Photomask blank, photomask and fabrication method thereof

A technology for photomasks and light-shielding films, applied in the field of photomasks, can solve problems such as hindering defect inspection, high film reflectivity, and the inability of photomask blank structures to satisfy fine photomask patterns satisfactorily. Increase dry etching rate, ensure etching resistance, and reduce thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] (Example 1: Light-shielding film of photomask blank according to the present invention)

[0066] In order to reduce the thickness of the photoresist used as a mask for forming a photomask pattern, it is necessary to reduce damage to the light-shielding film during etching of the light-shielding film in which the photoresist mask is patterned. To this end, it is necessary to reduce the time required to etch the light-shielding film by reducing the physical thickness of the light-shielding film to be patterned and / or by increasing the etching rate of the light-shielding film.

[0067] The inventor’s investigation and research prove that increasing the etching rate of the light-shielding film can be achieved by reducing the metal percentage content in the light-shielding film. This means that high-rate etching can be achieved by designing the commonly used chromium-based shading film to reduce the chromium content (percentage content) in the shading film.

[0068] For example,...

Embodiment 2

[0120] (Example 2: Basic structure of photomask blank)

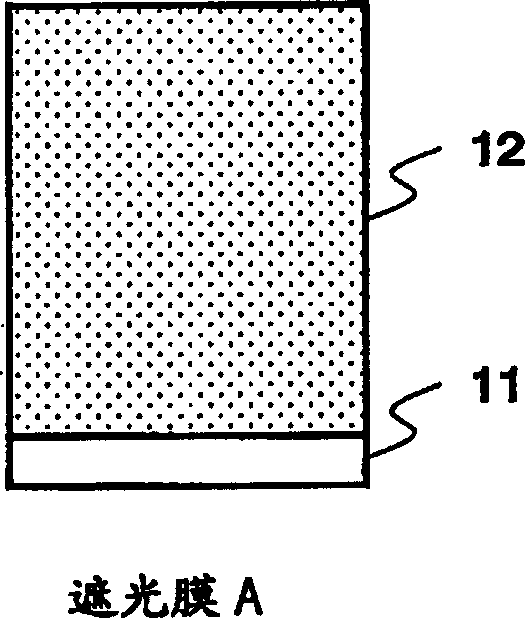

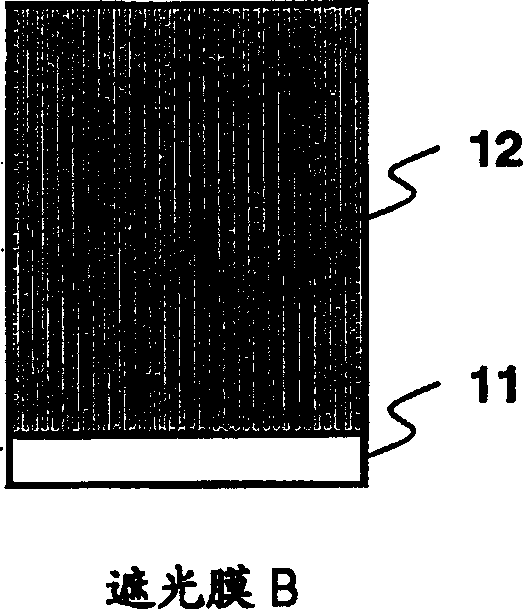

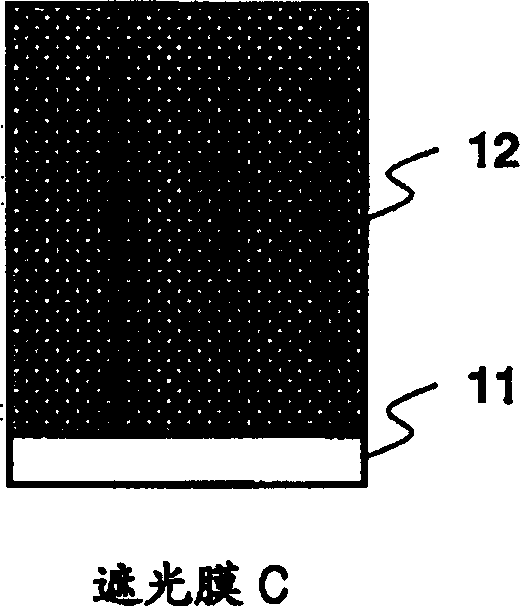

[0121] Figure 9A It is a schematic cross-sectional view for explaining an exemplary structure of a photomask blank according to the present invention, in which a light-shielding film 12 is formed on one principal plane of a transparent substrate 11 made of quartz or the like and used as a photomask substrate on. The light-shielding film 12 has a layered structure as described above with respect to Example 1, which serves not only as a "light-shielding film" but also as an anti-reflection film. The film with this composition is used because it has excellent dry etching properties, electrical conductivity and chemical resistance.

[0122] In the case where the photomask blank according to the present invention is designed to be used for making an ArF exposure mask, the thickness and composition of the light-shielding film 12 are selected so that the optical density OD of the light-shielding film 12 for light with a wavelengt...

Embodiment 3

[0132] (Embodiment 3: Photomask blank and the first embodiment of patterning process)

[0133] Picture 10 Showing an exemplary arrangement of a film deposition apparatus (sputtering apparatus) used to make a photomask blank according to the present invention, Figure 11A to 11D It is a view for explaining an exemplary process of patterning the photomask blank.

[0134] in Picture 10 Here, reference numeral 11 denotes a transparent substrate, which is a 6-inch rectangular quartz substrate. Generally, the surface and end faces of the quartz substrate are finely polished. Reference numeral 101 represents a cavity, reference numeral 102a represents a first target (target), reference numeral 102b represents a second target, reference numeral 103 represents a sputtering gas inlet, reference numeral 104 represents a gas outlet, reference numeral 105 represents a substrate turntable, and reference numerals 106a and 106b respectively represent the first target. One and the second target...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com