Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1041results about "Rotary press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Absorbent core for disposable absorbent article

InactiveUS7935207B2Mechanical working/deformationLamination ancillary operationsEngineeringMechanical engineering

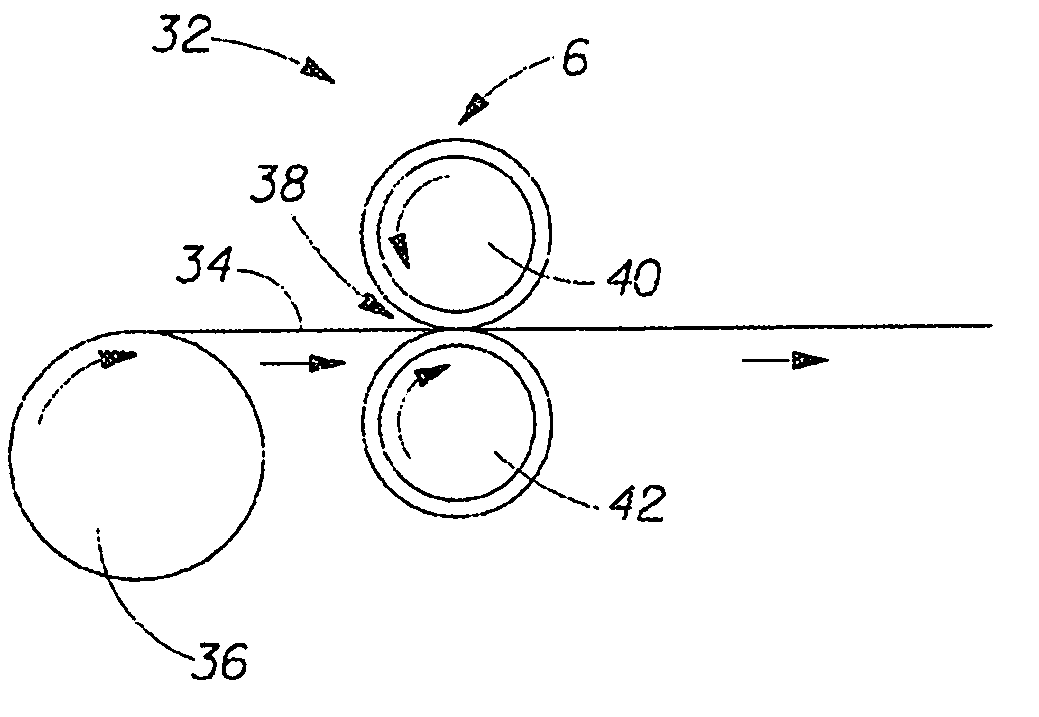

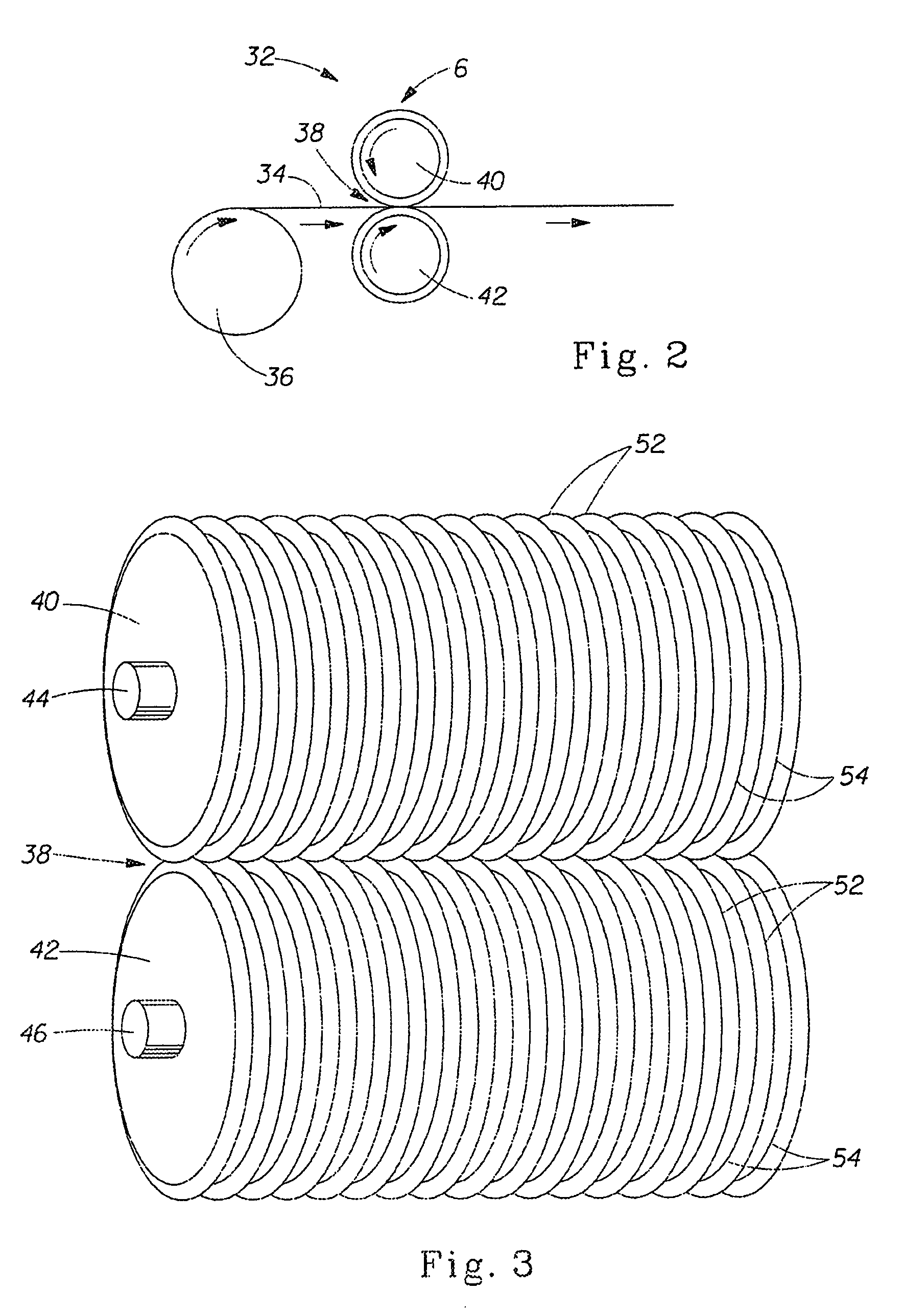

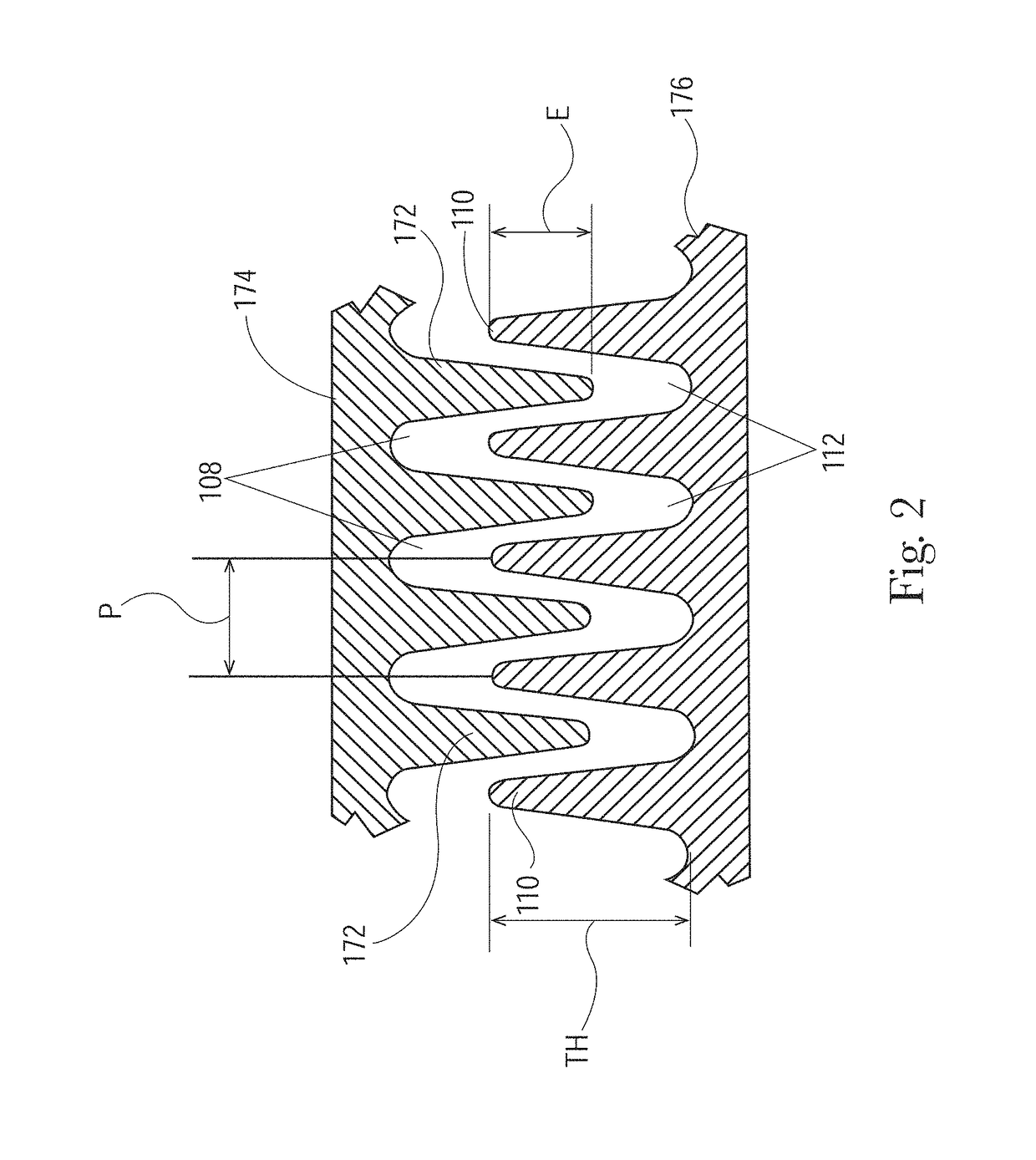

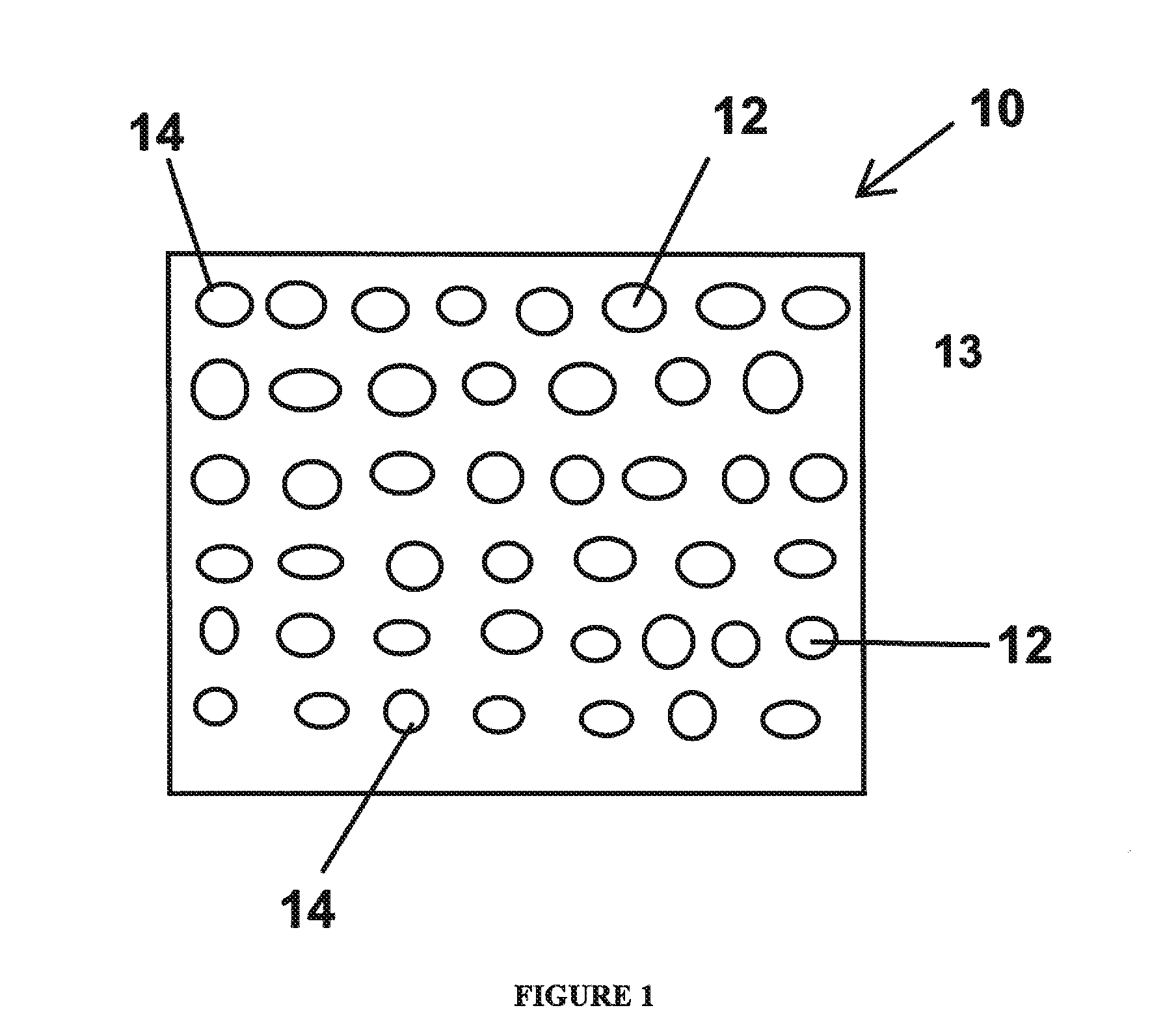

A method of making an absorbent core for use in an absorbent article. The method comprising the steps of:a. providing a first absorbent fibrous web material;b. providing a second absorbent fibrous web material;c. providing a pair of rolls forming a nip through which the first and second absorbent fibrous web materials can be processed, the pair of rolls being selected from the processes consisting of, ring rolling, SELF, micro-SELF, and rotary knife aperturing;d. deforming portions of the first absorbent fibrous web material by processing through the pair of rolls;e. deforming portions of the second absorbent fibrous web material by processing through the pair of rolls; andf. combining the first and second absorbent fibrous web materials to form the absorbent core.

Owner:PROCTER & GAMBLE CO

Absorbent core for disposable absorbent article

A method of making an absorbent core for use in an absorbent article. The method comprising the steps of:a. providing a first absorbent fibrous web material;b. providing a second absorbent fibrous web material;c. providing a pair of rolls forming a nip through which the first and second absorbent fibrous web materials can be processed, the pair of rolls being selected from the processes consisting of, ring rolling, SELF, micro-SELF, and rotary knife aperturing;d. deforming portions of the first absorbent fibrous web material by processing through the pair of rolls;e. deforming portions of the second absorbent fibrous web material by processing through the pair of rolls; andf. combining the first and second absorbent fibrous web materials to form the absorbent core.

Owner:THE PROCTER & GAMBLE COMPANY

Forming fabric and/or tissue molding belt and/or molding belt for use on an atmos system

ActiveUS20070251659A1Increase the opening areaLong dwell timePaper/cardboardMachine wet endPaper machine

A forming fabric for an ATMOS system or a TAD machine. The forming fabric includes a permeability value of between approximately 100 cfm and approximately 1200 cfm, a paper surface contact area of between approximately 0.5% and approximately 90% when not under pressure and tension, and an open area of between approximately 1.0% and approximately 90%. A belt press for a paper machine can utilize the forming fabric. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

Apparatus for calendering a sheet material web carried by a fabric

An apparatus for calendering a sheet material web being carried on or between one or more carrier fabrics. In a preferred embodiment, the apparatus includes a calender section having first and second calender rolls forming a nip therebetween. At least one carrier fabric is disposed between the first and second calender rolls. The first and second calender rolls apply a load to the carrier fabric and sheet material web as they pass through the nip between the calender rolls so as to reduce the caliper, or thickness, of the sheet material web. A method for calendering the sheet material web includes carrying the sheet material web on one or more carrier fabrics through the calender nip formed by the first and second calender rolls and applying a load to the carrier fabric, and sheet material carried thereby, so as to reduce the thickness of the sheet material web.

