Uniaxle integrated inertia measurement device based on single mass-block

An integrated inertial, single-mass technology, applied in measuring devices, measuring acceleration, gyroscopic effect for velocity measurement, etc., can solve the problems of complex structure, large volume and mass, achieve small size, strong anti-interference ability, and reduce separation effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

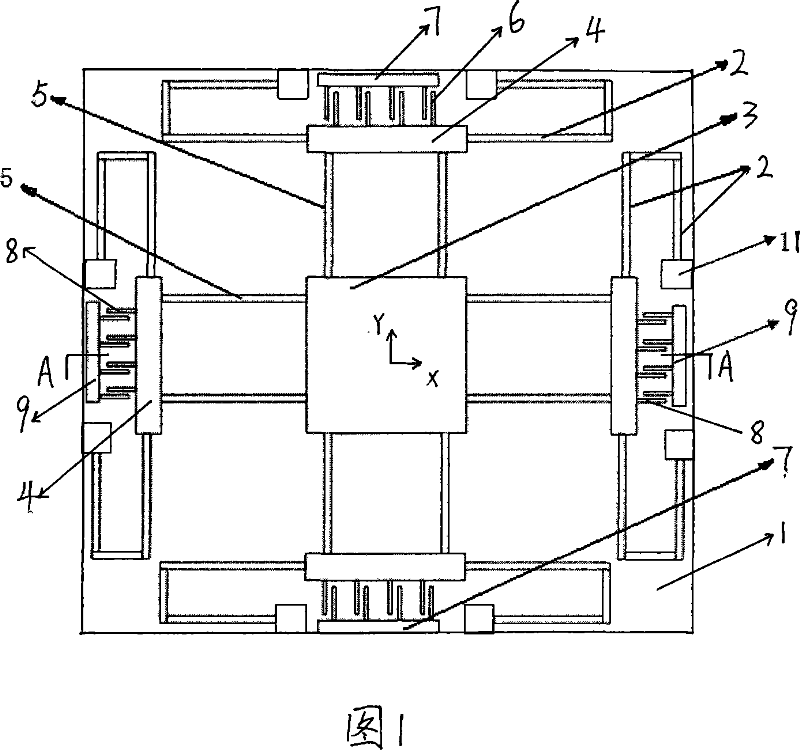

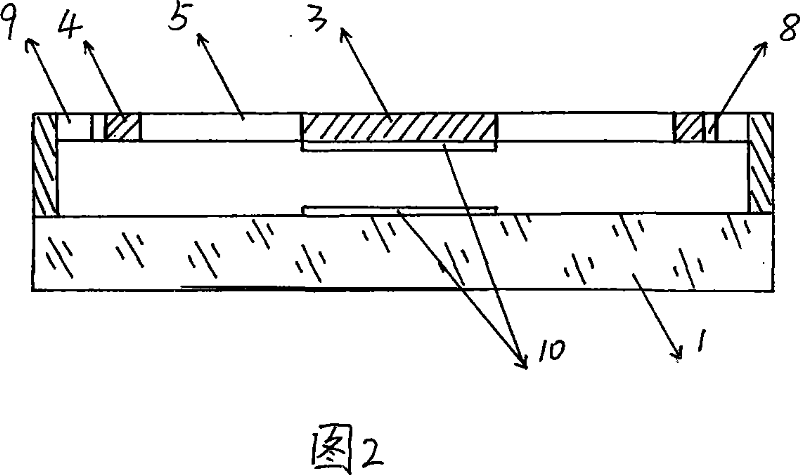

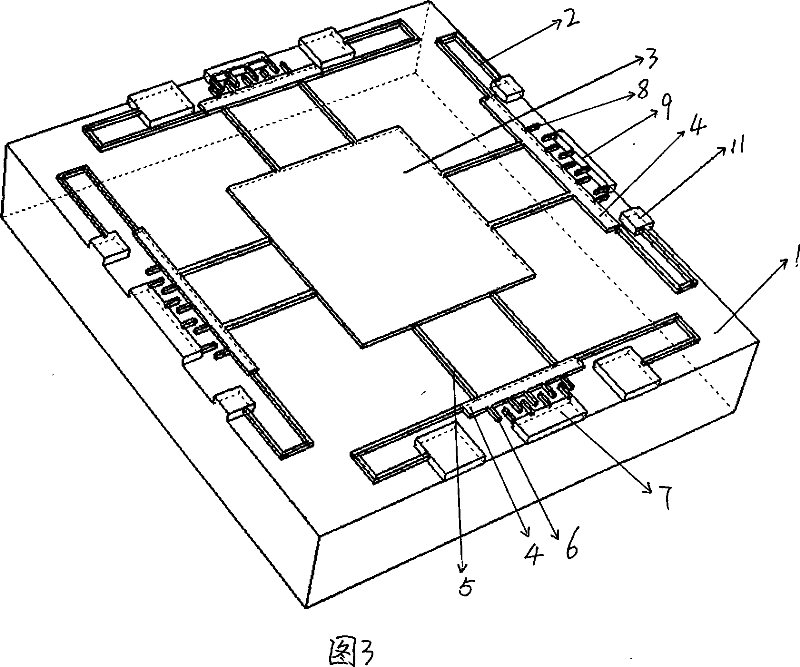

[0015] A single-axis integrated inertial measurement device based on a single mass block, including a mass block and a glass cover bottom 1, the mass block is suspended above the glass cover bottom 1 through 2 supporting beams, and the mass block is composed of a mass core block 3 and an elastic beam 5 respectively Four support bodies 4 fixed to the four sides of the quality core block 3 are formed. The outer side of the support body 4 opposite to the Y direction is fixed with a detection movable comb tooth 6, and the outer side of the support body opposite to the X direction is fixed with a driving movable comb tooth 8, which is consistent with the detection activity. The detection fixed comb 7 and the driving fixed comb 9 coordinated by the comb teeth 6 and the driving movable comb teeth 8 are fixed on the glass cover bottom 1, and the lower end surface of the mass core block 3 is correspondingly fixed on the glass cover bottom 1 to form a plate capacitor. The electrode 10. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com