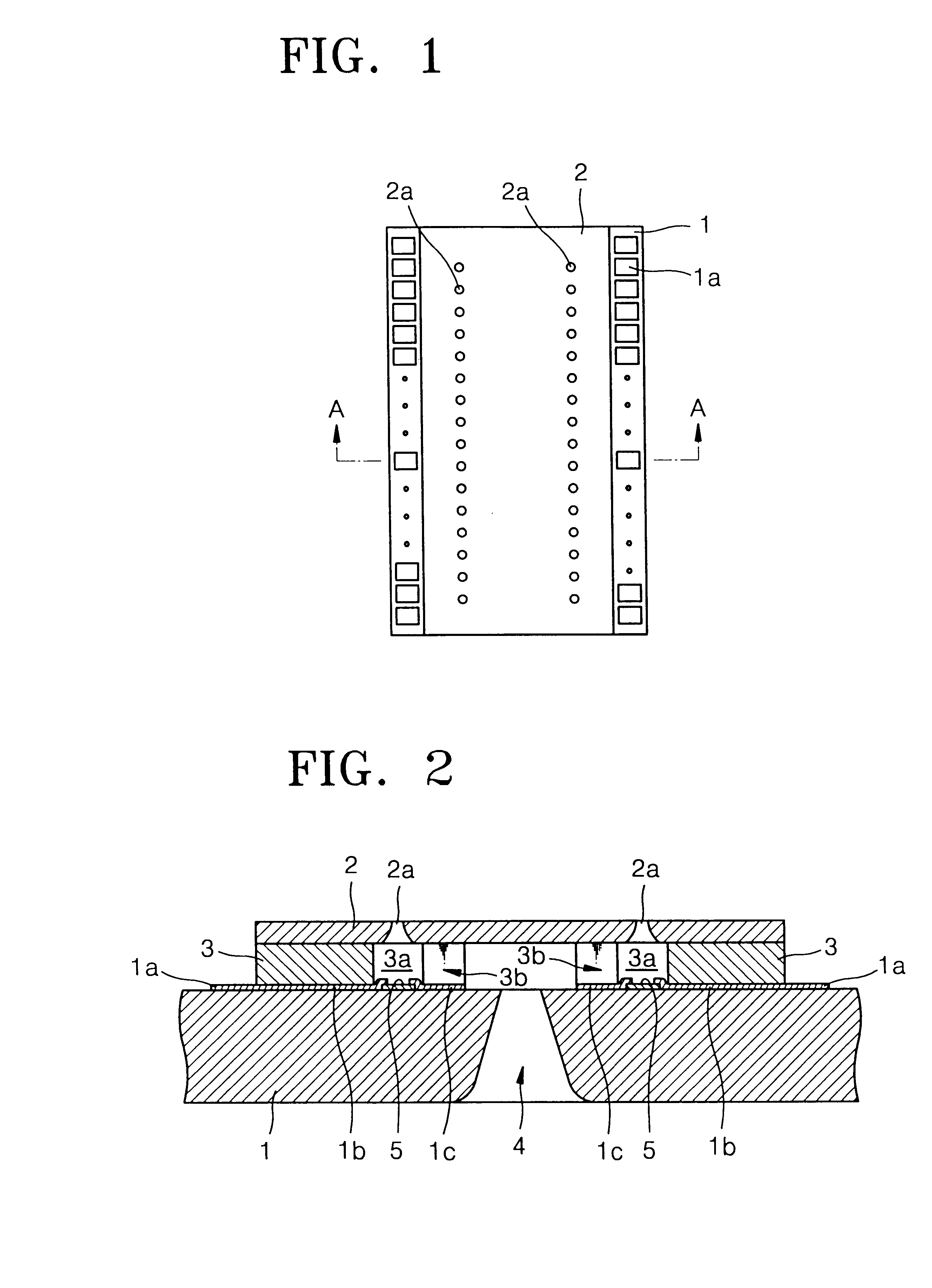

Film pattern formation method, device and method for manufacturing the same, electro-optical device, electronic device, and method for manufacturing active matrix substrate

ActiveUS20050064633A1Reduce width of grooveStable mannerMolten spray coatingElectric lighting sourcesElectro-opticsMechanical engineering

A method for forming a film pattern on a substrate includes the steps of: forming banks on the substrate; and making liquid drops of functional liquid land on the substrate to dispose the liquid drops in an area partitioned by the banks, wherein a spacing between the liquid drops are determined so that the liquid drops connect together after they land on the substrate, and a position in which a liquid drop of the liquid drops which lands the closest to an end of the area is spaced from the end of the area by less than a half of the spacing between the liquid drops.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

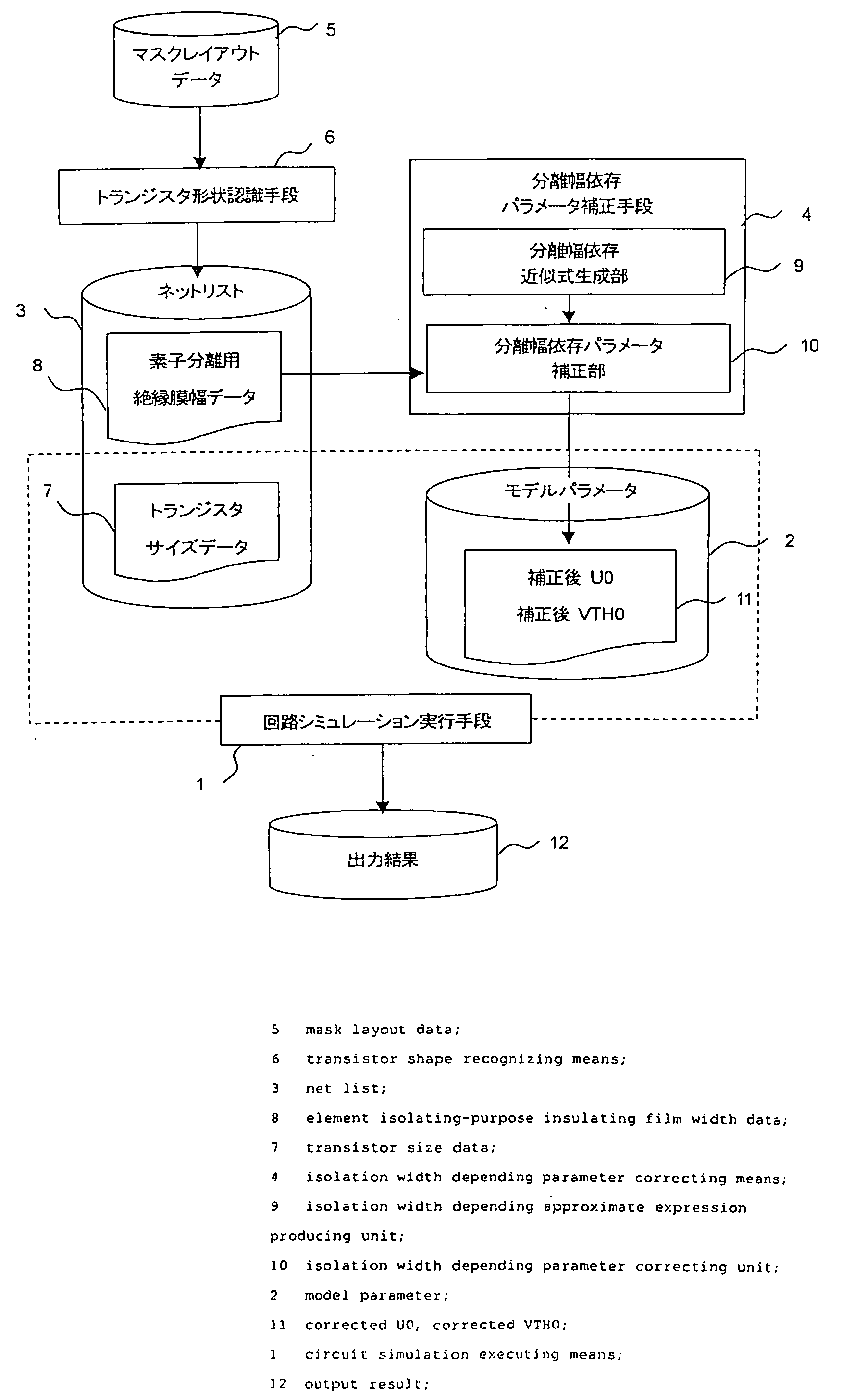

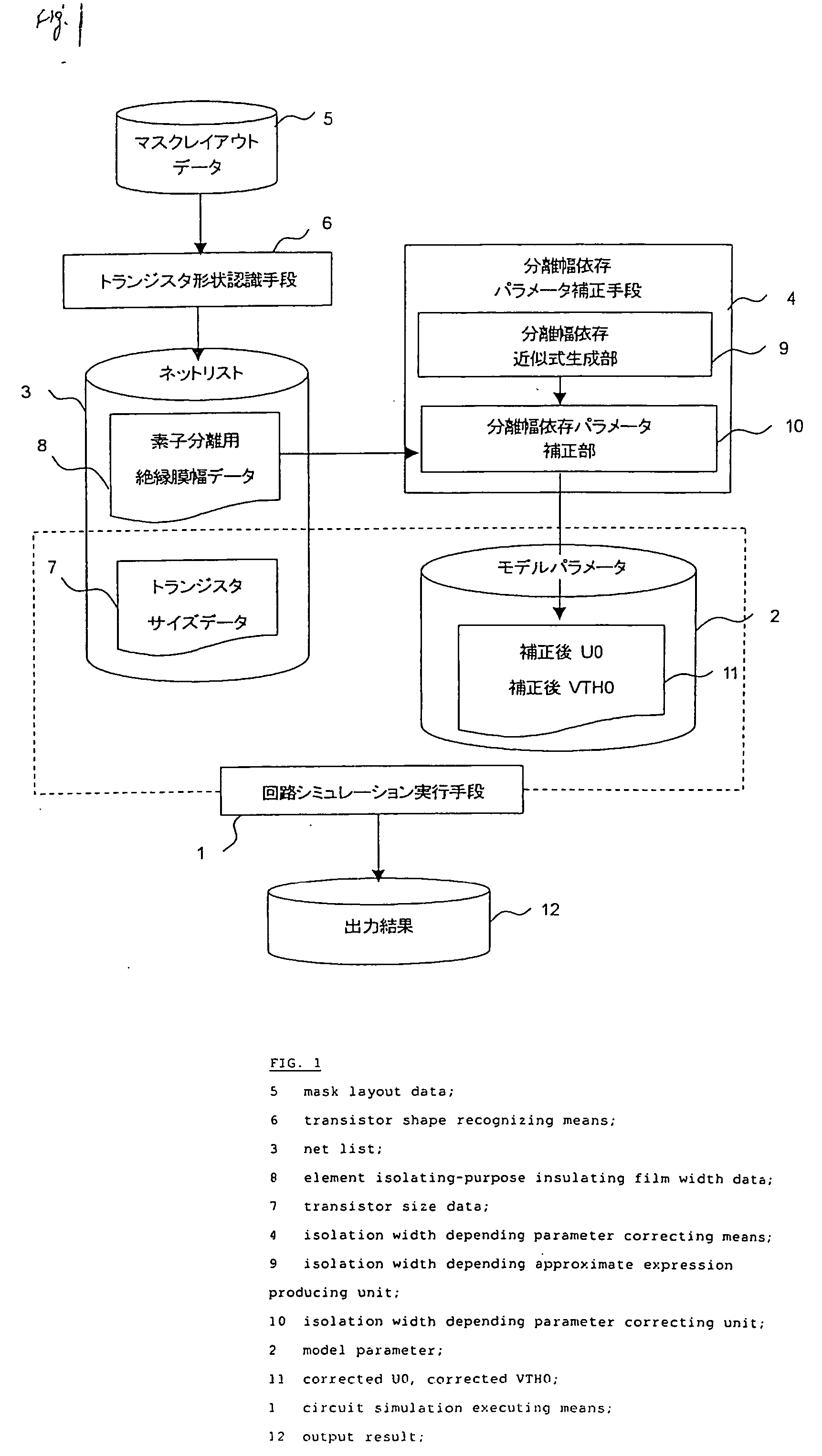

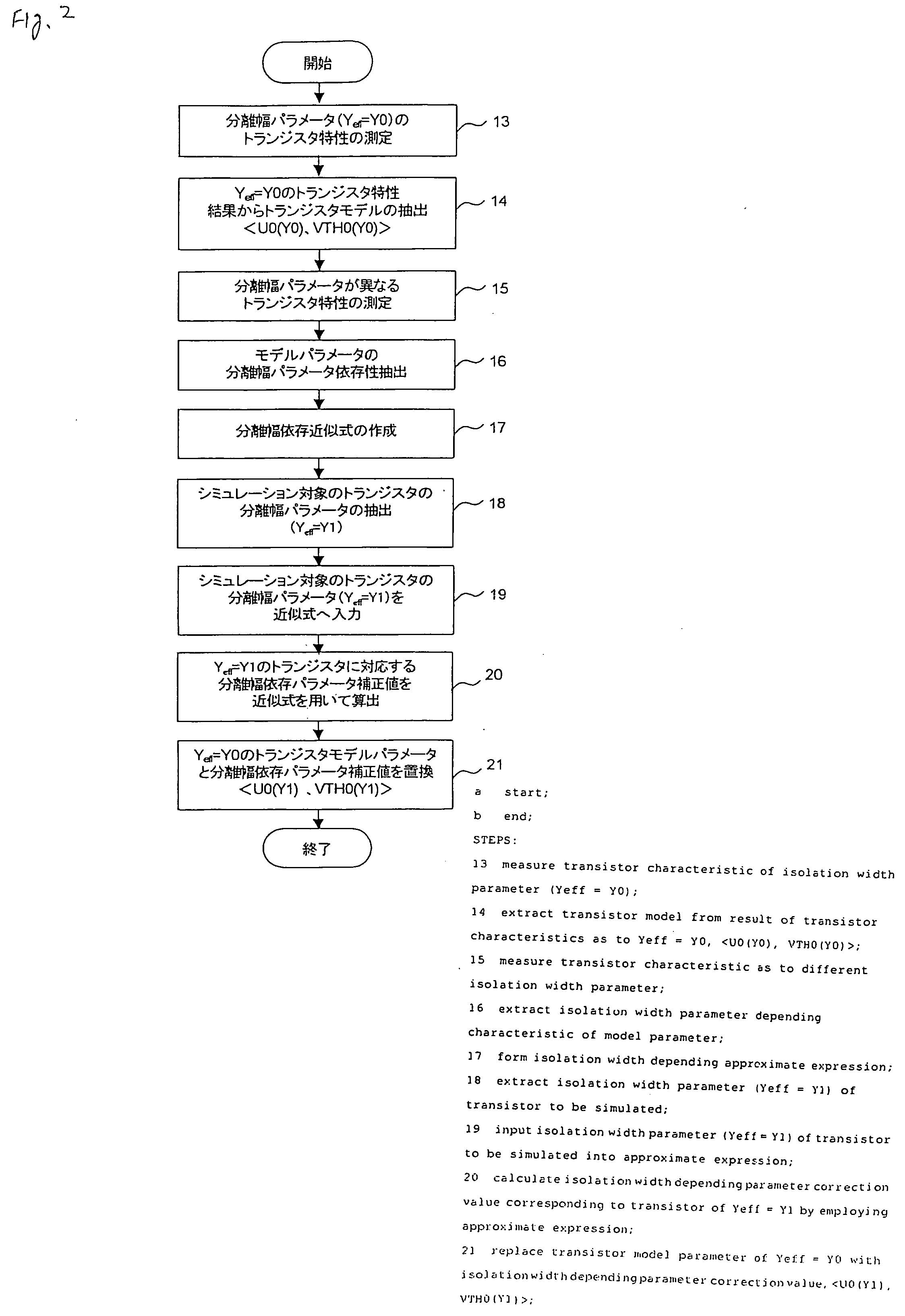

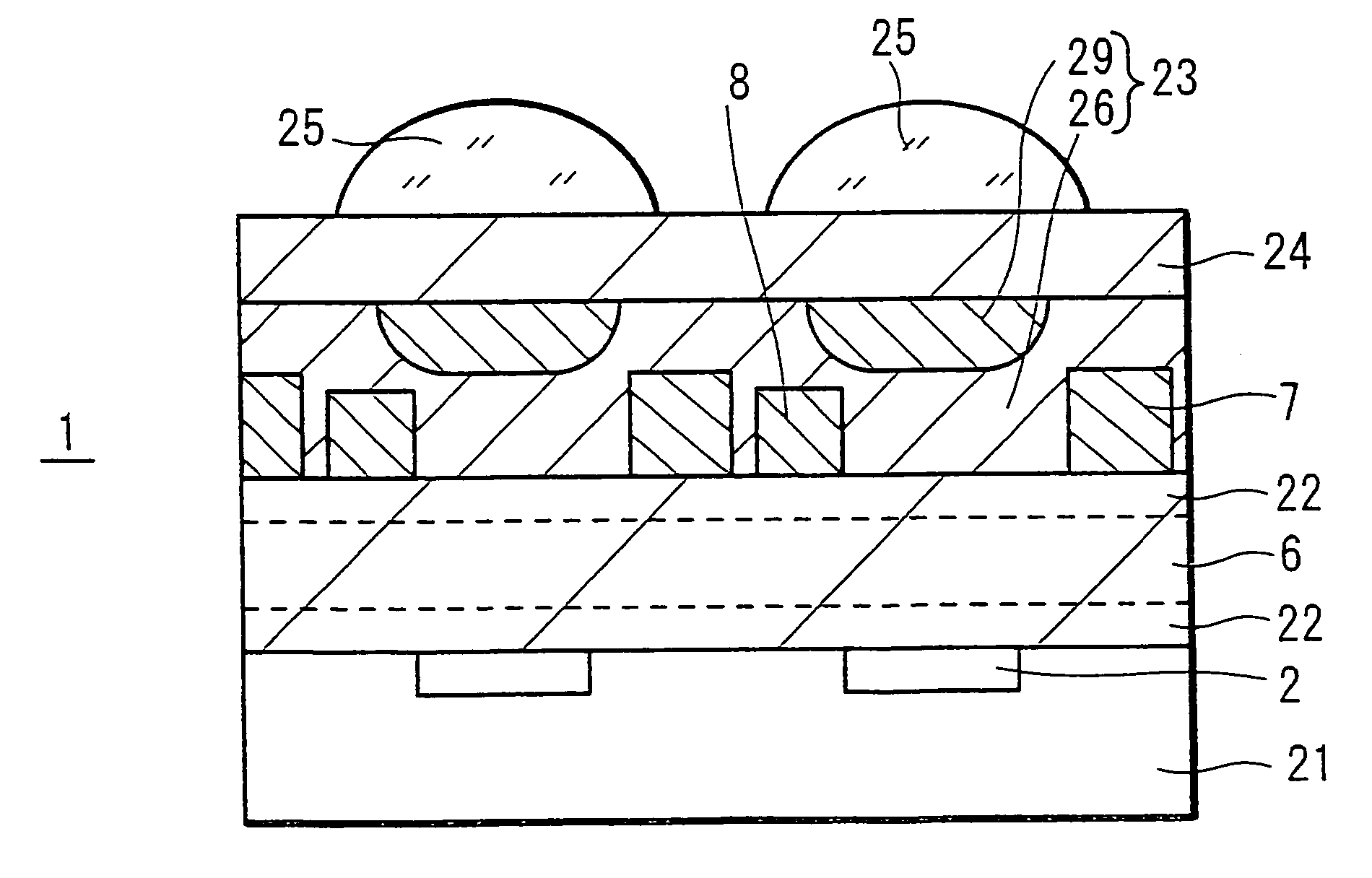

Circuit simulation method and circuit simulation apparatus

InactiveUS20060142987A1Improve accuracyHigh precision formingDetecting faulty computer hardwareComputer aided designEngineeringParameter dependent

