Wafer level optical sensor package and low profile camera module, and method of manufacture

A technology for optical sensors and cameras, applied in electric solid state devices, semiconductor devices, radiation control devices, etc., and can solve problems such as light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

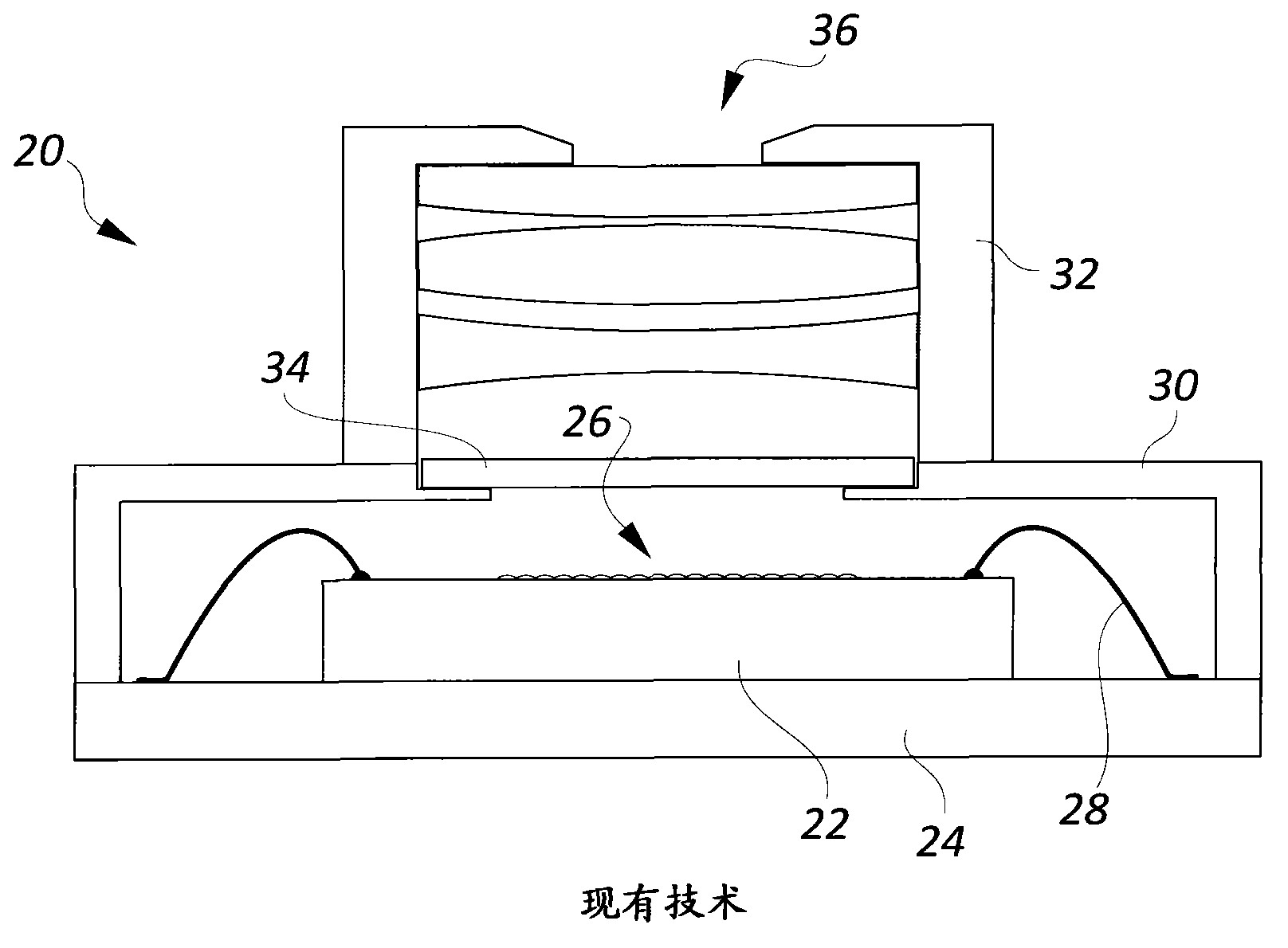

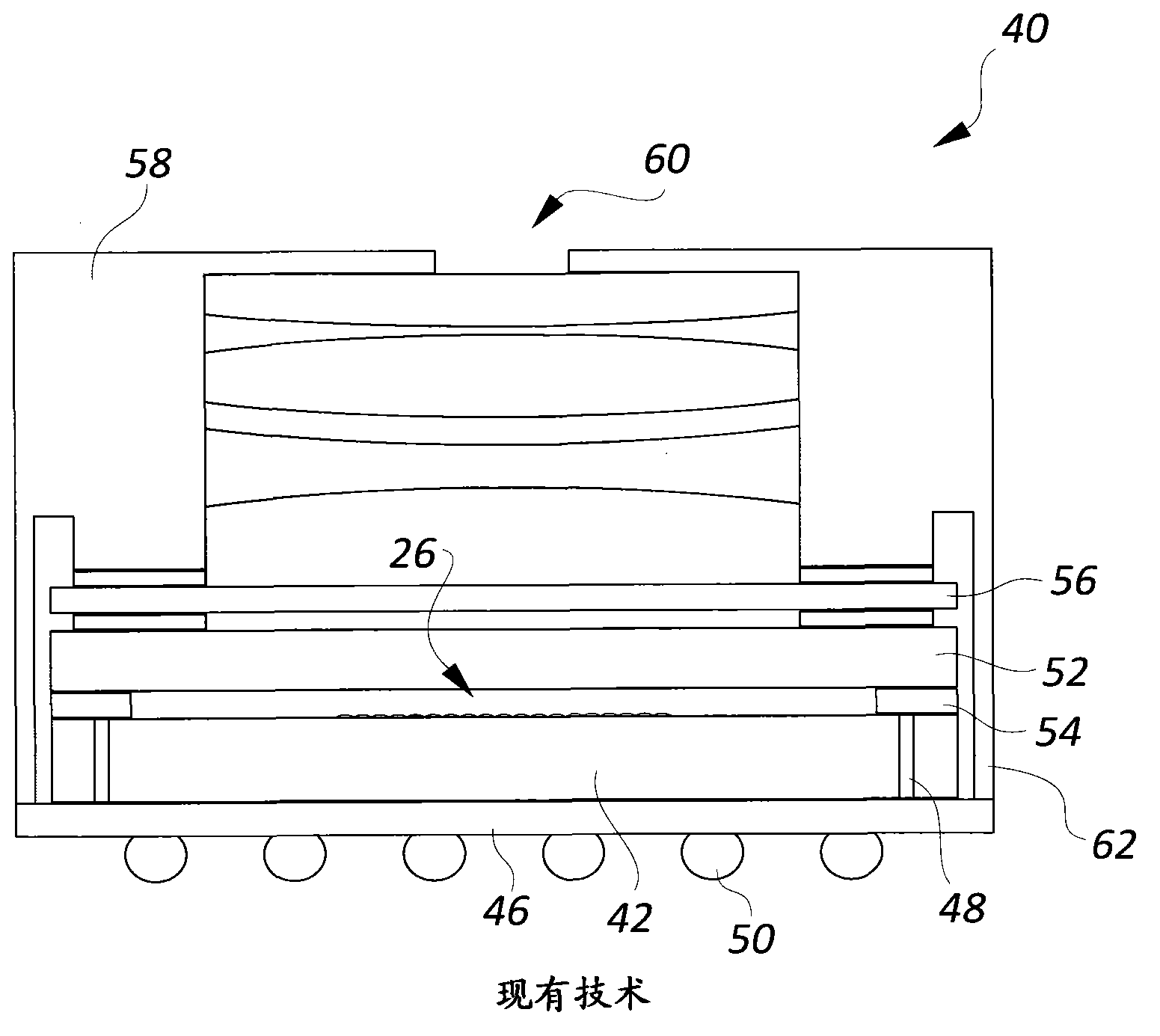

[0022] although figure 2 A prior art example of figure 1 The example of has a reduced height, but the inventors realize that there are a number of problems that may be associated with the second example. First, the associated semiconductor wafer and glass cover must be thinned to their final thickness before the wafer is singulated into individual die. However, if they are too thin, they become extremely brittle and will break during splitting. Furthermore, handling of the glass and die assemblies by assembly workers or robotic machinery used to assemble the camera modules can easily damage them. Also, planarity is an issue because the thinned die can bend slightly during assembly, causing the optical sensor to not function correctly or produce distorted images. Another problem is light leakage. If the lens assembly is not perfectly optically dense, or if any light scattering occurs inside the lens assembly, light can be transmitted from the edge of the cover glass into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com