Owner:KIMBERLY CLARK WORLDWIDE INC

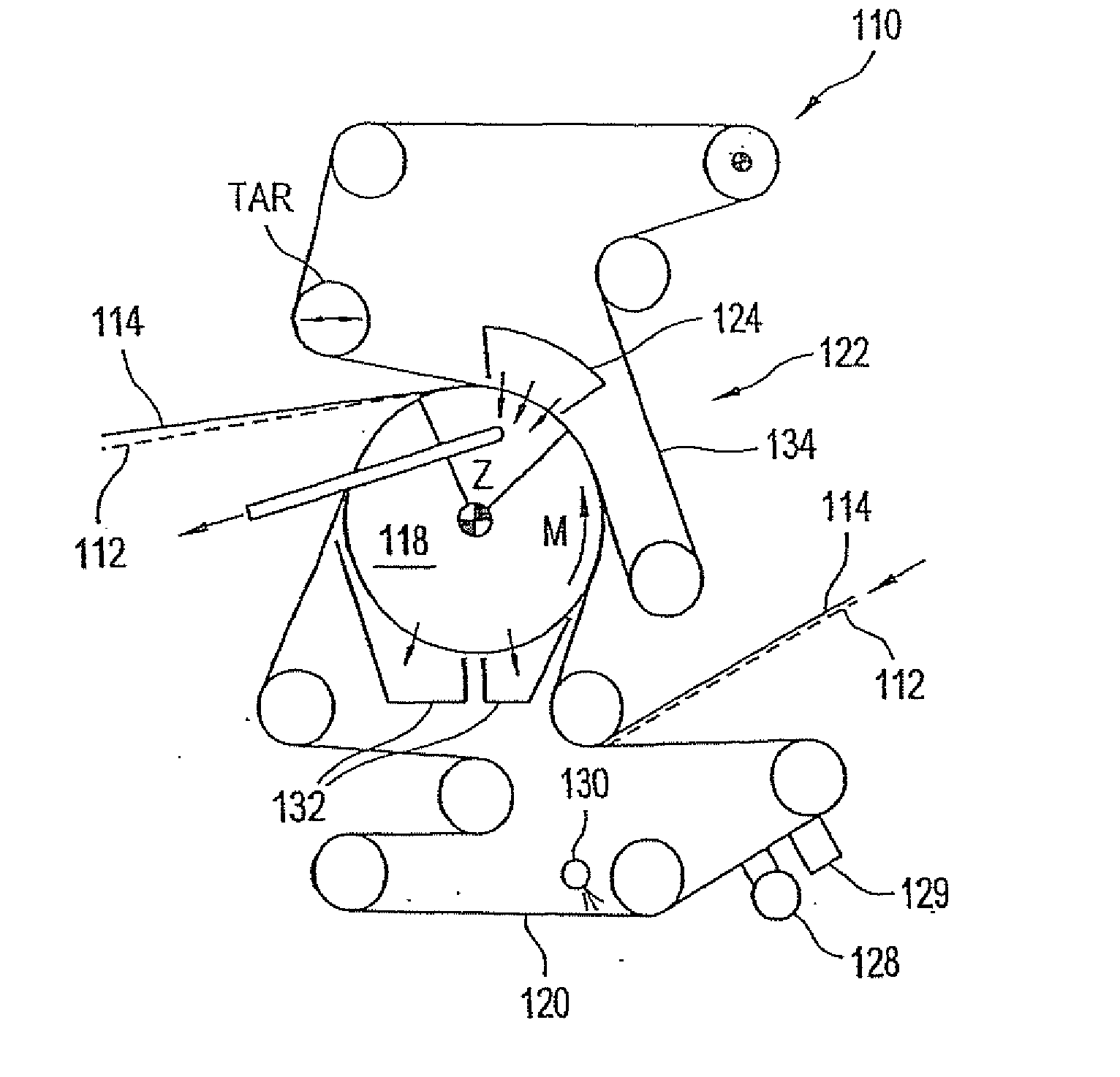

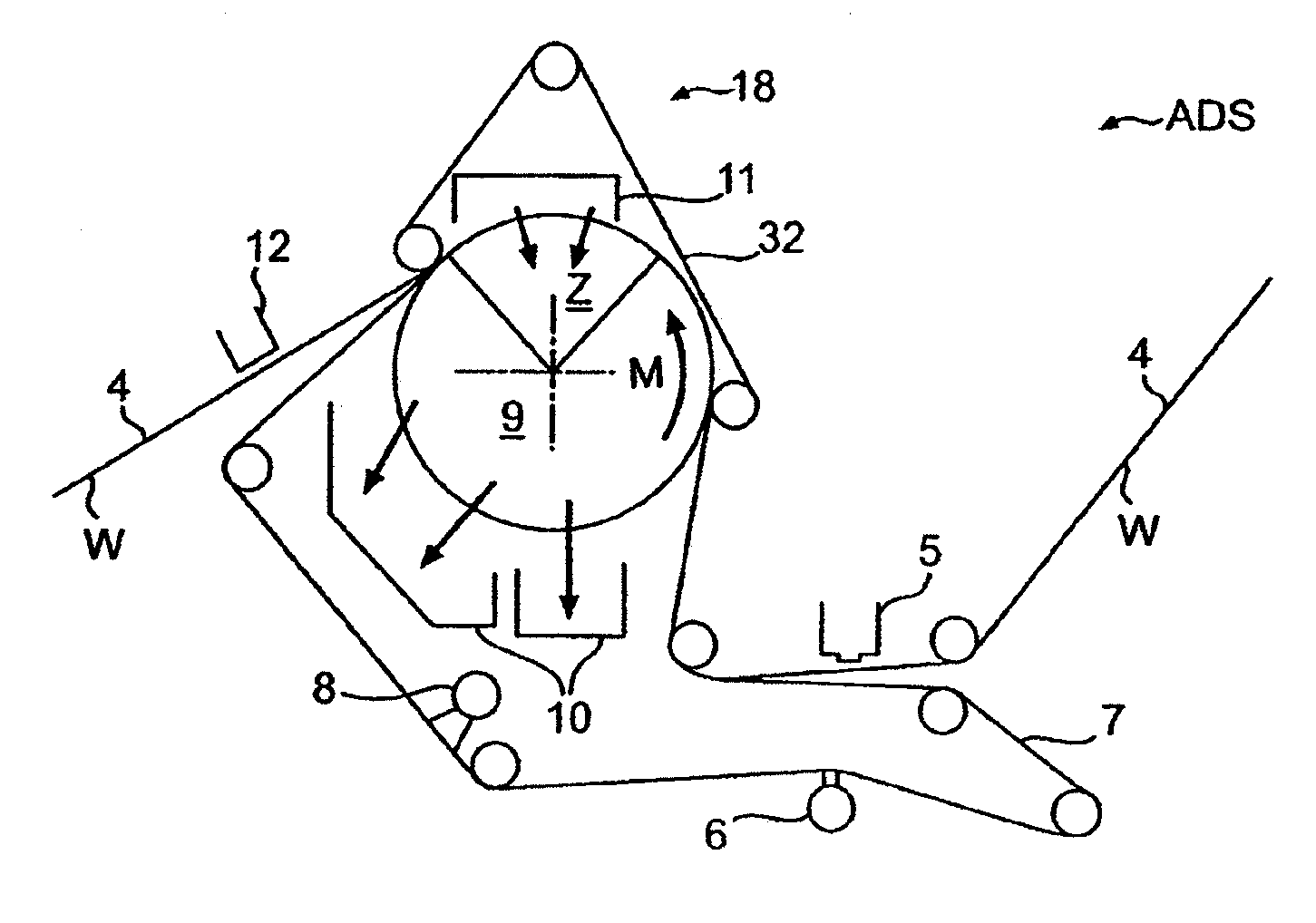

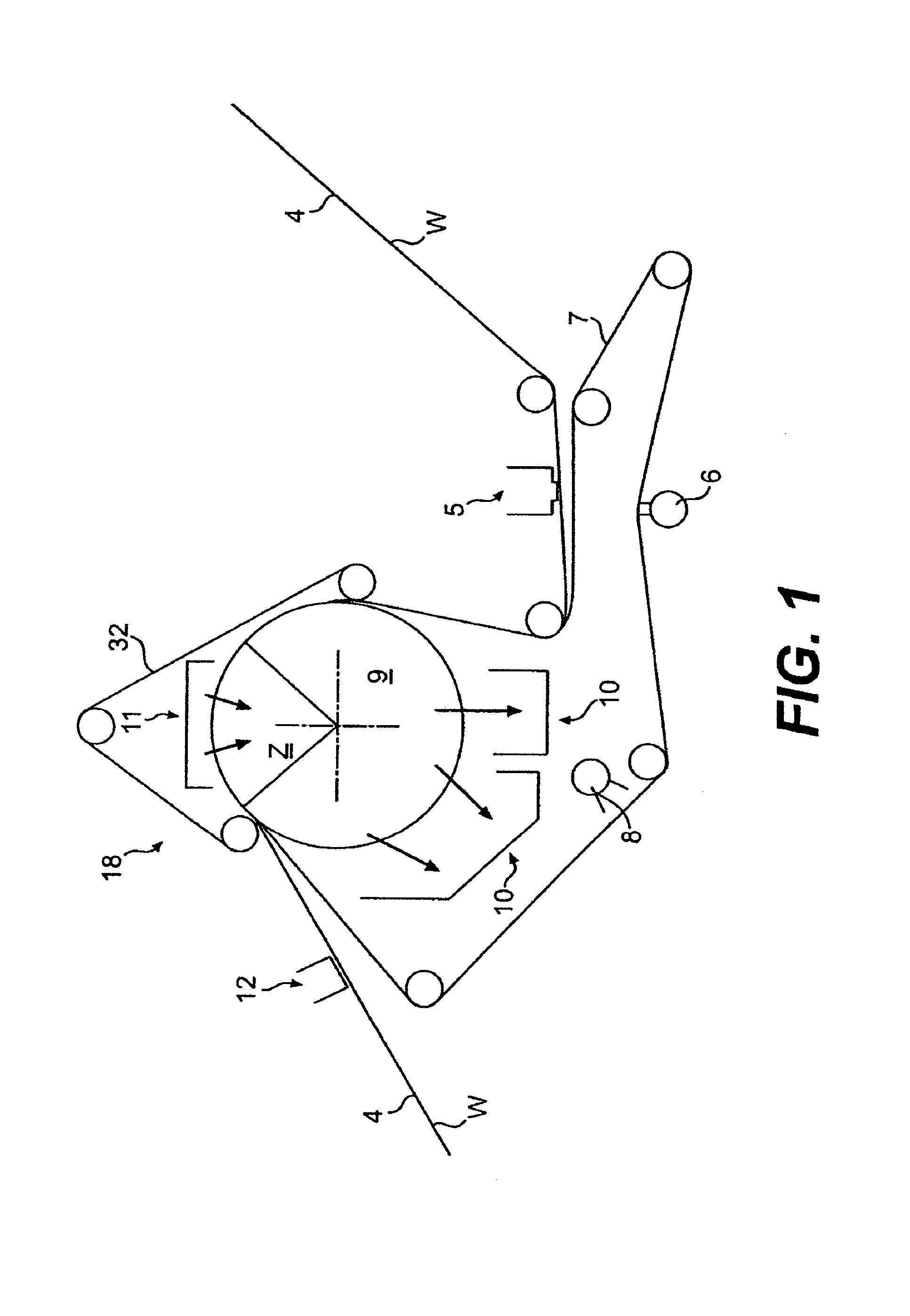

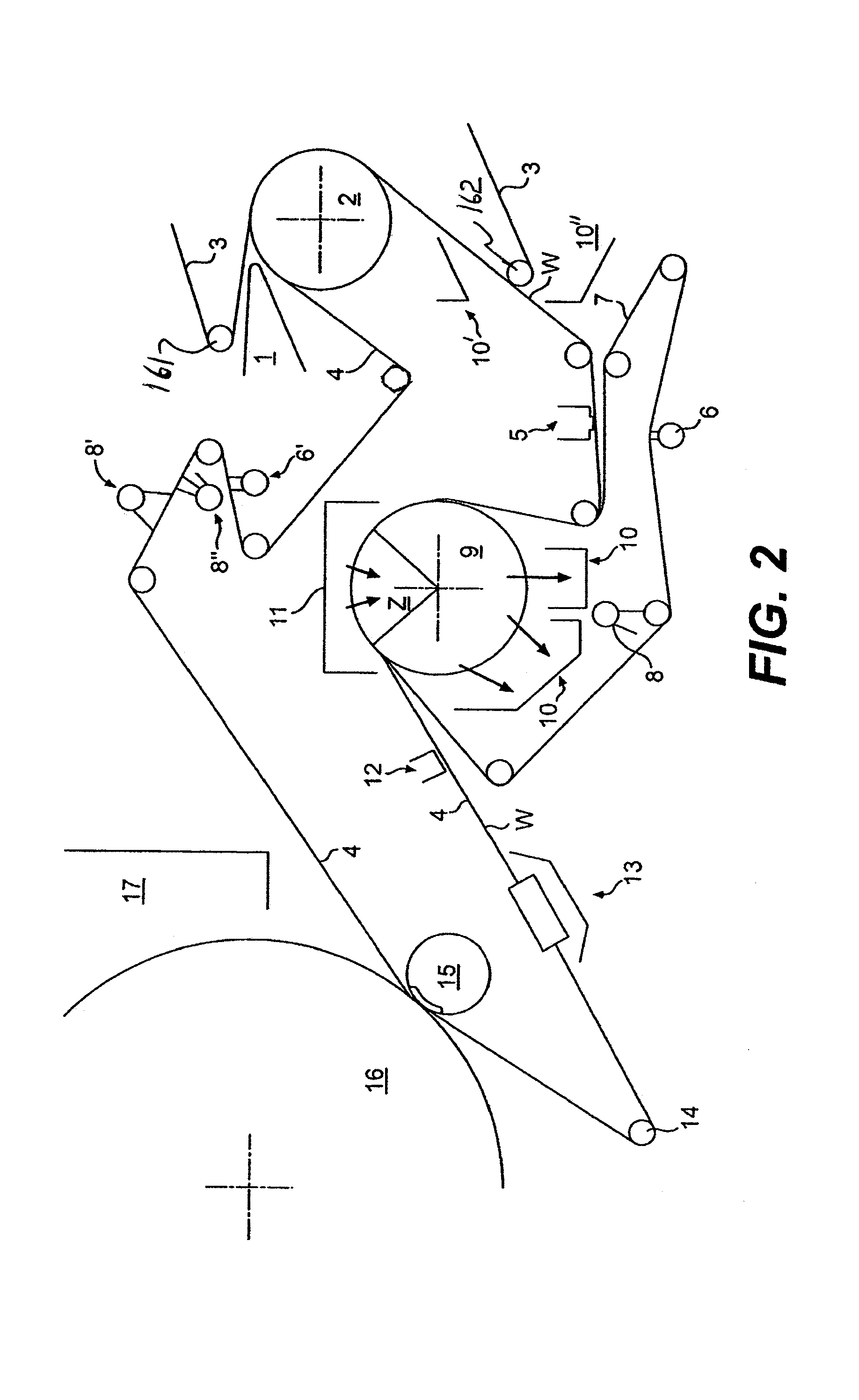

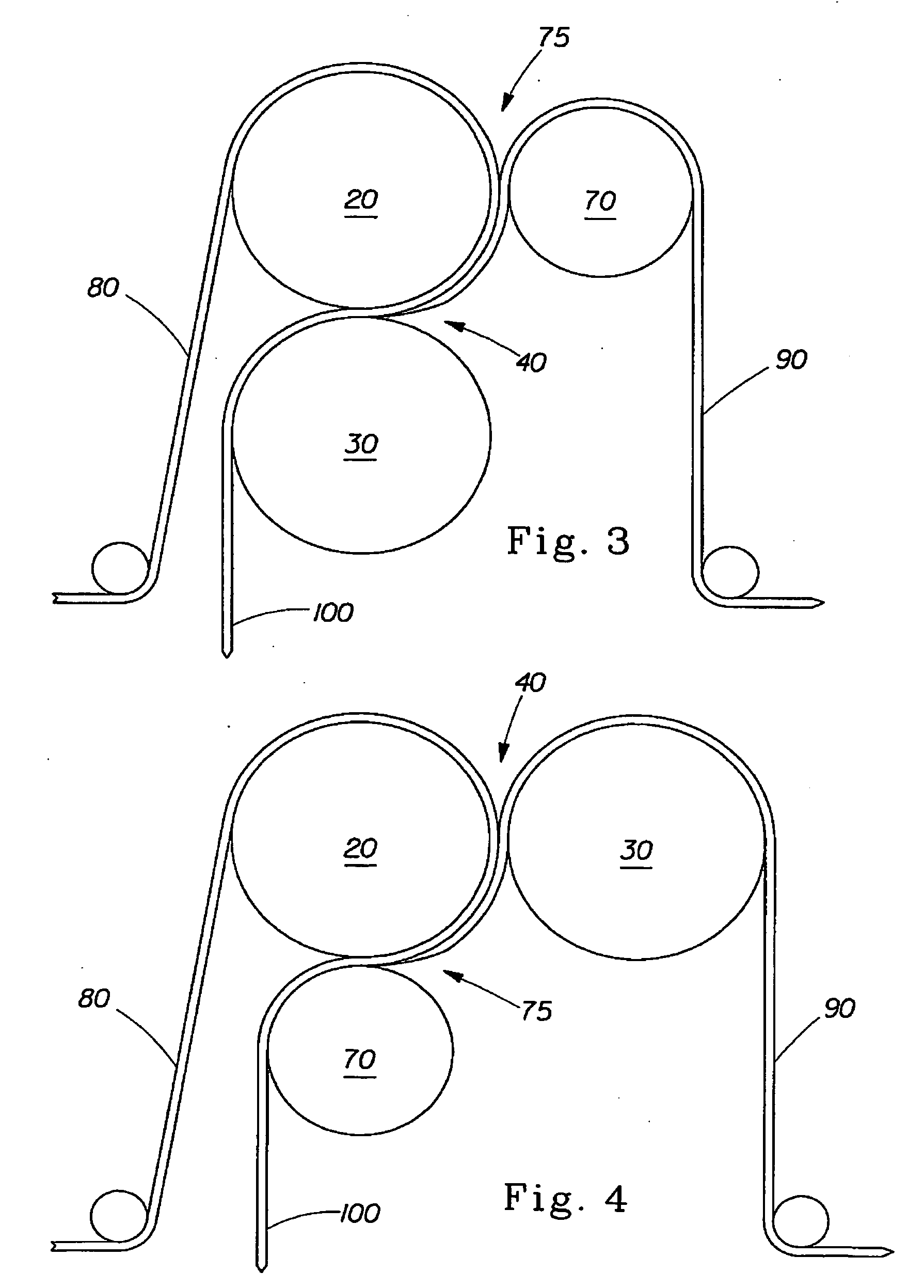

Advanced dewatering system

ActiveUS7510631B2Large tensionIncrease the opening areaDrying solid materials with heatDryer sectionFacial tissueHygiene

System for drying a tissue or hygiene web. The system includes a permeable structured fabric carrying the web over a drying apparatus. A permeable dewatering fabric contacts the web and is guided over the drying apparatus. A mechanism is utilized for applying pressure to the permeable structured fabric, the web, and the permeable dewatering fabric at the drying apparatus. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

Dewatering tissue press fabric for an atmos system and press section of a paper machine using the dewatering fabric

A dewatering fabric for an ATMOS system or a TAD machine that includes a caliper of between approximately 0.1 mm and approximately 15 mm, a permeability value of between approximately 1 cfm and approximately 500 cfm, an overall density of between approximately 0.2 g / cm3 and approximately 1.10 g / cm3, and a weight of between approximately 100 g / m2 and approximately 3000 g / m2. A belt press for a paper machine can utilize the dewatering fabric. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in anyway.

Owner:VOITH PATENT GMBH

Advanced dewatering system

ActiveUS20060085999A1Substantial airflowLarge tensionDrying solid materials with heatDryer sectionHygieneWaste management

System for drying a tissue or hygiene web. The system includes a permeable structured fabric carrying the web over a drying apparatus. A permeable dewatering fabric contacts the web and is guided over the drying apparatus. A mechanism is utilized for applying pressure to the permeable structured fabric, the web, and the permeable dewatering fabric at the drying apparatus. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

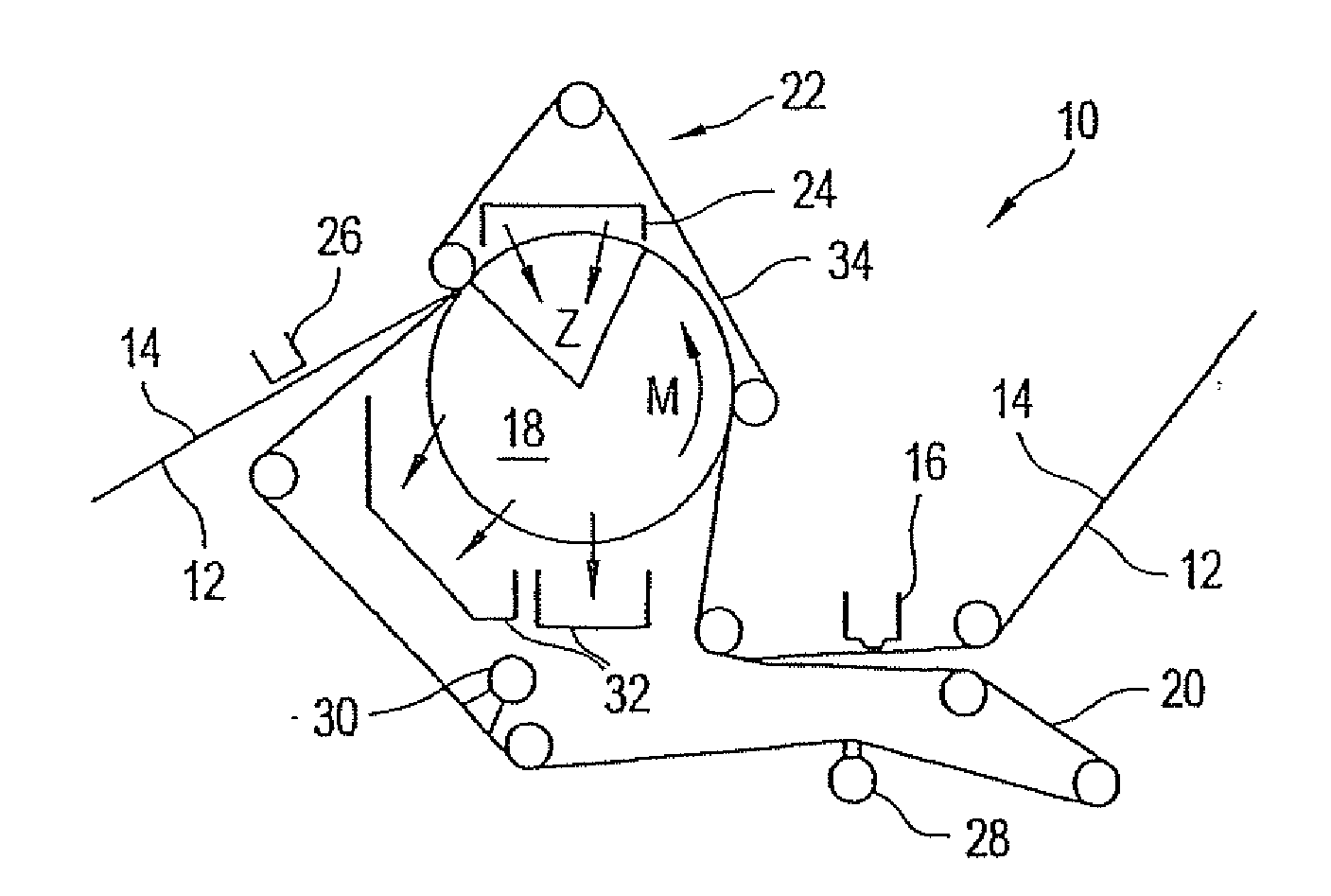

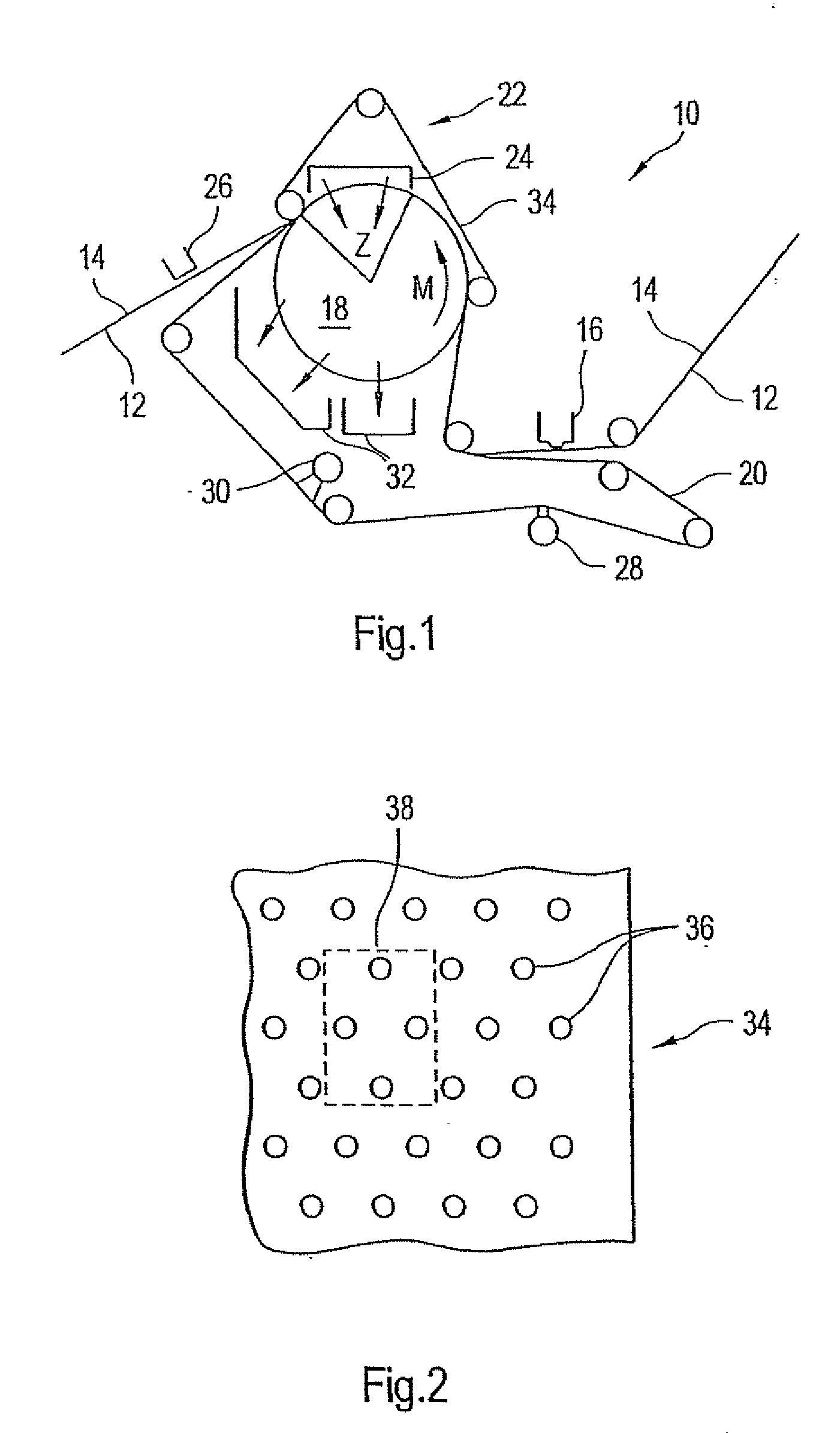

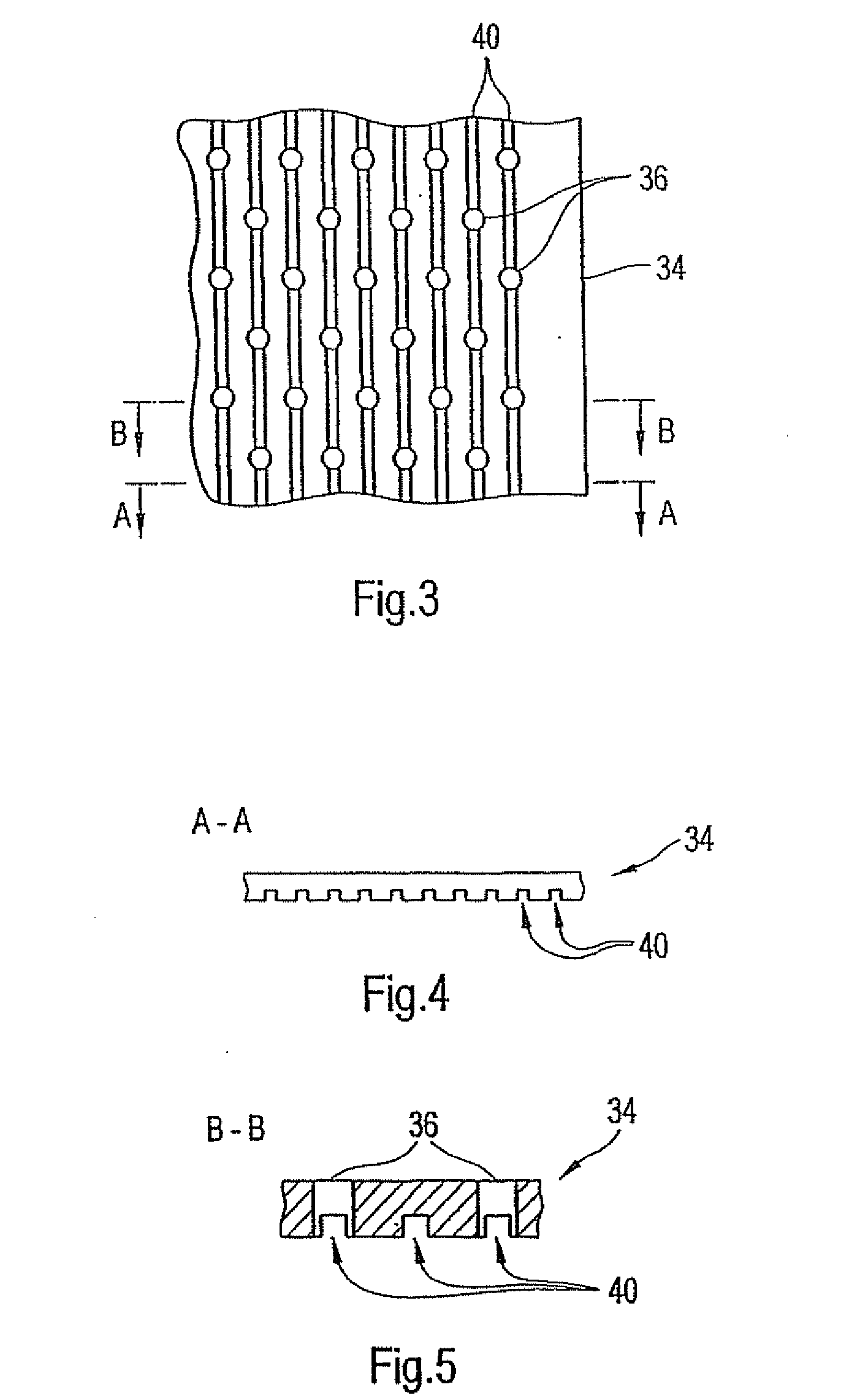

High tension permeable belt for an ATMOS system and press section of paper machine using the permeable belt

ActiveUS7527709B2Large tensionIncrease the opening areaPaper/cardboardPress sectionFiberSupport surface