A circuit simulation apparatus and a modeling method are provided which are useful to design an integrated circuit in a very fine manner by forming a model of such a transistor that widths of element isolating-purpose insulating films are different from each other. In an isolation width depending parameter correcting means 4 of the present invention, an approximate expression of a parameter having an element isolating-purpose insulating film width depending characteristic is formed, and a value of a corrected parameter obtained by employing the formed approximate expression is replaced by a value of an original parameter, so that a transistor model of such a transistor is formed in which element isolating-purpose insulating film widths are different from each other. As a consequence, circuit simulation can be carried out in high precision by considering a change in transistor characteristics caused by a stress, which are approximated to actually measured data.

Owner:PANASONIC CORP

Floor panel with a tongue, groove and a strip

InactiveUS20090151291A1Simpler and cheapImprove accuracyRoof covering using slabs/sheetsCovering/liningsSurface plate

Owner:VÄLINGE INNOVATION AB

Discharge device, control method thereof, discharge method, method for manufacturing microlens array, and method for manufacturing electrooptic device

InactiveUS7073727B2Improve accuracyHigh precision formingBurnersOptical filtersData selectionSignal on

Owner:SEIKO EPSON CORP

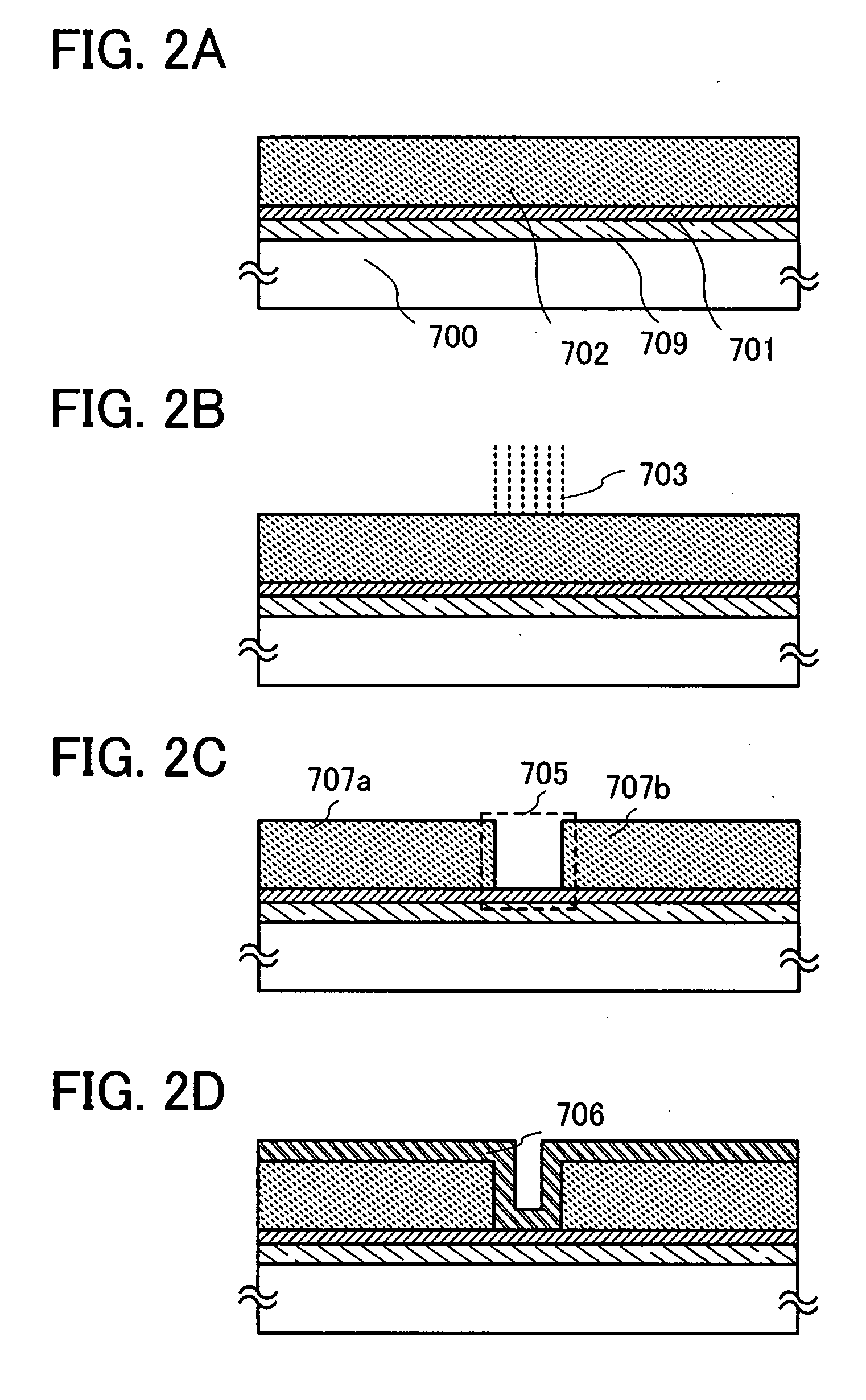

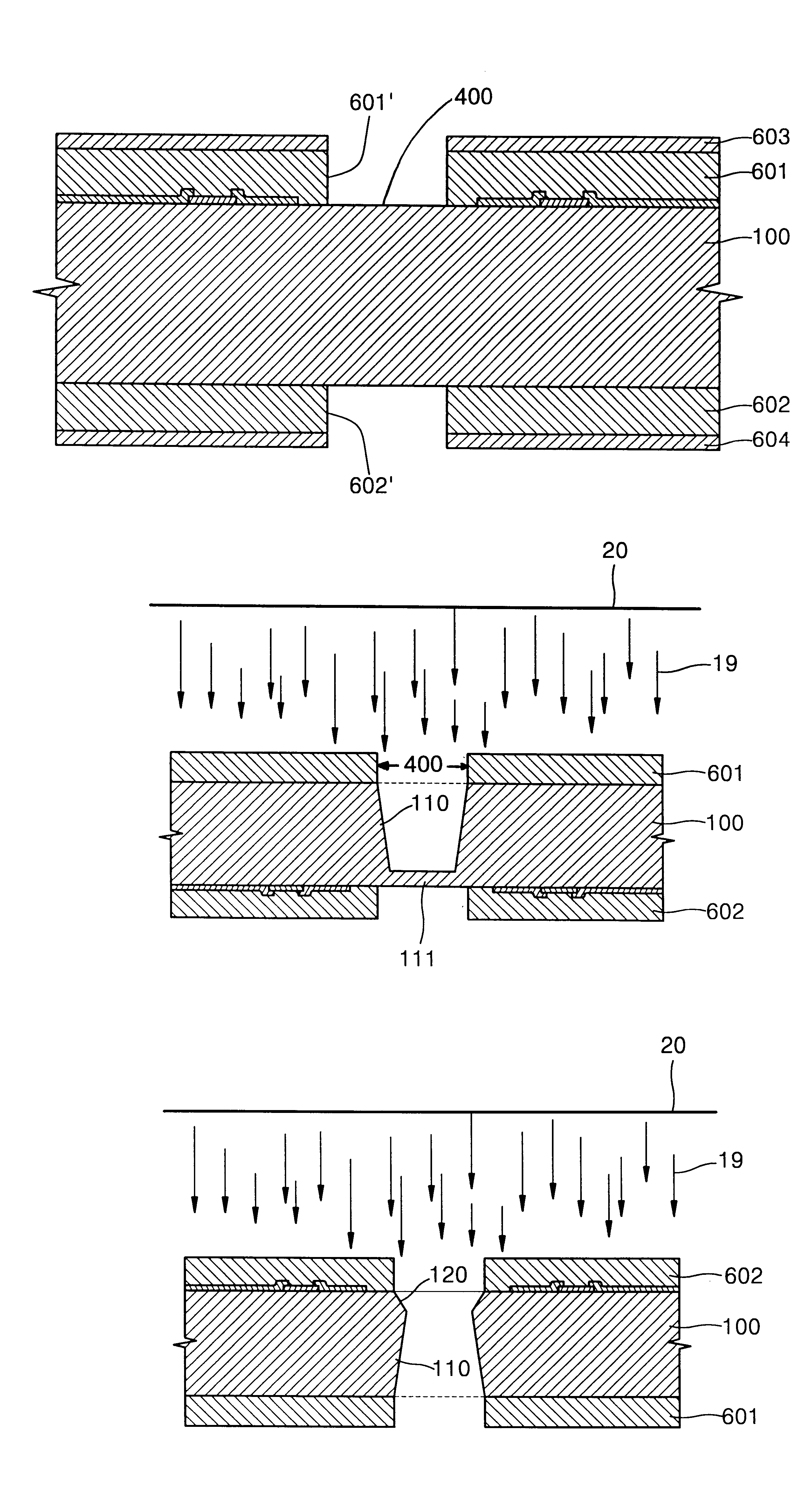

Method for manufacturing display device

InactiveUS20080227232A1Reduce in quantitySimple processSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

An object is to provide a display device that can be manufactured by improvement of use efficiency of a material and simplification of a manufacturing process. A light absorbing layer is formed, an insulating layer is formed over the light absorbing layer, the light absorbing layer and the insulating layer are selectively irradiated with laser light, an irradiated region in the insulating layer is removed to form an opening in the insulating layer, and a conductive film is formed in the opening so as to be in contact with the light absorbing layer. The conductive film is formed in the opening so as to be in contact with the light absorbing layer, which is exposed, so that the light absorbing layer and the conductive layer can be electrically connected with the insulating layer interposed therebetween.

Owner:SEMICON ENERGY LAB CO LTD

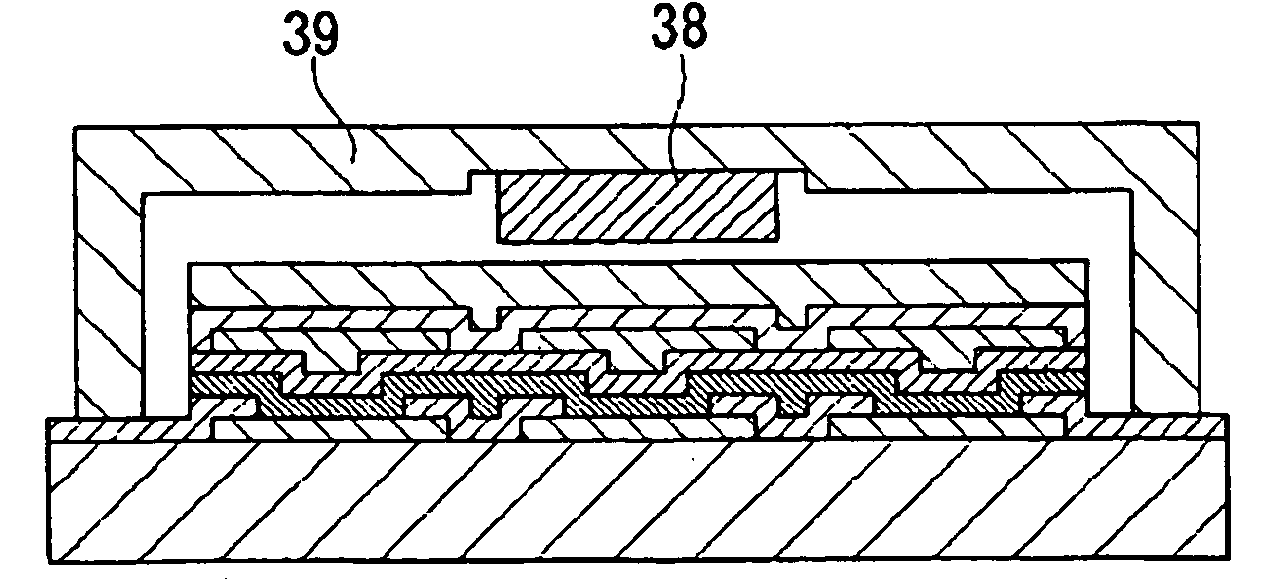

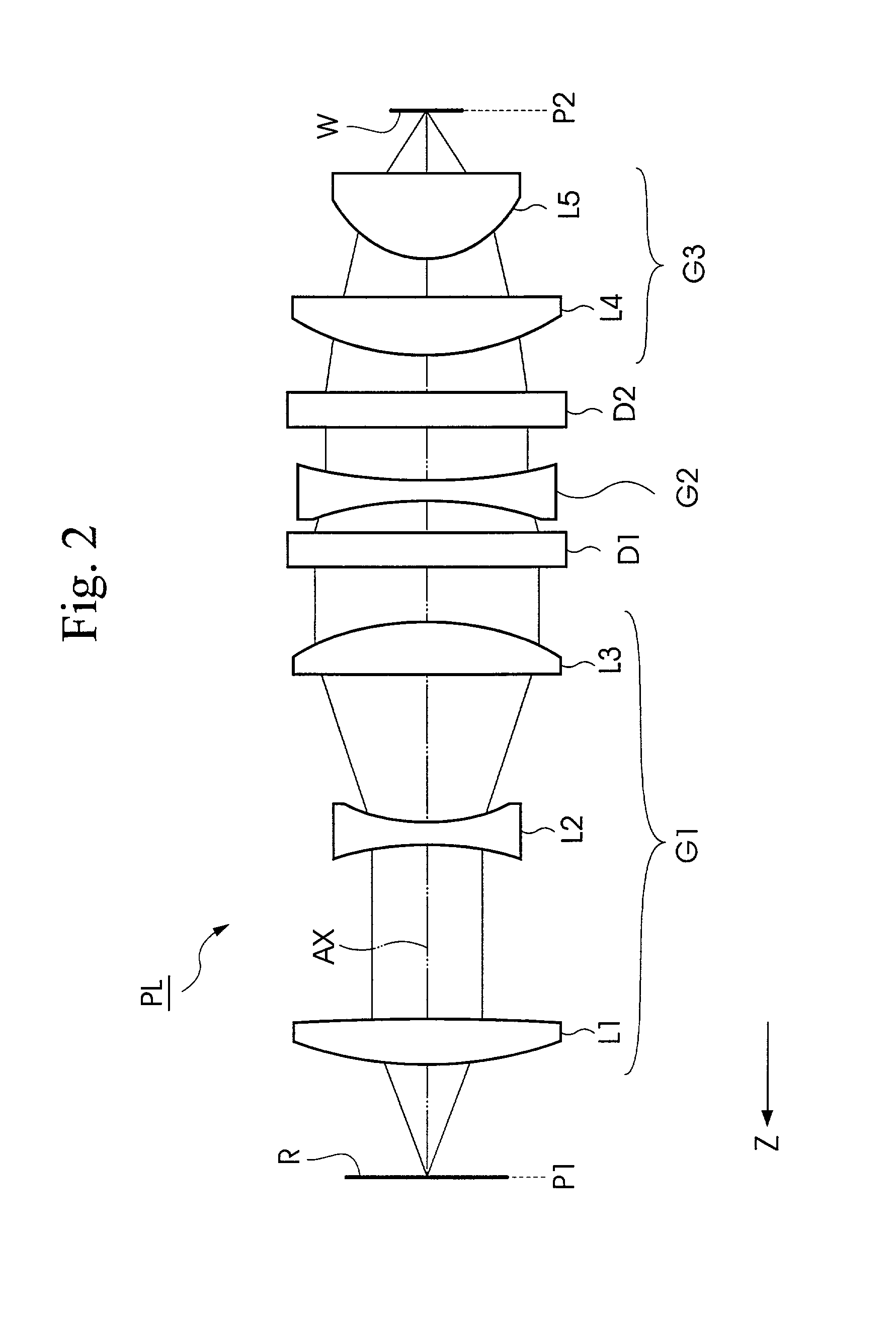

Projection optical system, exposure apparatus incorporating this projection optical system, and manufacturing method for micro devices using the exposure apparatus

InactiveUS20020005938A1Improve accuracyHigh precision formingSemiconductor/solid-state device manufacturingDiffraction gratingsMicro devicesNegative power

In a projection optical system which forms an image of a first plane on a second plane, using extreme ultraviolet illumination light, an object of the invention is to form an image on the first plane on the second plane under suitable conditions. This projection optical system comprises a first diffractive optical element arranged in an optical path between the first plane and the second plane; a second diffractive optical element arranged in the optical path on the side of the second plane from the first diffractive optical element; and an optical system having a negative power, arranged in the optical path between the first diffractive optical element and the second diffractive optical element.

