Lithium ion battery cathode material and method for preparing same

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of large fluctuation range of tap density, poor electrical conductivity, complicated process, etc., to improve the tap density and volume specific capacity, Good electrical conductivity and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

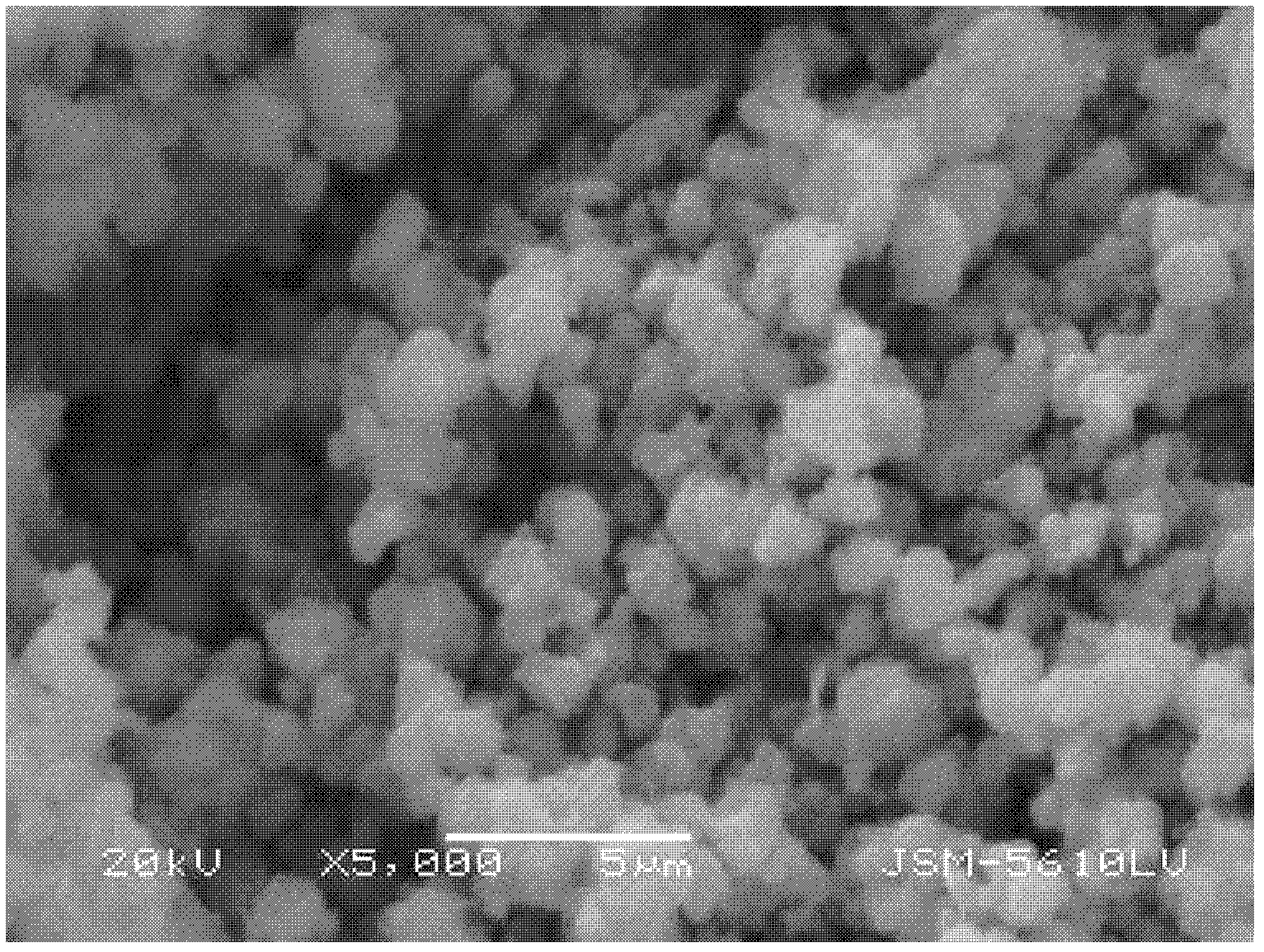

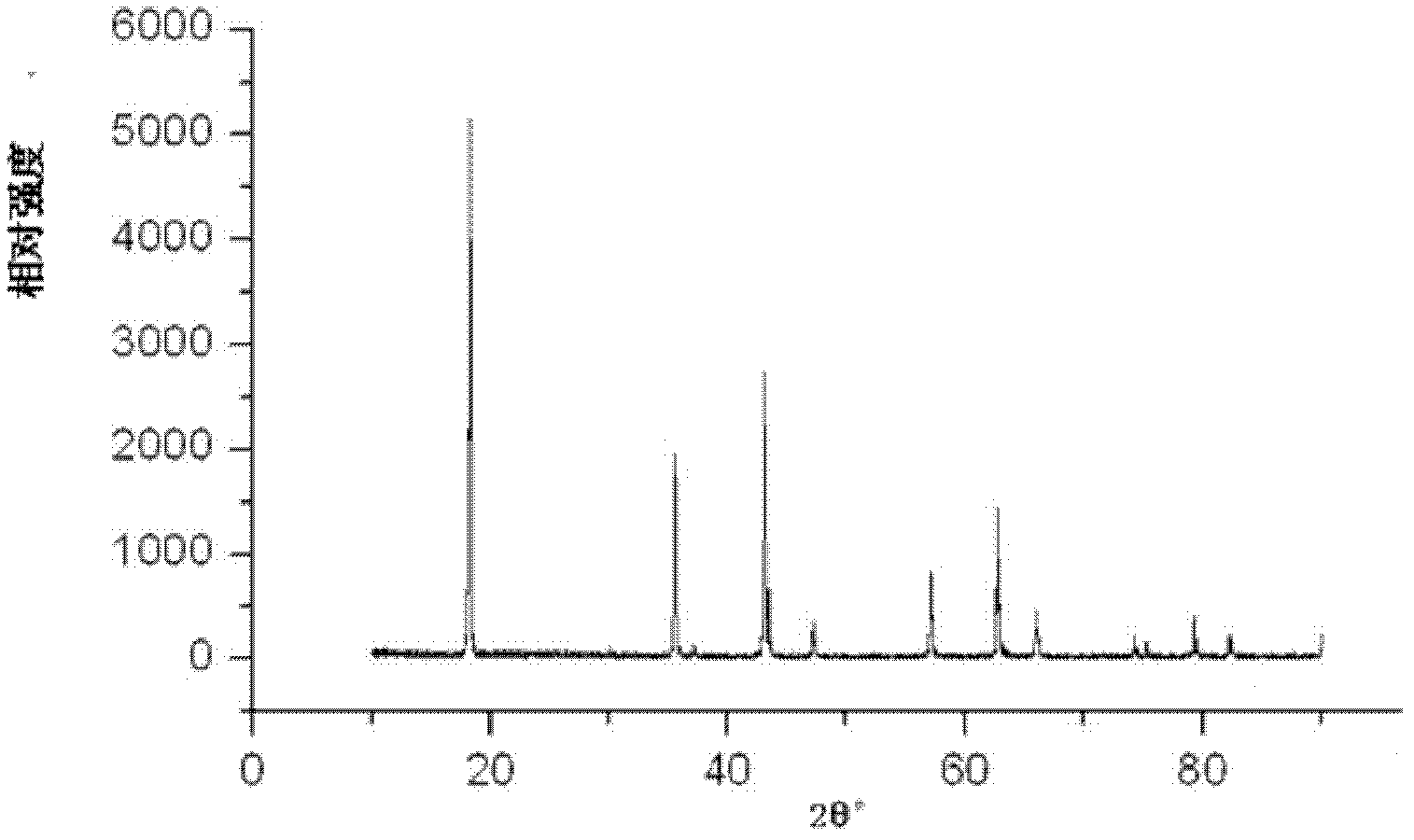

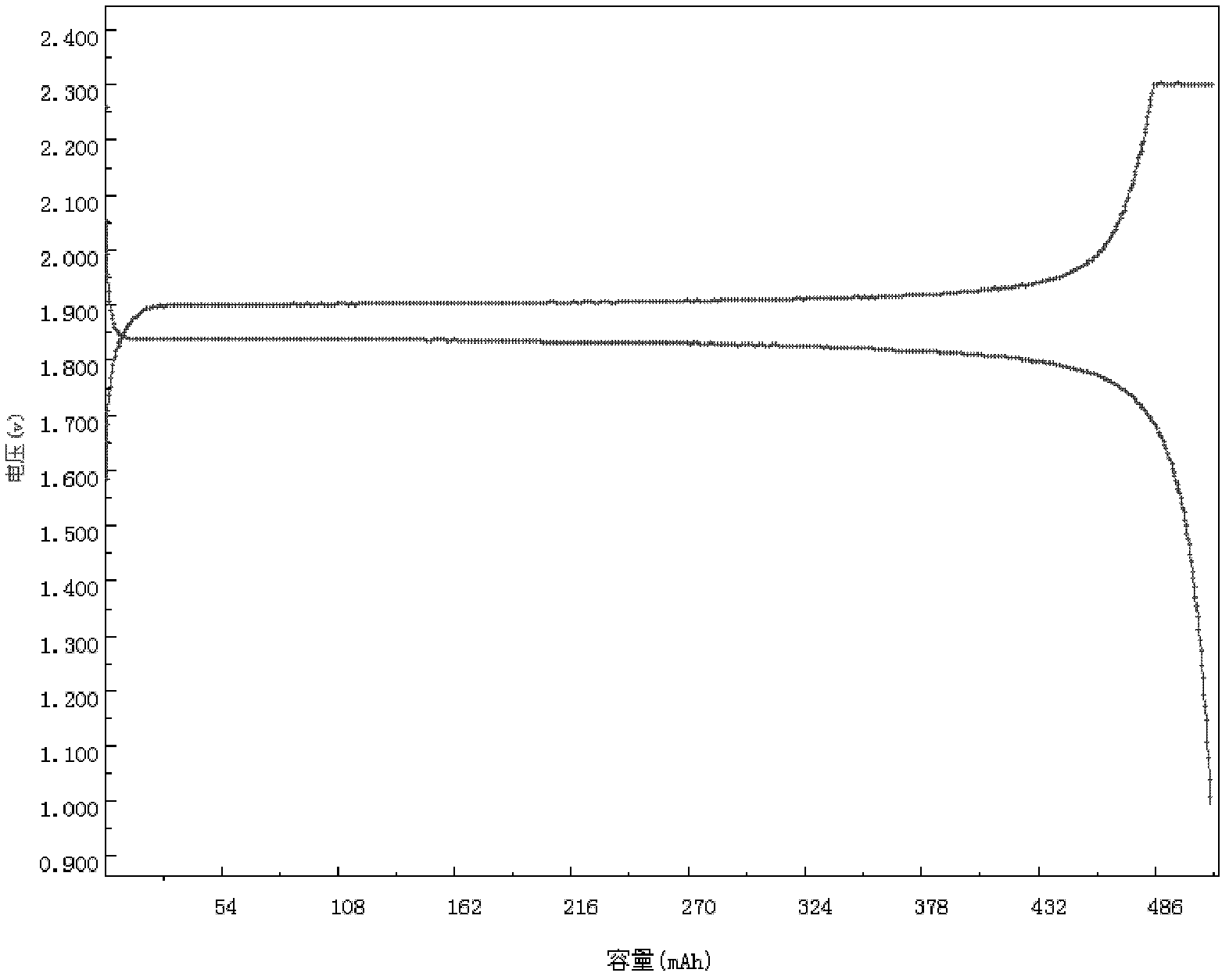

[0048] Separately sieve the raw materials titanium dioxide, lithium carbonate, and magnesium oxide, and keep those ≤2 μm for later use. Weigh 766.7 grams of titanium dioxide, 301.5 grams of lithium carbonate, and 16.1 grams of magnesium oxide, add deionized water, and wet mill for 4 hours. Dry in vacuum at 110°C for 6 hours. Under the protection of nitrogen, the temperature of the material is raised to 650°C at a rate of 5-8°C / min, and the temperature is kept for 16 hours. Cool down to 80°C at 4-8°C / min and discharge. Then add 68.9 grams of glucose powder, ball mill for 4 hours and mix evenly. The material is put into a carbon-coated furnace, and under the protection of nitrogen, the