Coating method for improving electrochemical property of high-nickel ternary nickel cobalt manganese anode material

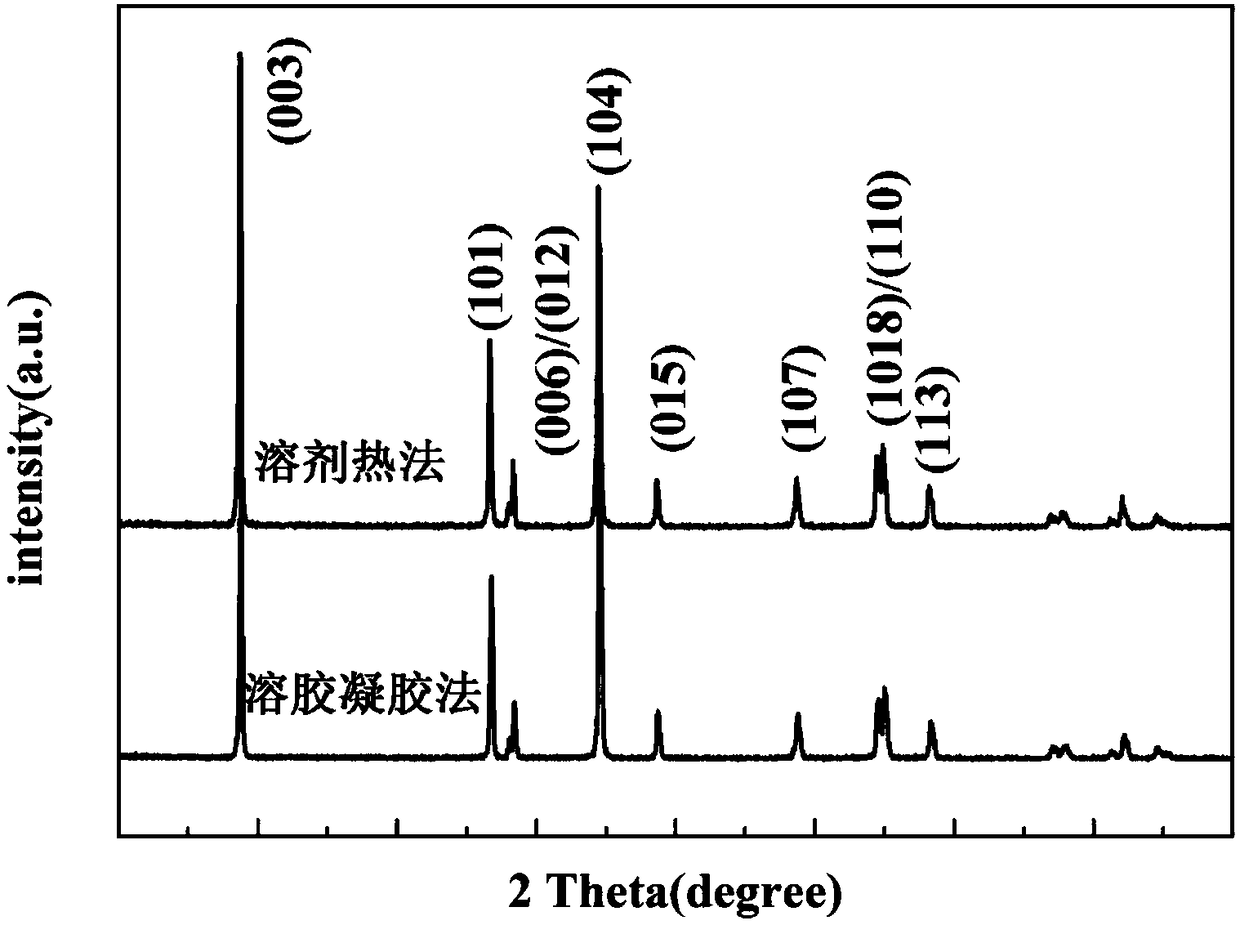

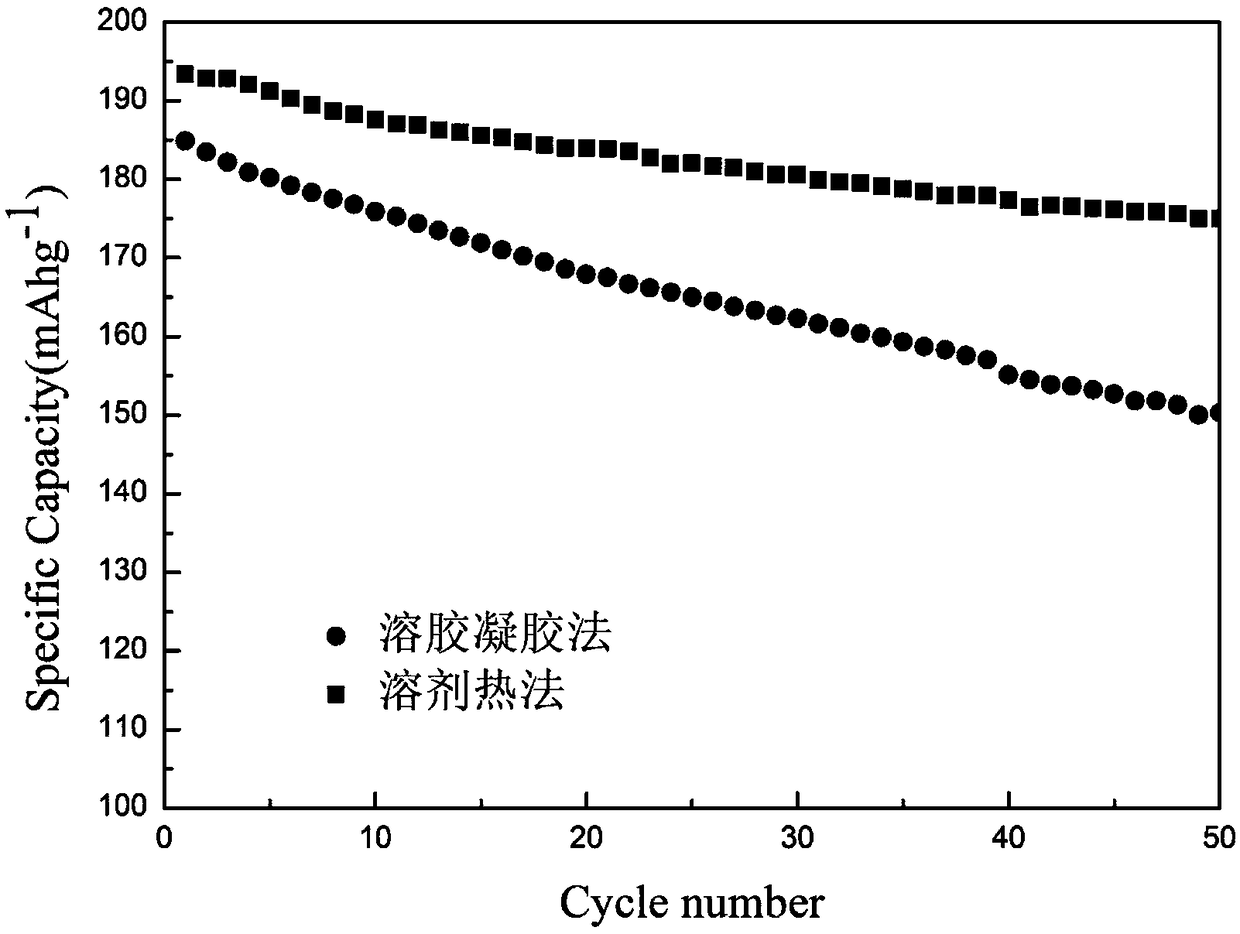

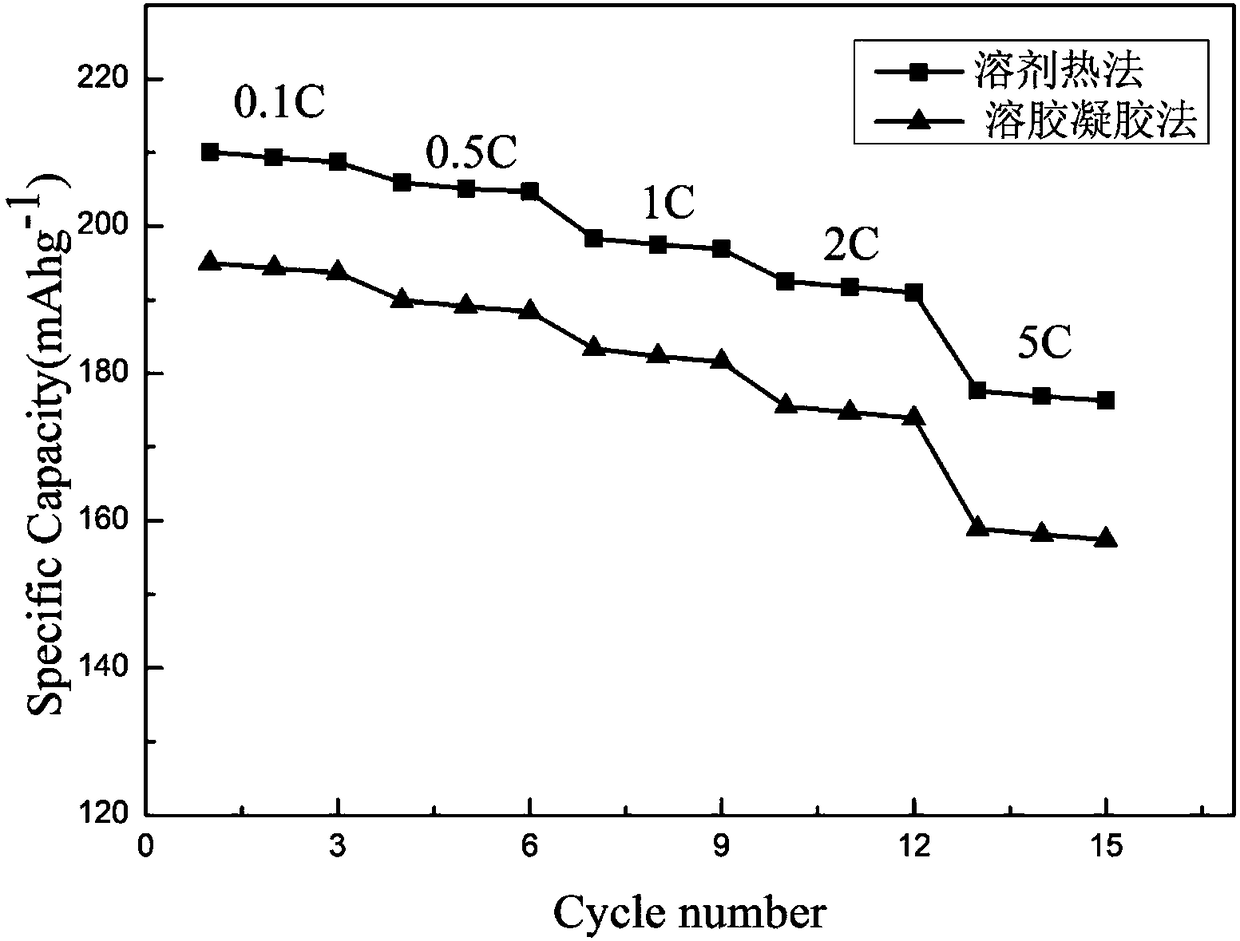

A cathode material, nickel cobalt manganese technology, applied in the field of lithium ion battery cathode materials, can solve the problems of poor product uniformity, uneven coating layer, etc., to inhibit the dissolution of metal ions, promote Li + diffusion, and improve discharge capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A coating method for improving the electrochemical performance of a high-nickel ternary nickel-cobalt-manganese positive electrode material proposed by the present invention comprises the following steps:

[0033] S1. According to lithium titanate: high-nickel ternary nickel-cobalt-manganese cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 The mass ratio is 1:100. Dissolve n-butyl titanate in 30ml of absolute ethanol, dissolve under 400rpm magnetic stirring to form a solution, add lithium acetate to dissolve, and then add citric acid to obtain a mixed solution;