Owner:NIKON CORP

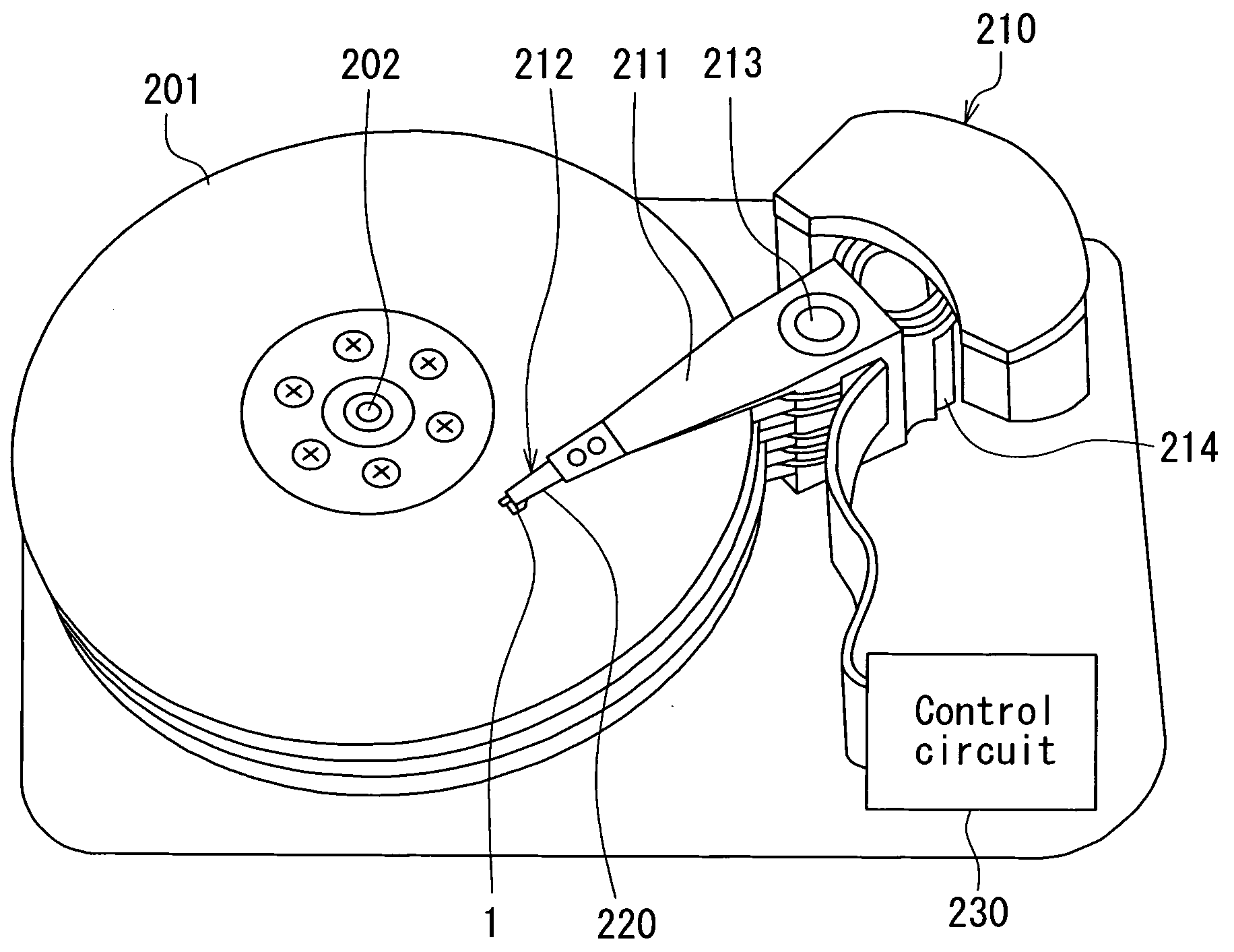

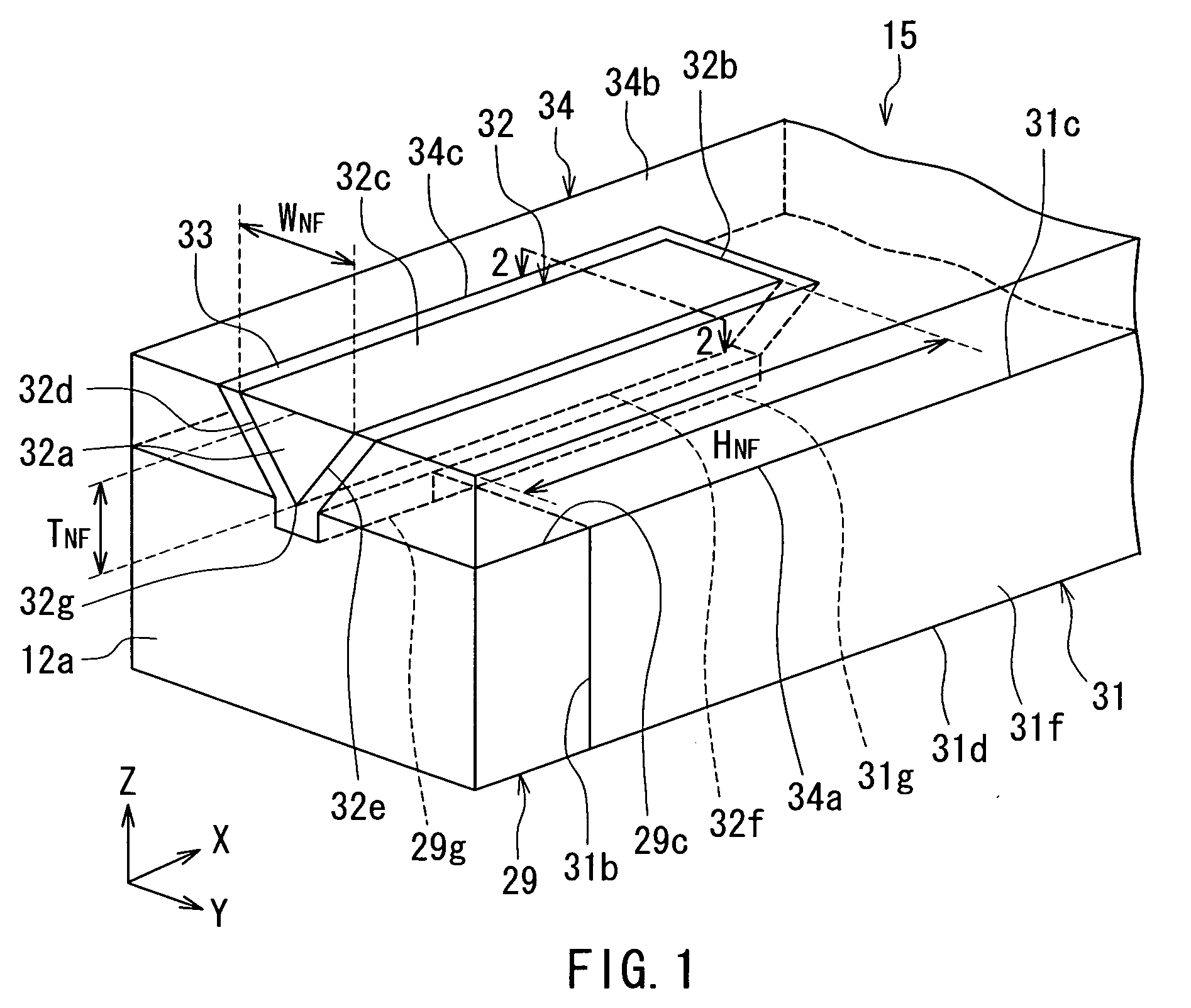

Near-field light generating device including near-field light generating element with edge part opposed to waveguide

ActiveUS20100290323A1Improve efficiencyReduce spot diameterCombination recordingRecord information storageWaveguide

A near-field light generating device includes: a waveguide having a groove that opens in the top surface; a clad layer disposed on the top surface of the waveguide and having an opening that is contiguous to the groove; a near-field light generating element accommodated in the opening; and a buffer layer interposed between the near-field light generating element and each of the waveguide and the clad layer in the groove and the opening. The near-field light generating element includes: first and second side surfaces that decrease in distance from each other toward the groove; an edge part that connects the first and second side surfaces to each other and is opposed to the groove with the buffer layer therebetween; and a near-field light generating part that lies at one end of the edge part and generates near-field light.