temperature is raised to 850° C. at 5-8° C. / min, and the temperature is kept for 12 hours. Cool down to 80°C at 4-8°C / min and discharge. Ball mill and sieve the material to obtain magnesium-doped carbon-coated lithium titanate Li 4 Ti 4.8 Mg 0.2 o 12 product. The performance index of the m...

Embodiment 2

[0055] Separately sieve the raw materials titanium dioxide, aluminum oxide, and chromium oxide, and use those with a thickness of ≤2 μm for later use. Weigh 342.4 grams of lithium hydroxide monohydrate and add deionized water, after dissolving, add 766.7 grams of titanium dioxide, 15.2 grams of chromium oxide, 10.2 grams of aluminum oxide, and wet mill for 6 hours. Dry in vacuum at 120°C for 5 hours. Under the protection of nitrogen, the temperature of the material is raised to 750° C. at a rate of 5-8° C. / min, and the temperature is kept for 12 hours. Cool down to 80°C at 4-8°C / min and discharge. Then add 86.9 grams of sucrose (or lactose, the carbon content of lactose and sucrose is the same), ball mill for 6 hours and mix well, put the material into the carbon-coated furnace, under the protection of nitrogen, 5-8°C / min to heat up to 750°C, Keep warm for 16 hours. Cool down to 80°C at 4-8°C / min and discharge. Ball mill and sieve the material to obtain aluminum-chromium-d...

Embodiment 3

[0059] The raw materials titanium dioxide and vanadium pentoxide are graded separately, and the ones ≤2um are used for later use. Weigh 816.1 grams of lithium acetate and add it to deionized water. After dissolving, add 782.7 grams of titanium dioxide and 18.2 grams of vanadium pentoxide, and wet mill for 6 hours. Dry in vacuum at 100°C for 6 hours. Under the protection of nitrogen, the temperature of the material is raised to 720°C at a rate of 5-8°C / min, and the temperature is kept for 14 hours. Cool down to 80°C at 4-8°C / min and discharge. Then add 47.2 grams of lactose (or sucrose, the carbon content of lactose and sucrose is the same), ball mill for 6 hours and mix well, put the material into the carbon-coated furnace, under the protection of nitrogen, 5-8°C / min to heat up to 800°C, Keep warm for 16 hours. Cool down to 80°C at 4-8°C / min and discharge. Ball mill and sieve the material to obtain vanadium-doped and carbon-coated lithium titanate Li 4 Ti 4.9 V 0.1 o 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com