Composite core-shell particles

A composite particle, core-shell technology, applied in active material electrodes, structural parts, electrical components, etc., can solve the problem of lack of impermeability of Si/C composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0125] Porous core-shell composite particles from Example 1 were provided with a coating of amorphous carbon (based on soft carbon; 10% by weight):

[0126] 3.89 g of the porous composite particles obtained in Example 1 after the carbonization step were combined with 630 mg of pitch (high melting point; softening point 235° C. ) were dispersed together in 60ml of p-xylene. The suspension was stirred at reflux for 90 minutes and cooled to room temperature over a period of 14 hours. The solvent was removed under reduced pressure, and the pitch-coated composite particles were transferred to a fused silica calciner (QCS GmbH) with a gas containing sample element type N and argon / H 2 Cascade control carbonization as an inert gas: first, the heating rate is 10°C / min, and the temperature is 250°C; then, the heating rate is 5°C / min, and the temperature is 550°C; Time 2 hours, Ar / H 2 The flow rate is 200ml / min for further carbonization directly. After cooling, 3.99 g of a black pow...

Embodiment 4

[0144] Embodiment 4 (Ex.4):

[0145] The conductive carbon black-containing porous core-shell composite particles from Example 3 were provided with an additional coating consisting of amorphous carbon (soft carbon; 10% by weight):

[0146] 4.54 g of the porous composite particles obtained in Example 3 after the carbonization step and 720 mg of pitch (high melting point; softening point 235° C. ) were dispersed together in 60ml of p-xylene. The suspension was stirred at reflux for 90 minutes and cooled to room temperature over a period of 14 hours. The solvent was removed under reduced pressure, and the pitch-coated composite particles were transferred to a fused silica calciner (QCS GmbH) with a gas containing sample element type N and argon / H 2 Cascade control carbonization as an inert gas: first, the heating rate is 10°C / min, the temperature is 250°C; then the heating rate is 5°C / min, the temperature is 550°C; 2 hours, Ar / H 2 The flow rate is 200ml / min for further carbon...

Embodiment 5

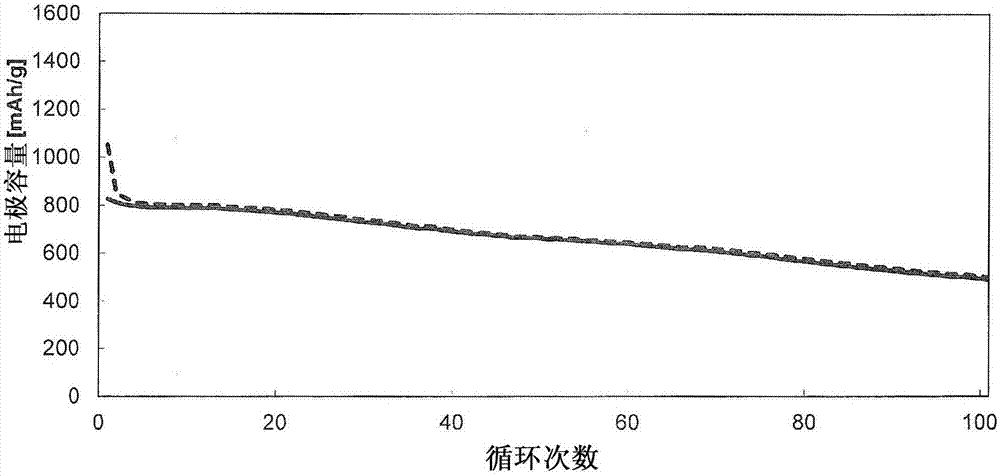

[0153] Electrode coatings were produced using composite materials from Example 4:

[0154] 0.24 g of conductive carbon black (Imerys, Super C65) was dissolved in 11.34 g of press- 1.4% by weight of sodium carboxymethylcellulose (Daicel, Grade 1380) in aqueous solution. After adding 1.50 g of the composite material from Example 4, 1.02 g of water and 0.60 g of ethanol, the mixture was then stirred for a further 30 minutes at a peripheral speed of 12 m / s. After degassing, the dispersion was applied to a copper foil (Schlenk Metallfolien, SE-Cu58) with a thickness of 0.030 mm by means of a film drying rack (Erichsen, type 360) with a gap height of 0.16 mm. Subsequently, the electrode coating produced in this way was dried for 60 minutes at 80° C. and an air pressure of 1 bar. The average weight per unit area of the dry electrode coating is 1.55 mg / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com