Owner:TDK CORPARATION

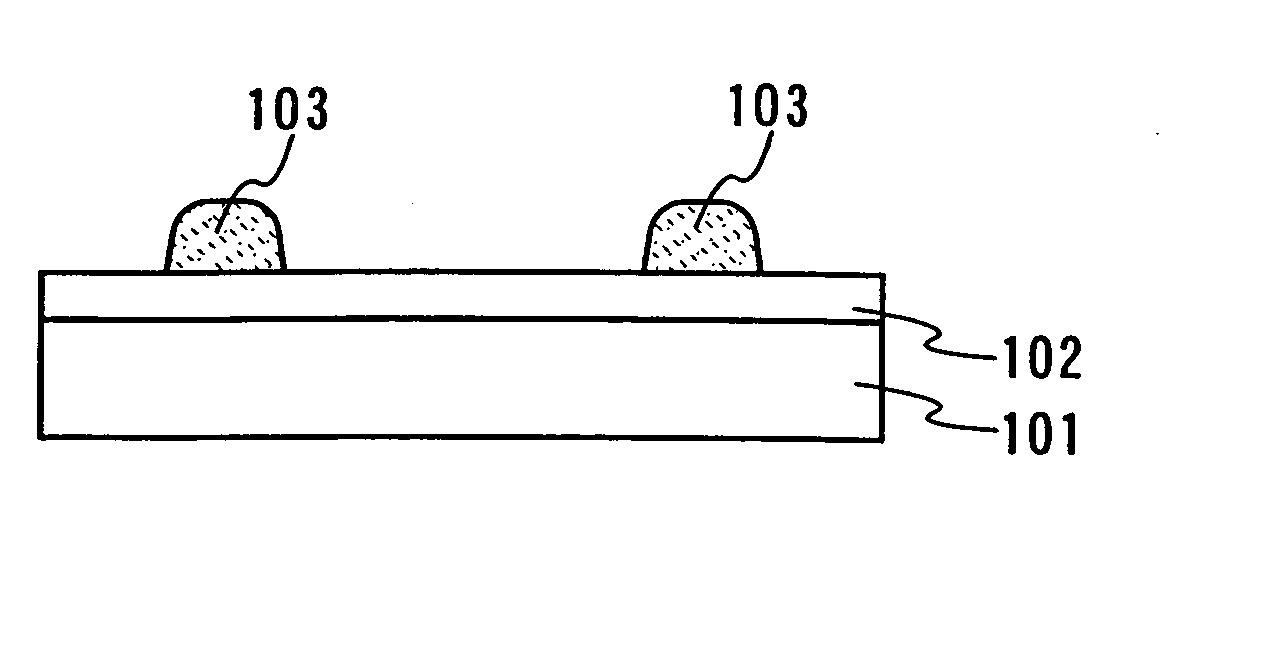

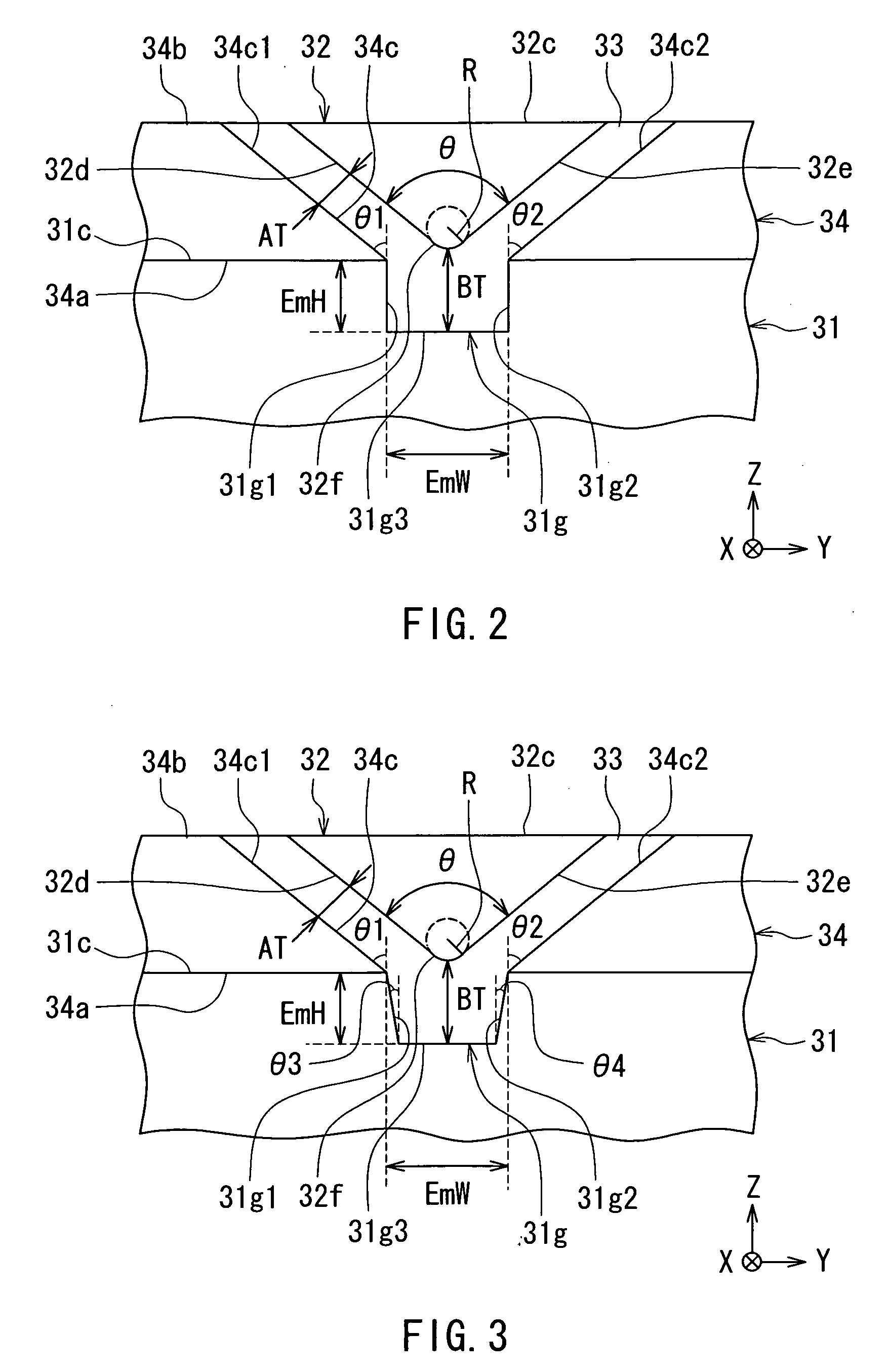

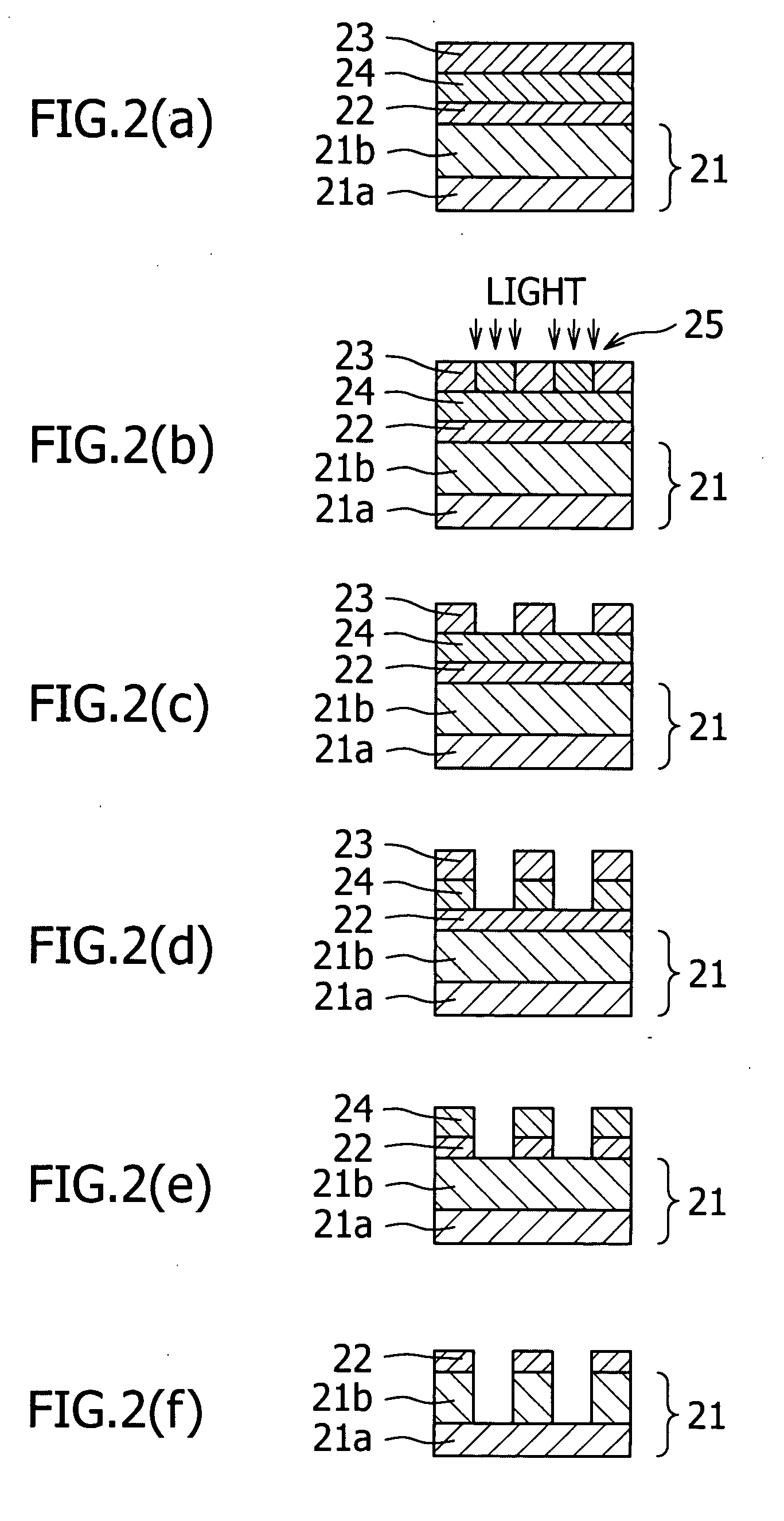

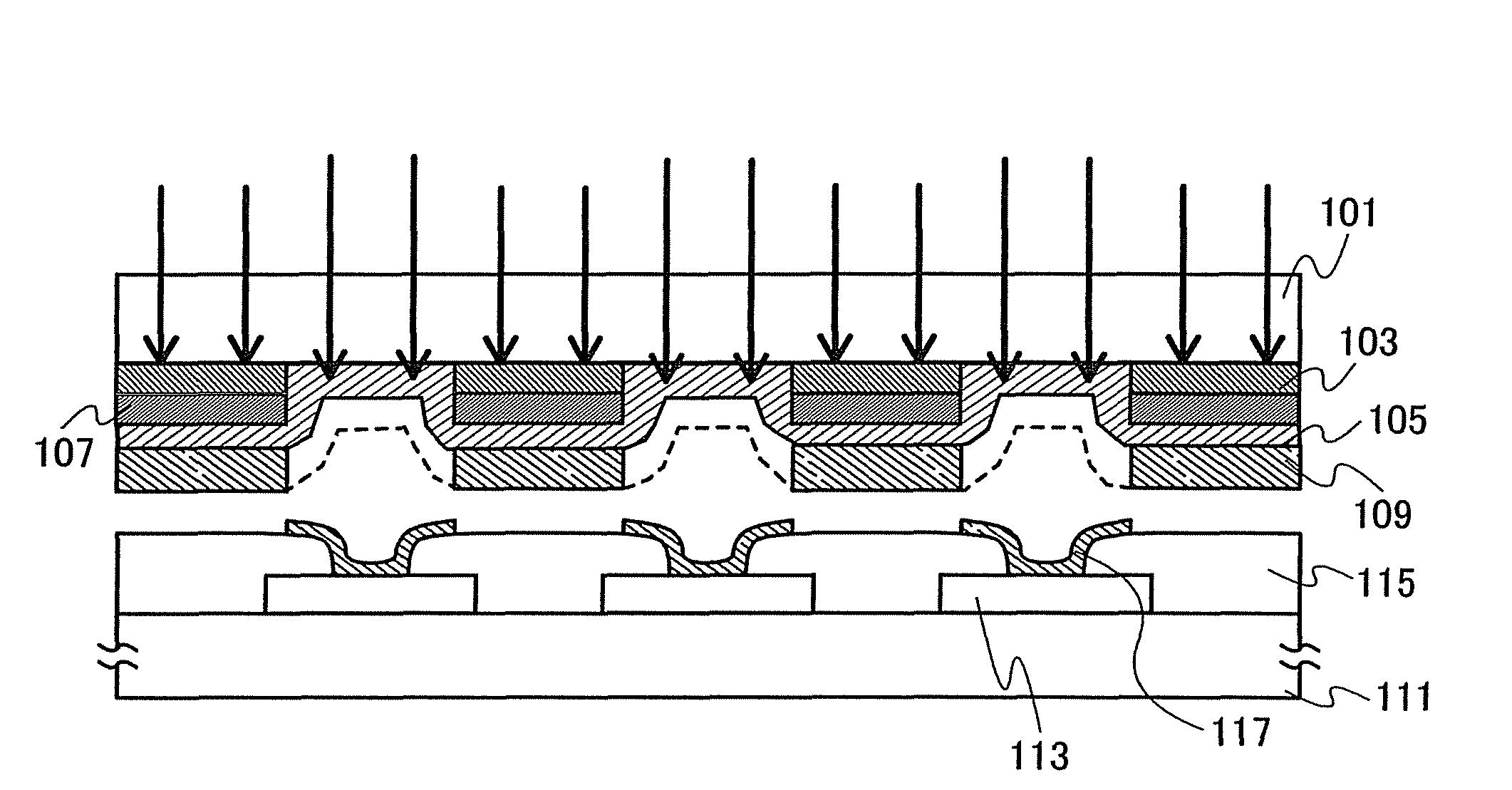

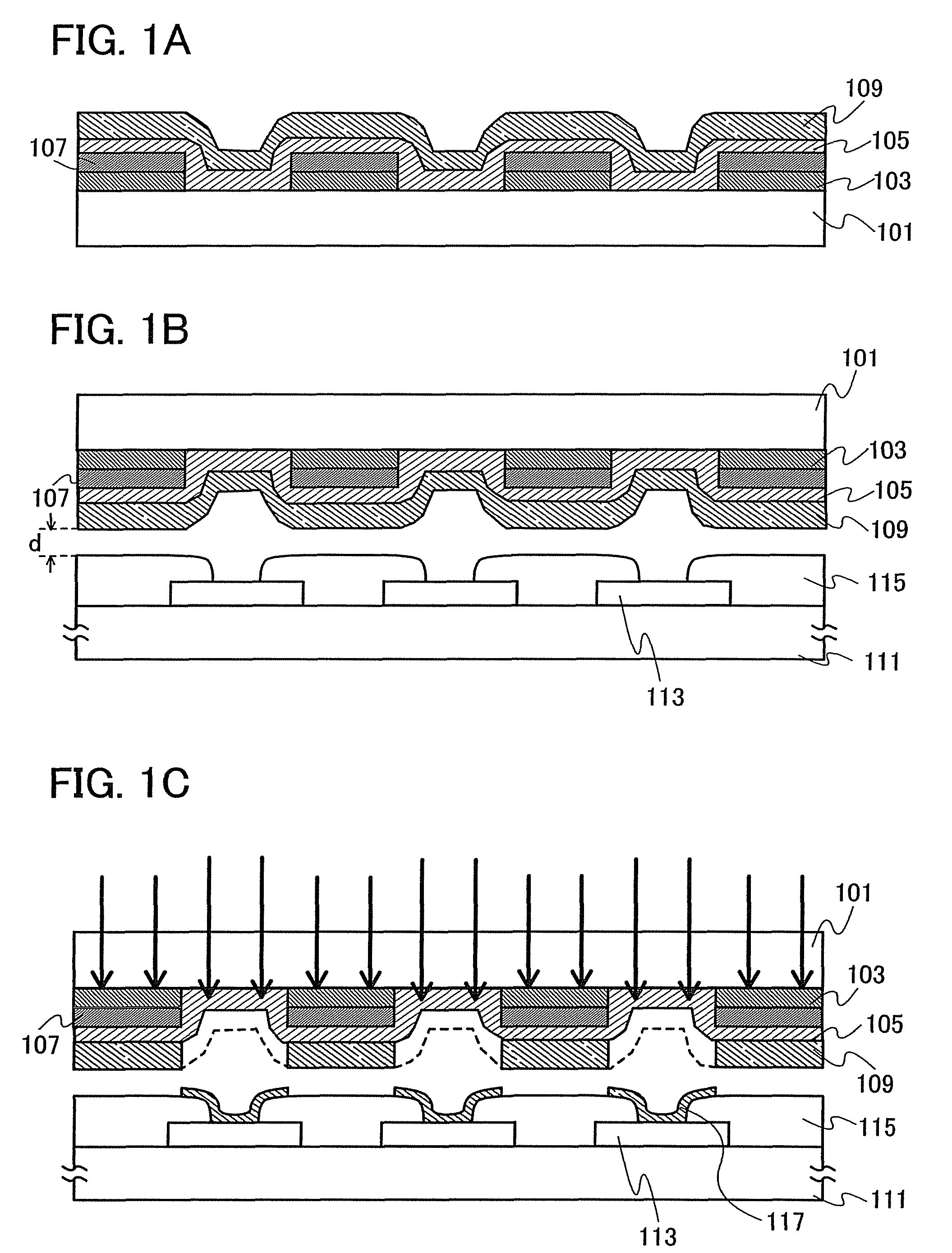

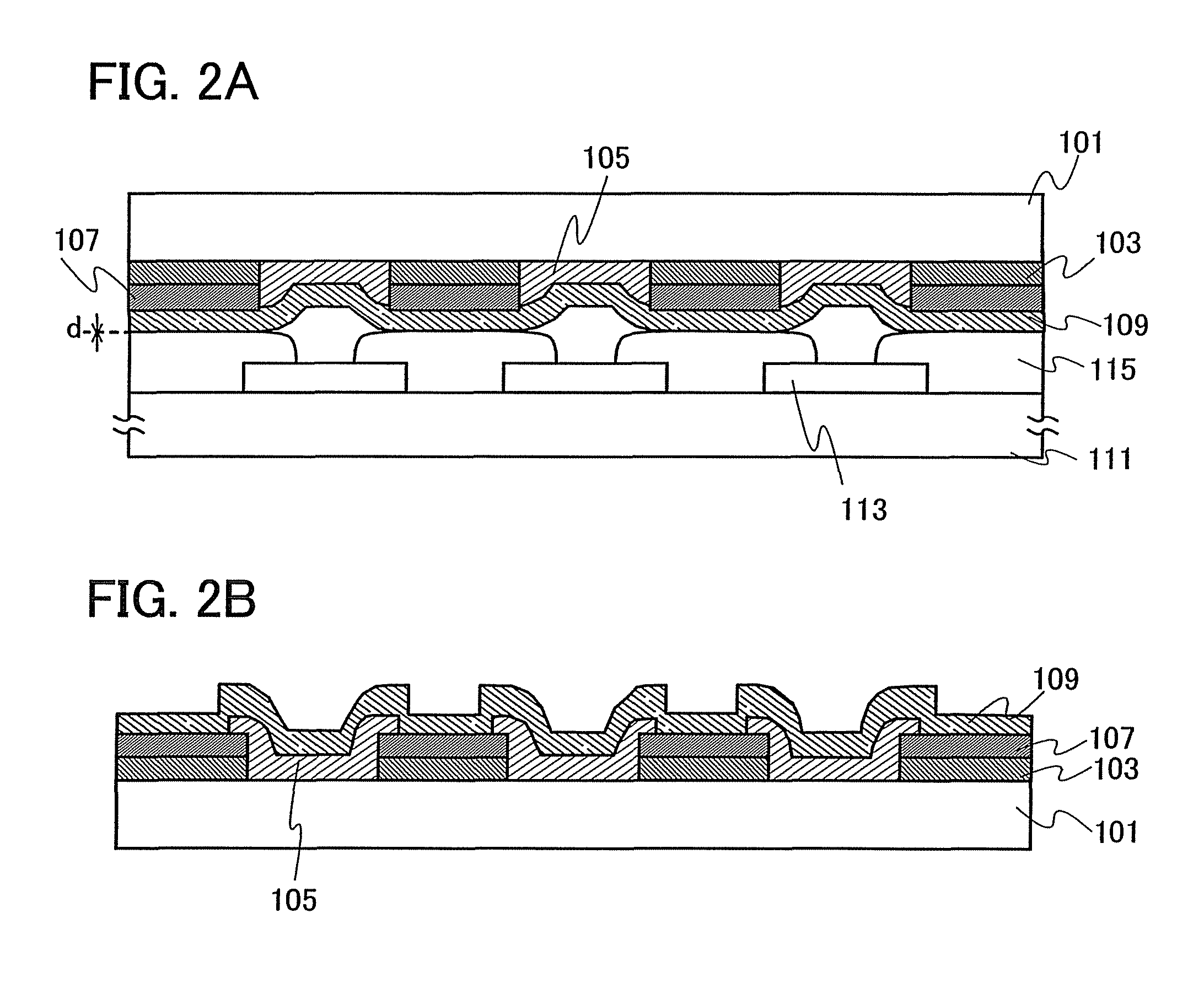

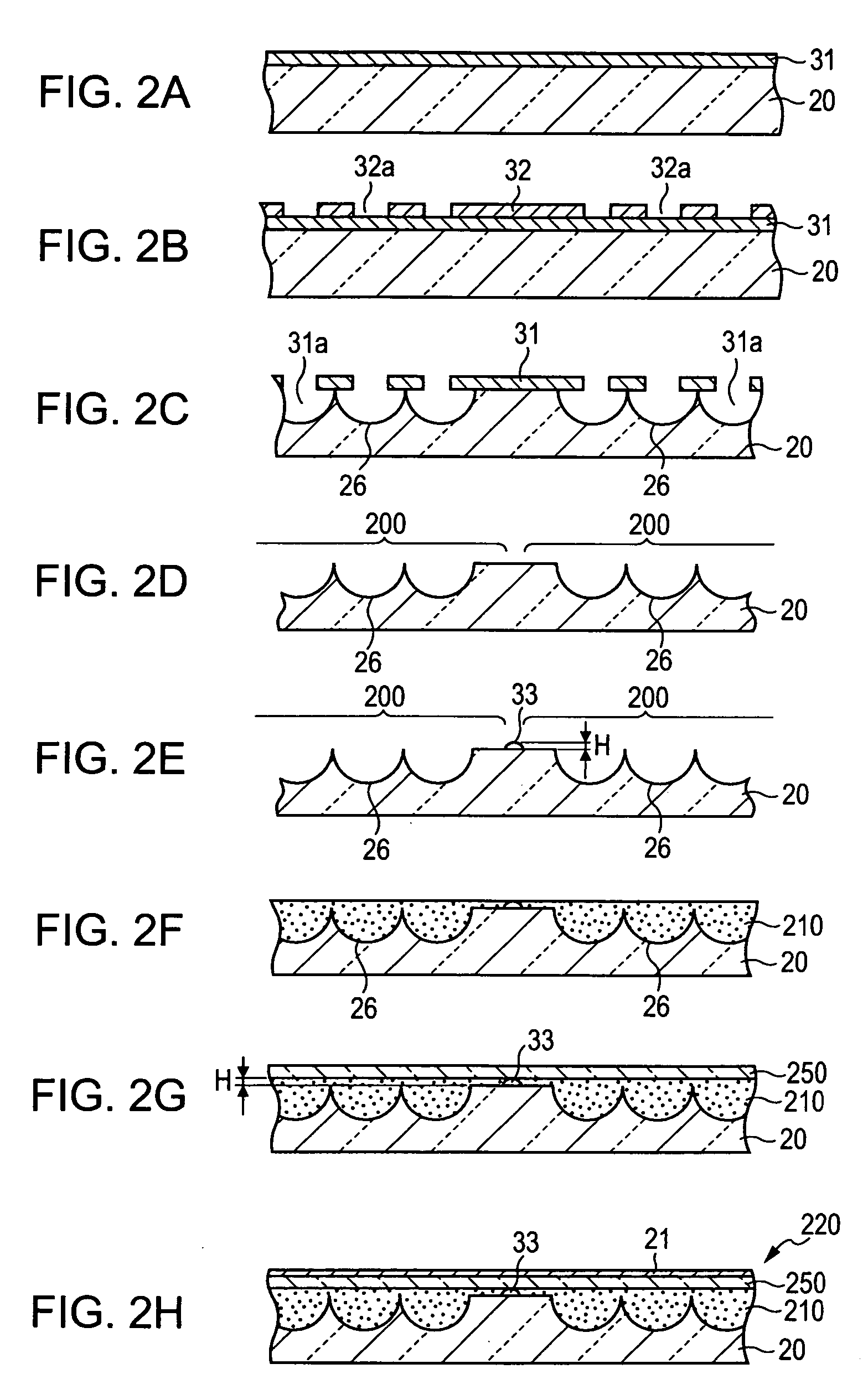

Solid state imaging device and production method therefor

InactiveUS20060151818A1Optimum condensingImprove accuracySolid-state devicesSemiconductor/solid-state device manufacturingCMOSInsulation layer

The present invention relates to a CMOS-type solid-state imaging device and a method for manufacturing thereof, and provides a solid-state imaging device capable of optimally condensing light by a single intra-layer lens and a manufacturing method capable of forming an intra-layer lens with high precision. The solid-state imaging device according to the present invention includes a plurality of wirings and a plurality of lenses above a light-receiving portion, in which at least one of the plurality of lenses is formed of a single intra-layer lens. The method for manufacturing the solid-state imaging device according to the present invention includes the processes of forming a concave surface or convex surface onto a first insulation layer with a first refractive index using a selective etching method and forming a second insulation layer with a second refractive index onto the concave surface or convex surface to form the intra-layer lens corresponding to the light-receiving portion.