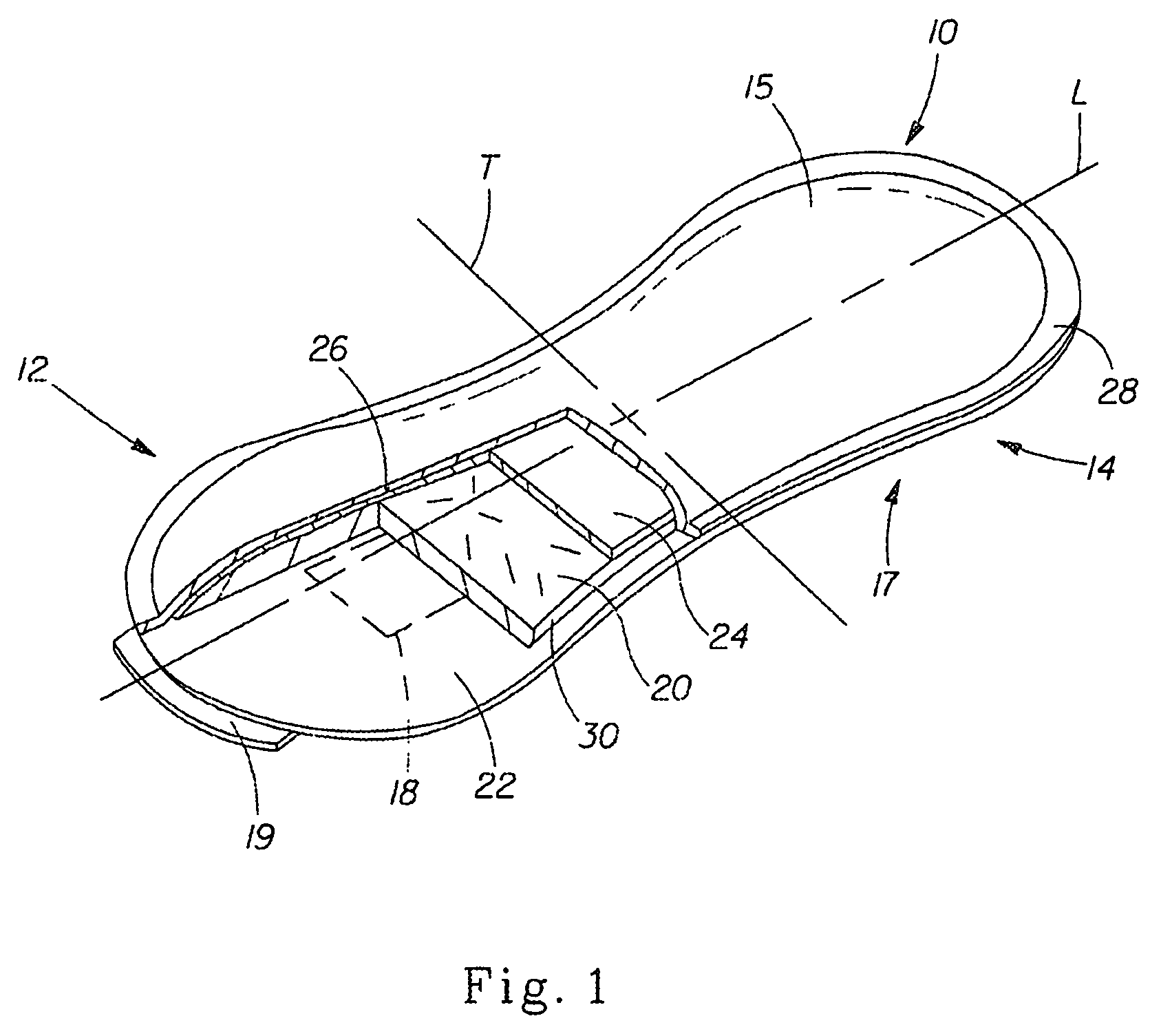

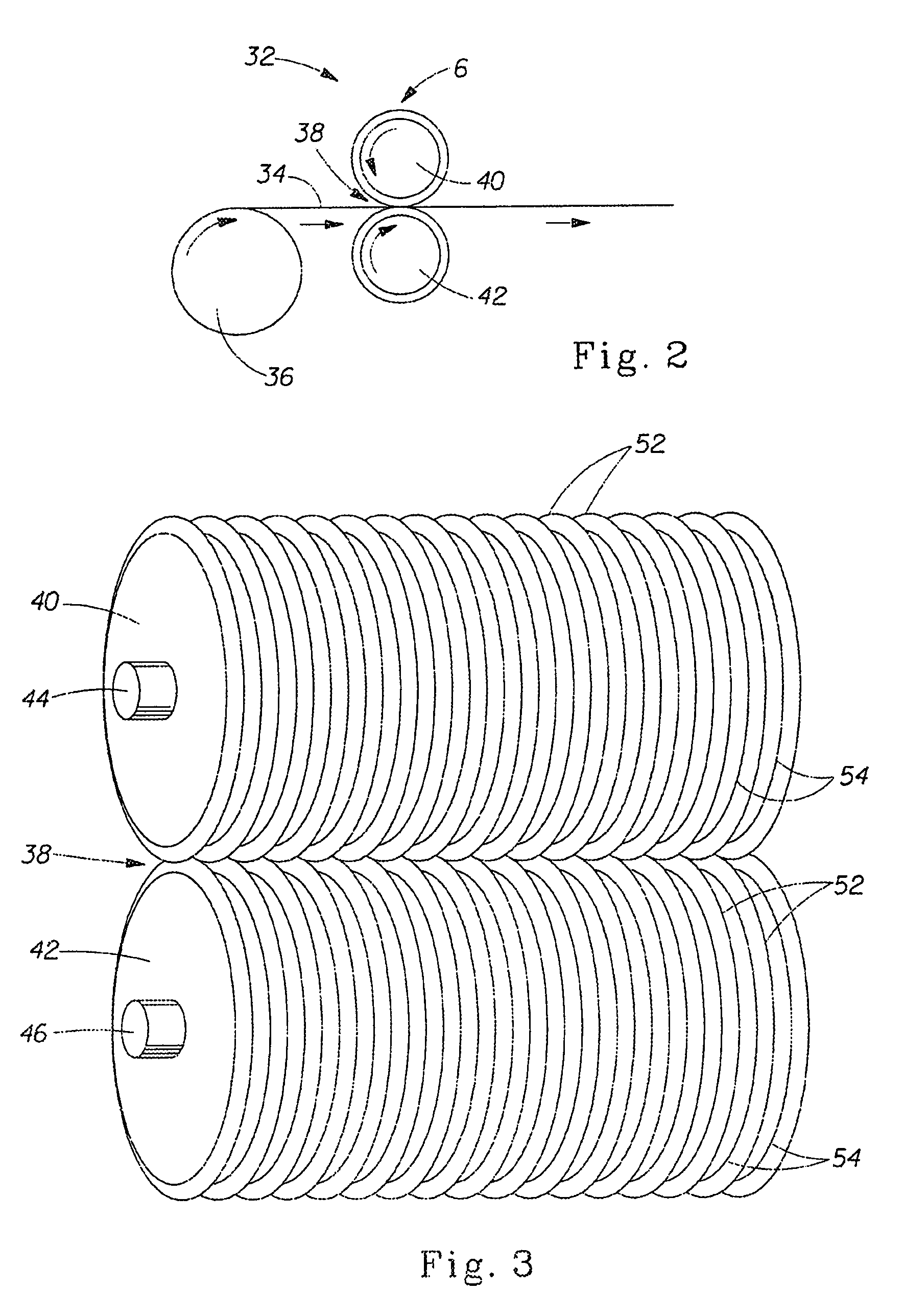

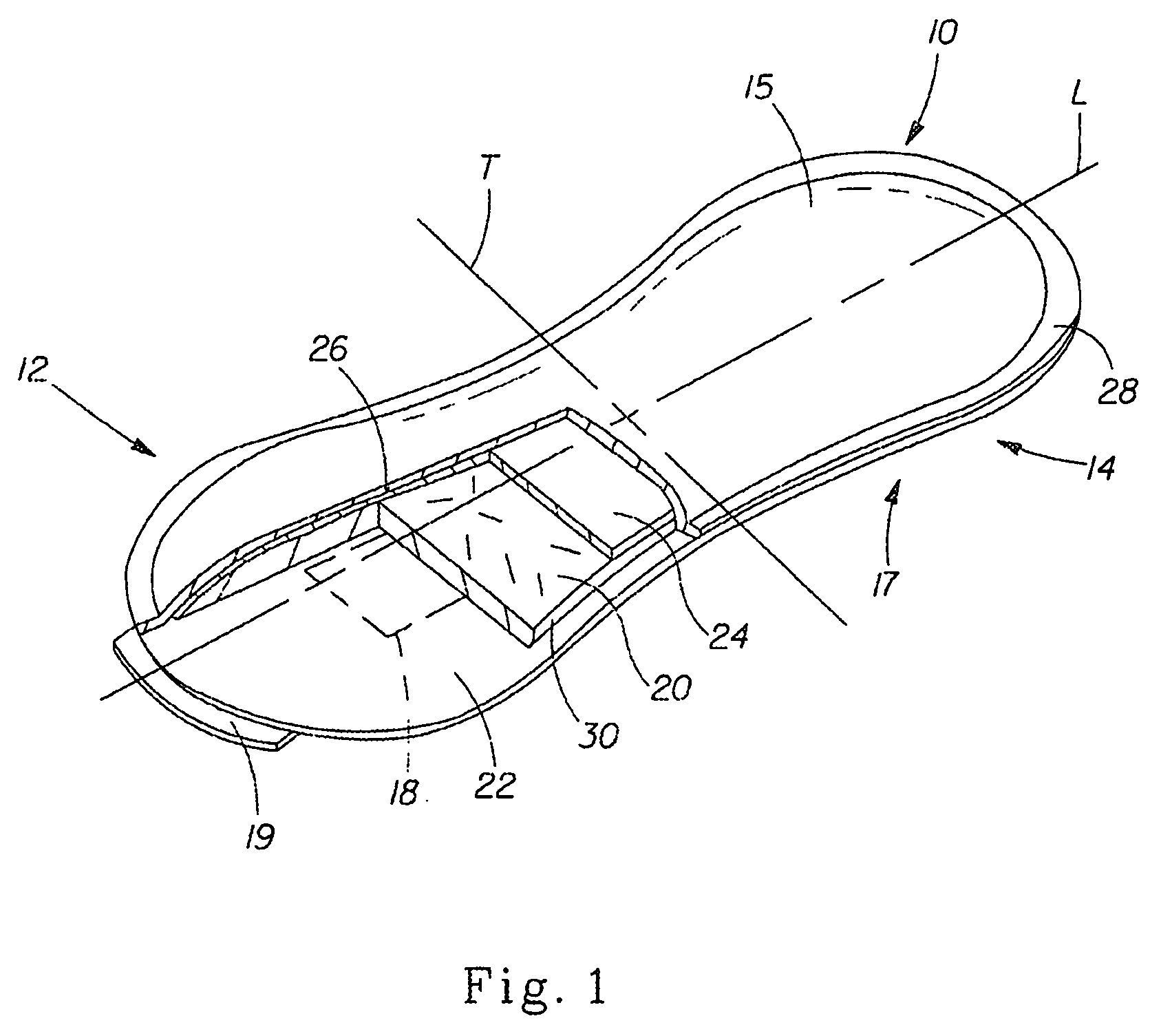

A permeable belt, a belt press including a roll having an exterior surface and the permeable belt, and a method of drying or pressing a web with the permeable belt. The permeable belt has a paper web facing side and is guided over a support surface. The permeable belt can have a tension of between approximately 20 kN / m and approximately 100 KN / m, a permeability value of between approximately 100 cfm and approximately 1200 cfm, a surface contact area of the paper web side that being between approximately 0.5% and approximately 90% when not under tension, and an open area of between approximately 1.0% and approximately 85%. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

