Carrying apparatus and carrying control method for sheet-like substrate

a technology of carrying apparatus and carrying control method, which is applied in the direction of electrical apparatus, thin material handling, article separation, etc., can solve the problems of large-sized thin plates, difficult to carry heavy, and large-sized thin plates upward, and achieve high speed and stably high-speed transport.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

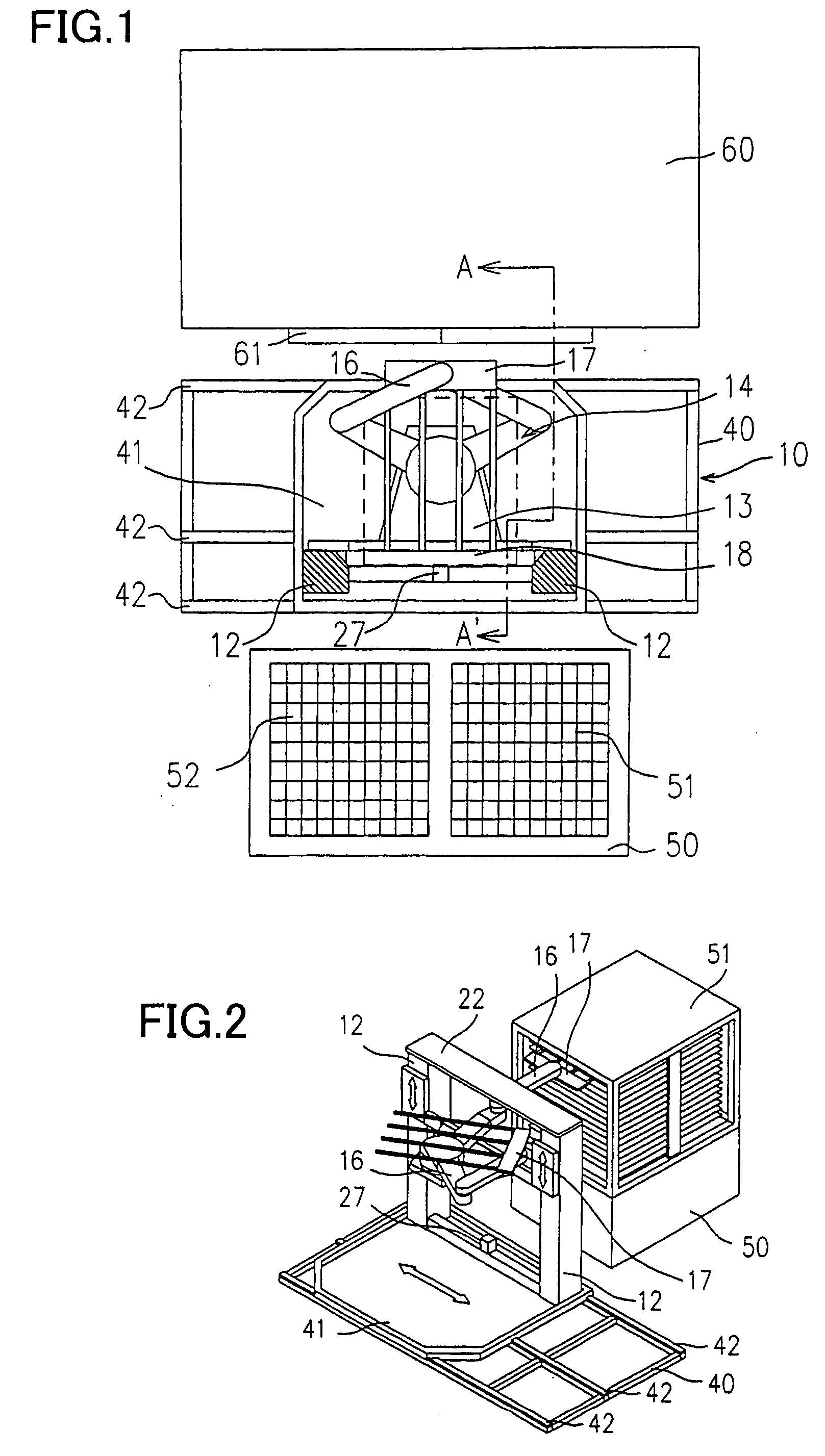

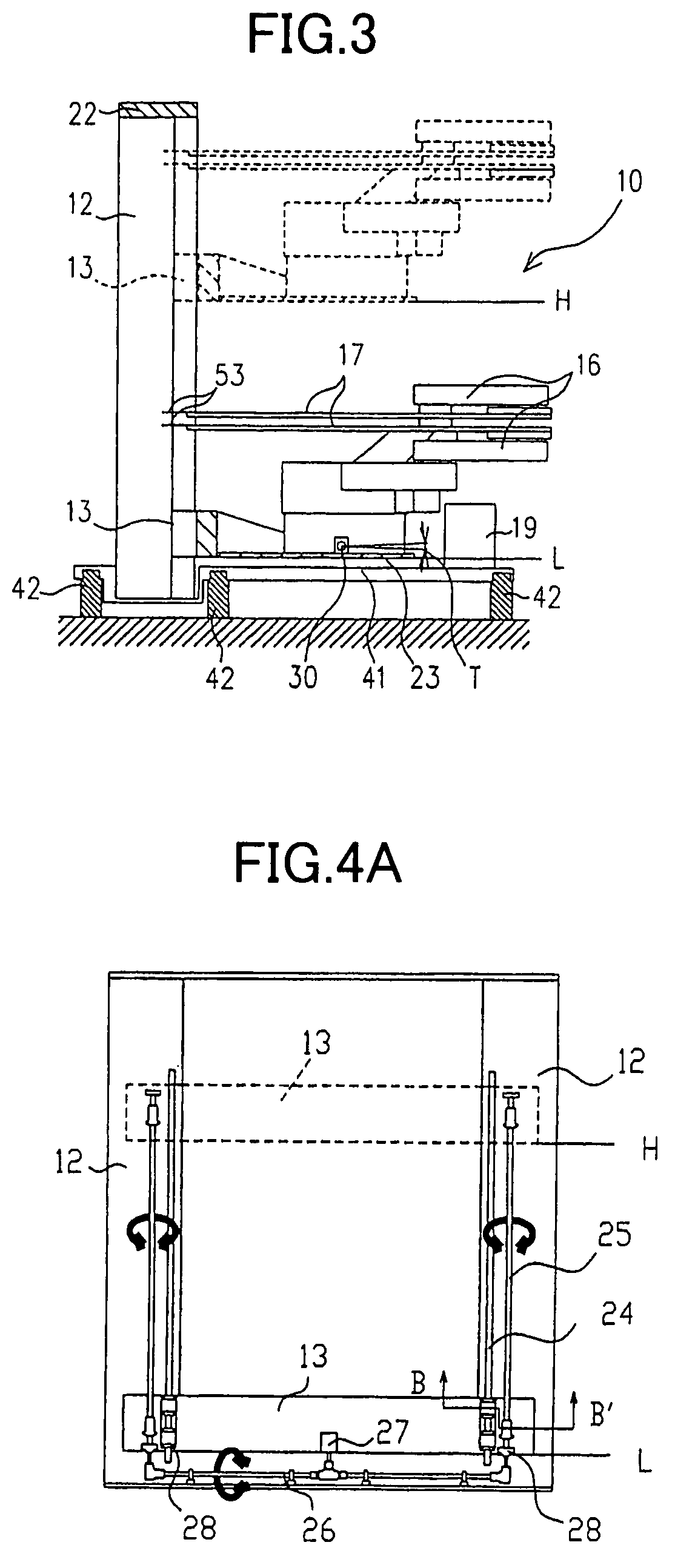

[0081] With reference to the attached drawings, embodiments for carrying out the present invention will be described in detail below. The following description deals with the case for transporting a glass plate of about 2 m square as a thin plate. As a transporting apparatus of the present invention is an apparatus for transporting a sheet member used in manufacturing a semiconductor integrated circuit, the transporting apparatus is operated in an environment of certain cleanness which is lower than that of clean room. Accordingly, the transporting apparatus of the present invention is a transporting apparatus which meets predetermined requirements for operating in the clean environment, for example, prevention of dust from occurring, and is completely different in behavior from transporting apparatus including a normal crane vehicle and a lifting machine in a storage warehouse.