[0034] S2, 5g high-nickel ternary nickel-cobalt-manganese cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 Disperse evenly in 50ml of absolute ethanol, stir thoroughly for 30min with magnetic force, add the mixed solution in S1 dropwise, and stir with magnetic force for 30min, transfer to 100ml hydrothermal reaction kettle after mixing evenly, place in a drying oven, at 180°C Reaction 24h obtains reaction solution...

Embodiment 2

[0039] A method for coating the electrochemical performance of a high-nickel ternary nickel-cobalt-manganese positive electrode material, comprising the following steps:

[0040] S1. According to lithium titanate: high-nickel ternary nickel-cobalt-manganese cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 The mass ratio is 1:100. Dissolve n-butyl titanate in 30ml of absolute ethanol, dissolve under 400rpm magnetic stirring to form a solution, add lithium acetate to dissolve, and then add citric acid to obtain a mixed solution;

[0041] S2, 5g high-nickel ternary nickel-cobalt-manganese cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 Disperse evenly in 50ml of absolute ethanol, stir fully with magnetic force for 30min, add the mixed solution in S1 dropwise, and fully magnetically stir for 30min, stir and evaporate to gel at 70°C, add to a vacuum drying oven, at 80 Drying at ℃ for 12h to obtain the positive electrode material mixture;

[0042] S3. Heating the positive electrode m...

Embodiment 3

[0053] A coating method for improving the electrochemical performance of a high-nickel ternary nickel-cobalt-manganese positive electrode material proposed by the present invention comprises the following steps:

[0054] S1, dissolving the titanium source in a solvent to form a solution, adding a lithium source to dissolve, and then adding citric acid to obtain a mixed solution;

[0055] S2, uniformly dispersing the high-nickel ternary nickel-cobalt-manganese positive electrode material in a solvent, adding the mixed solution in S1, mixing evenly, and performing a hydrothermal reaction to obtain a reaction solution;

[0056] S3, evaporating the reaction solution in S2 to a gel state, and obtaining the positive electrode material mixture after drying;

[0057] S4. Calcining the positive electrode material mixture in S3 to obtain a high-nickel ternary nickel-cobalt-manganese positive electrode material with a lithium titanate coating layer on the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com