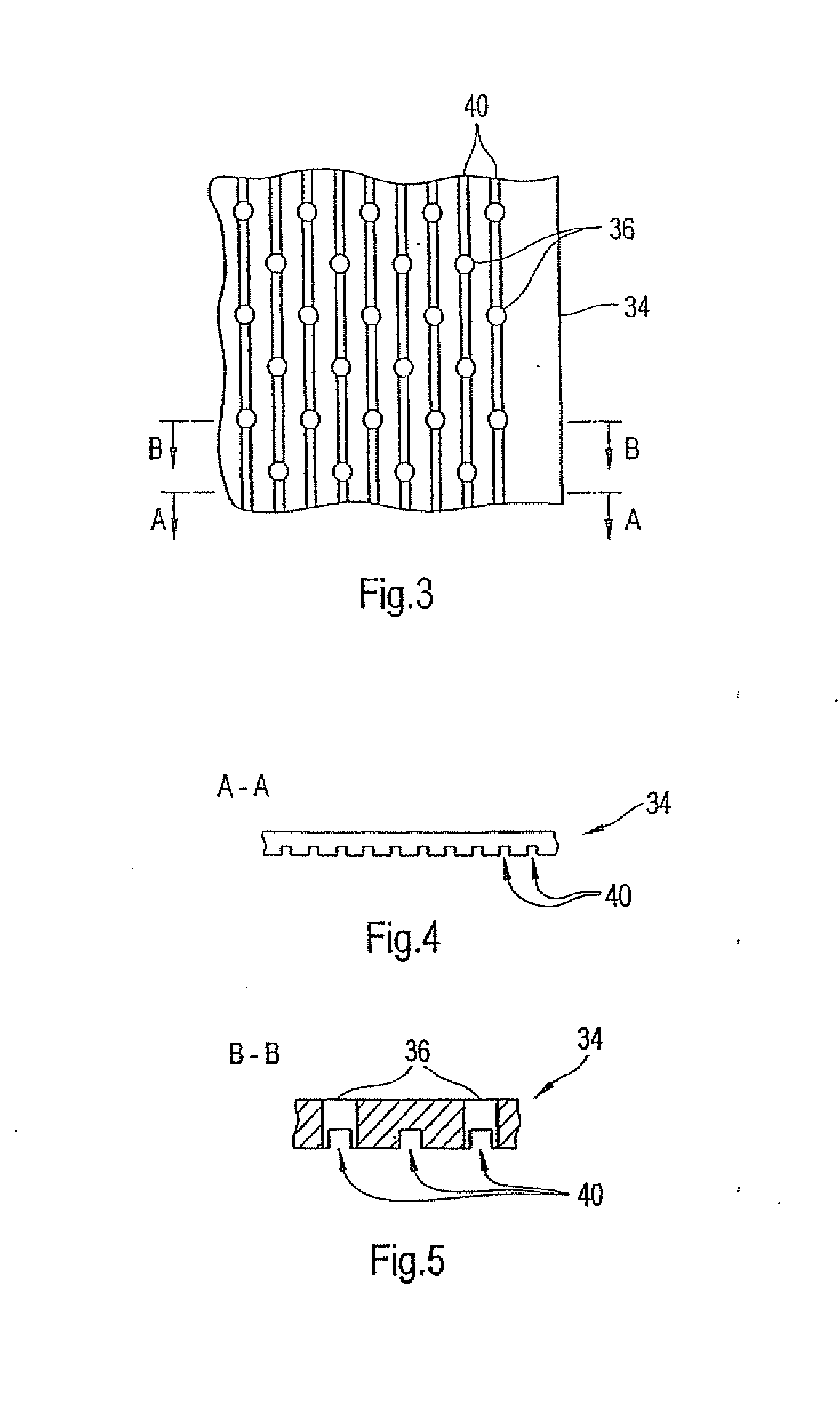

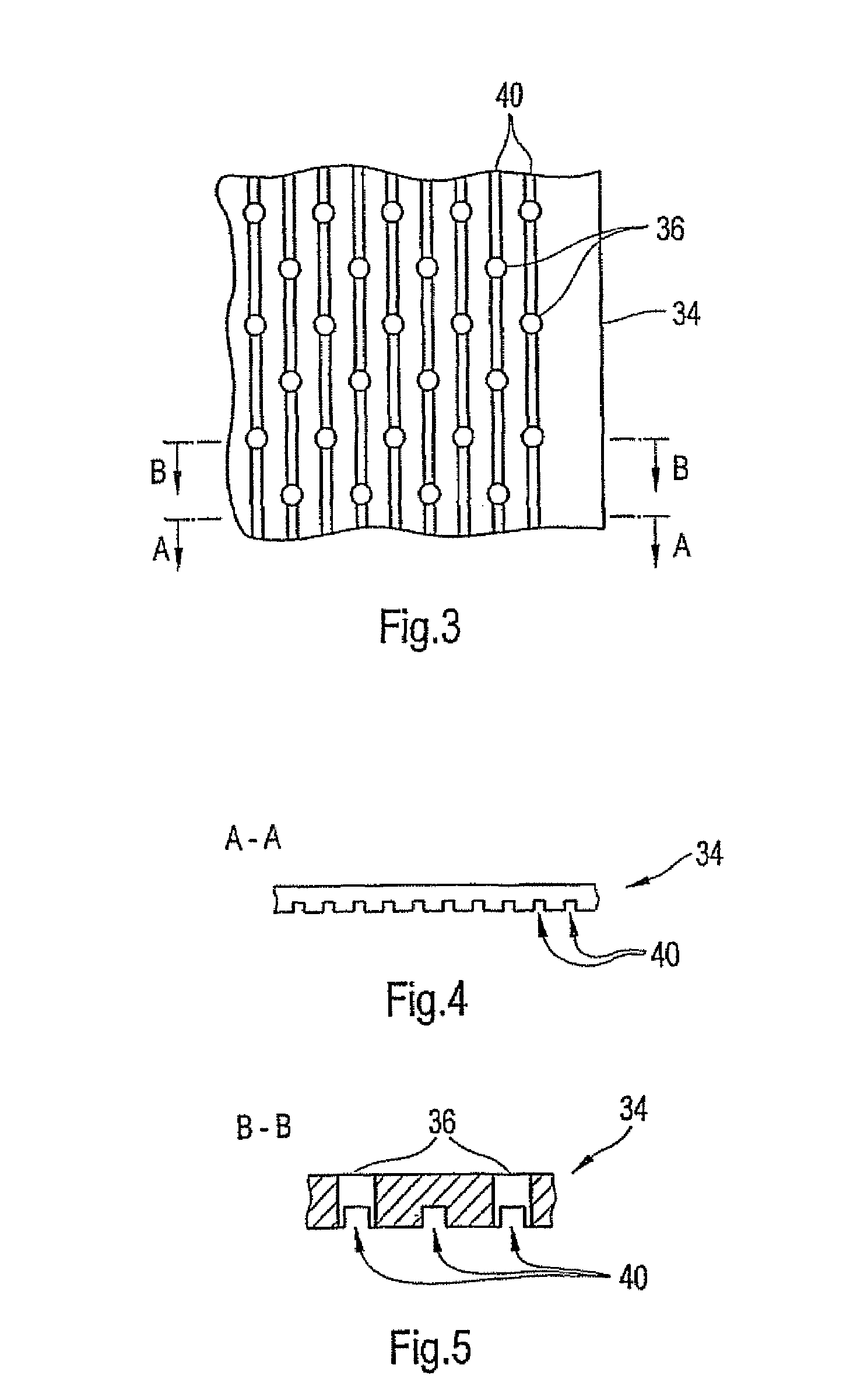

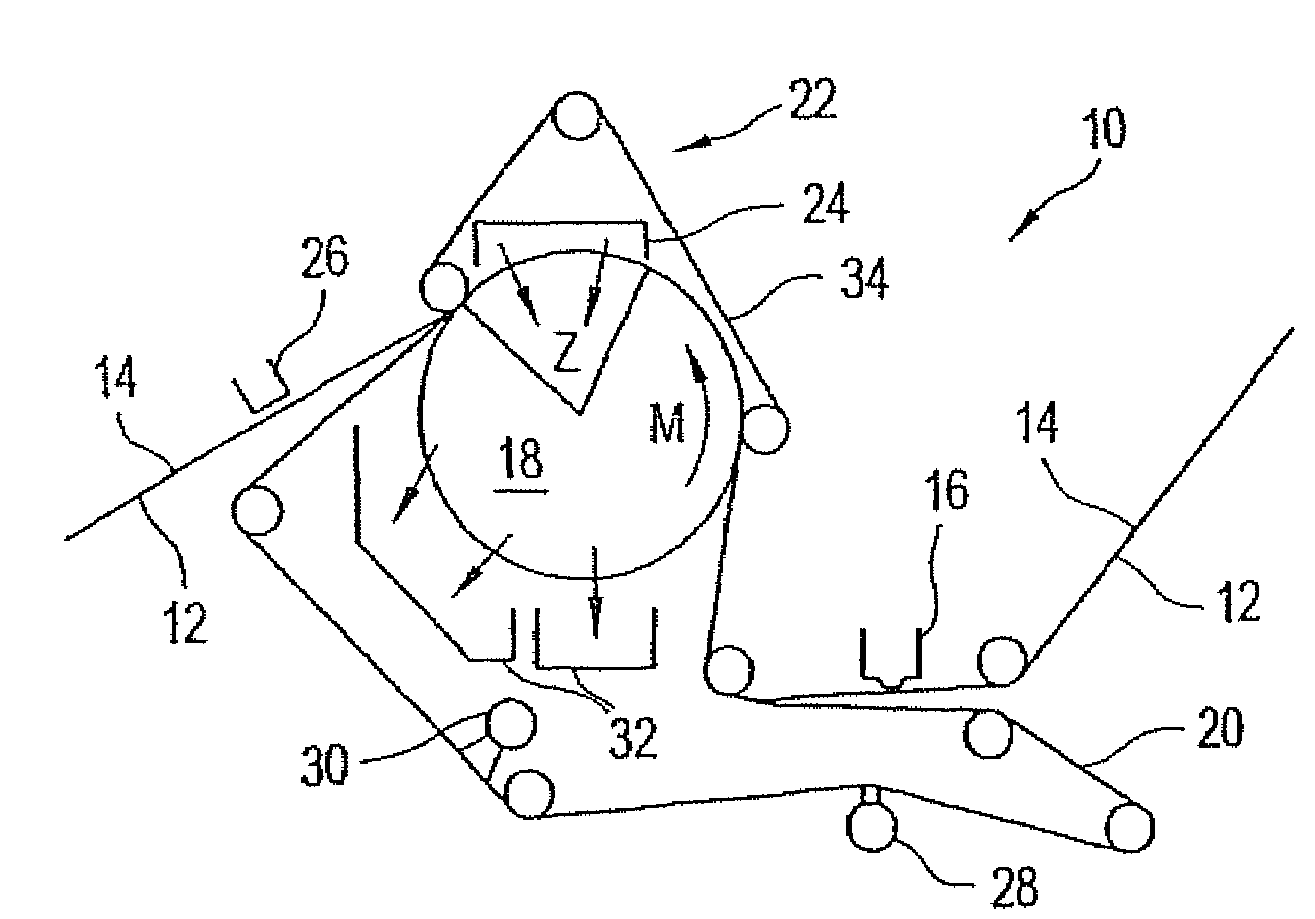

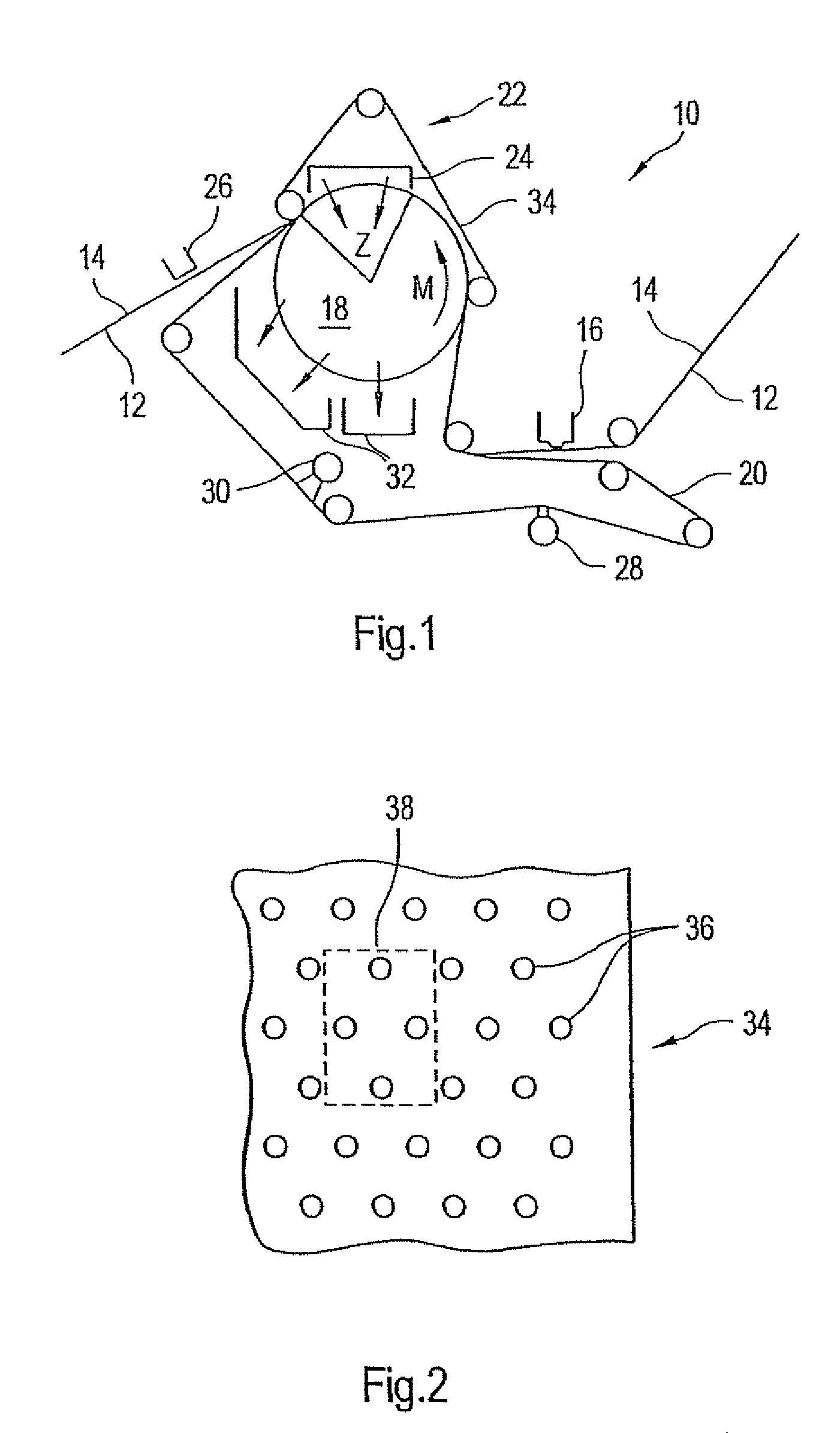

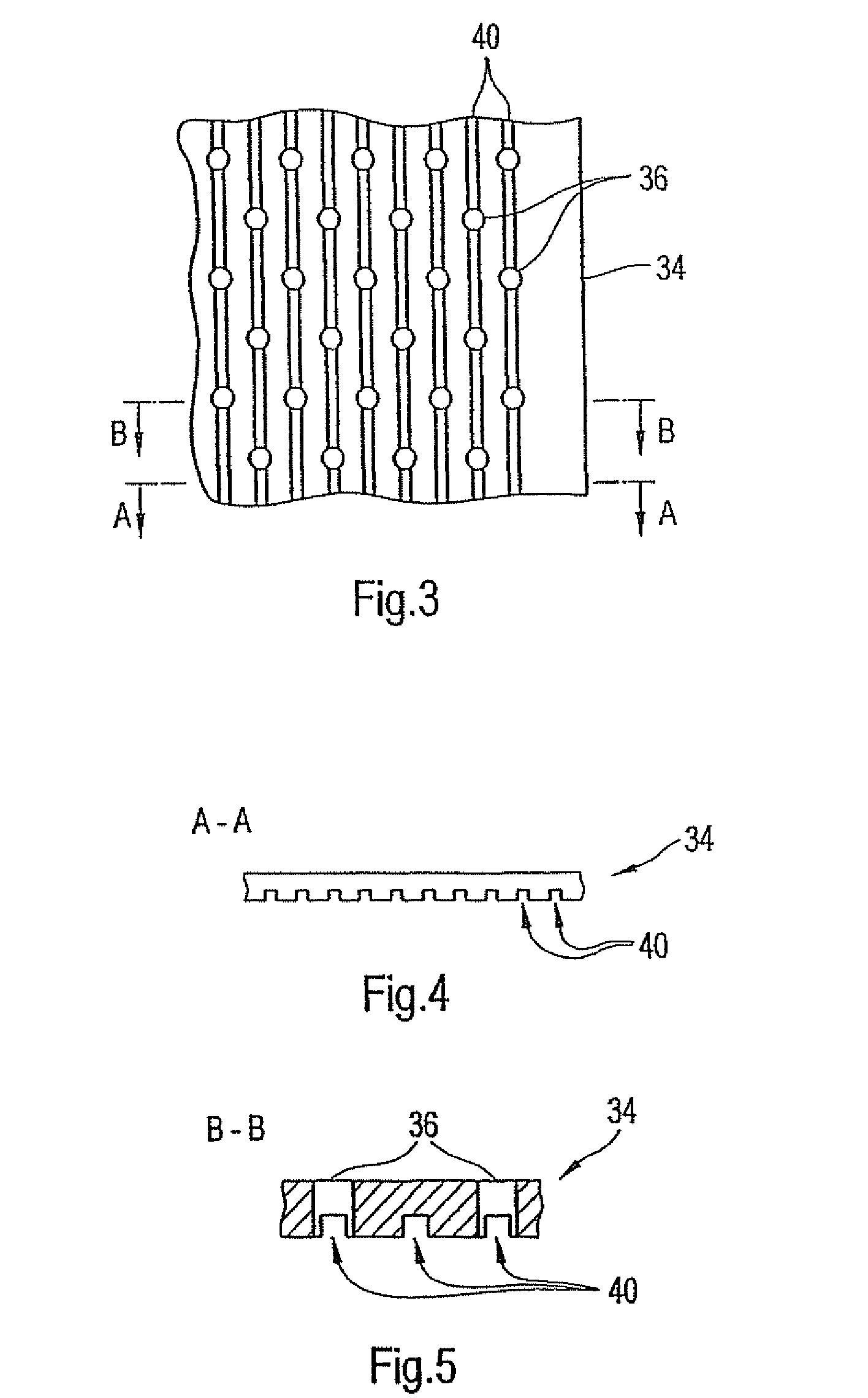

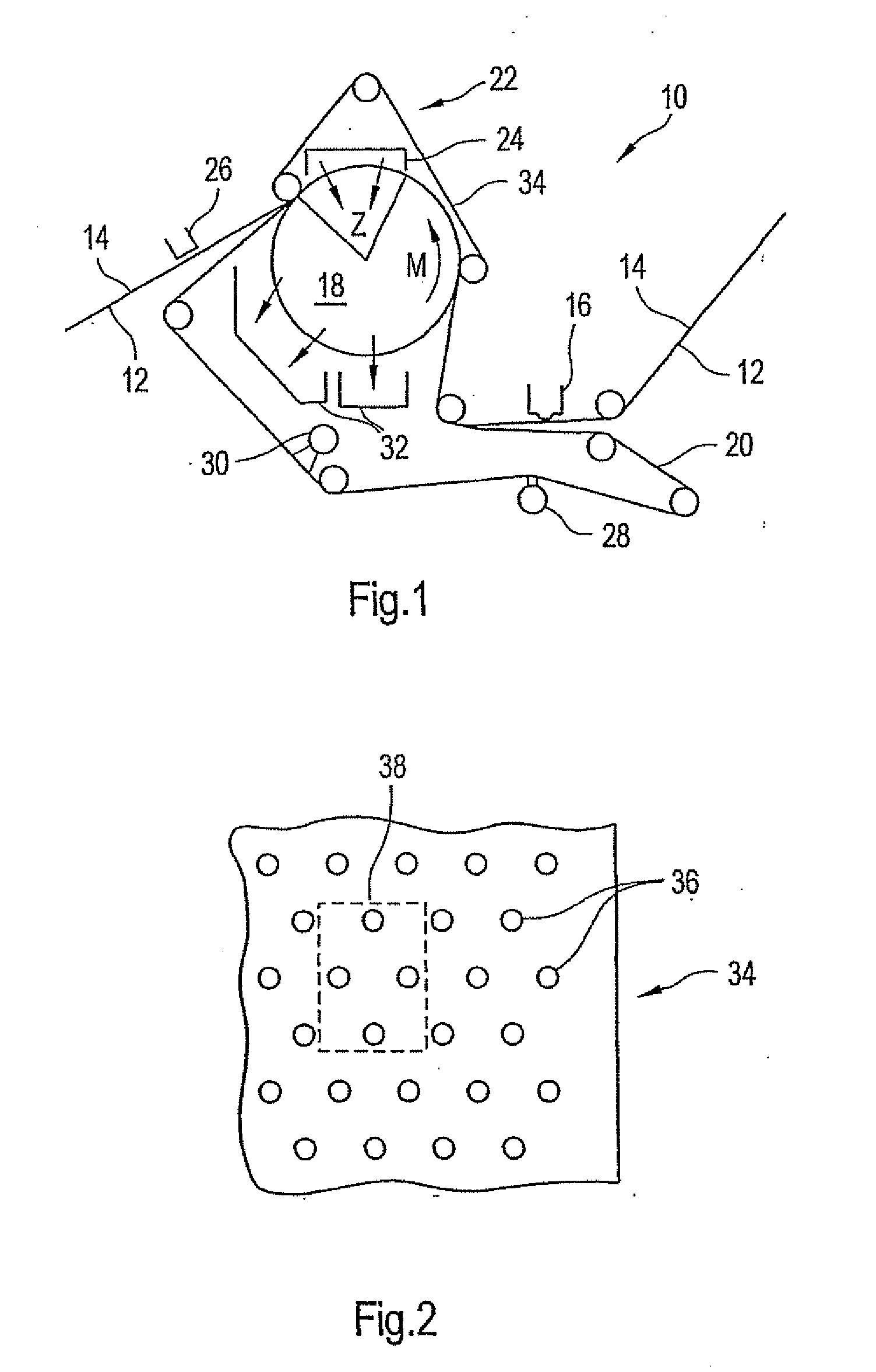

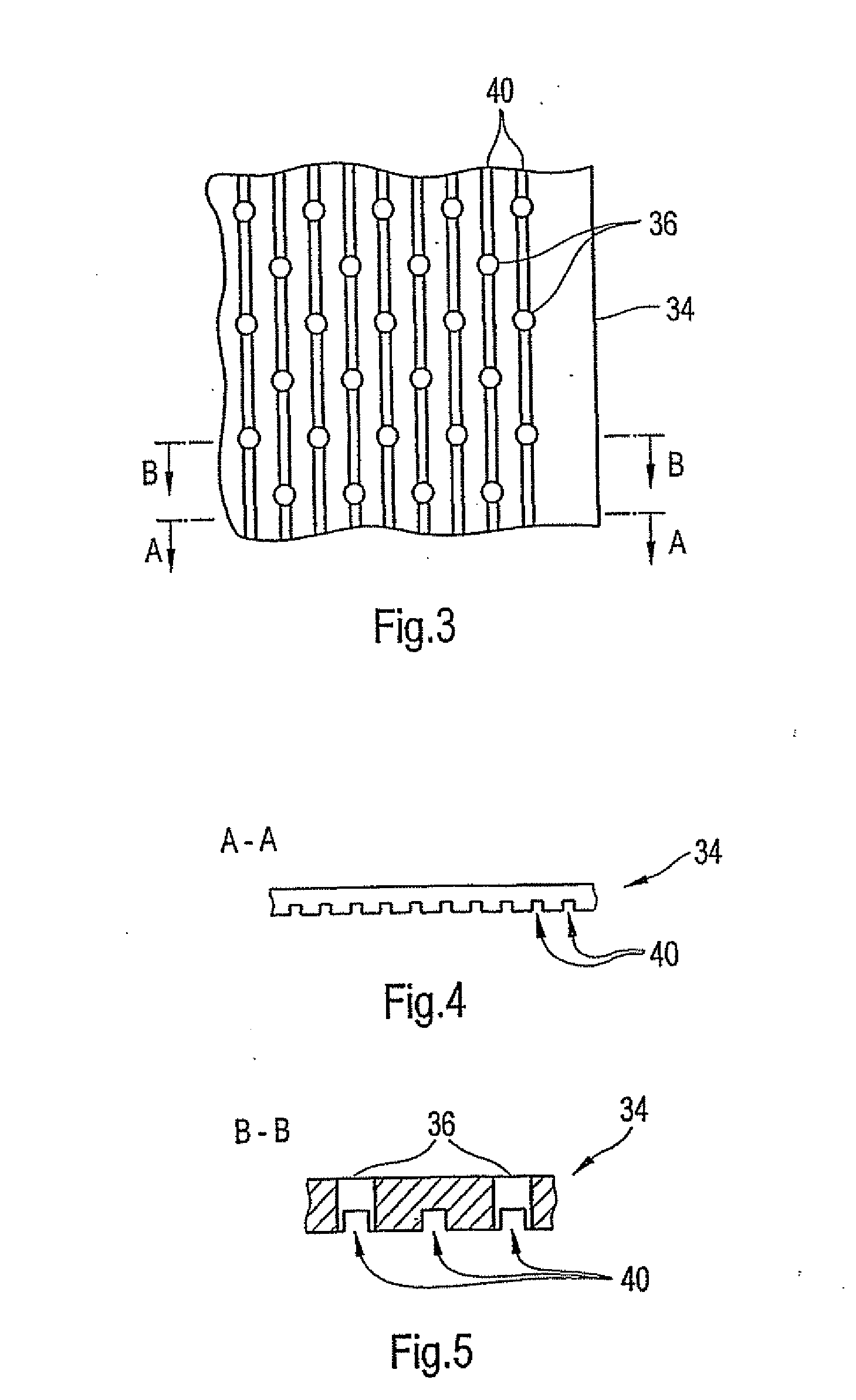

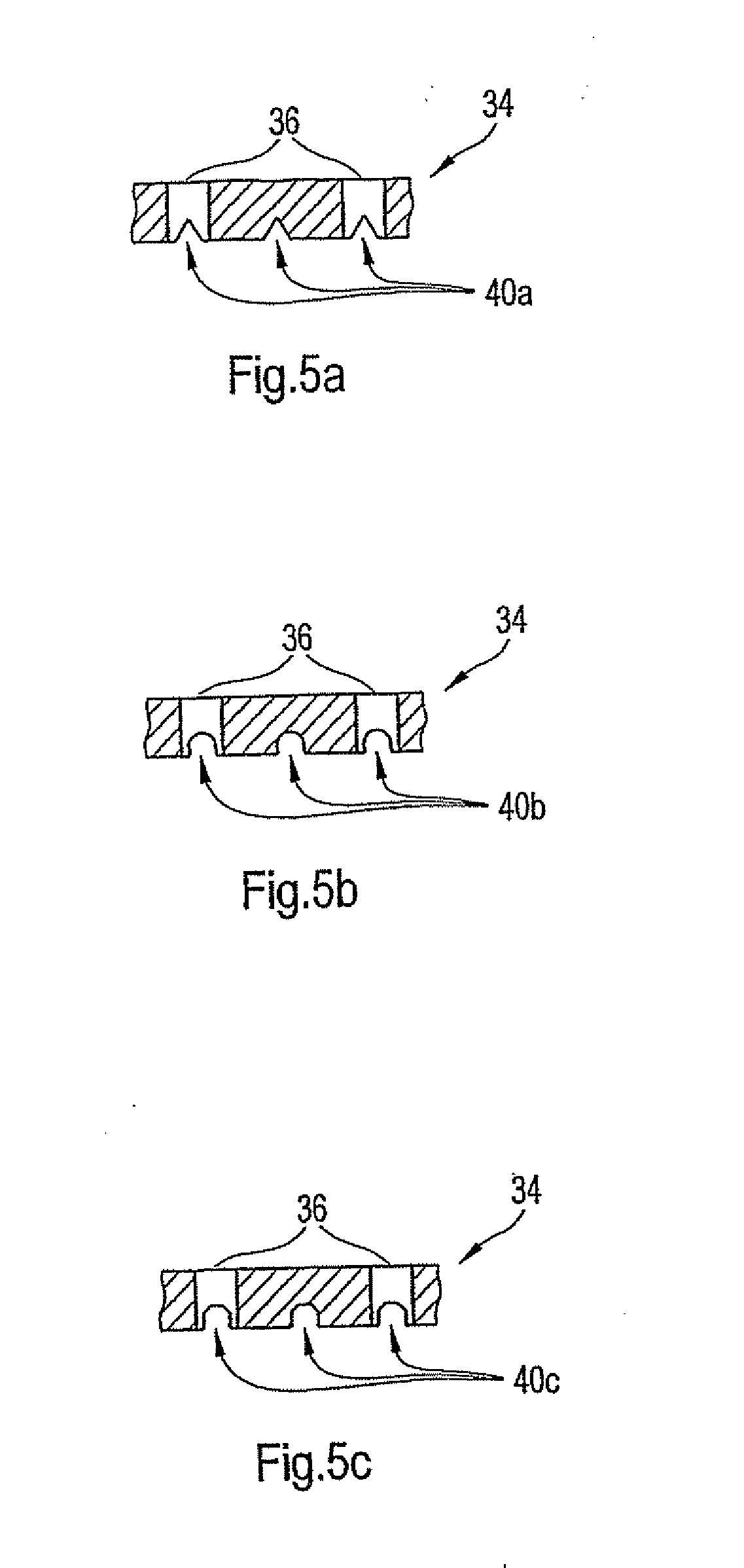

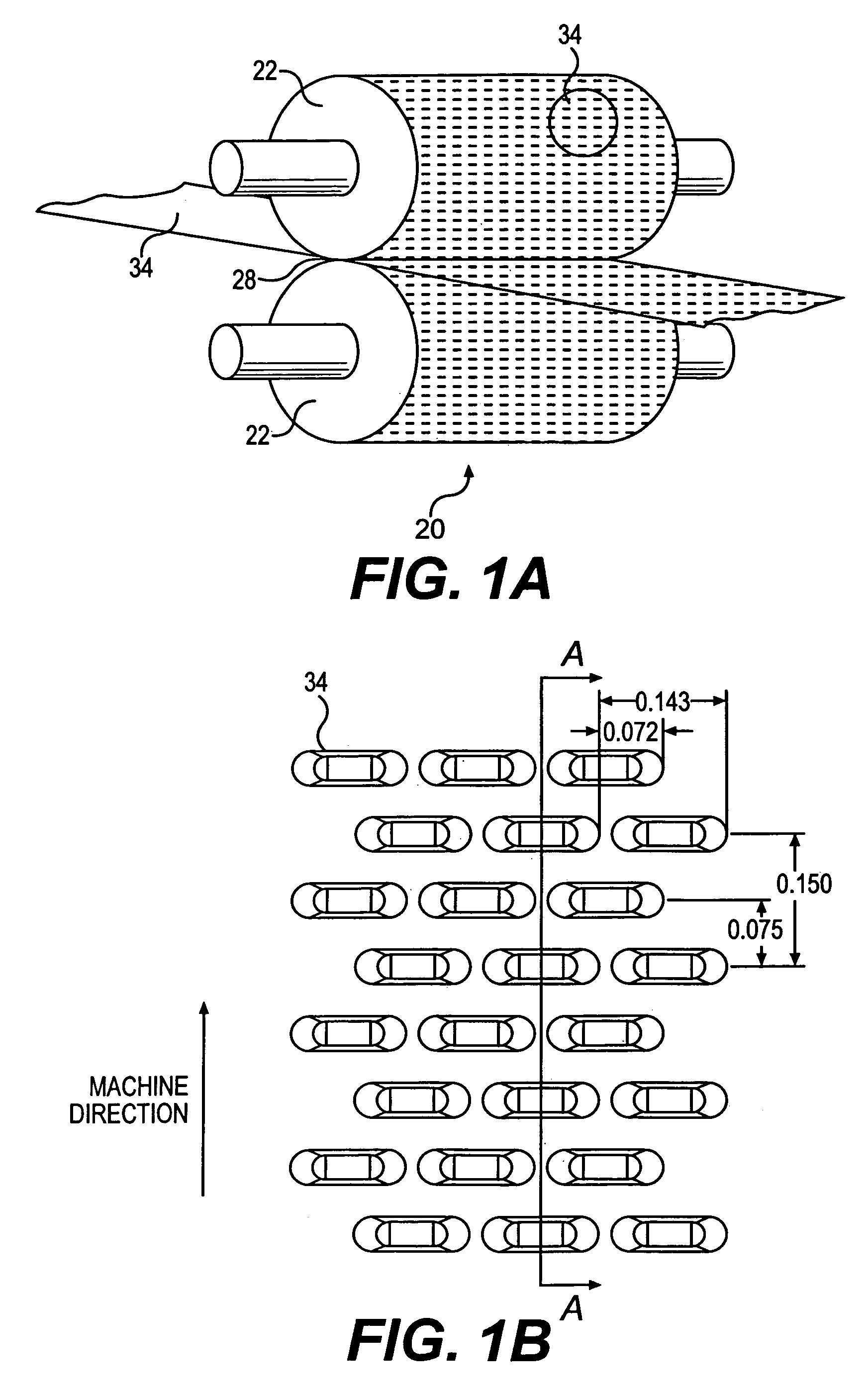

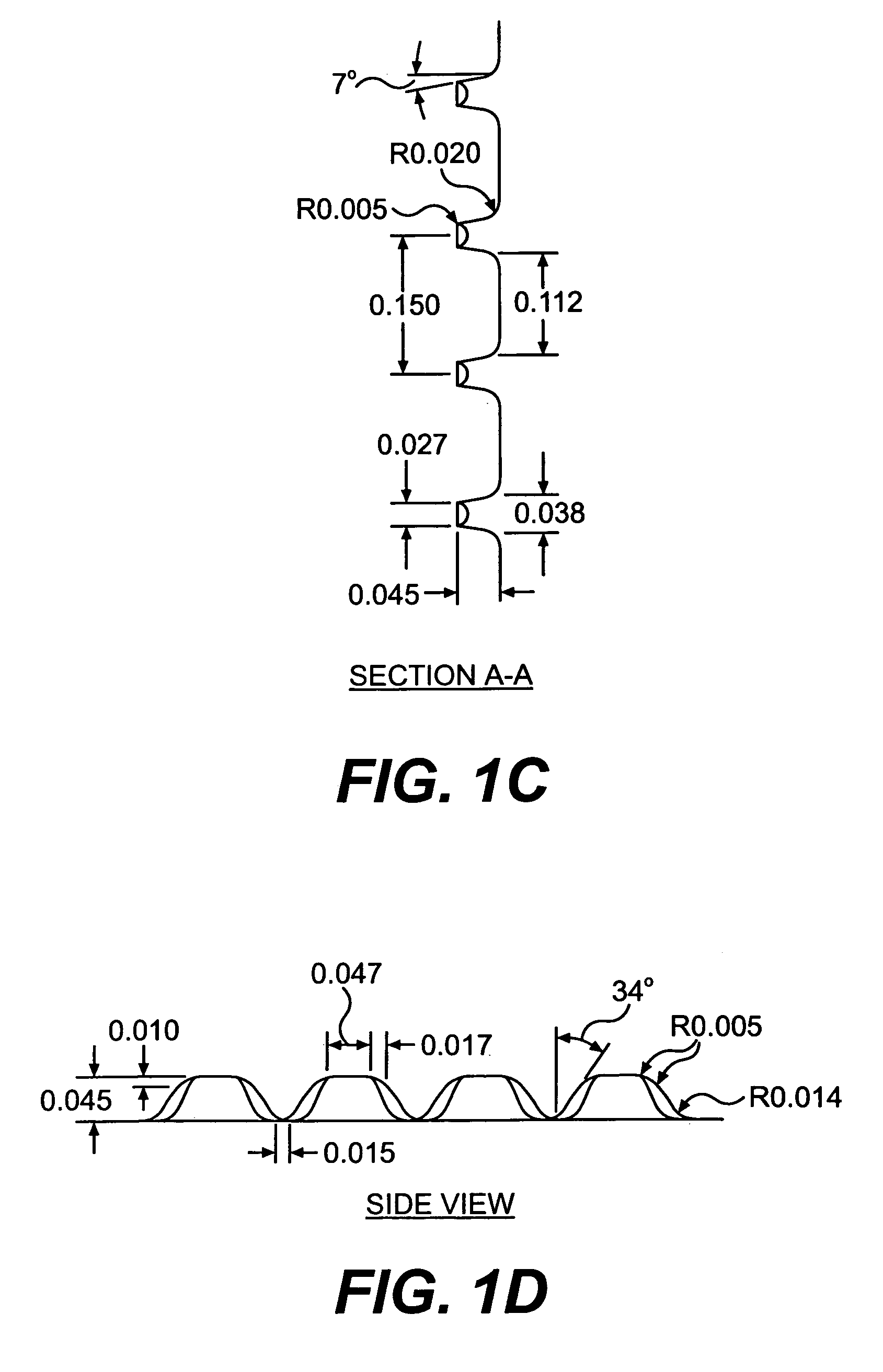

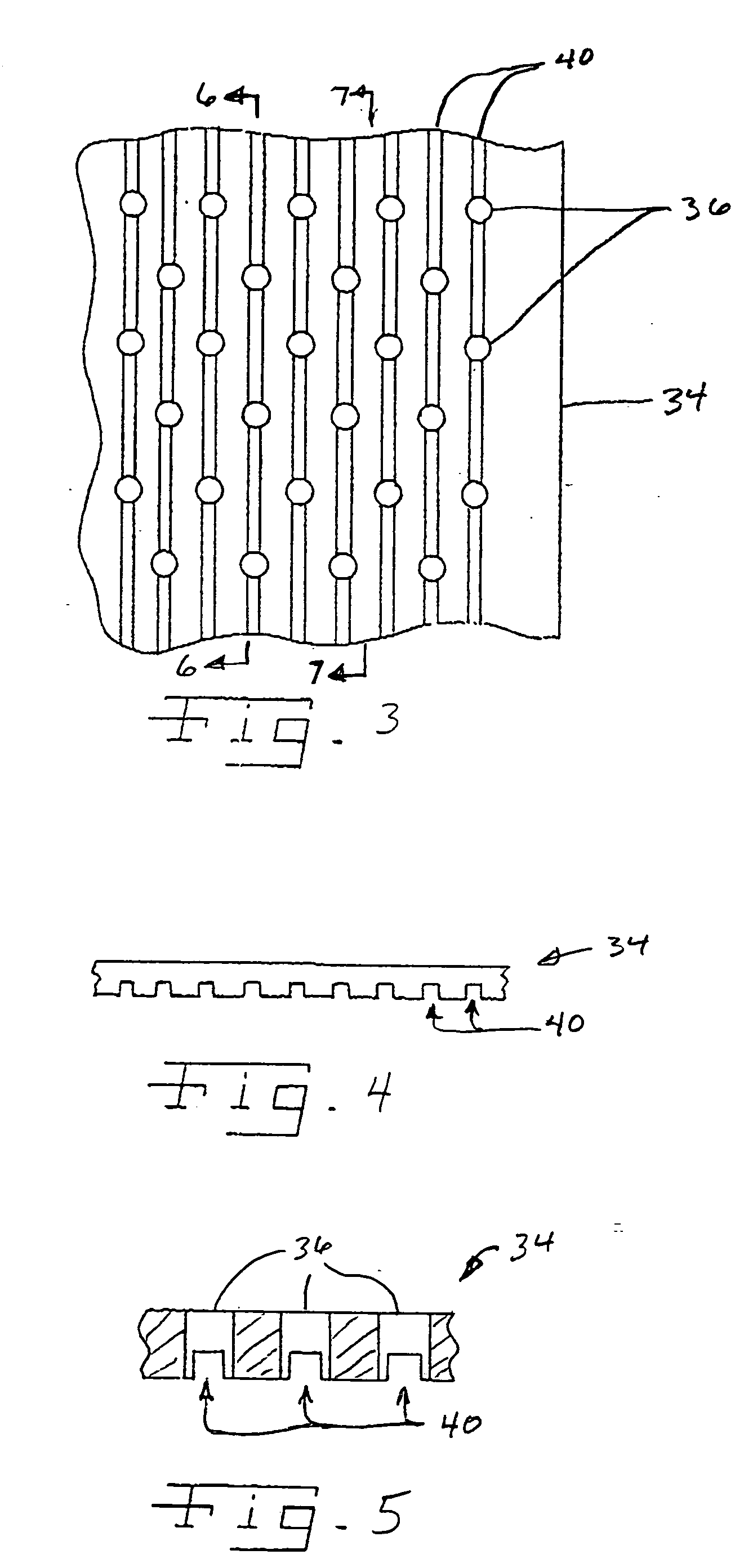

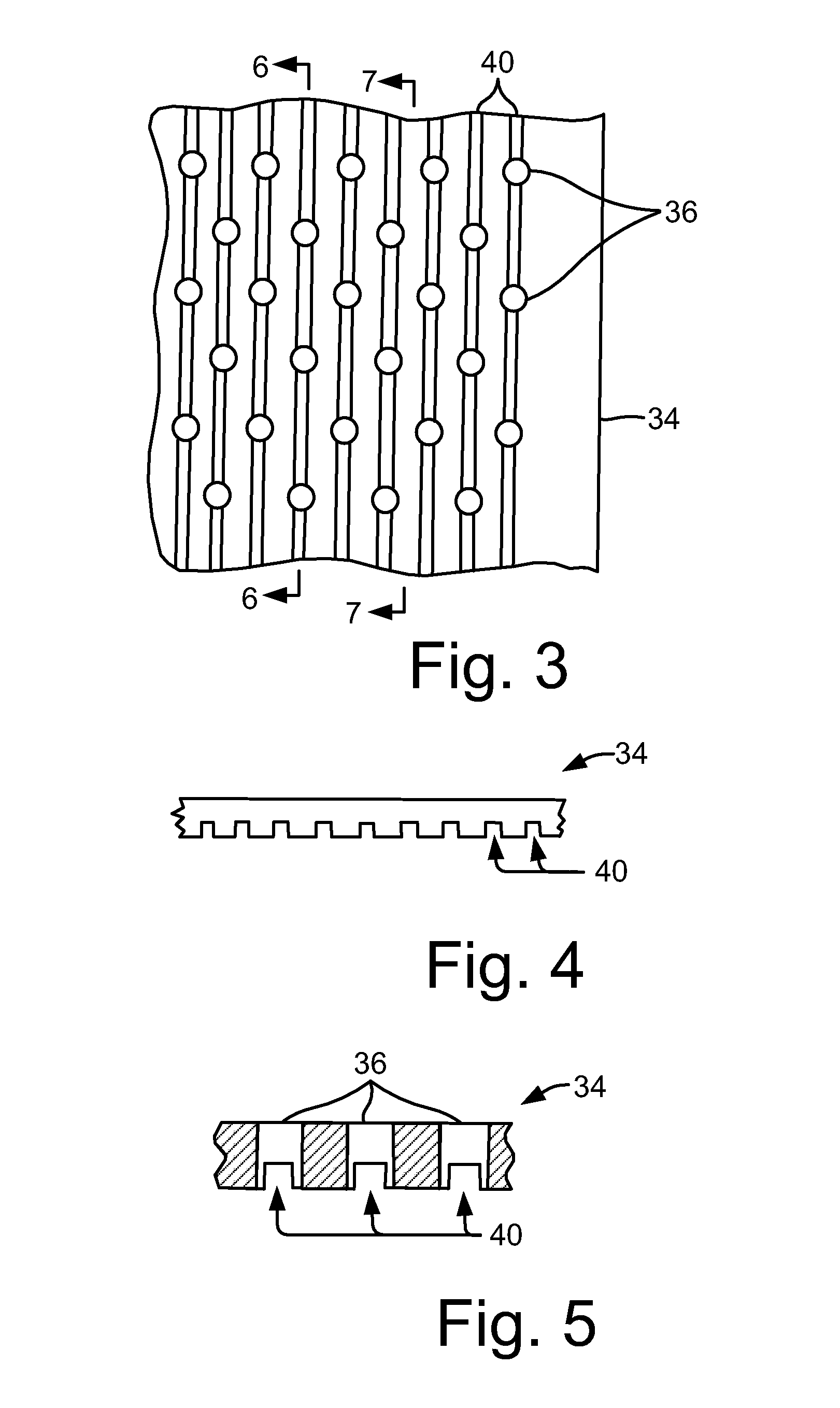

Embossing process including discrete and linear embossing elements

InactiveUS20060278355A1Non-fibrous pulp additionNatural cellulose pulp/paperEngineeringRandom pattern

An apparatus for producing an embossed product including a first embossing member having a plurality of discrete embossing elements disposed in a first non-random pattern having at least one first single pattern unit. The total area of the distal ends of the discrete embossing elements in the first single pattern unit is less than about 5.0 cm2. The apparatus also includes a second embossing member having a plurality of linear embossing elements disposed in a second non-random pattern having at least one second single pattern unit. The total area of the second distal ends in the second single pattern unit is less than about 10 cm2. The second non-random pattern is coordinated with the first non-random pattern such that when engaged with each other the first single pattern unit and the second single pattern unit make up an embossing pattern single pattern unit.