Owner:SONY CORP

Optical image measuring apparatus and optical image measuring method

InactiveUS7492466B2Improve accuracyHigh precision formingInterferometersUsing optical meansObject basedSignal light

Provided is an optical image measuring apparatus forming a three-dimensional image based on tomographic images of an object, acquired at various depths even when the object moves during measurement. Including a half mirror (6) for dividing a light beam signal light (S) and reference light (R), a frequency shifter (8), a reference mirror (9) and a piezoelectric element (9A) used to change an optical path length of the reference light (R), CCDs (21, 22) for receiving interference light beams (L) resulting from interference light produced by superimposing the signal light (S) and the reference light (R) on each other by the half mirror (6) and outputting detection signals, an image forming portion for forming tomographic images based on the detection signals, a measurement depth calculating means (53), and an image processing portion (57). Forming a three-dimensional image or the like based on the arranged tomographic images.

Owner:KK TOPCON

Resist lower layer material, resist lower layer substrate comprising the material and method for forming pattern

ActiveUS20080032231A1Reduce harmful effectHigh precisionPhotosensitive materialsRadiation applicationsResistChemistry

Provided is a method for forming a resist lower layer material for use in a multilayer resist process, especially two-layer resist process or three-layer resist process, having a function of neutralizing an amine contaminant from a substrate, thereby reducing a harmful effect such as trailing skirts of a resist pattern of an upper layer resist. Specifically, there is provided a material for forming a lower layer of a chemically amplified photoresist layer comprising a crosslinkable polymer and a thermal acid generator that can generate an acid by heating at 100° C. or greater and is represented by the general formula (1a):R1CF2SO3−(R2)4N+, (1a)as well as a resist lower layer substrate comprising a resist lower layer formed using said material.

Owner:SHIN ETSU CHEM IND CO LTD

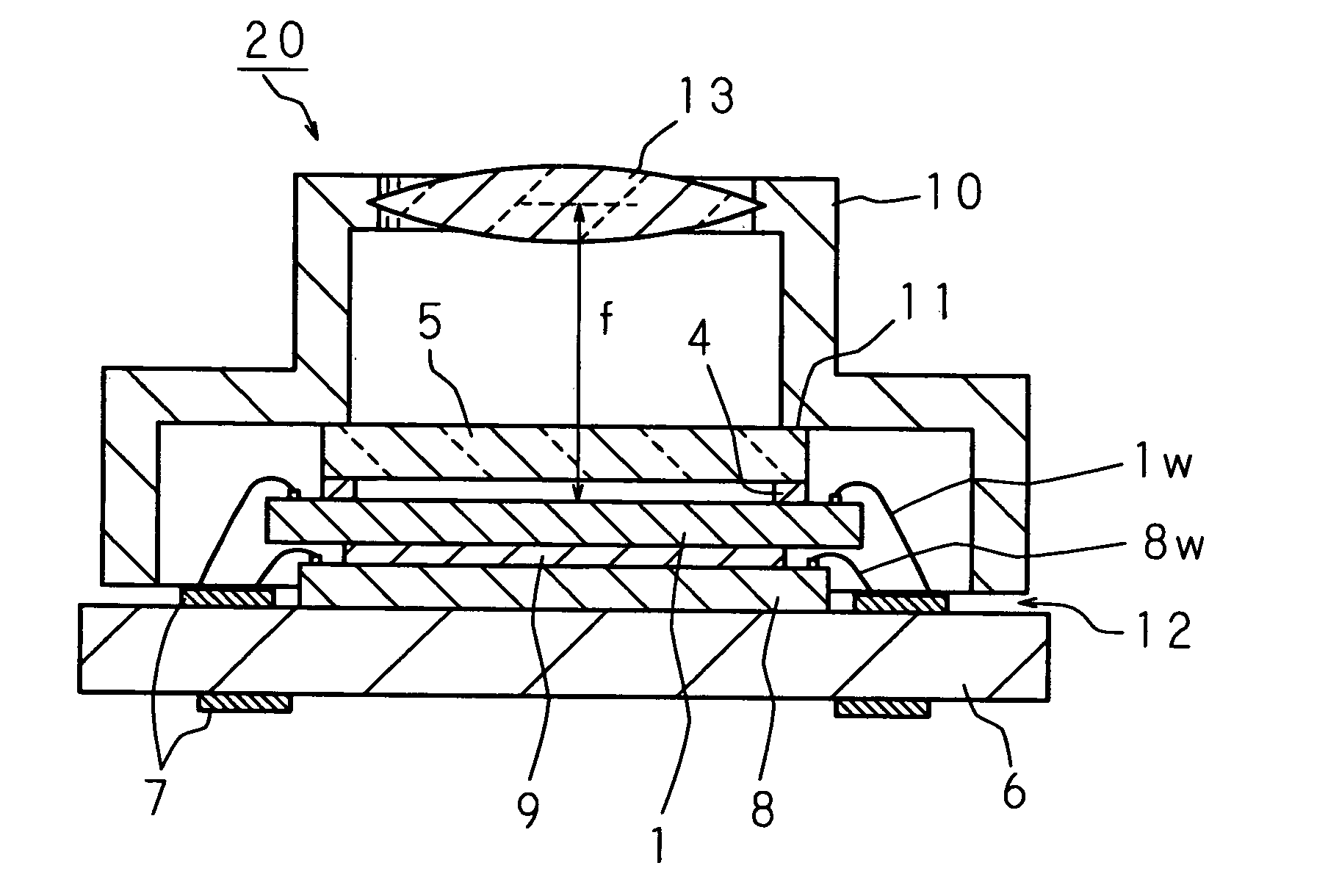

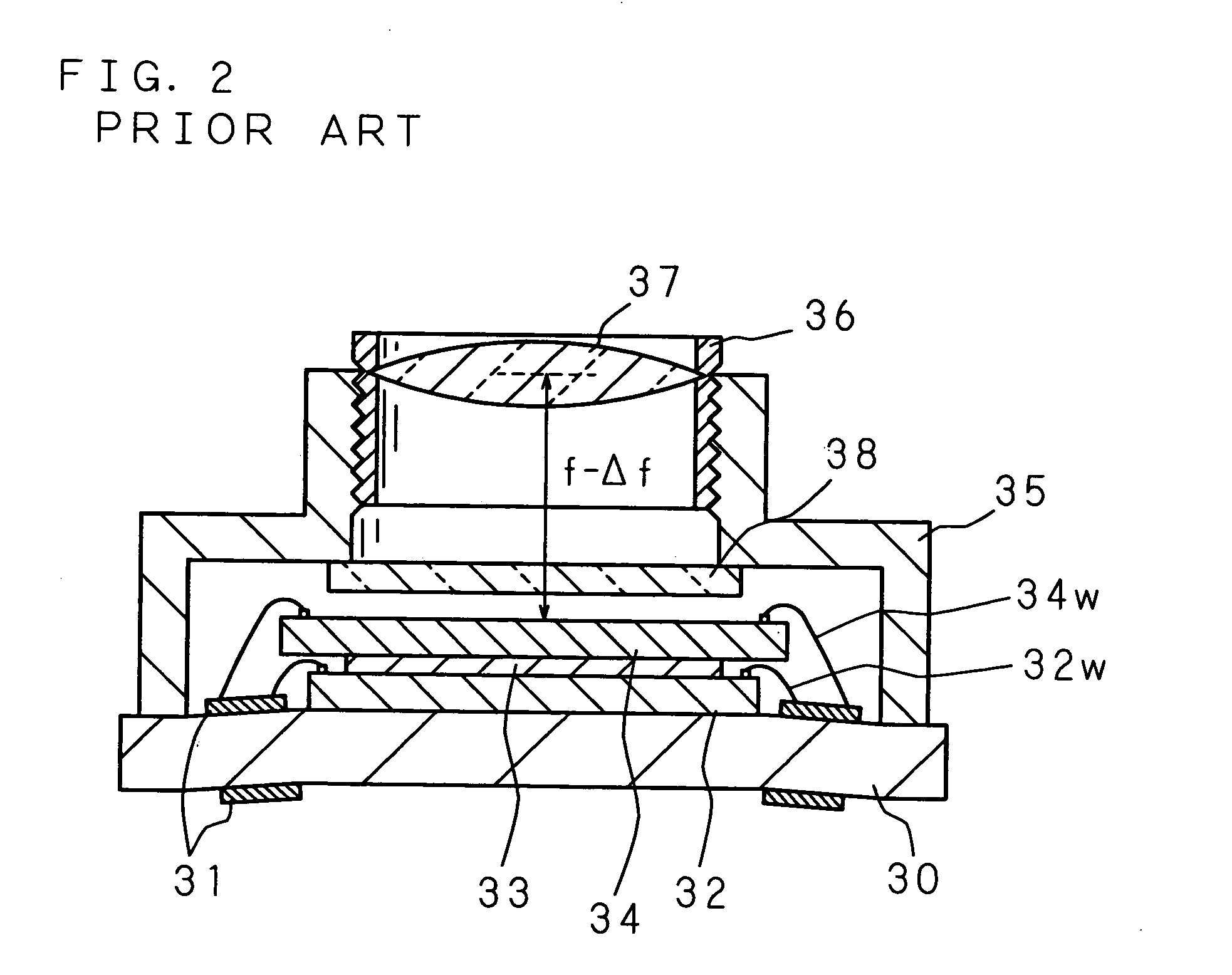

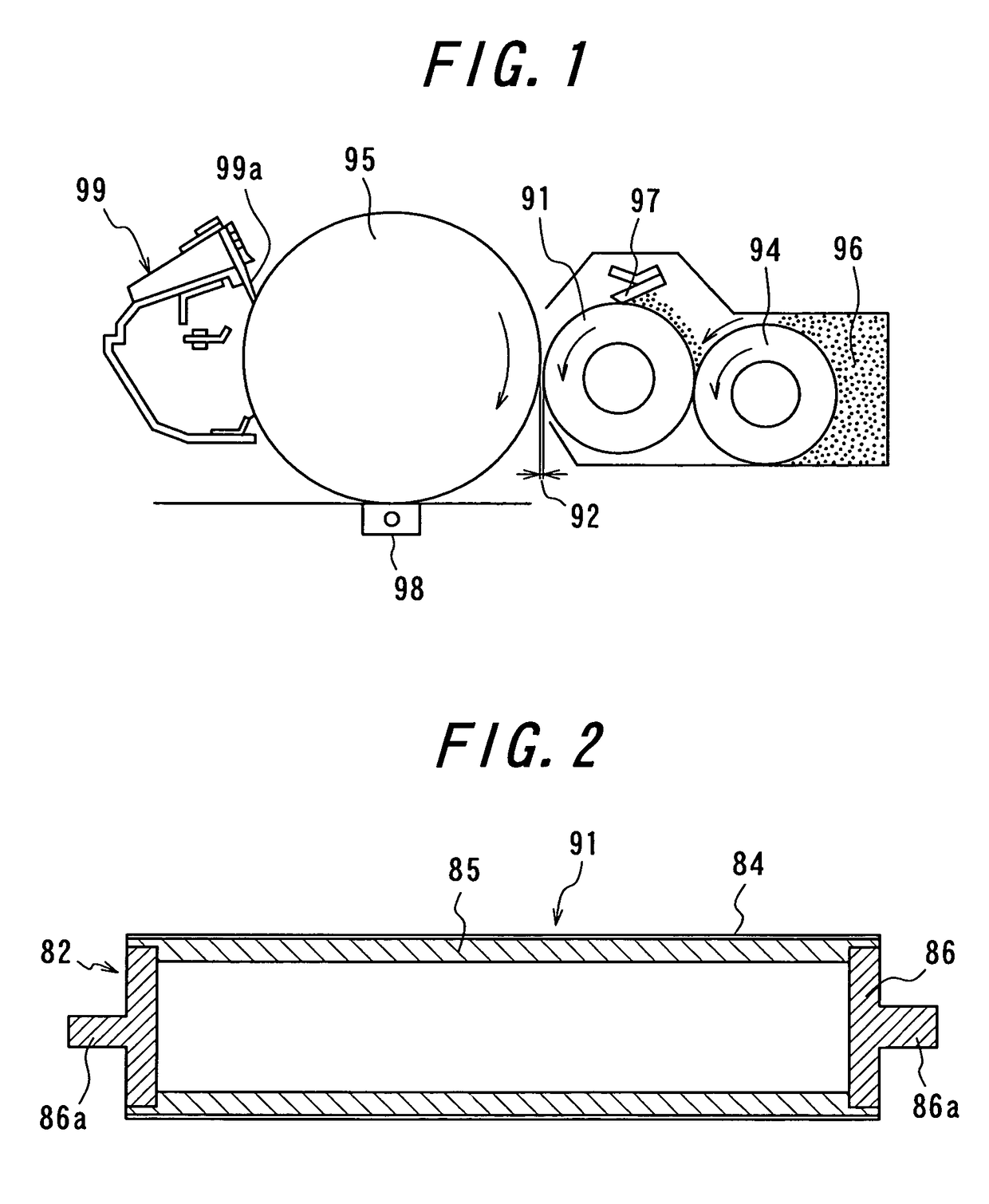

Module for optical device, and manufacturing method therefor

ActiveUS7112864B2Low costSimple processTelevision system detailsSemiconductor/solid-state device detailsEngineeringSolid-state

A module for an optical device being provided with a wiring substrate having a conductive wiring patterned thereon, a solid-state image sensor, a DSP for controlling the operation of the solid-state image sensor and processing a signal outputted from the same, and a lens holder being placed opposite to the solid-state image sensor and having a function of an optical path demarcating unit for demarcating the optical path to the solid-state image sensor, wherein a transparent cover bonded to the surface of the solid-state image sensor is joined to the lens holder at a joint portion. It is unnecessary to provide a focus adjuster for matching the optical distance between the lens and the solid-state image sensor with the focal length of the lens.