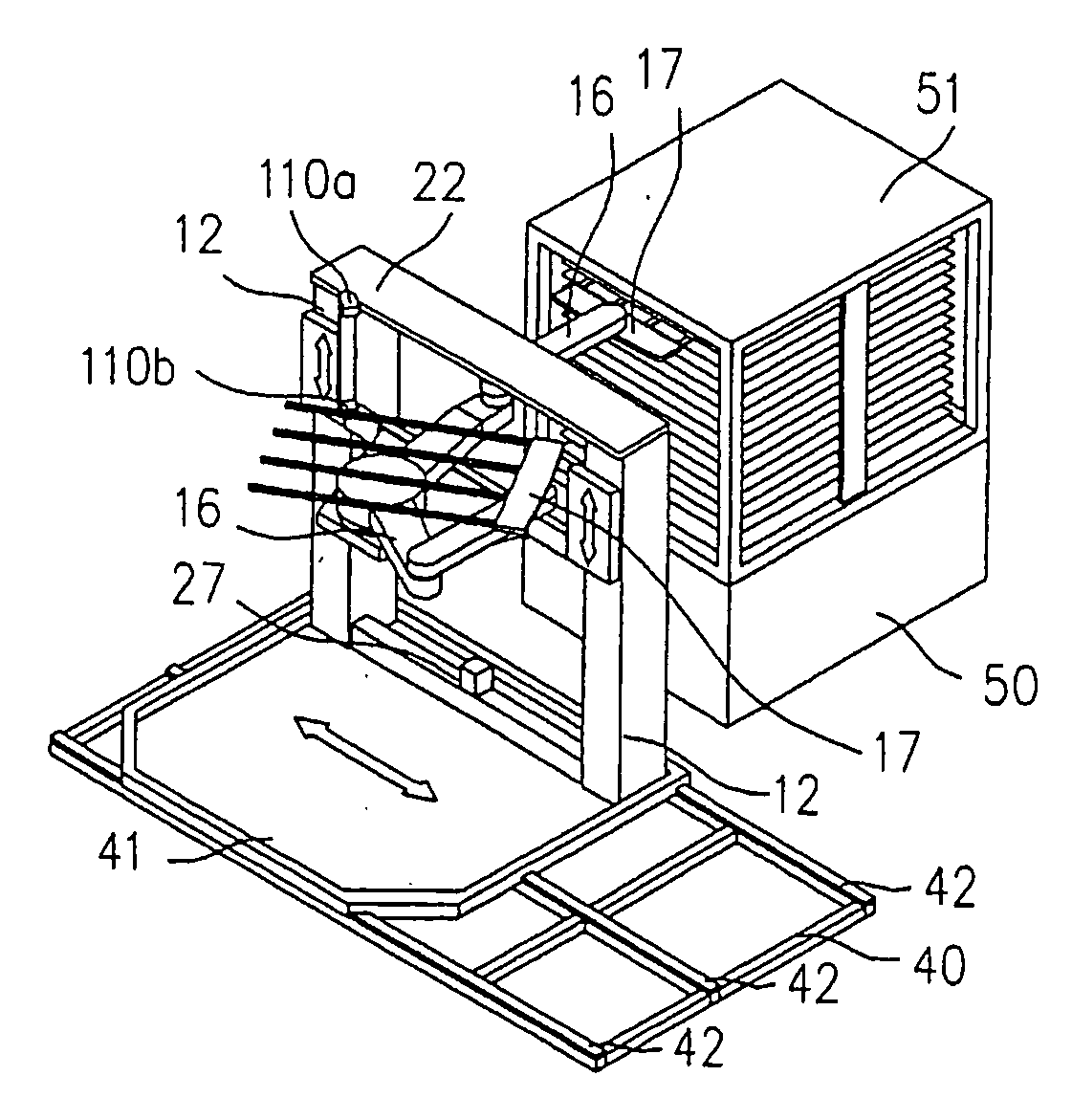

[0082]FIG. 1 is a plane view illustrating a sheet manufacturing system for semiconductor integrated circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com