Owner:THE PROCTER & GAMBLE COMPANY

Dewatering tissue press fabric for an ATMOS system and press section of a paper machine using the dewatering fabric

ActiveUS7550061B2Large tensionIncrease the opening areaPaper/cardboardMachine wet endVolumetric Mass DensityPaper machine

Owner:VOITH PATENT GMBH

High tension permeable belt for an atmos system and press section of paper machine using the permeable belt

ActiveUS20070215304A1Substantial airflowLarge tensionDrying solid materials without heatPaper/cardboardSupport surfaceHigh tension

A permeable belt, a belt press including a roll having an exterior surface and the permeable belt, and a method of drying or pressing a web with the permeable belt. The permeable belt has a paper web facing side and is guided over a support surface. The permeable belt can have a tension of between approximately 20 kN / m and approximately 100 KN / m, a permeability value of between approximately 100 cfm and approximately 1200 cfm, a surface contact area of the paper web side that being between approximately 0.5% and approximately 90% when not under tension, and an open area of between approximately 1.0% and approximately 85%. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

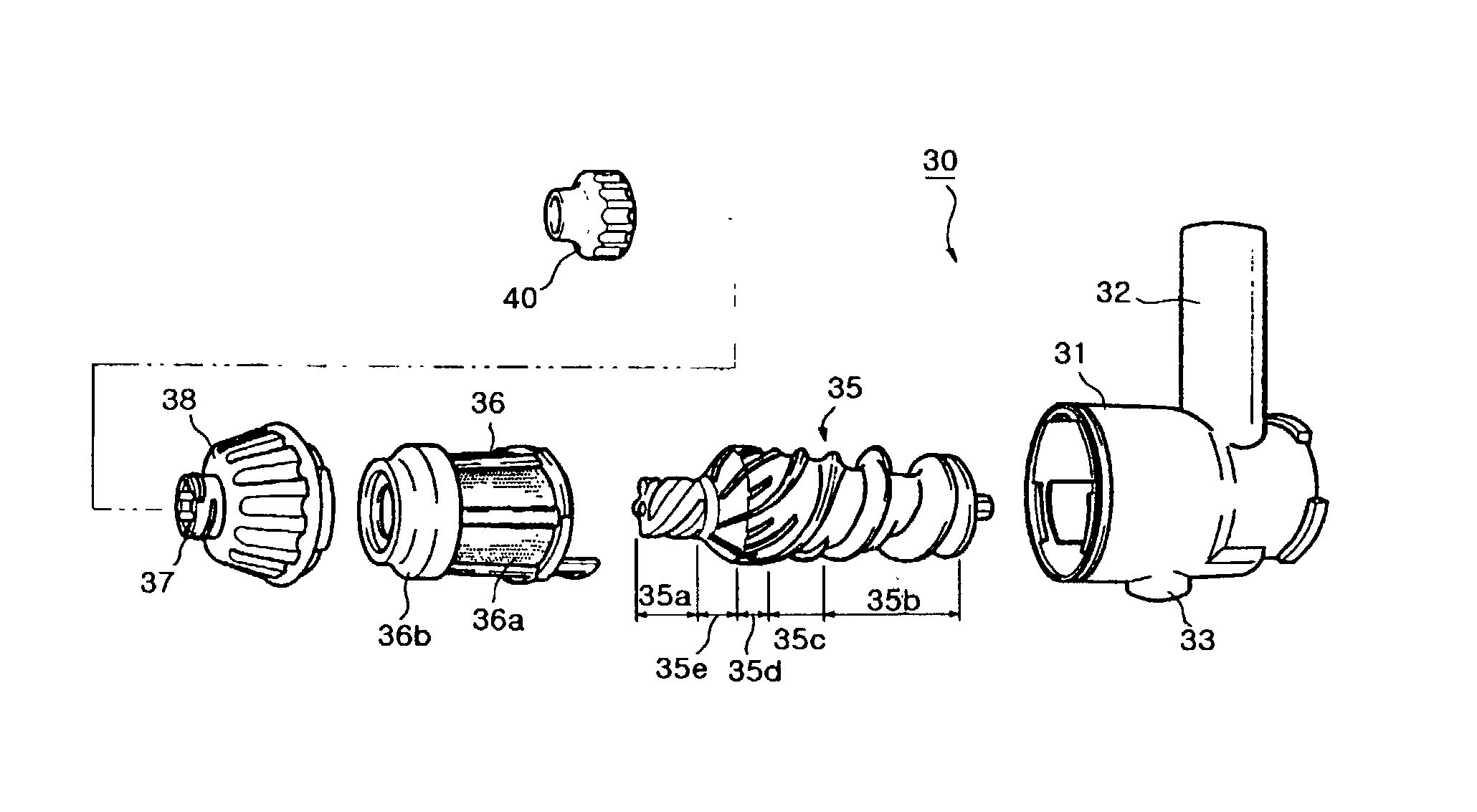

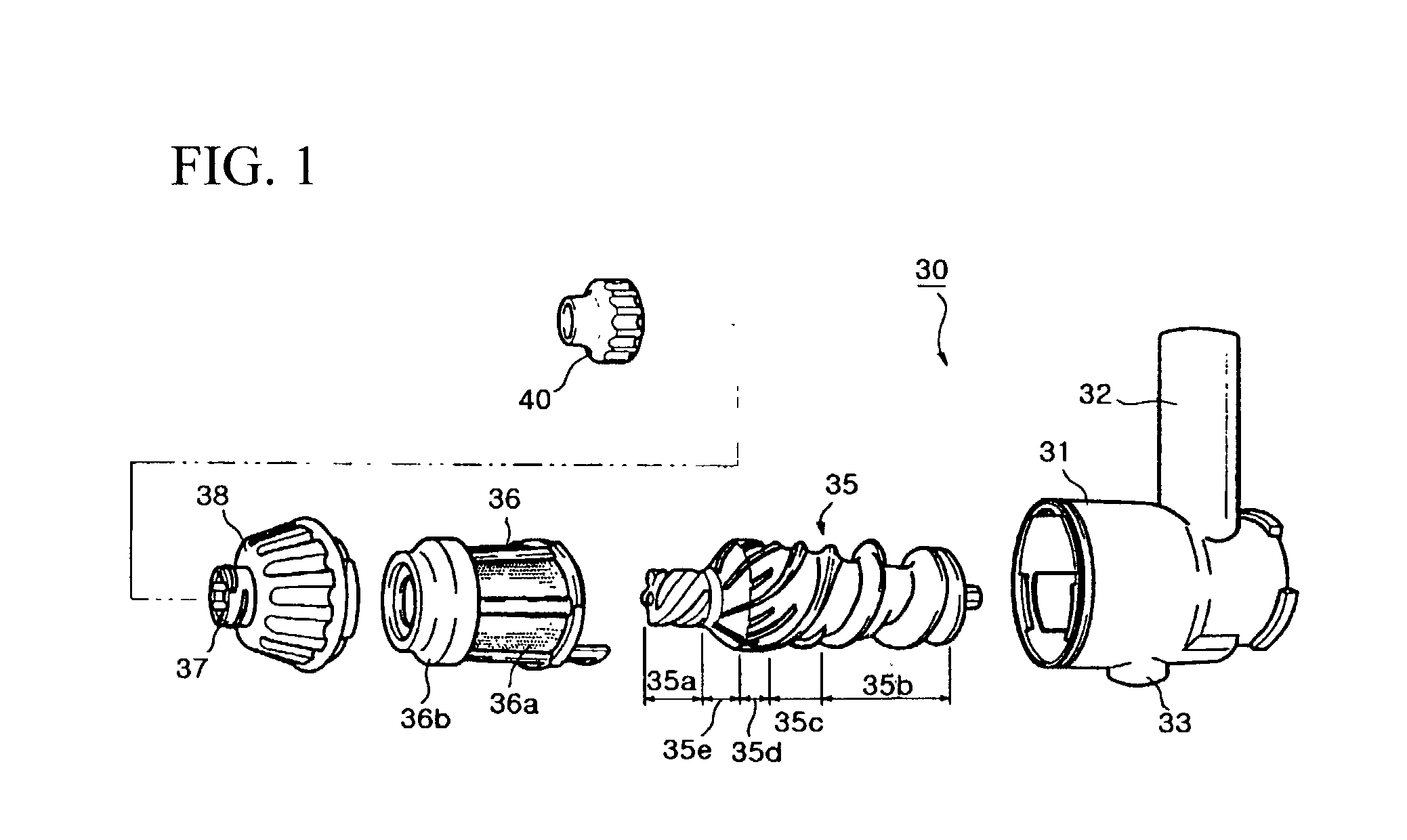

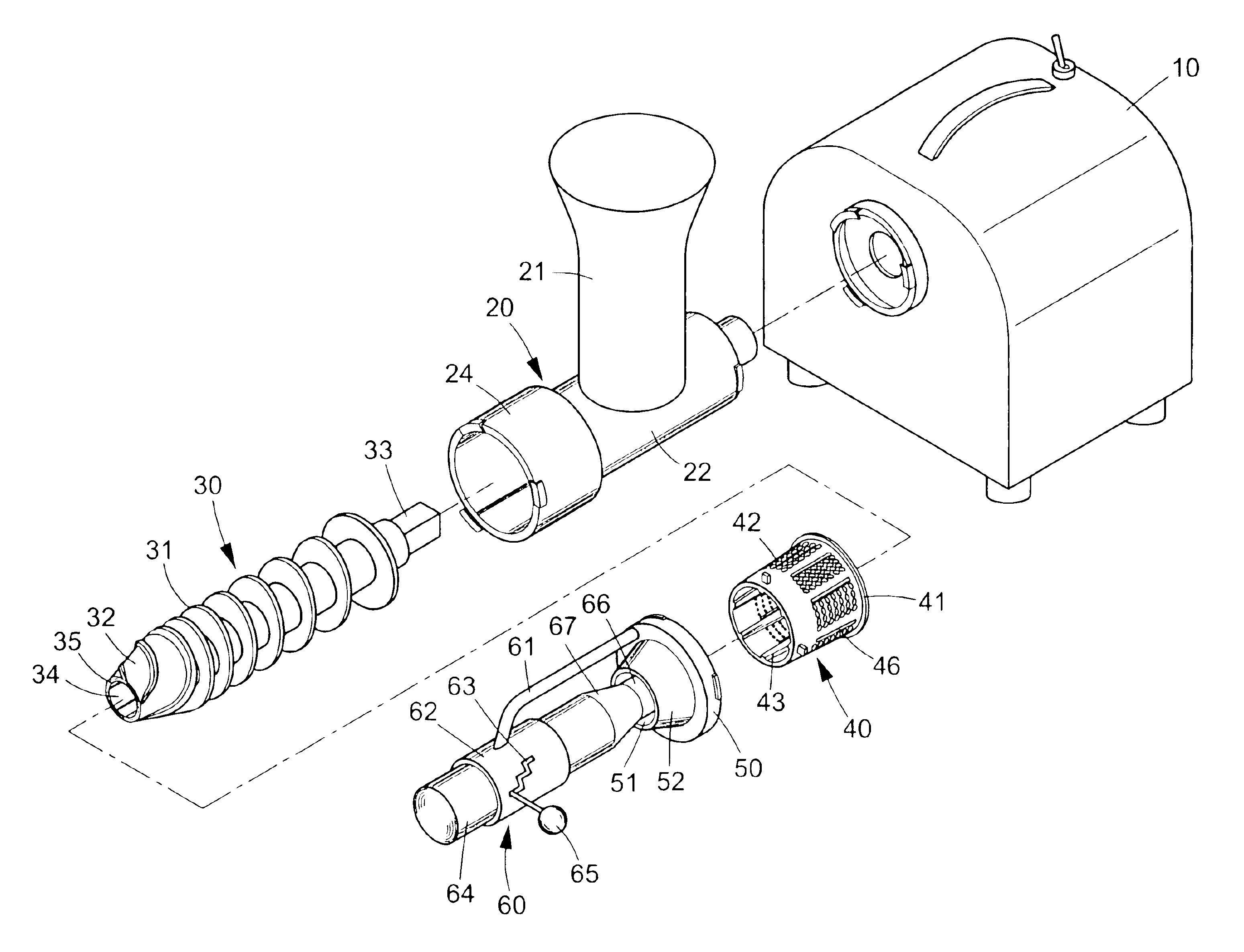

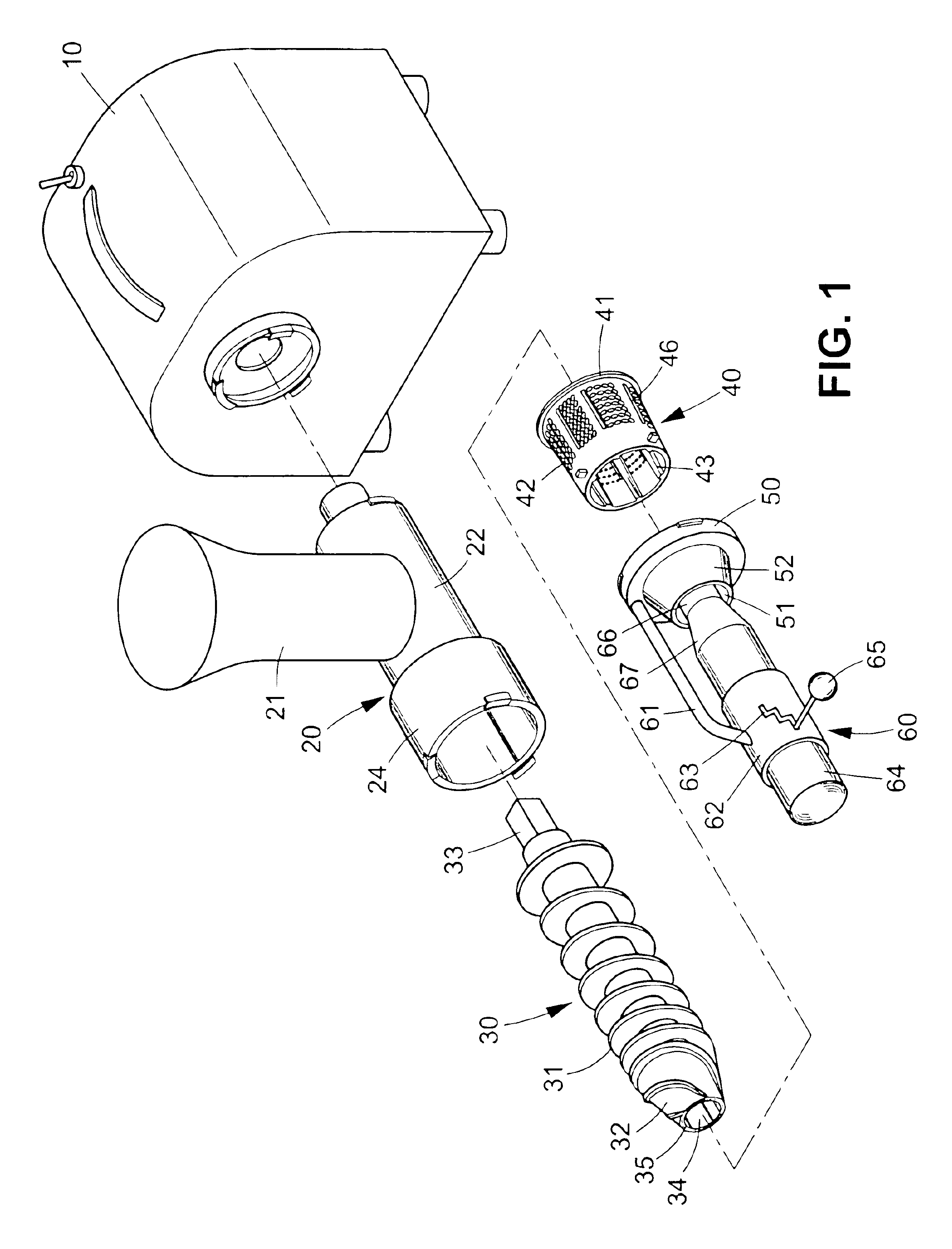

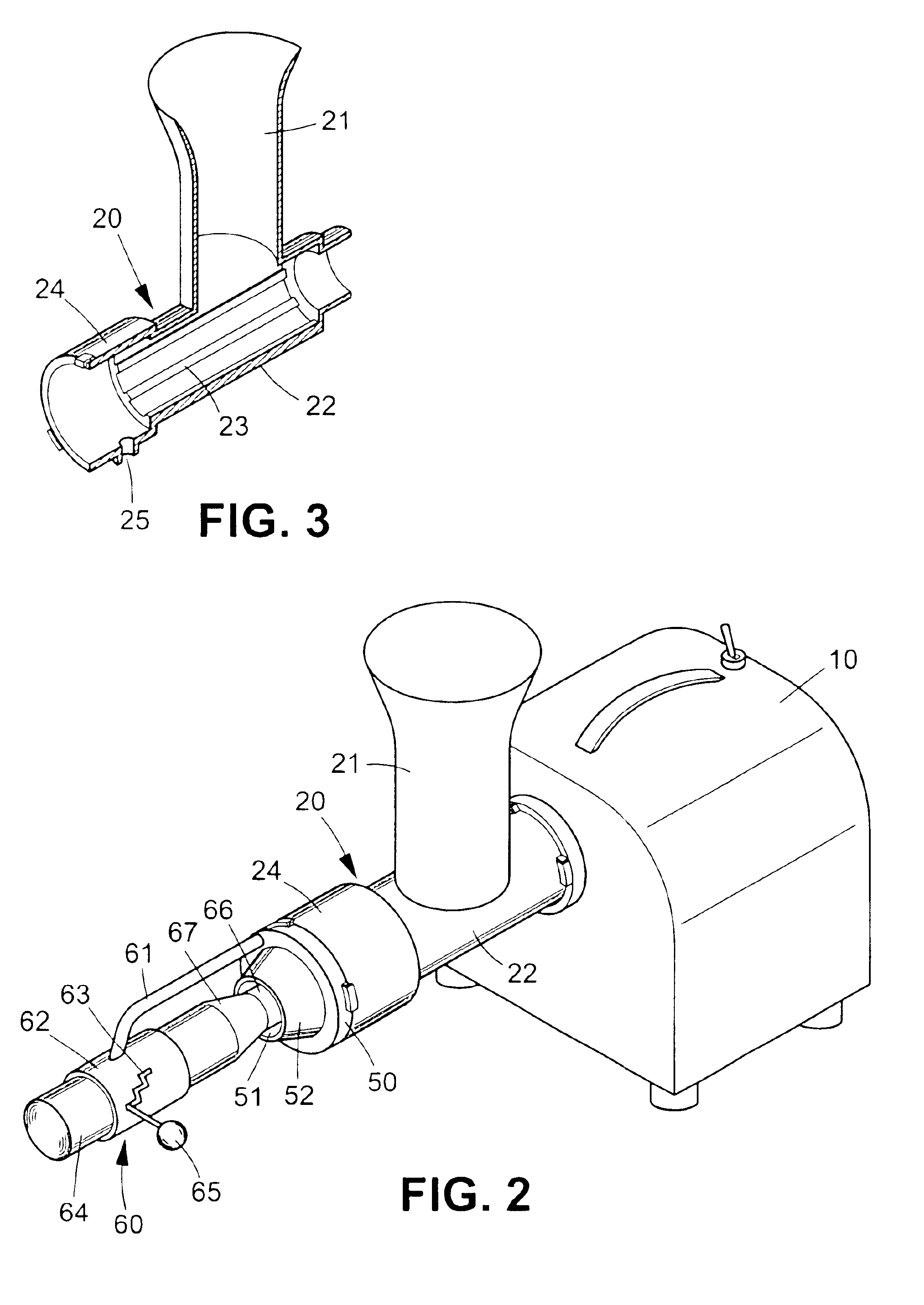

Juice extractor

The present invention is directed to devise a juice extractor, The juice extractor 1 according to the present invention includes a helical spindle 6 connected to a power driven source 5, a housing 2 having an inlet 3 in the upper part and an outlet 4 in the lower part, a fine grinding portion 35c and a refine grinding portion 35d, at the end part of the helical spindle 6, a drum cap 10 which includes endurable bushing element 9, for the detail structure of the drum cap 10, a thread tube 15 formed to the lateral direction to join with a pressure control cap 16 which has a squeezing flange 17 formed on the inner part of the circumference so as to press a circular protrusion 13 of the bushing element 9 in order to control the optimum squeezing pressure and provide the best squeezing force and maximize the effectiveness of the compression of foodstuff such as fruit or vegetable.