Owner:SHARP KK

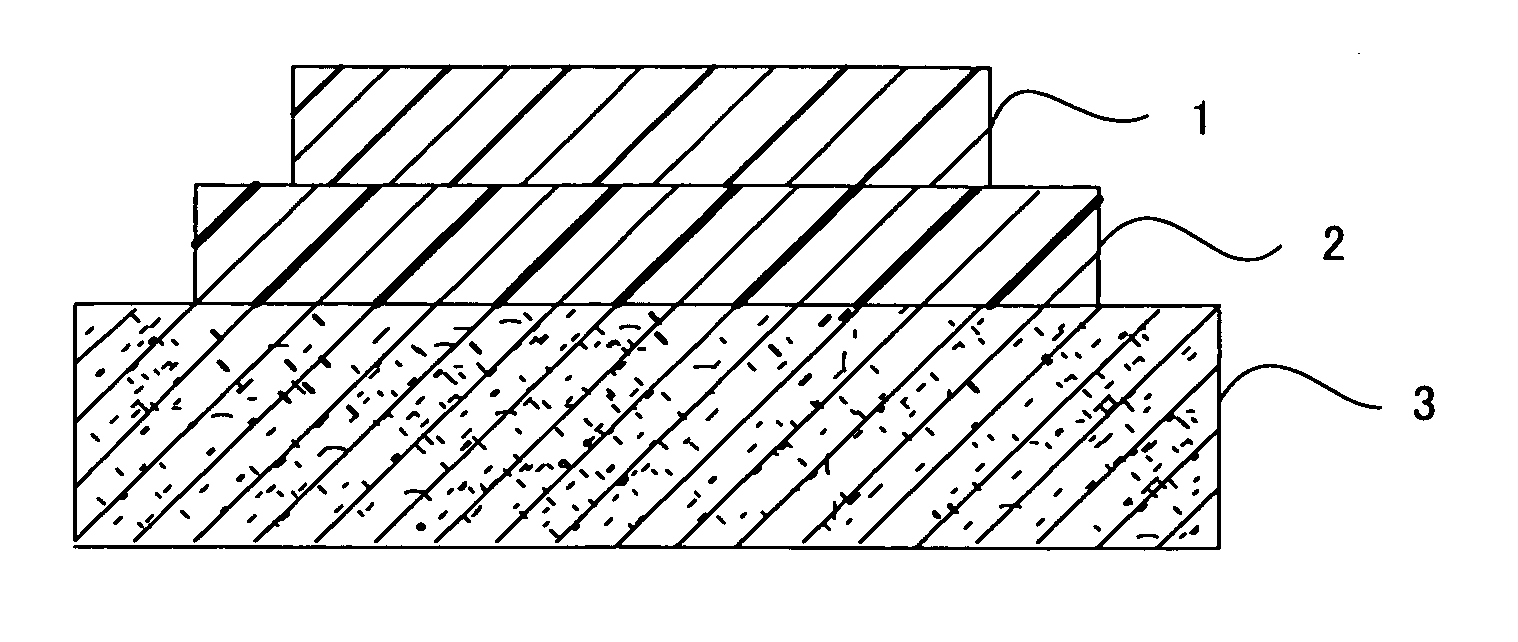

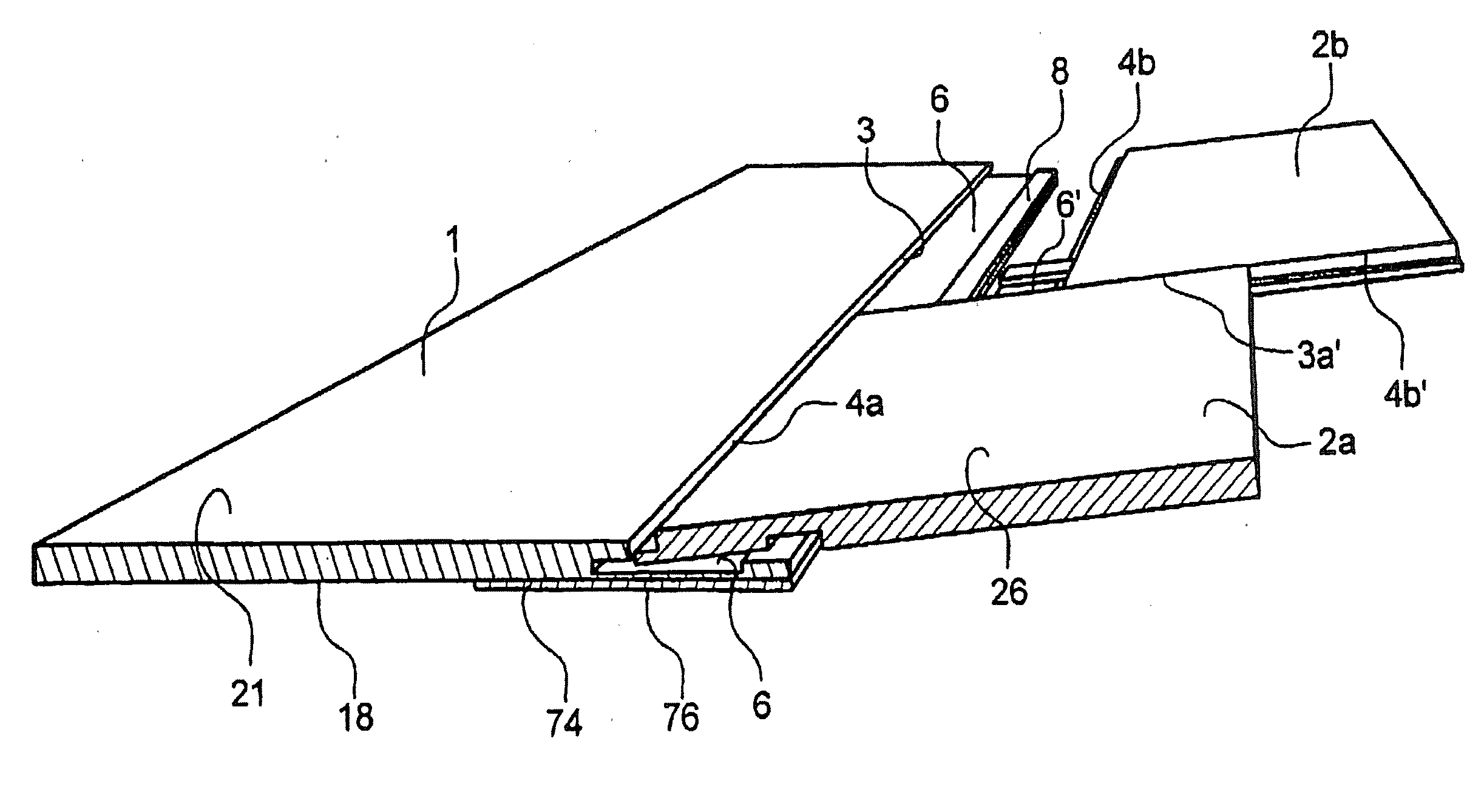

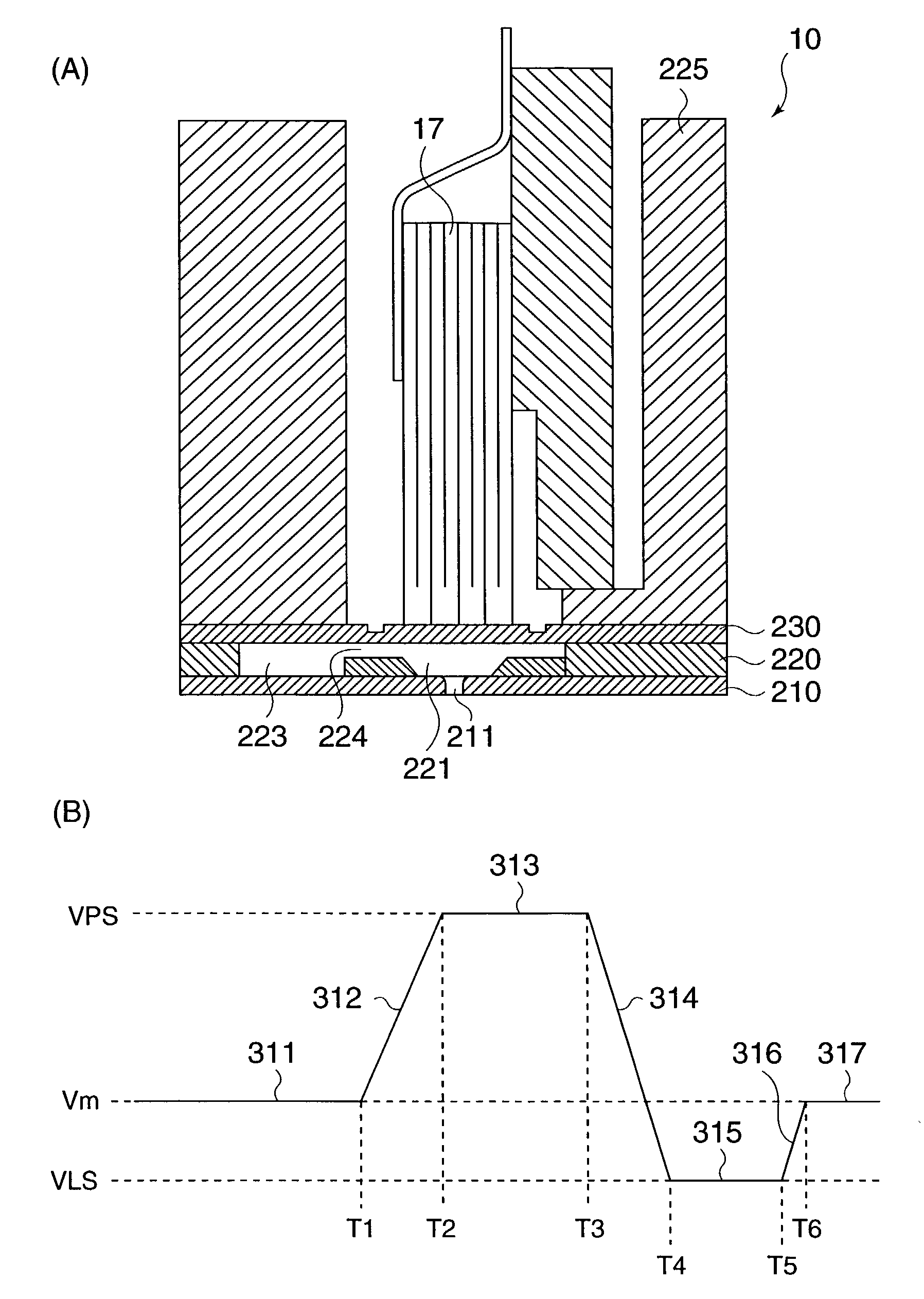

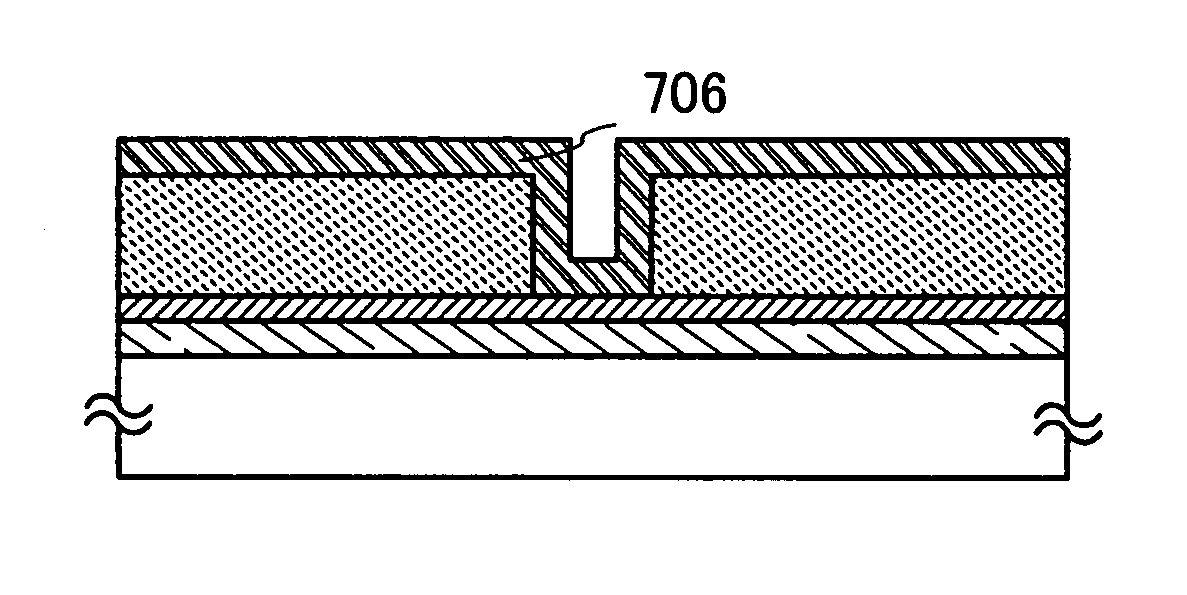

Method of manufacturing light-emitting device, and evaporation donor substrate

ActiveUS8153201B2Accurate layeringHigh precisionDiffusion transfer processesLiquid surface applicatorsTarget surfaceDisplay device

The present invention provides a method of manufacturing a light-emitting device and an evaporation donor substrate, by which the precision of patterning of an EL layer of each color can be improved in manufacture of a full color flat panel display using emission colors of red, green, and blue. A first substrate which includes a reflective layer including an opening portion, a heat insulating layer including an opening portion in a position overlapped with the opening portion of the reflective layer over the reflective layer, a light absorption layer covering the opening portion of the reflective layer and the opening portion of the heat insulating layer over the heat insulating layer, and a material layer over the light absorption layer is used. While one surface of the first substrate is disposed close to a deposition target surface of a second substrate, the first substrate is irradiated with light from the other surface of the first substrate. The irradiation light is absorbed in the light absorption layer in the position overlapped with the opening portion of the reflective layer to heat an evaporation material. The heated evaporation material is evaporated onto the second substrate.

Owner:SEMICON ENERGY LAB CO LTD

Method for manufacturing conductive pattern forming body

InactiveUS20050112810A1Excellent conductive pattern forming bodyEasy to produceMaterial nanotechnologySemiconductor/solid-state device manufacturingMetal colloidsForming processes

It is a main object of the present invention to provide a method for manufacturing a conductive pattern capable of forming a highly precise pattern, also capable of forming by using a simple process, and being free from problems such as treatment of waste fluids. In order to attain the above object, the present invention provides a method for manufacturing a conductive pattern forming body comprising: a pattern forming body substrate preparing process of preparing pattern forming body substrate comprising a base material, and a photocatalyst containing layer formed on the base material comprising a photocatalyst and a binder whose wettability of an energy irradiated part is changed so as a contact angle to a liquid is reduced; a wettability pattern forming process of forming wettability pattern comprising a liquid repellent area and a lyophilic area on the photocatalyst containing layer by irradiating the photocatalyst containing layer in a pattern with energy; a metal colloid coating process of adhering a metal colloid only to the lyophilic area of the surface of the photocatalyst containing layer on which the wettability pattern is formed, by coating the metal colloid; and a conductive pattern forming process of forming conductive pattern by solidifying the metal colloid adhered to the lyophilic area of the wettability pattern.

Owner:DAI NIPPON PRINTING CO LTD

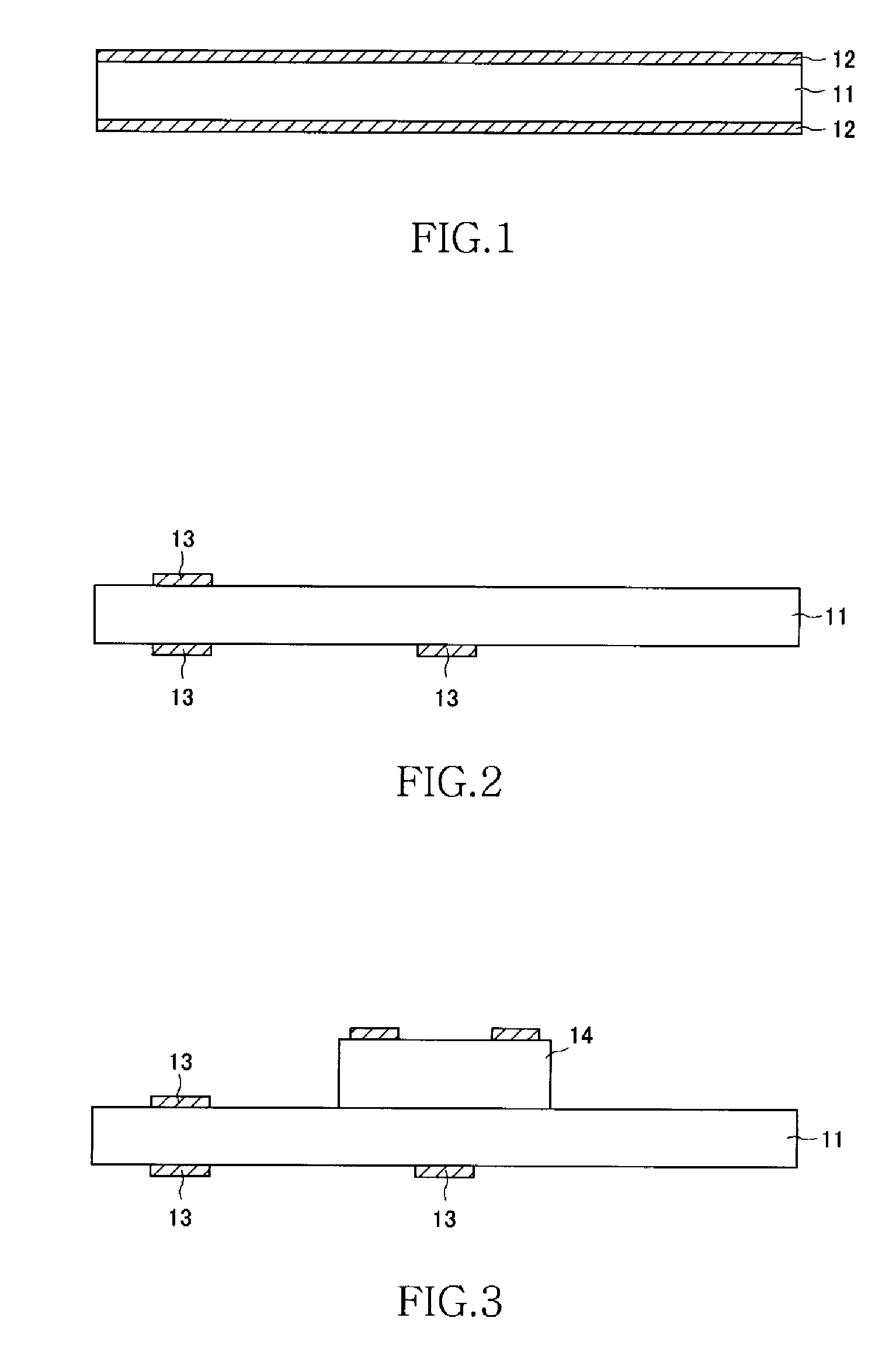

Method for manufacturing ic-embedded substrate

ActiveUS20070141759A1Increase productivityExpand the number of processesPrinted circuit assemblingElectrically conductive connectionsMaterials scienceIntegrated circuit

A method for manufacturing an IC-embedded substrate comprises a first step for encapsulating at least an IC chip having a pad electrode in an insulating layer, a second step for forming a metal layer having at least a first aperture in a location directly above the pad electrode of the IC chip and a second aperture in a location above an area other than the area in which the IC chip is mounted, and a third step for selectively removing the insulating layer by a blasting treatment in which the metal layer is used as a mask, whereby forming a first via hole that corresponds to the first aperture and a second via hole that corresponds to the second aperture.