Owner:KIM YOUNG KI

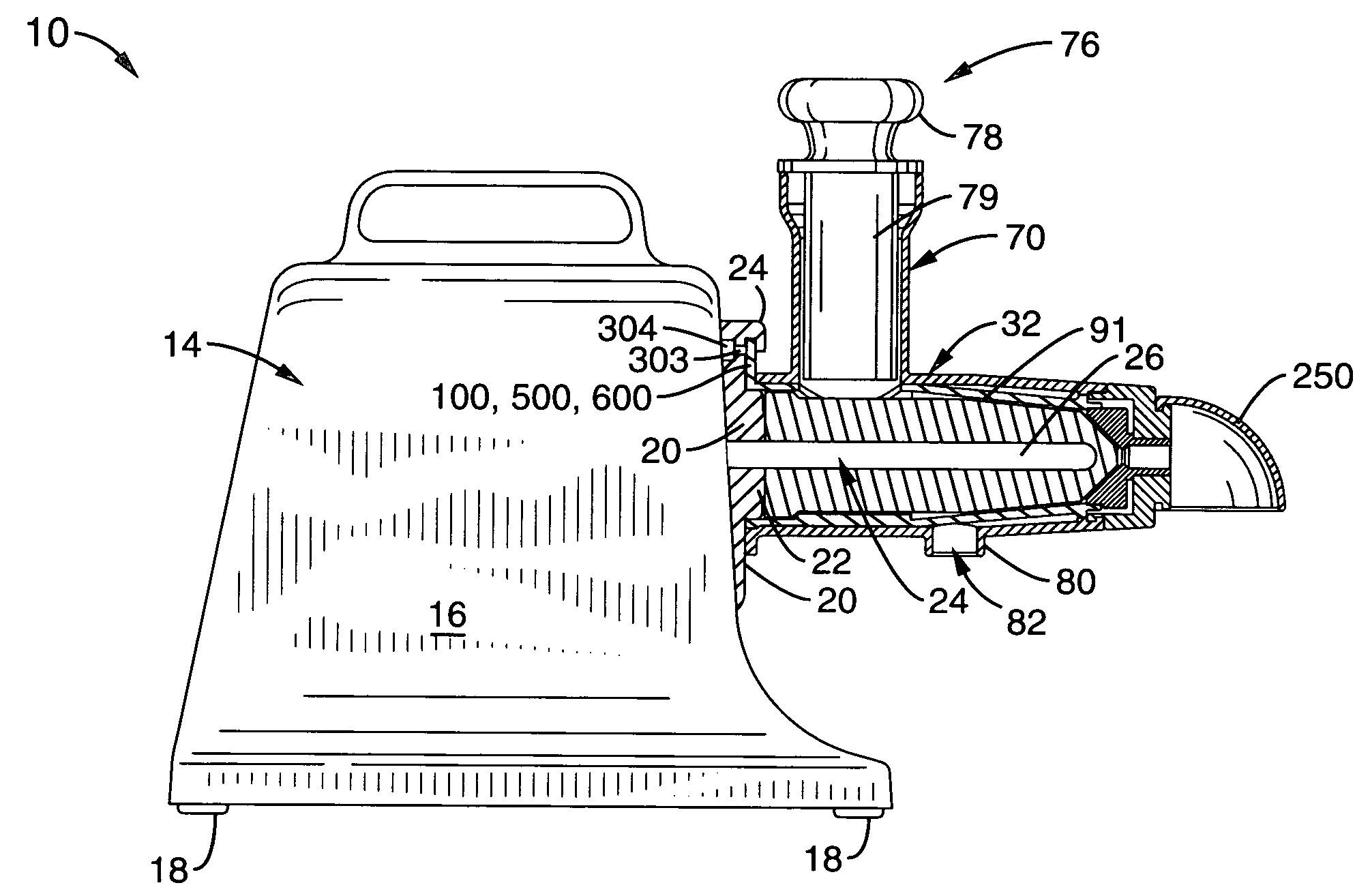

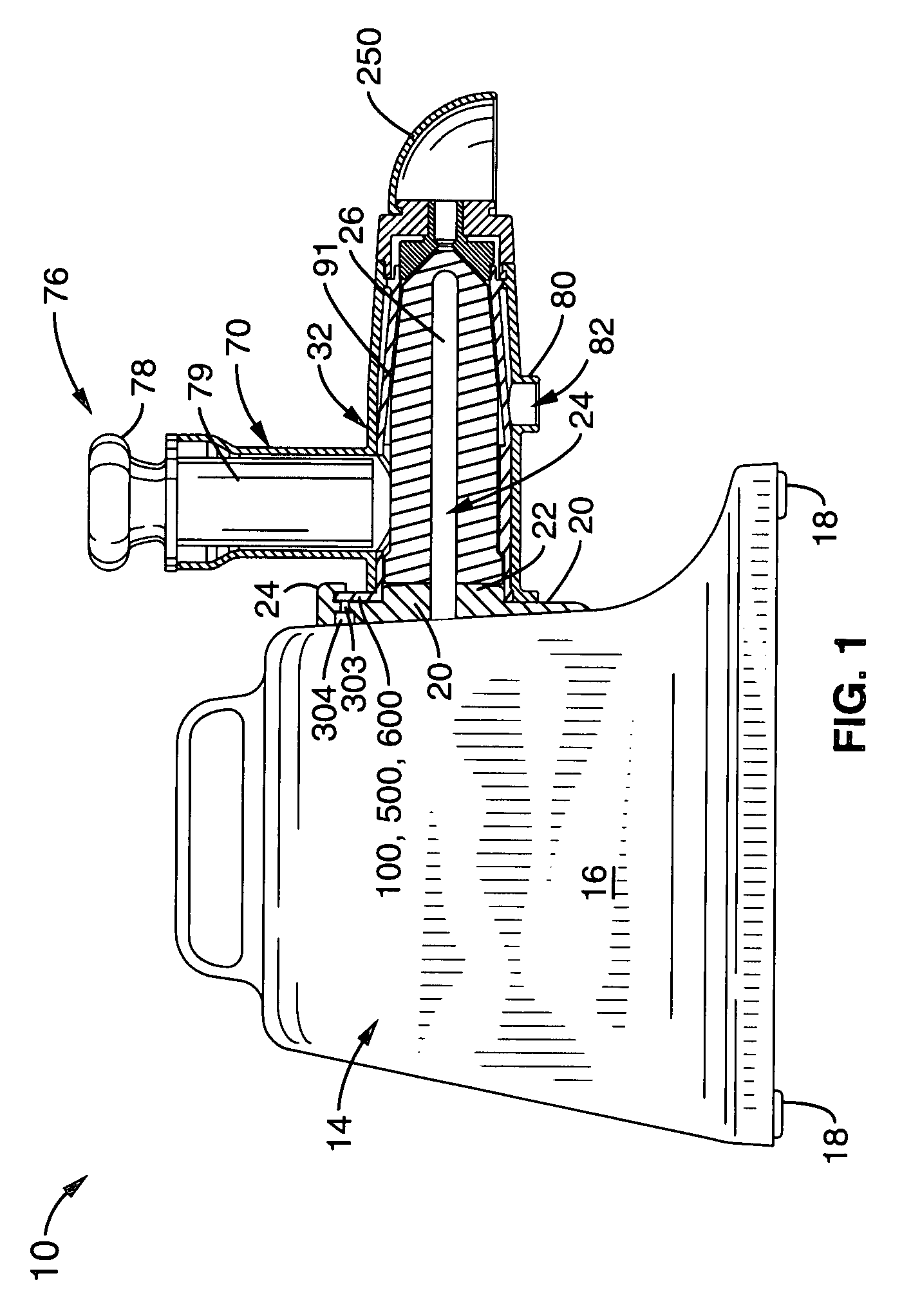

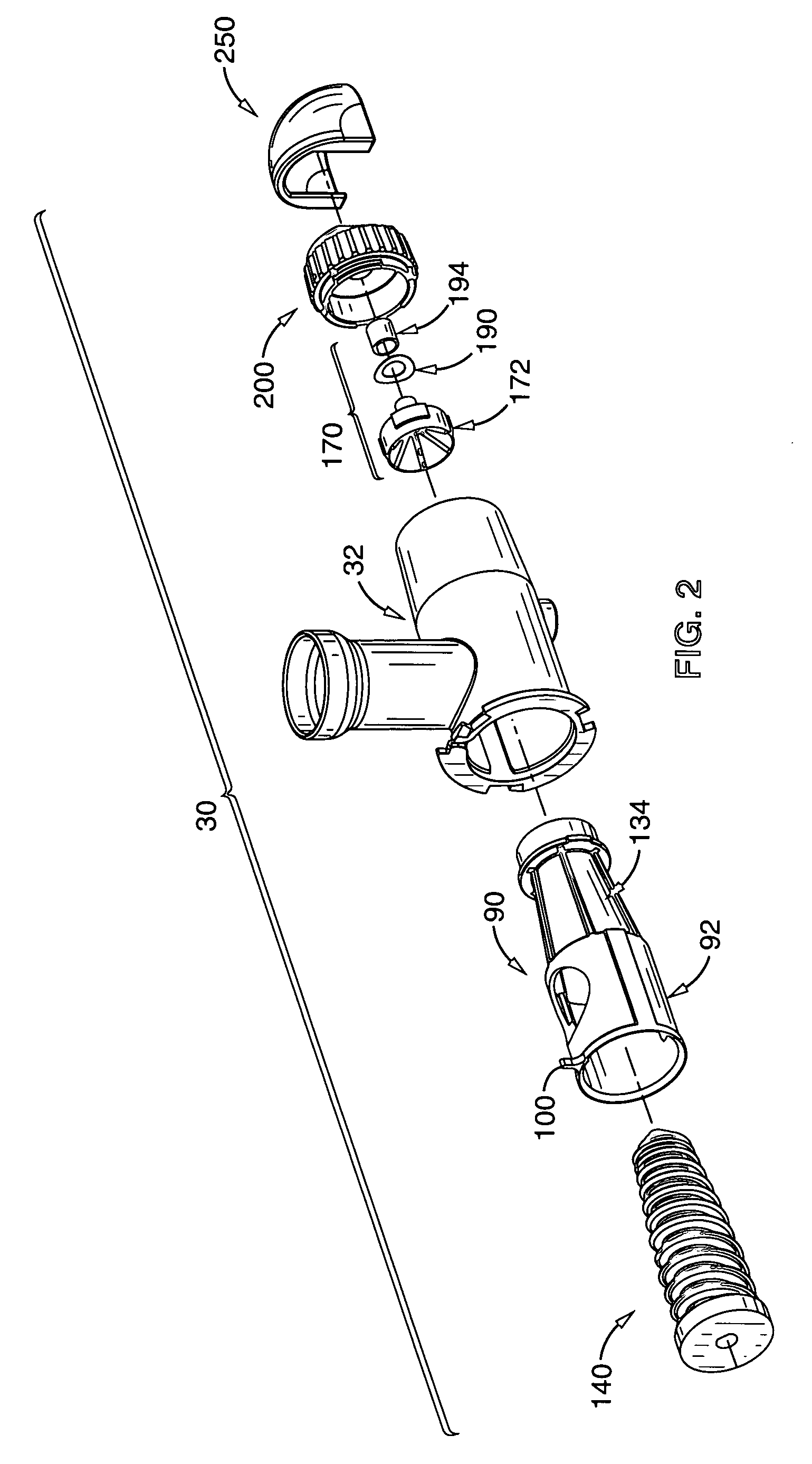

Juicer with alternate cutters

ActiveUS20090064875A1Easily and quickly and efficiently juiceSimple processGrain huskingAutomatic control devicesMinced foodEngineering

A juicer device comprised of a motor disposed within a housing and having an output shaft projecting away from the housing; at least two alternate cutters each individually detachably connectable to the output shaft; a plurality of alternate inserts wherein a selected one of the plurality of alternate inserts circumscribes a selected one of the at least two alternate cutters detachably connected to the output shaft; and a body circumscribing the selected one of the plurality of alternate inserts wherein the body and the selected one of the plurality of alternate inserts include openings for feeding food to the selected one of the at least two alternate cutters detachably connected to the output shaft and openings for receiving juice, homogenized food, or shredded food therefrom upon actuation of the motor under the control of a safety system.

Owner:TROVINGER RUSSELL T

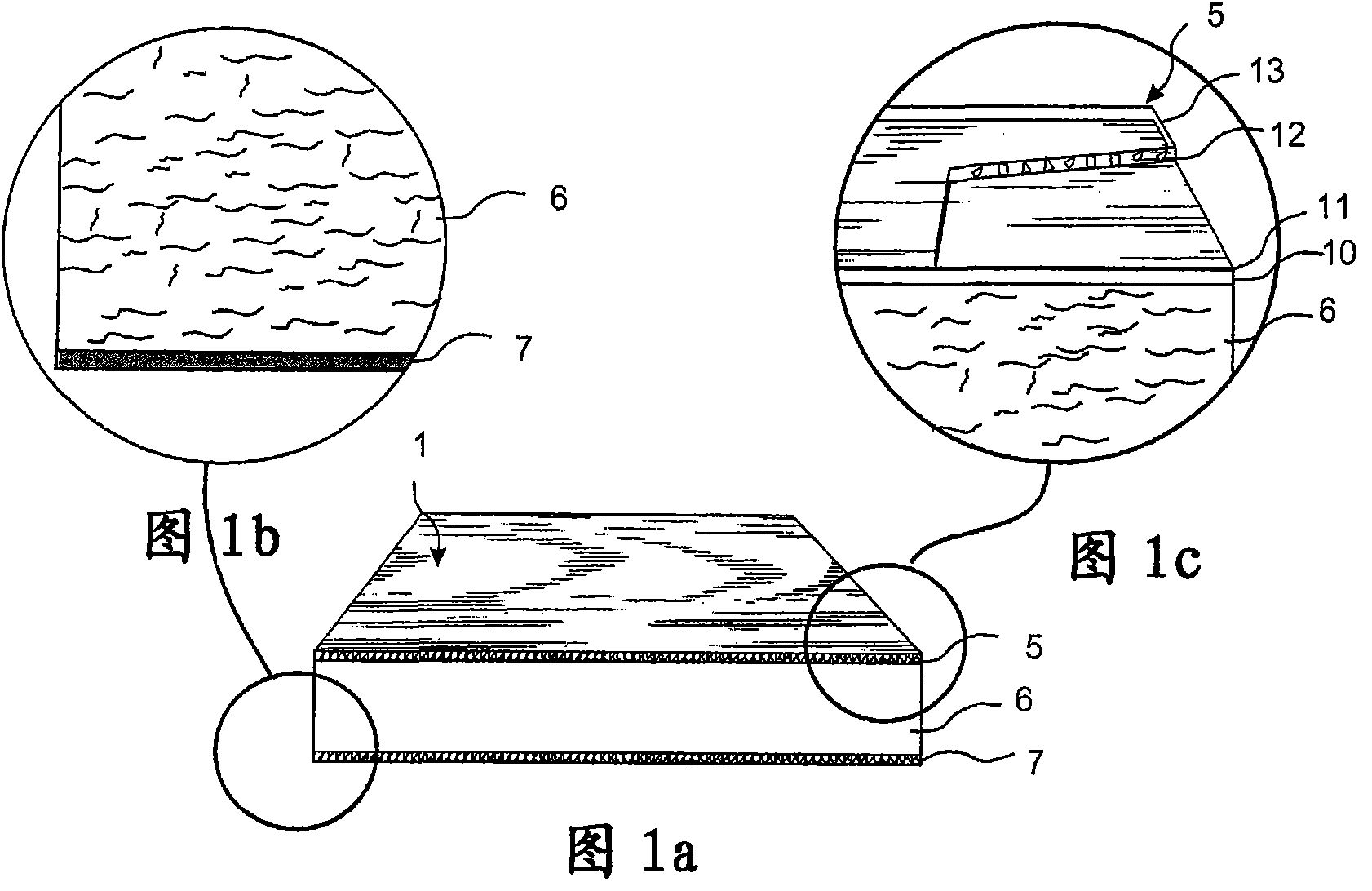

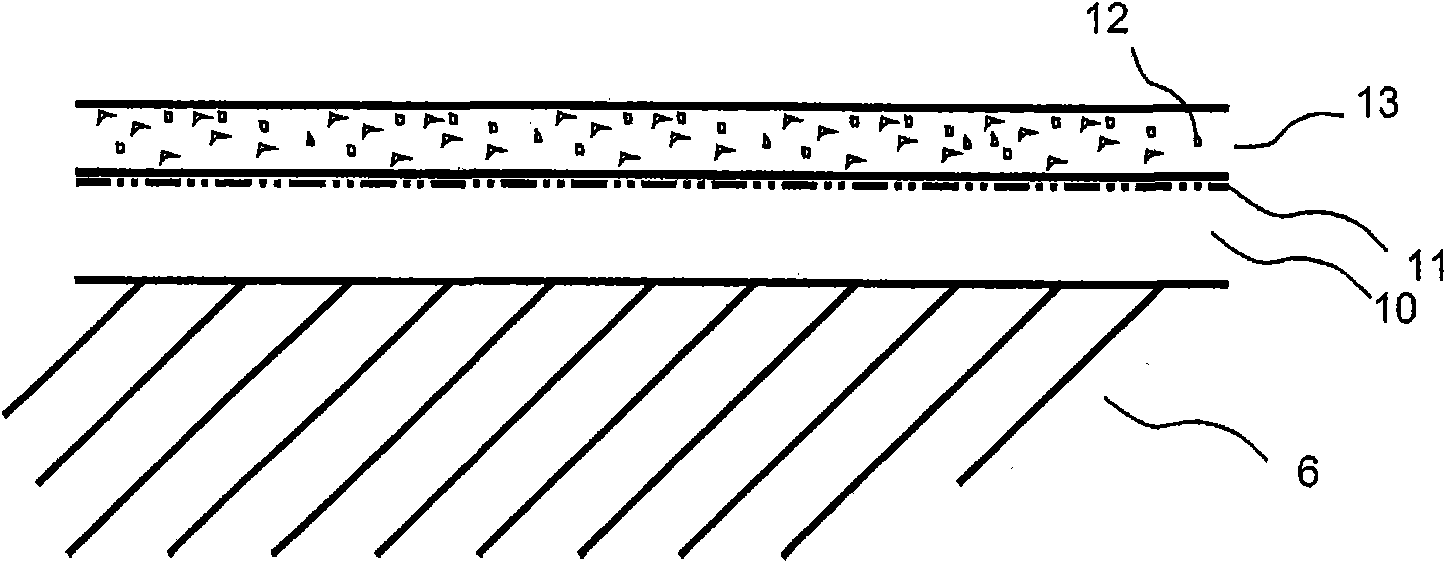

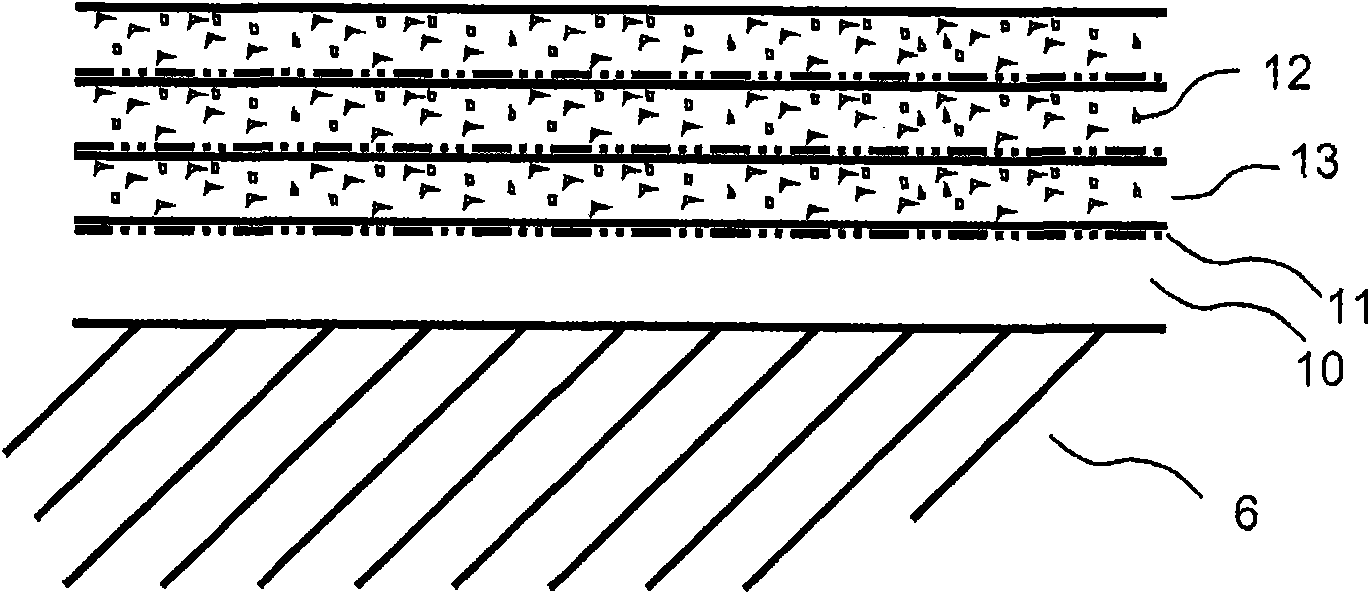

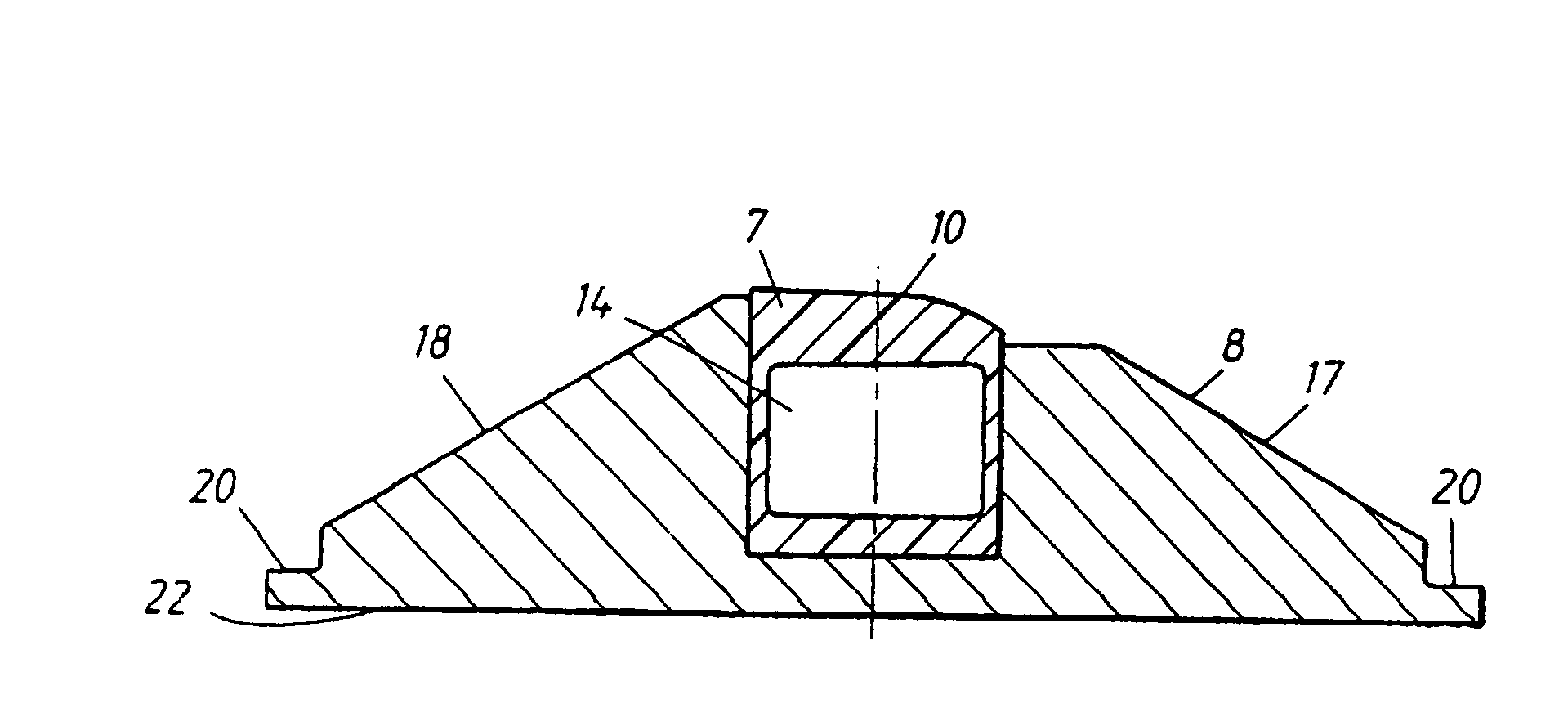

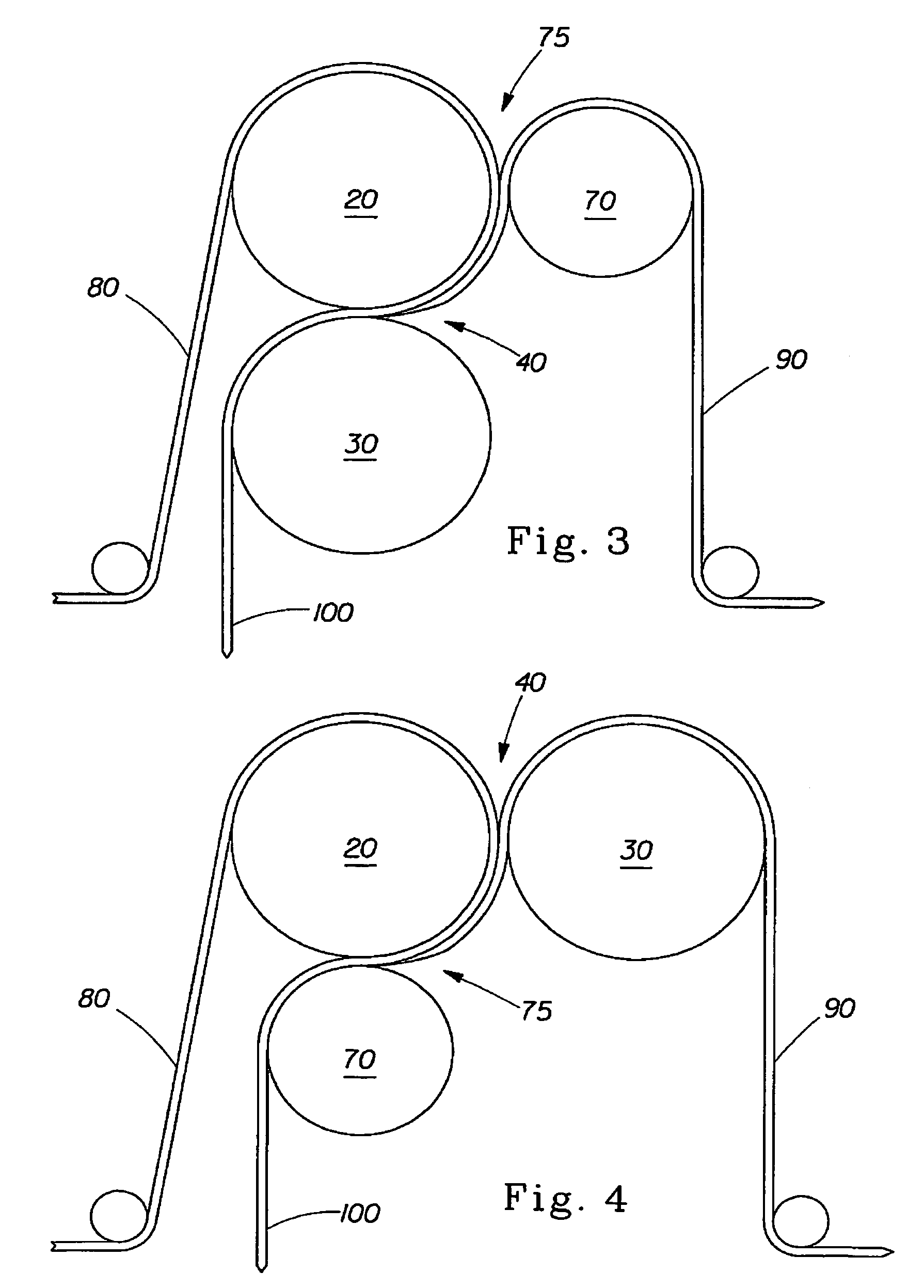

Fibre based panels with a wear resistance surface

ActiveCN101909836AImprove wear resistanceImprove impact resistanceCovering/liningsSpecial ornamental structuresSurface layerWear resistant

A flooring panel (1) comprising a core (6) and a surface layer (5), the surface layer (5) comprising cork particles (14) or wood fibres (14) comprising lignin resin, melamine resin as binder (19), colour pigments (15), and aluminium oxide as wear resistant particles (12), all components being homogenously mixed, and the core (6) comprising fibres and binder and being provided with a mechanical locking system (4) at its edges and a rear balancing layer (7). Also disclosed is a method of manufacturing said flooring panel by - homogenously mixing the dry particles of the surface layer; - scattering them on an embossed pressure matrix; - applying the core layer as scattered or prefabricated layer on the surface layer; - applying a balancing layer as scattered or prefabricated layer on the core layer; - pre-pressing the panel; - printing and brusching the surface layer; - forming the panel by a further pressing and heating step; - machining the mechanical locking system.