Owner:TDK CORPARATION

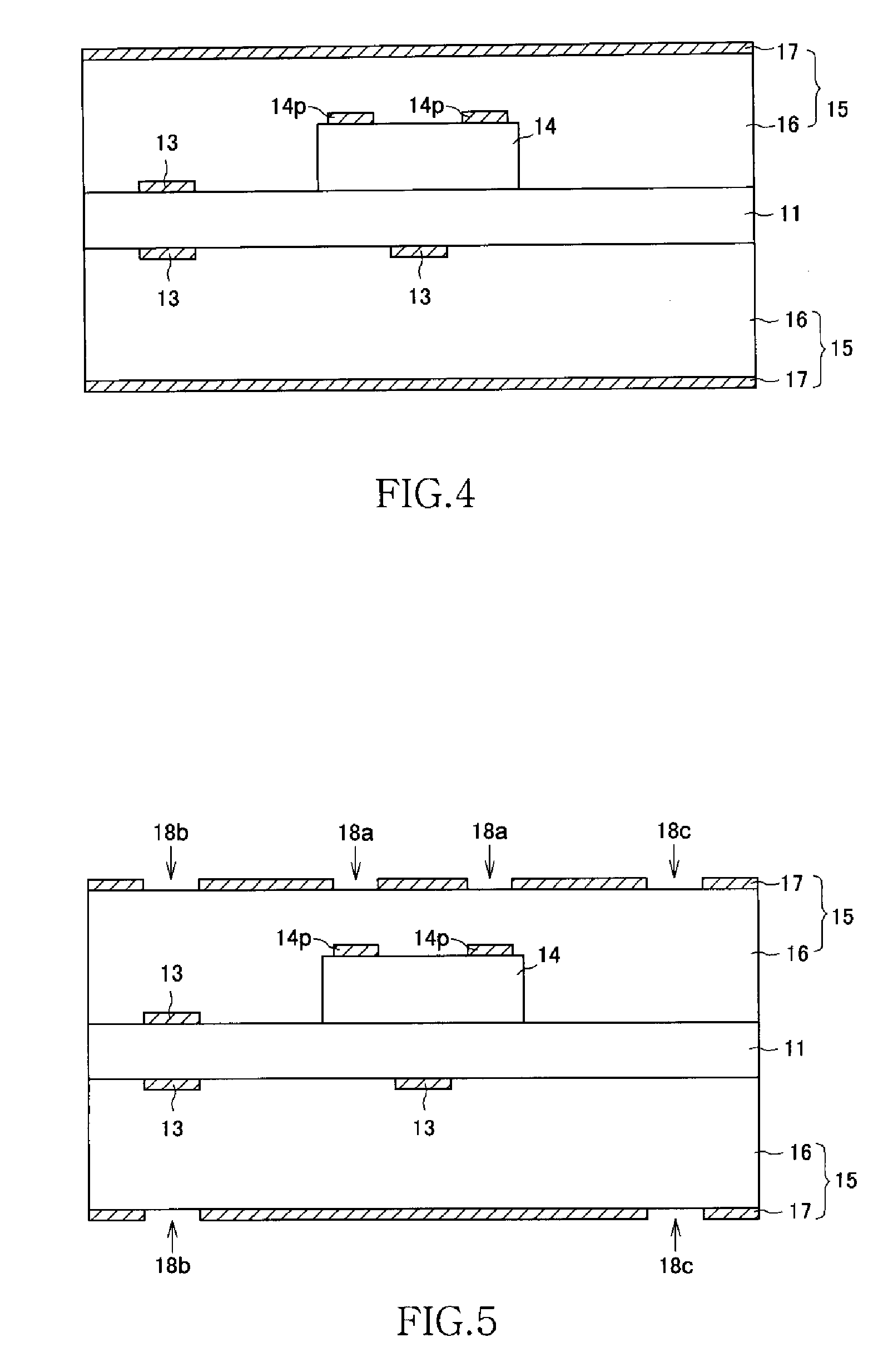

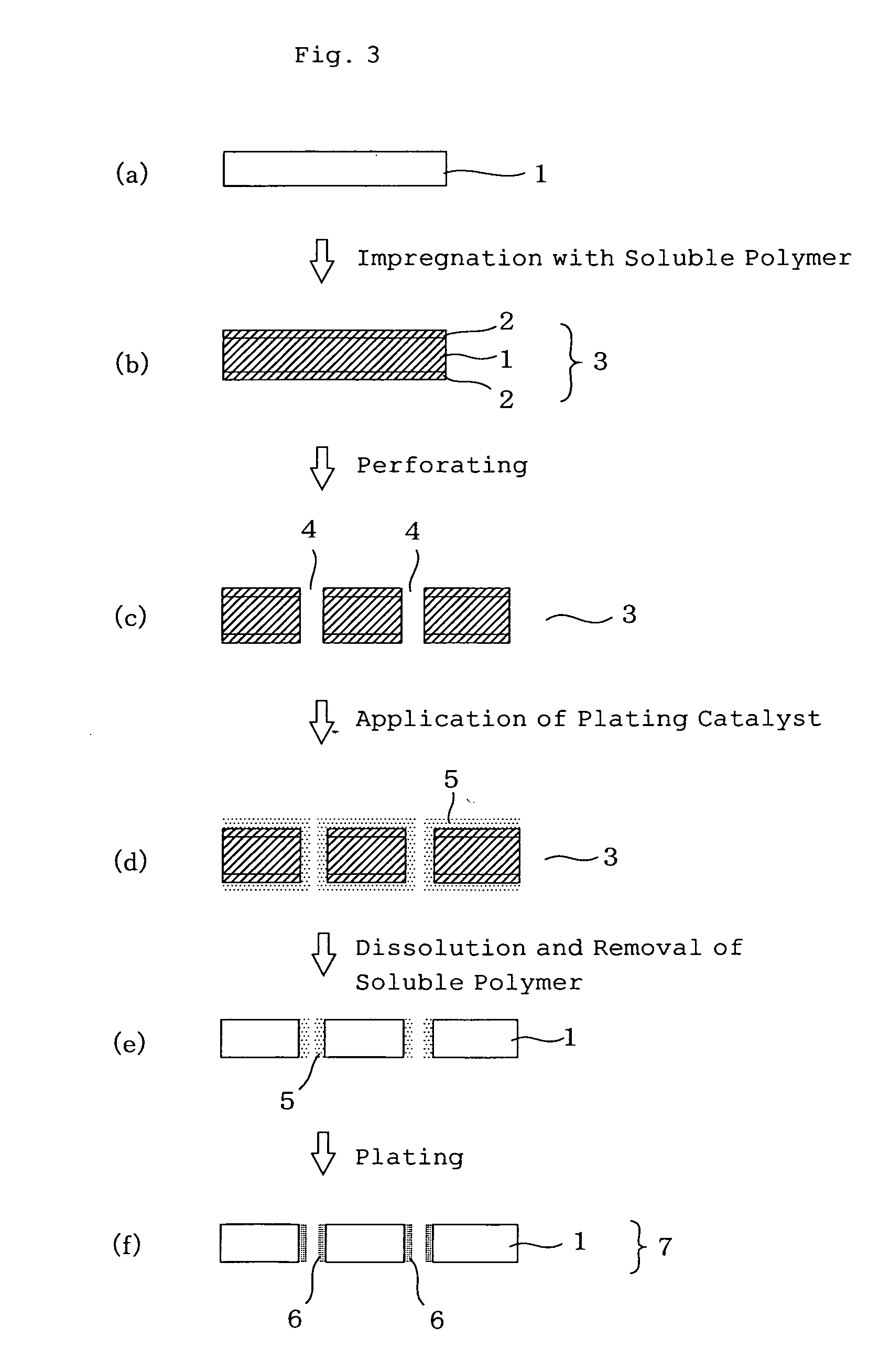

Drilled porous resin base material, and method of manufacturing porous resin base material with conductive drilled inner wall surface

InactiveUS20060141159A1Low dielectric constantUse of materialPorous dielectricsPretreated surfacesSolid substanceMetal

A production process of a perforated porous resin base, comprising Step 1 of impregnating the porous structure of a porous resin base with a liquid or solution; Step 2 of forming a solid substance from the liquid or solution impregnated; Step 3 of forming a plurality of perforations extending through from the first surface of the porous resin base having the solid substance within the porous structure to the second surface in the porous resin base; and Step 4 of melting or dissolving the solid substance to remove it from the interior of the porous structure, and a production process of a porous resin base with the inner wall surfaces of the perforations made conductive, comprising the step of selectively applying a catalyst only to the inner wall surfaces of the perforations to apply a conductive metal to the inner wall surfaces.

Owner:SUMITOMO ELECTRIC IND LTD

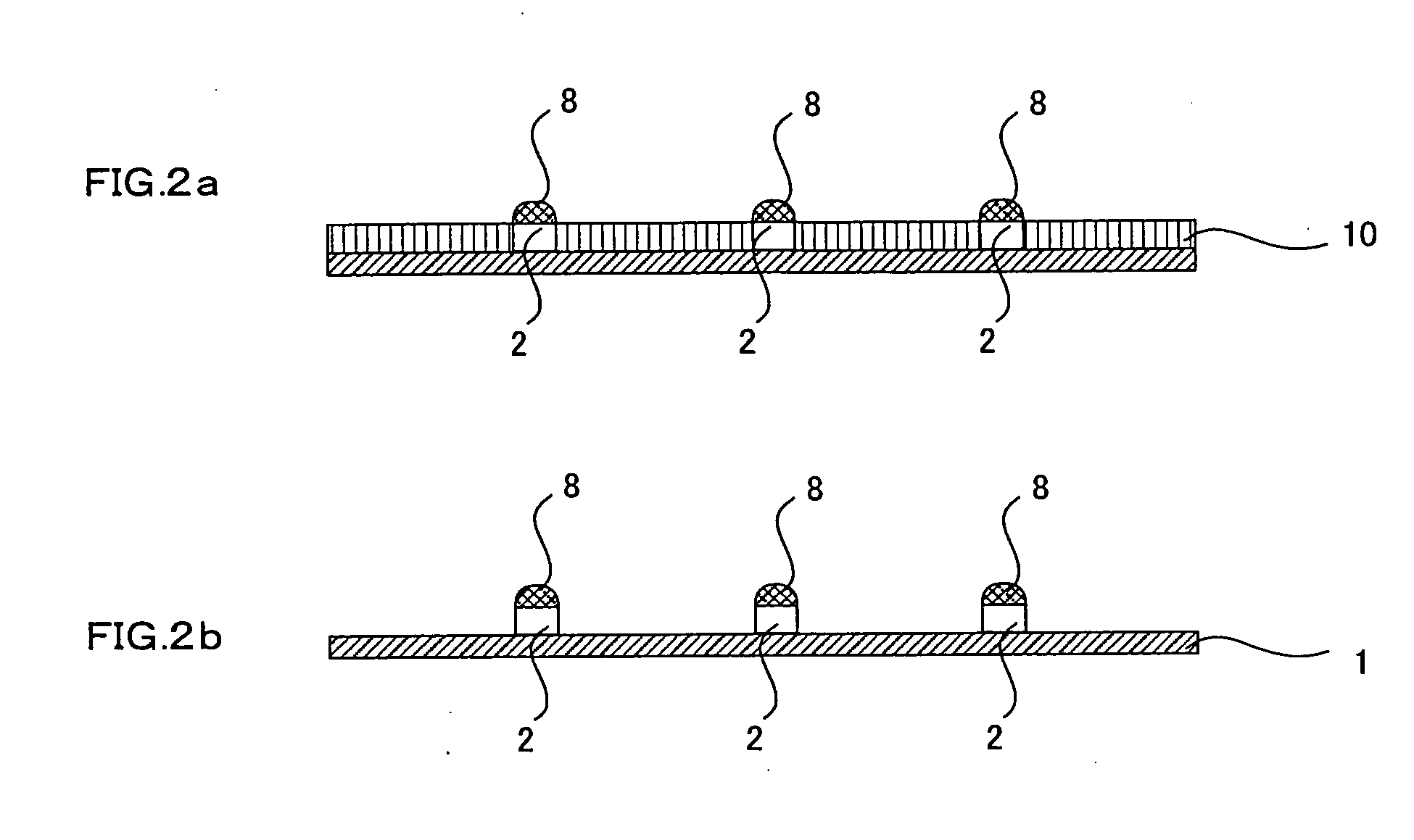

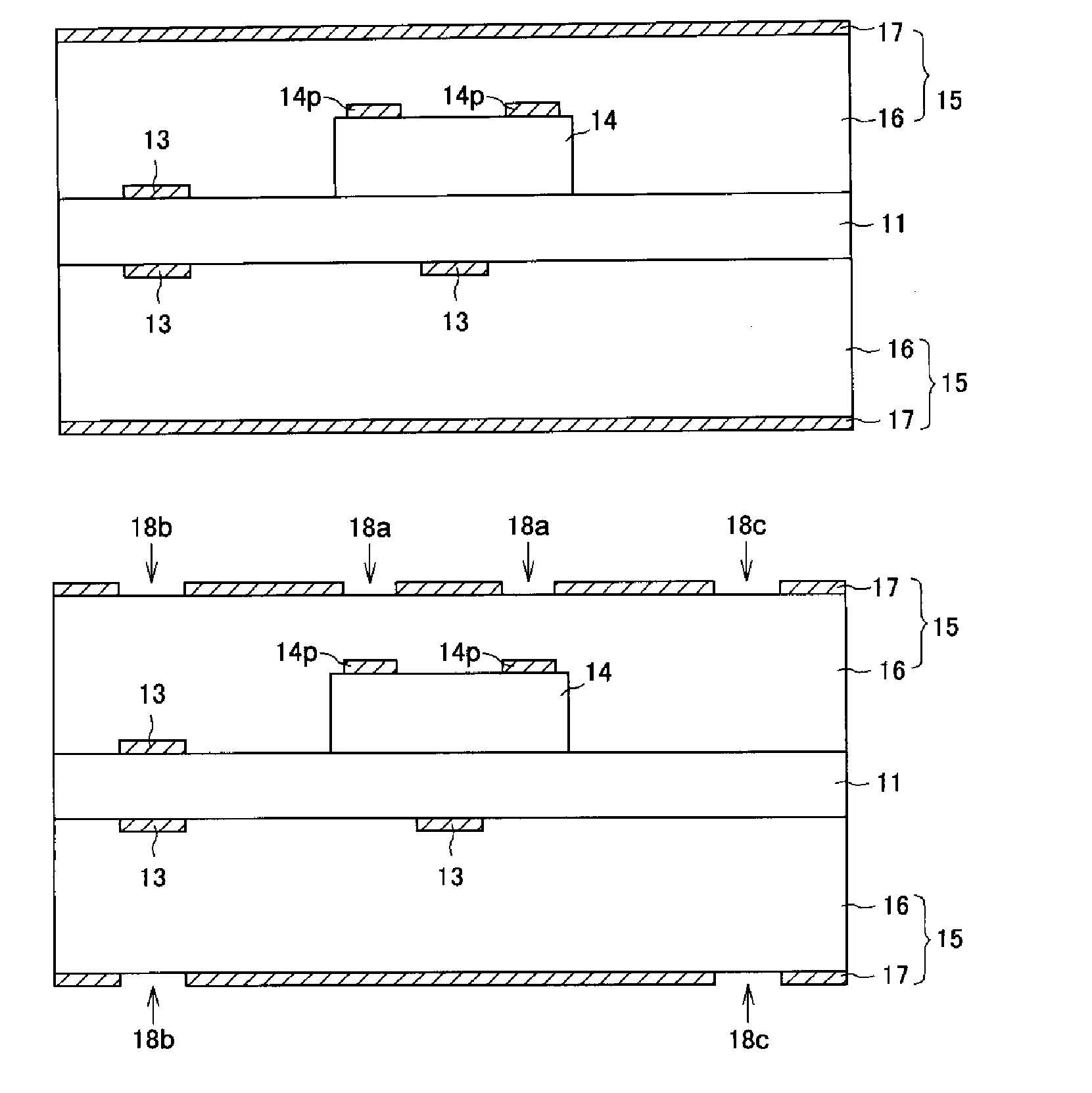

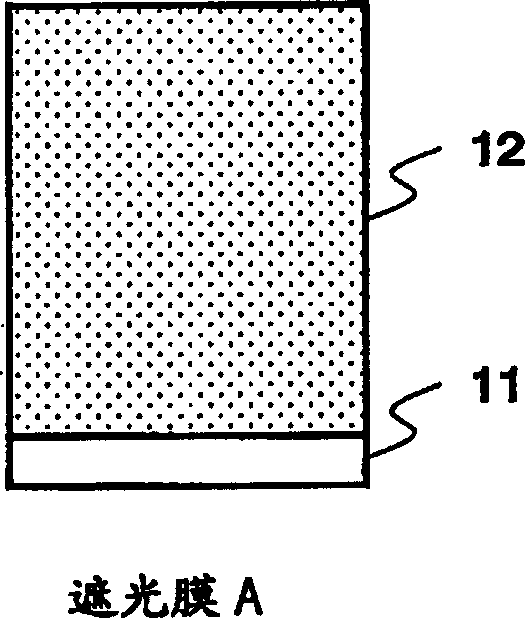

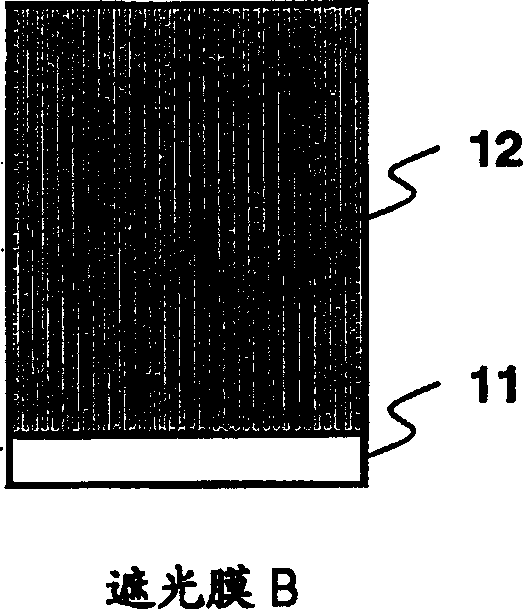

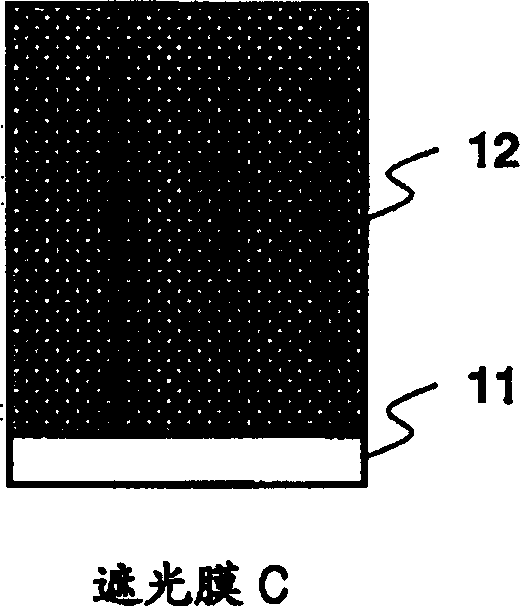

Photomask blank, photomask and fabrication method thereof

ActiveCN1900819AIncrease etch rateLow metal percentage contentVacuum evaporation coatingSemiconductor/solid-state device manufacturingPhase shiftedTransmittance

PROBLEM TO BE SOLVED: To provide a halftone type phase shift mask on which a fine photomask pattern is formed with high accuracy, and to provide a mask blank for producing the above mask. ŽSOLUTION: A semitransparent film 15 having a predetermined phase shift and transmittance to exposure light and a light shielding film 12 placed on the semitransparent film 15 are disposed on one principal face of a transparent substrate 11 such as quartz as a photomask substrate. The light shielding film 12 is surely a so-called "light shielding film" but it can also act as an antireflection film. The semitransparent film 15 is a halftone phase shift layer comprising a halftone material containing both of silicon (Si) and molybdenum (Mo) as an absorbent material. In order to use the halftone phase shift mask blank for producing a mask for ArF exposure, the film thickness and composition of the light shielding film 12 are selected to obtain the optical density OD of the film in the range of 1.2 to 2.3 with respect to light at 193 or 248 nm wavelength. Ž

Owner:SHIN ETSU CHEM IND CO LTD +1

Method for forming throughhole in ink-jet print head

InactiveUS6757973B2Short timeLow costRecording apparatusDecorative surface effectsWaferingSand blasting

Owner:SAMSUNG ELECTRONICS CO LTD

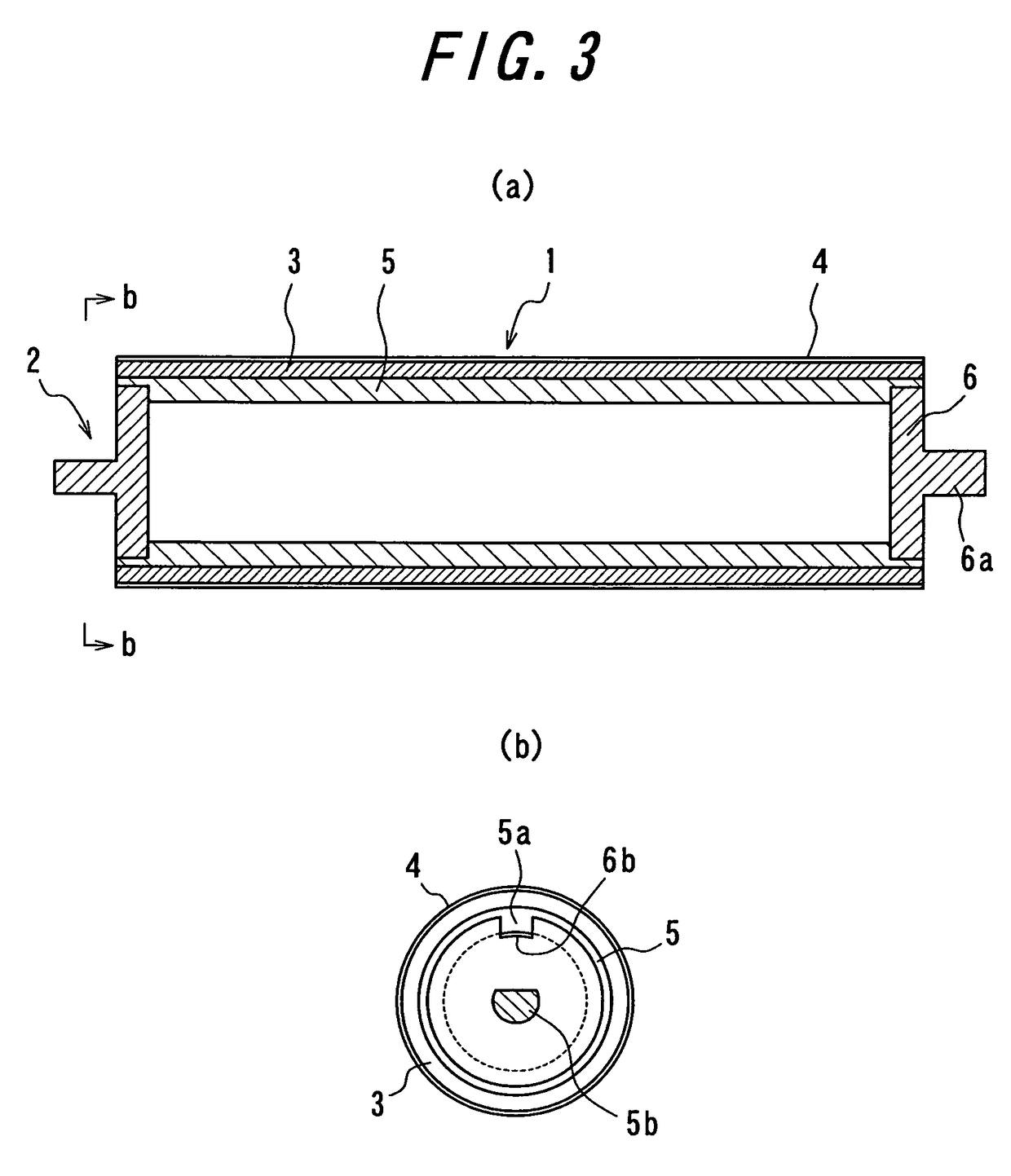

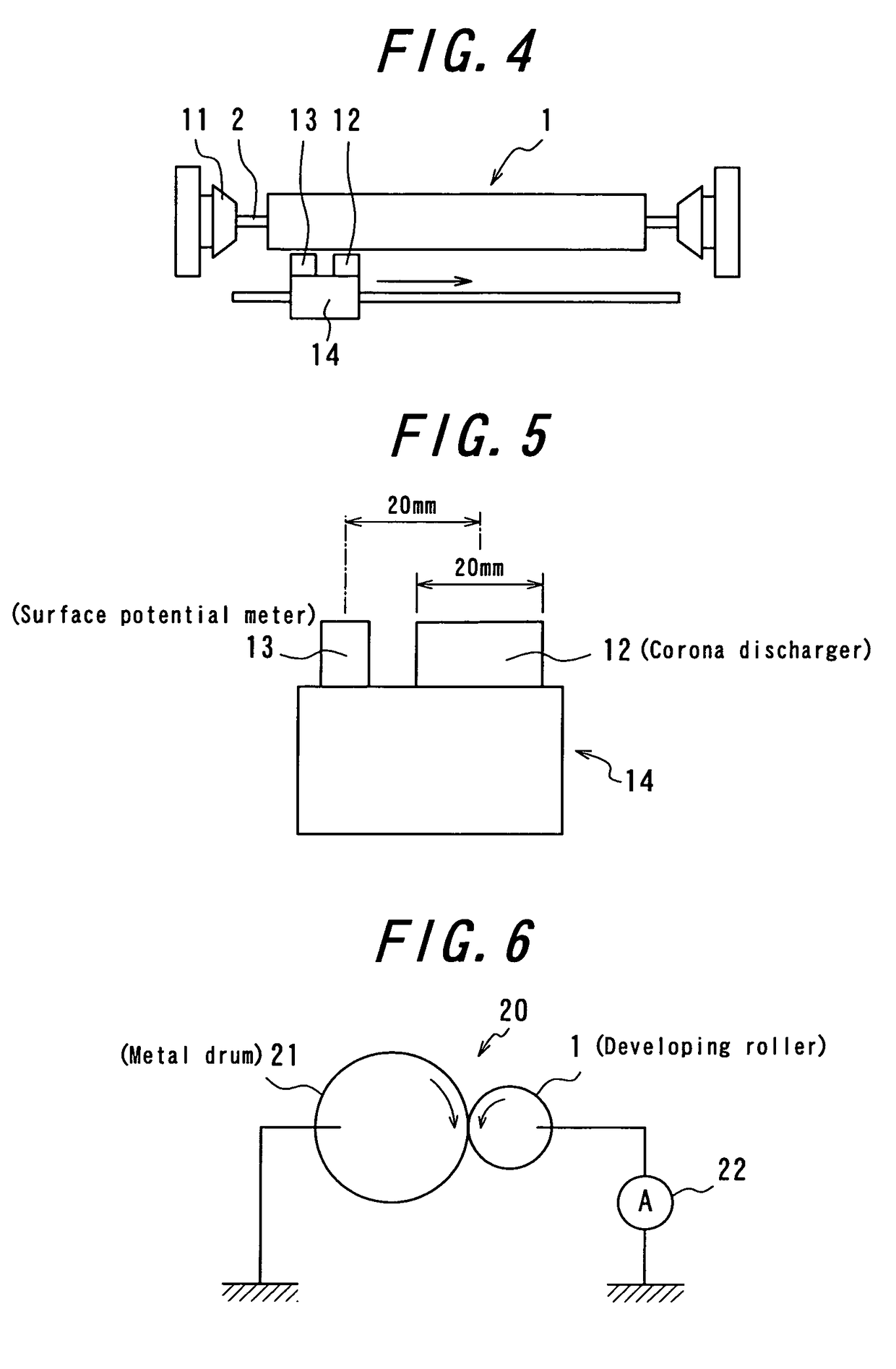

Developing roller and imaging apparatus using the same

InactiveUS7907878B2Easy curingReduce the amount requiredElectrographic process apparatusUV curingUltraviolet

A developing roller includes an ultraviolet-curing type resin layer and using a carbon-based electrically conducting agent for giving an electrical conductivity to the resin layer, as well as an imaging apparatus using the same. The developing roller 1 includes a shaft member 2 of a metal pipe and a resin layer 4. The resin layer 4 is a resin having fine particles dispersed therein, wherein the ratio a / b of average particle size of fine particles a to total thickness of resin layers b is greater than 2.0 and less than or equal to 5.0.

Owner:BRIDGESTONE CORP

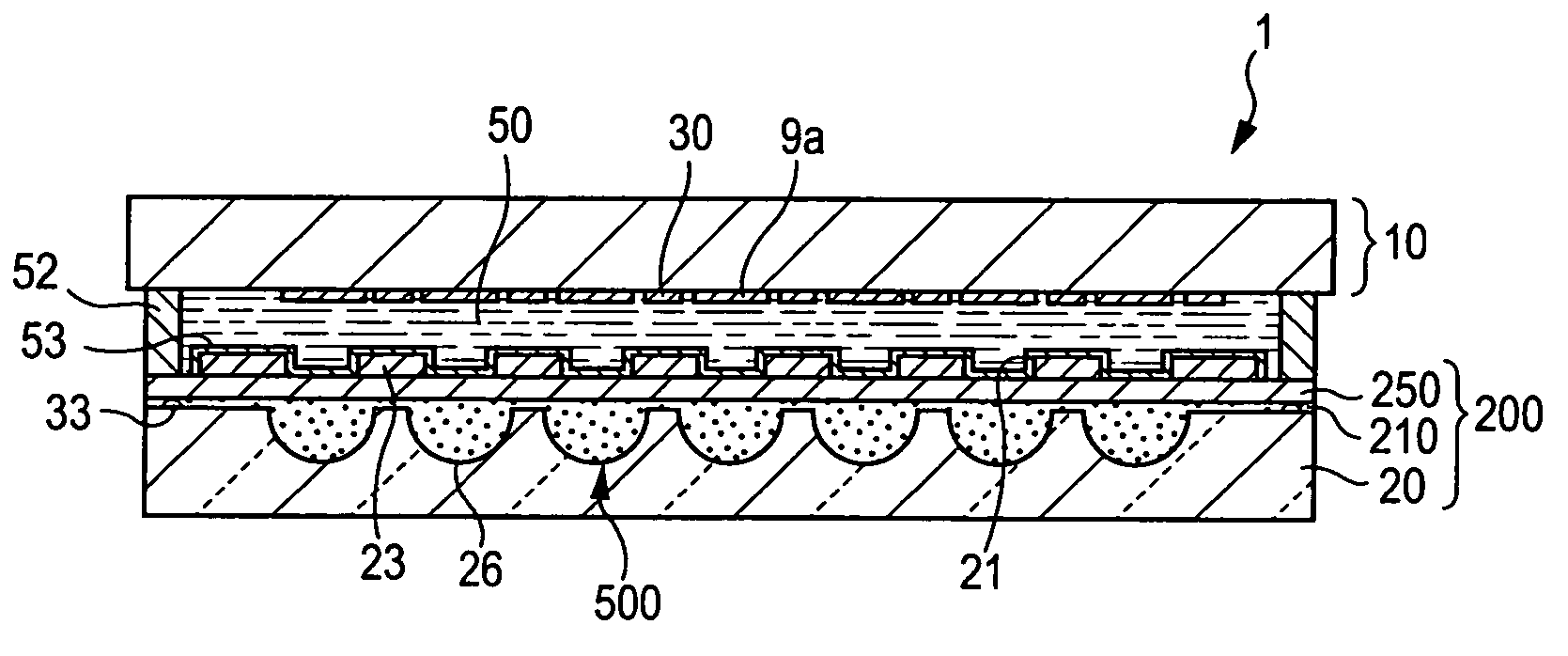

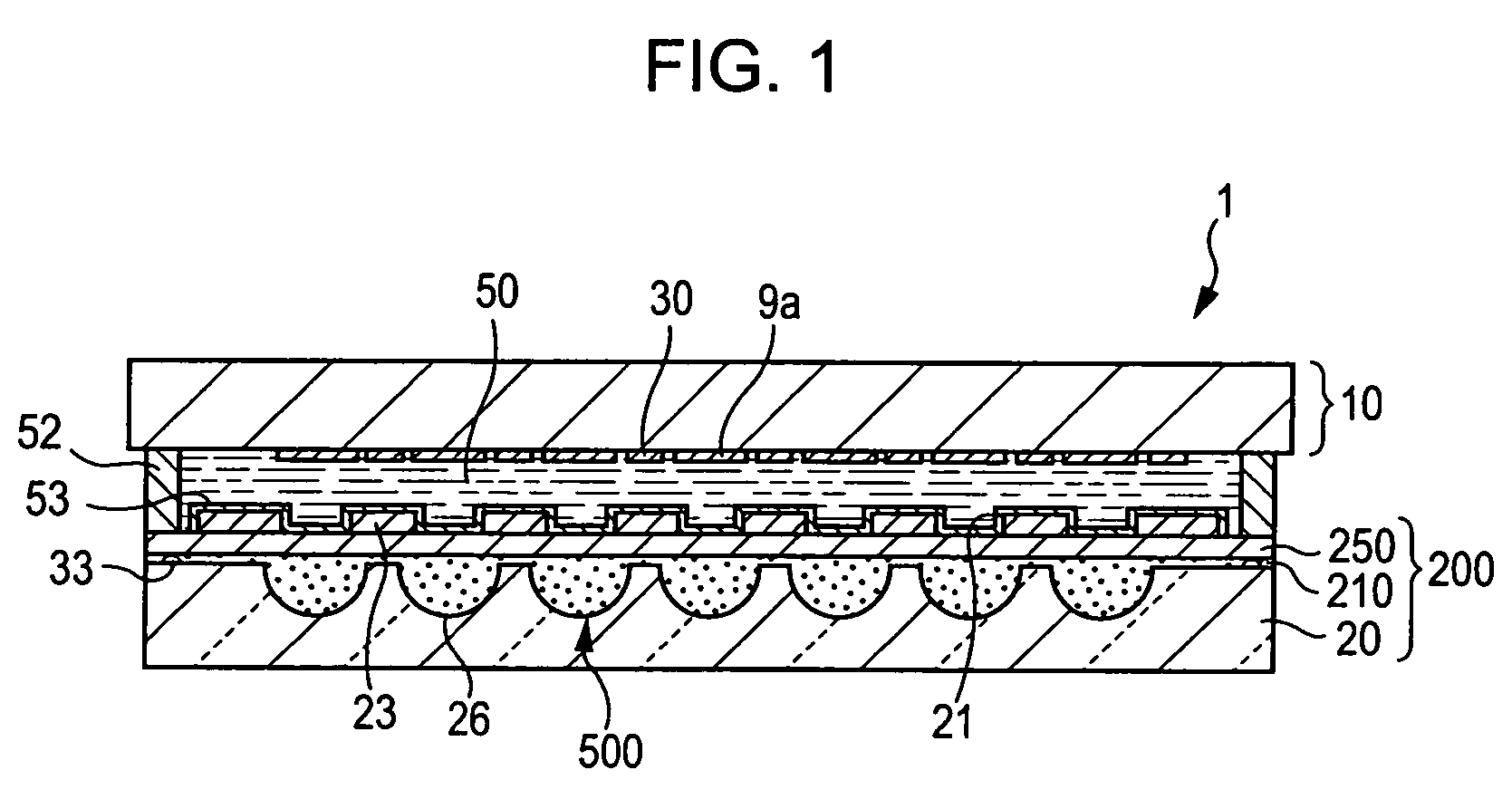

Electro-optical device, method of manufacturing the same, and electronic apparatus using electro-optical device

InactiveUS20050274969A1Uniform performanceImprove image qualitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringCover glass

An electro-optical device includes first and second substrates that face each other, support bodies that are interposed between both substrates so as to define a gap between both substrates, and a microlens layer that is formed between both substrates. The first substrate is a lens glass substrate that has a plurality of concave portions and the second substrate is a cover glass substrate that faces the first substrate. A thickness of the microlens layer is defined by the support bodies.

Owner:SEIKO EPSON CORP

Projection optical apparatus, exposure method and apparatus, photomask, and device and photomask manufacturing method

ActiveUS20080165334A1Better pattern transferImage degradationPhotomechanical apparatusOriginals for photomechanical treatmentLight beamLine segment

When forming a magnified image of a mask pattern on an object with a plurality of projection optical systems, projected images of the projection optical systems are formed to be accurately continuous to enable satisfactory pattern transfer. A first projection optical system directs light beam from point a on a mask to point A on a plate and forms a magnified image of the mask on the plate. A second projection optical system directs light beam from point b on the mask to point on the plate and forms a magnified image of the mask on the plate. A first line segment linking point A and point a′, which orthogonally projects point a on the plate, and a second line segment linking point B and point b′, which orthogonally projects point b on the plate PT, overlap each other as viewed in a non-scanning direction.

Owner:NIKON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com