Owner:VÄLINGE INNOVATION AB

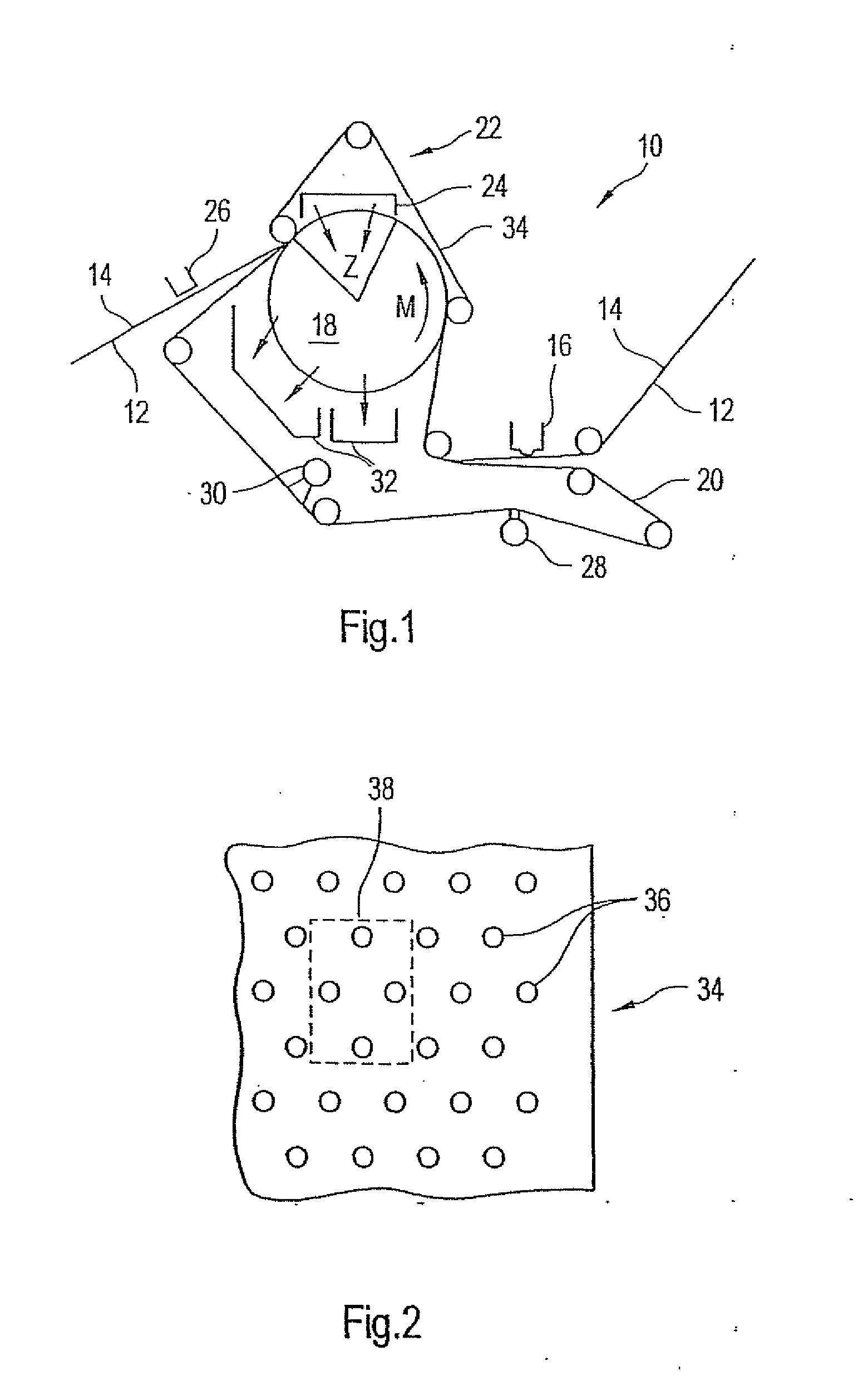

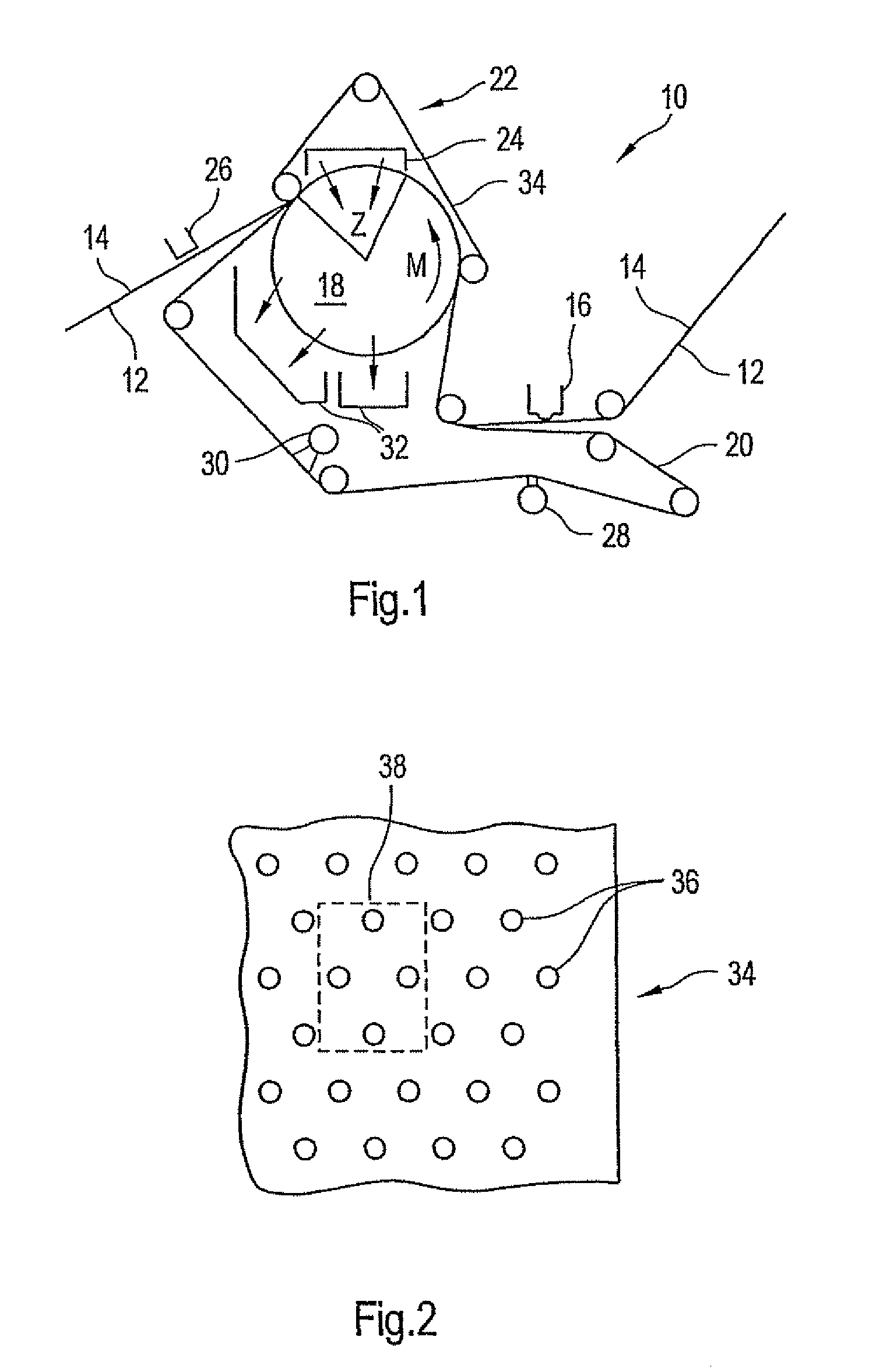

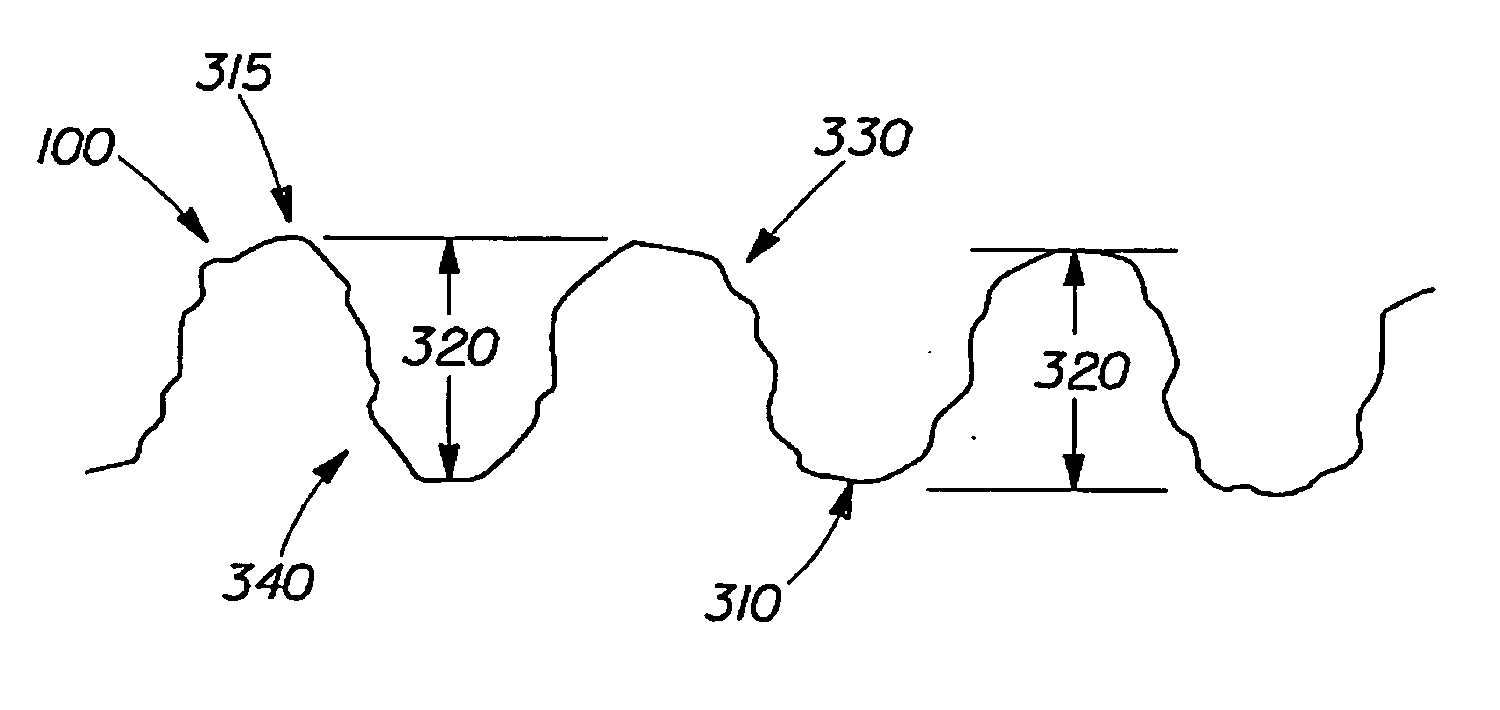

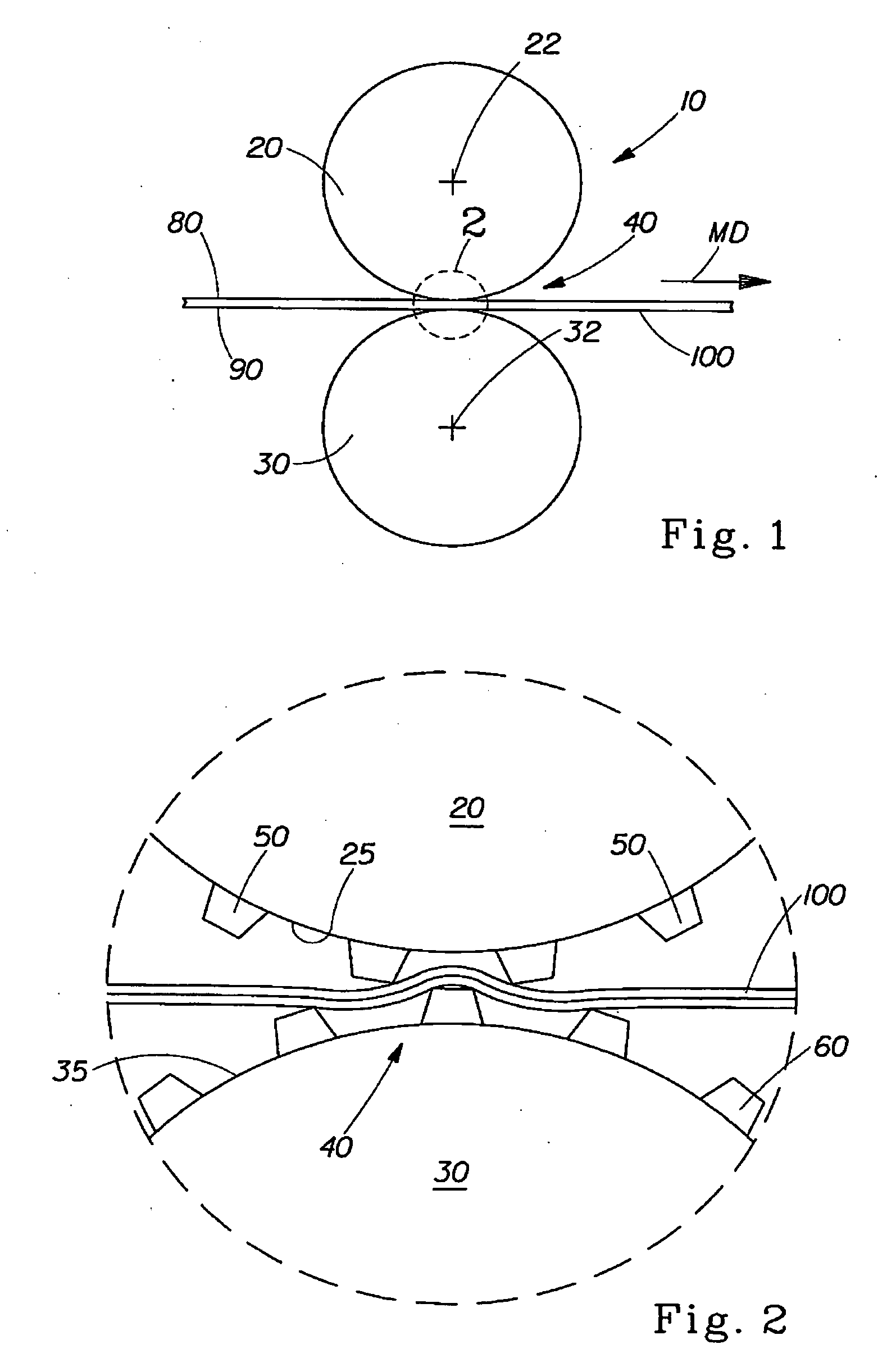

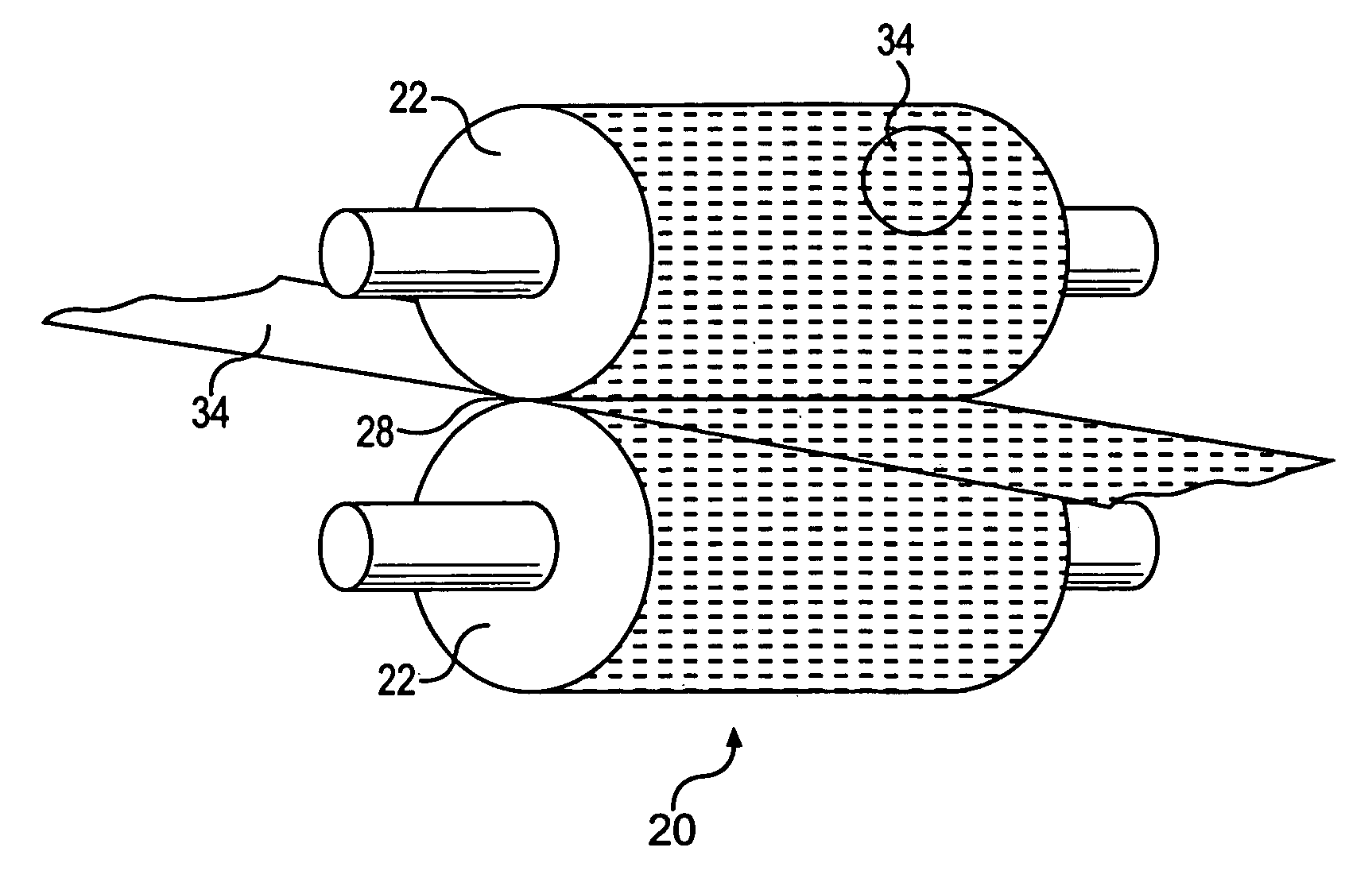

Apparatus and method for degrading a web in the machine direction while preserving cross-machine direction strength

InactiveUS7326322B2Prevent degradationIncrease flexibilityNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringUltimate tensile strength

An embossing system is provided for embossing a web having a first embossing roll having embossing elements and a second embossing roll having embossing elements, wherein at least a portion of the embossing elements of the first and second embossing rolls are substantially oriented in the cross-machine direction. The embossing roll may be crowned, may have alignment means, and may be provided with precision gearing.

Owner:GPCP IP HLDG LLC

Press section and permeable belt in a paper machine

InactiveUS20050167068A1Substantial airflowLarge tensionMachine wet endPress sectionEngineeringPaper machine

Owner:VOITH PATENT GMBH

Press section and permeable belt in a paper machine

InactiveUS7294237B2Large tensionIncrease the opening areaLayered productsMachine wet endPaper machineEngineering

Owner:VOITH PATENT GMBH

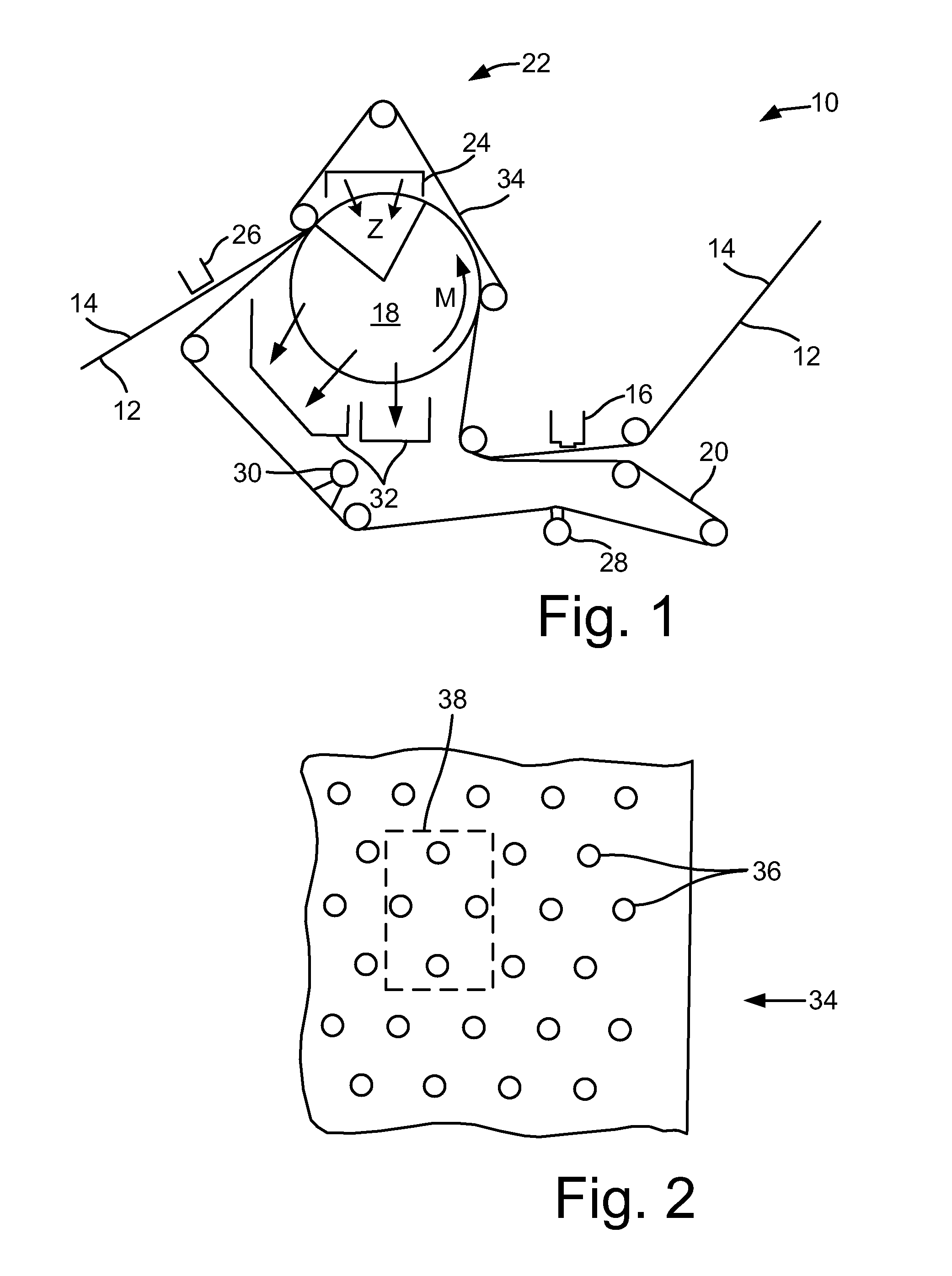

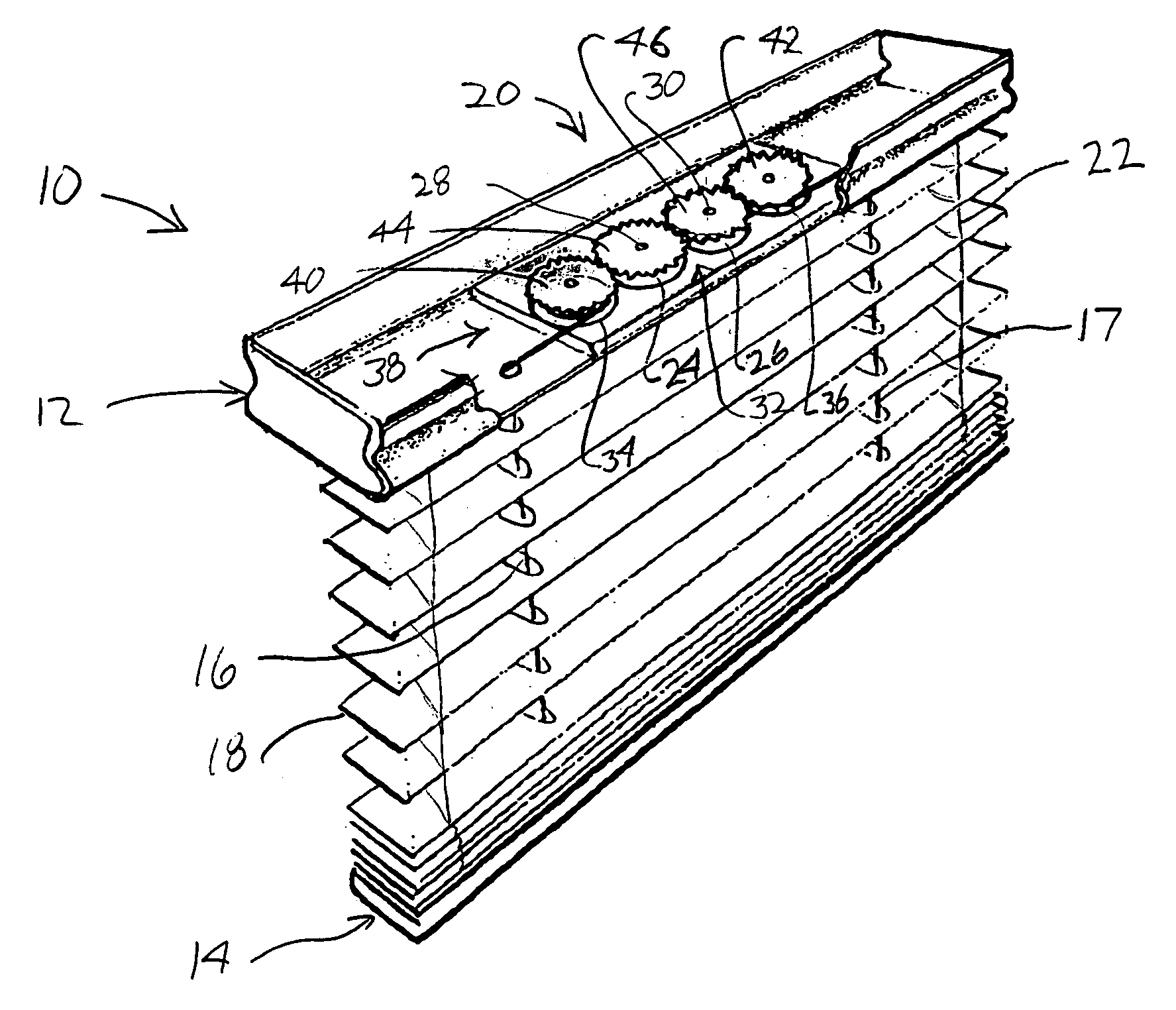

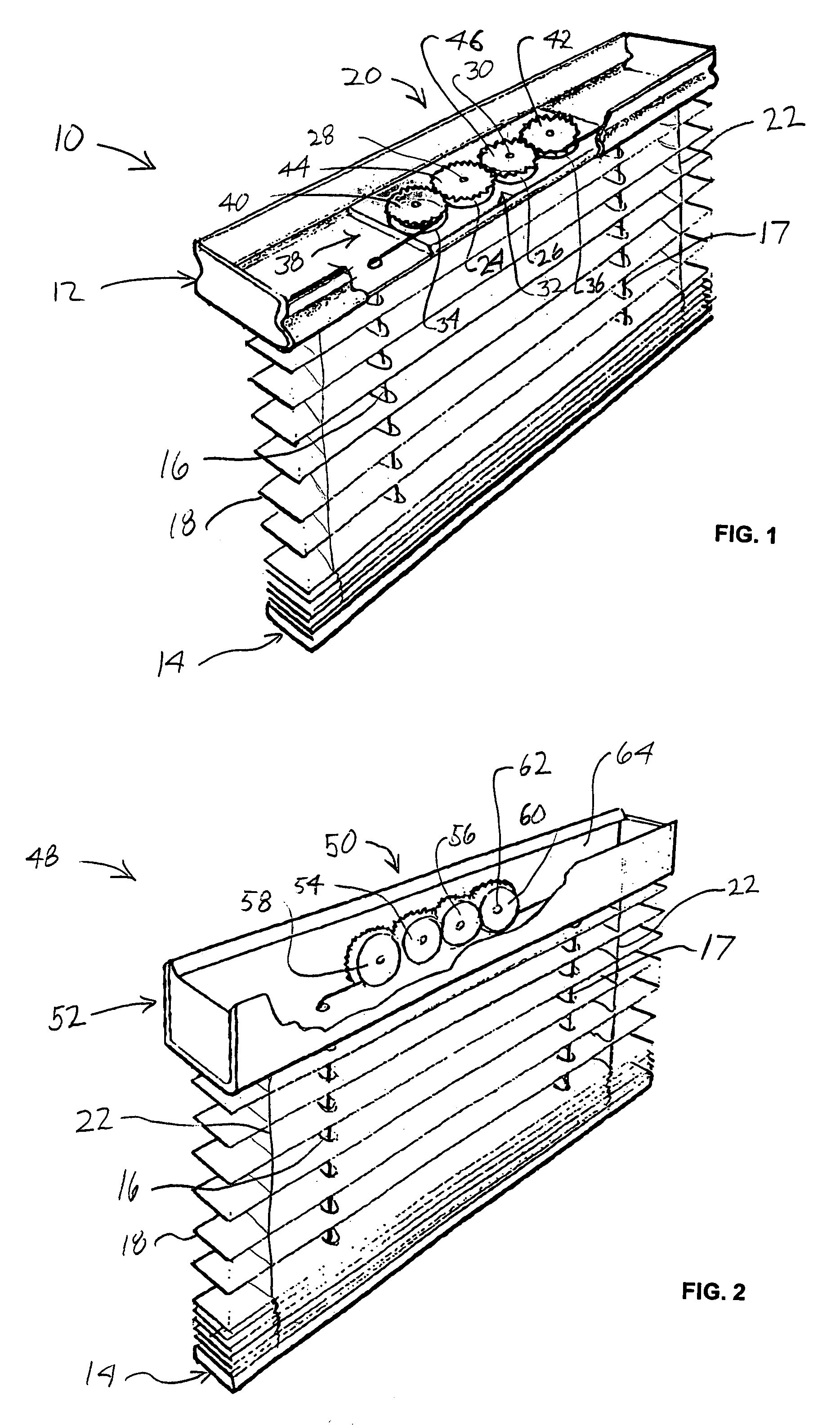

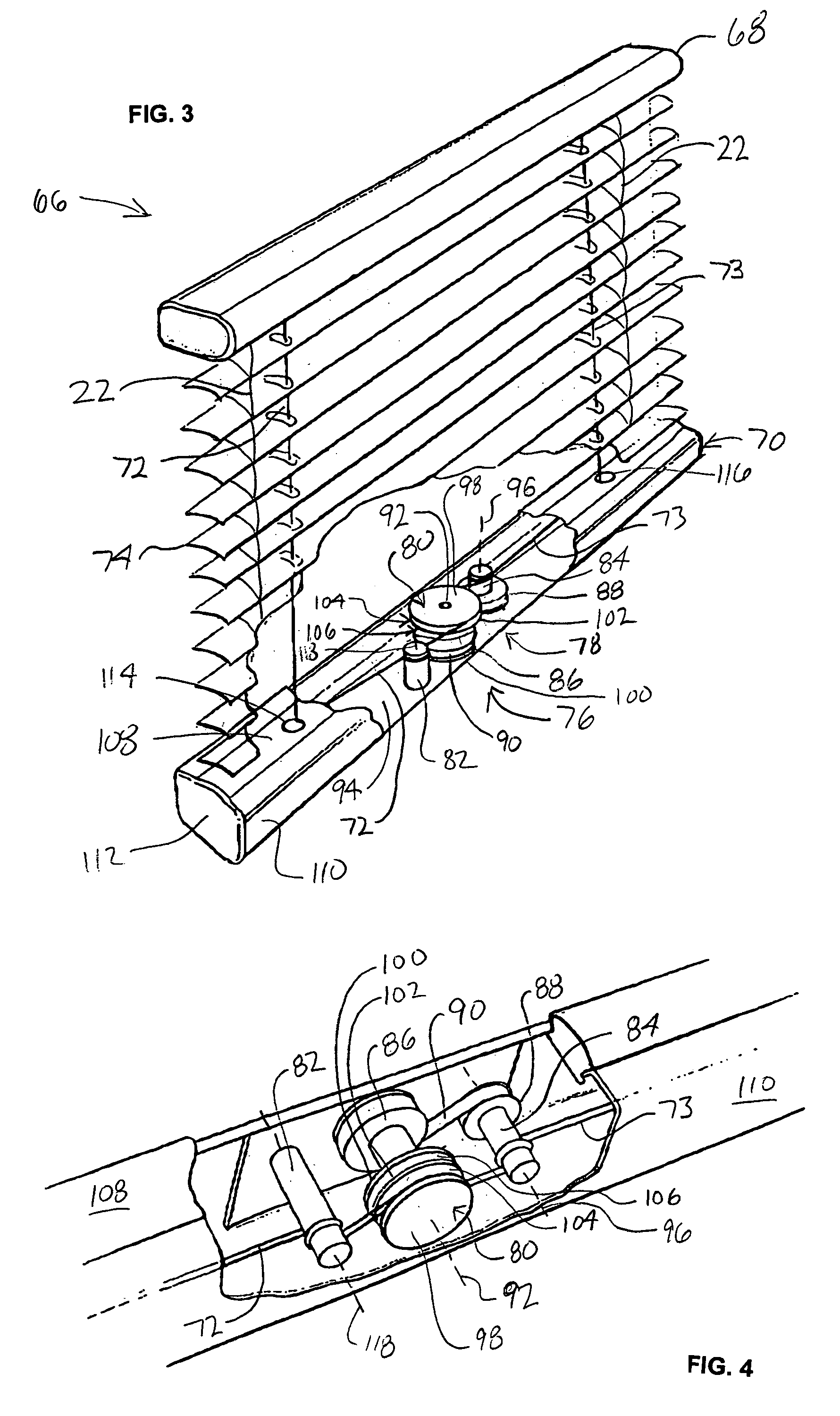

Cordless blind

InactiveUS7228797B1Increase or decrease weightAdjusting the performance characteristics of the blindDoor/window protective devicesRotary pressEngineeringActuator

A cordless blind includes a headrail, a bottom rail suspended from the headrail by a first cord and a second cord, a wall covering disposed between the headrail and the bottom rail, and a drive actuator. The drive actuator includes a spring motor, a spool coupled to the spring motor, a first tensioning mechanism, and a second tensioning mechanism. The first and second tensioning mechanisms are configured to impact a resistant force on movement of the first and second cords. The drive actuator may include a spool, a spring motor, a biasing element configured to provide a force biased against movement of the bottom rail, and a bias relief mechanism that is configured to provide for selective application and relief of the biasing force by the biasing element. The drive actuator may include a constant biasing element, a generally rigid strap, a mandrel, a biasing member, and a traction wheel including a plurality of cogs extending from the circumference of the traction wheel such that movement of the strap rotates the traction wheel.

Owner:HUNTER DOUGLAS INDS SWITZERLAND

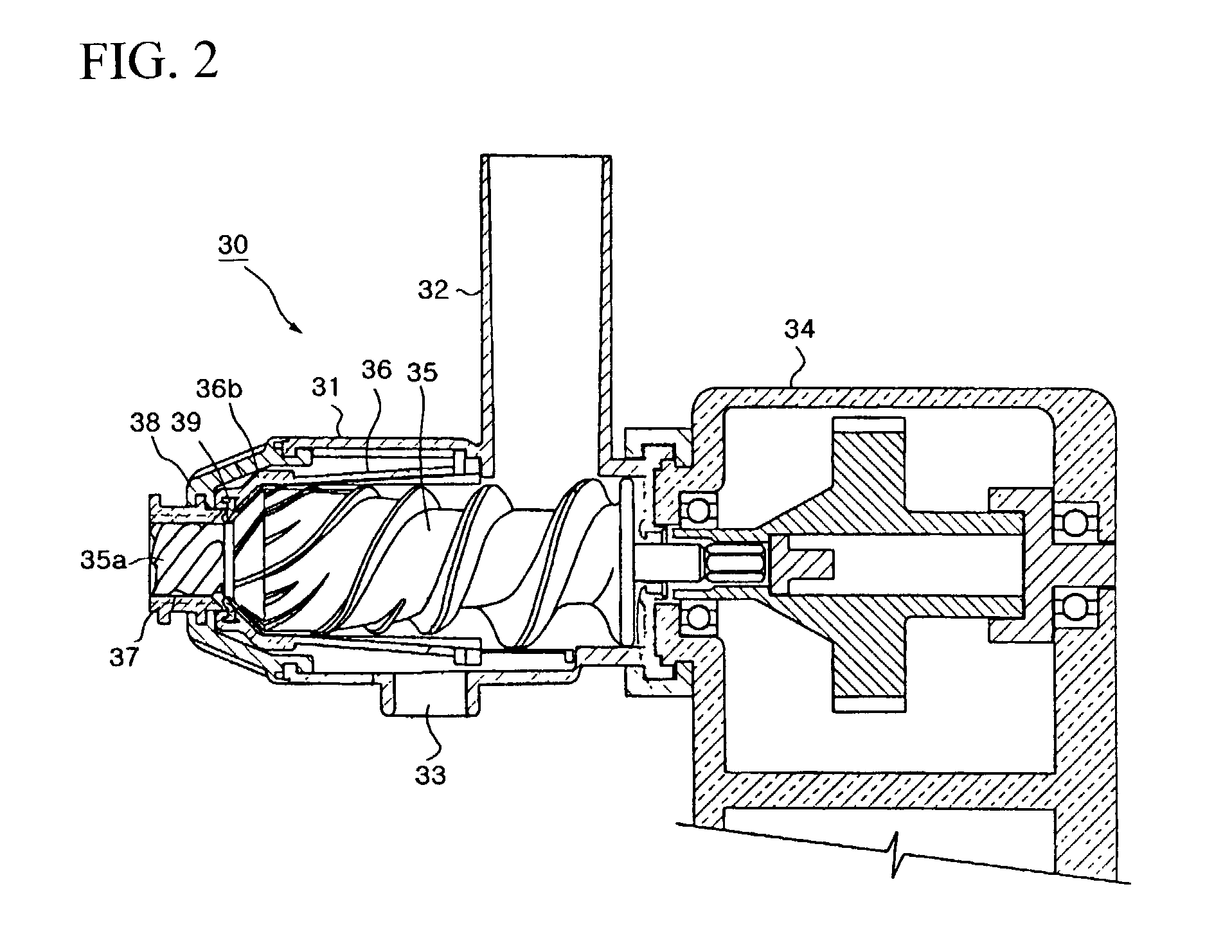

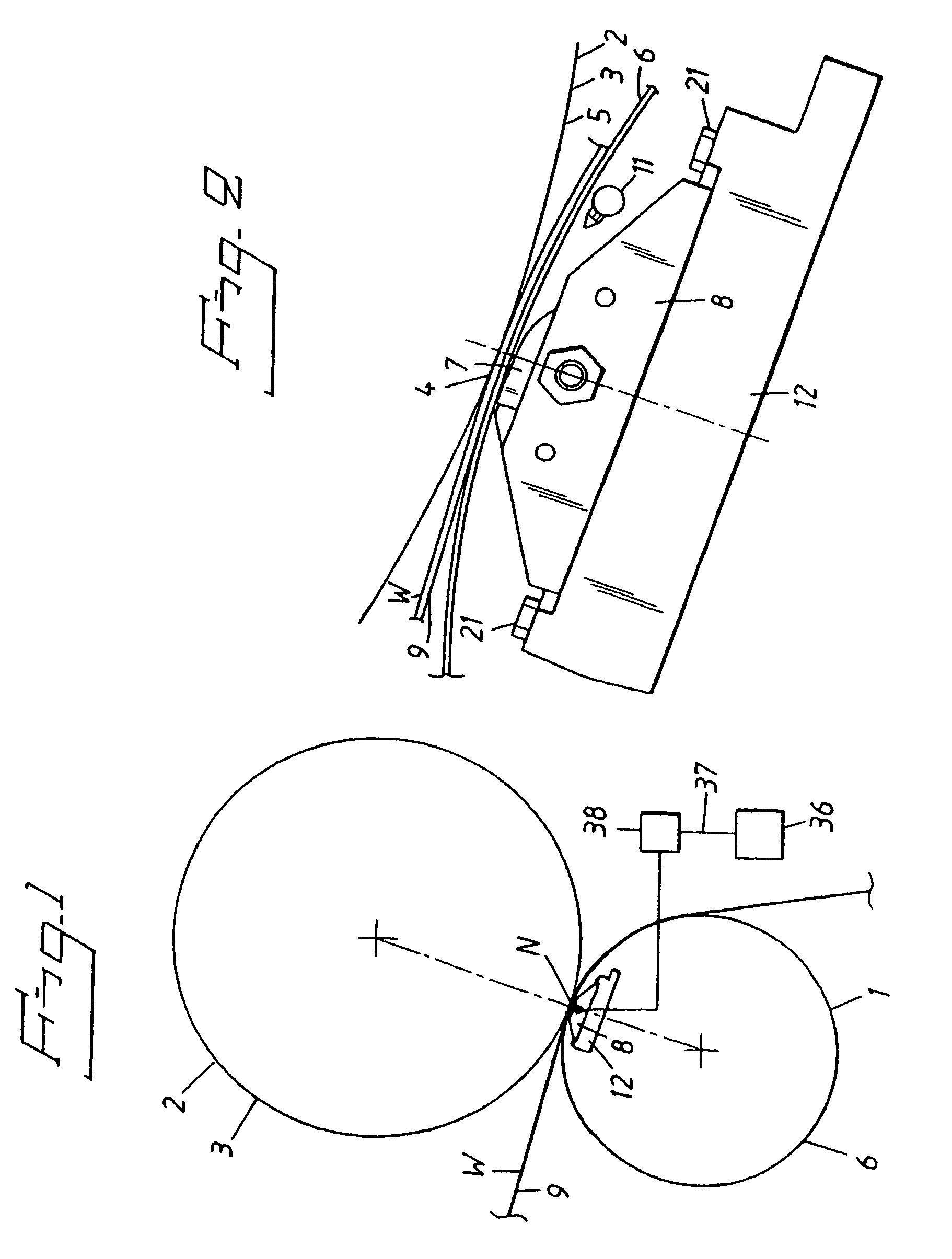

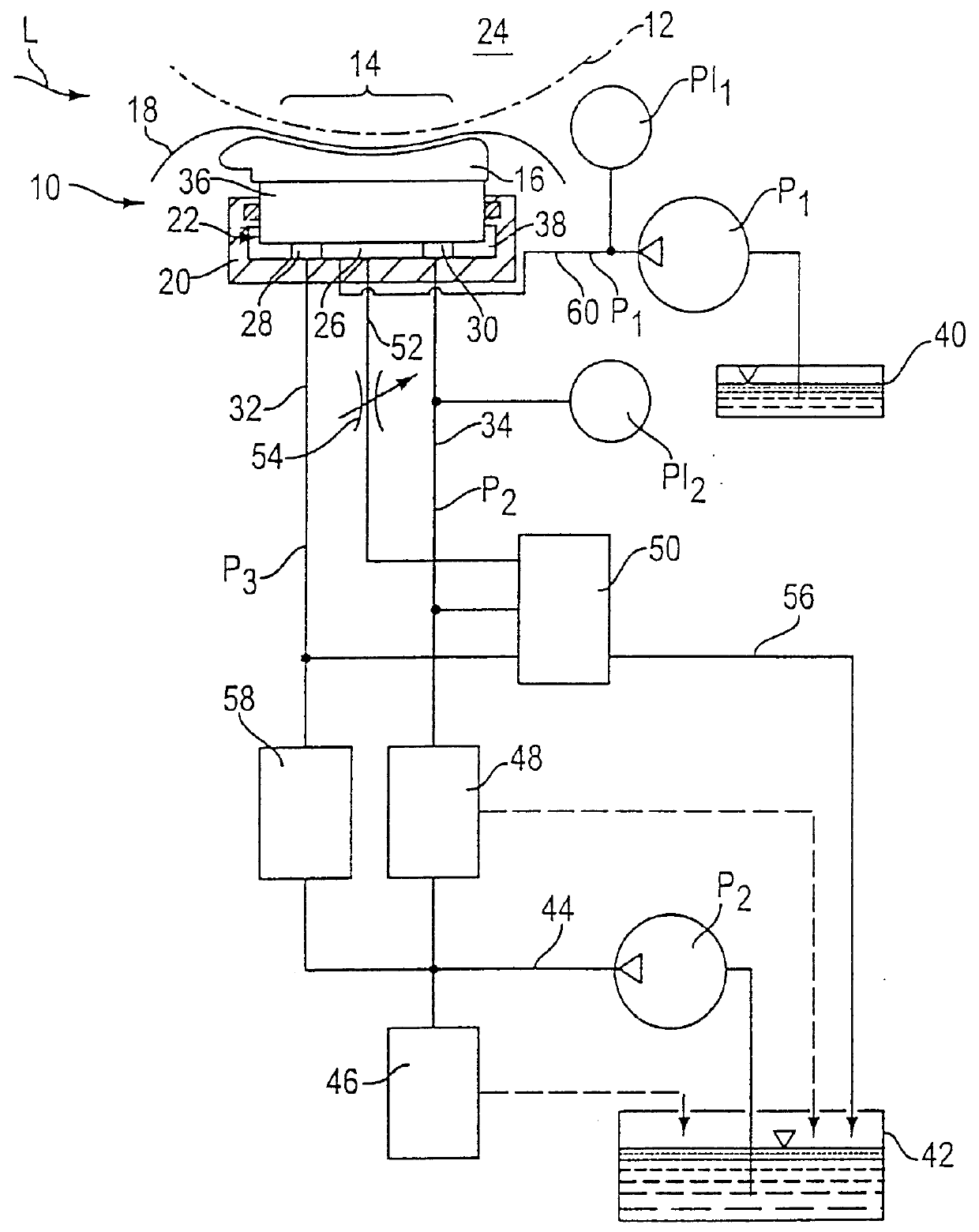

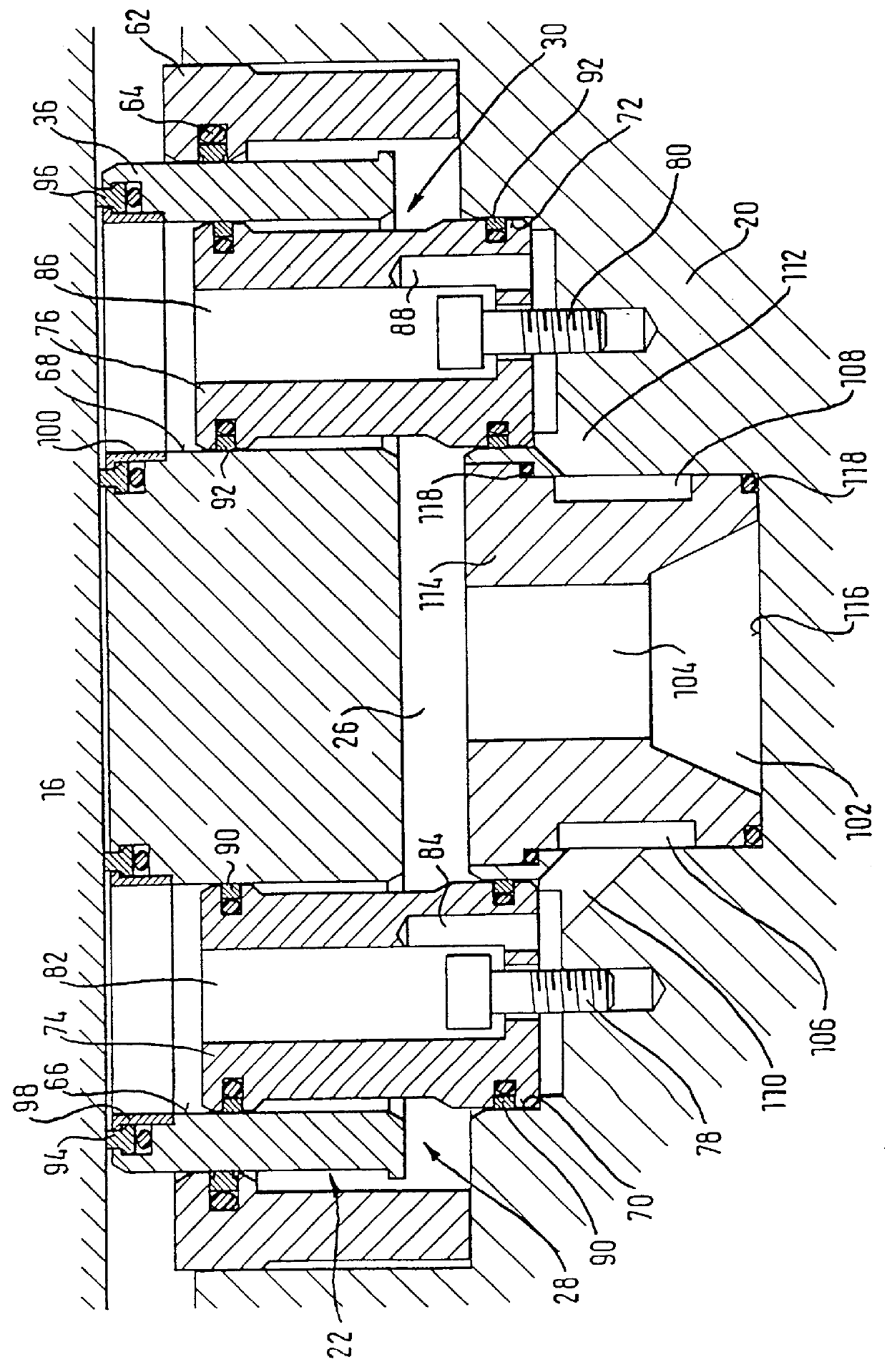

Shoe press unit

InactiveUS6036820ASimple wayControl is possibleNon-fibrous pulp additionNatural cellulose pulp/paperLine tubingEngineering

Shoe press unit and method for treatment of a fibrous pulp web. The shoe press unit includes at least one press shoe, an opposing surface, a flexible press belt guided over the press shoe, and at least one force element composed of a cylinder / piston unit supported on a carrier. The at least one force element presses the press belt against the opposing surface to form a press zone elongated in a web run direction, and the cylinder / piston unit include a pressure chamber having at least one pair of cylinder / piston subunits successively positioned in the web run direction. Pressure fluid lines are coupled to respective ones of the at least one pair of cylinder / piston subunits to separately supply pressure fluid to each cylinder / pressure subunit to impart a tilting moment long a tilt axis substantially perpendicular to the web run direction. The method includes supplying a pressure fluid to a first and second pressure fluid line from a common pressure fluid source at a source pressure, supplying pressure fluid through the first pressure fluid line at a first fluid pressure to a first subunit of the at least one pair of cylinder piston subunits, supplying pressure fluid through the second pressure fluid at a second fluid pressure to a second subunit of the at least one pair of cylinder piston subunits, and maintaining a sum of the first and second fluid pressures to be substantially equal to the source pressure.

Owner:VOITH SULZER PAPIERMASCHEN GMBH

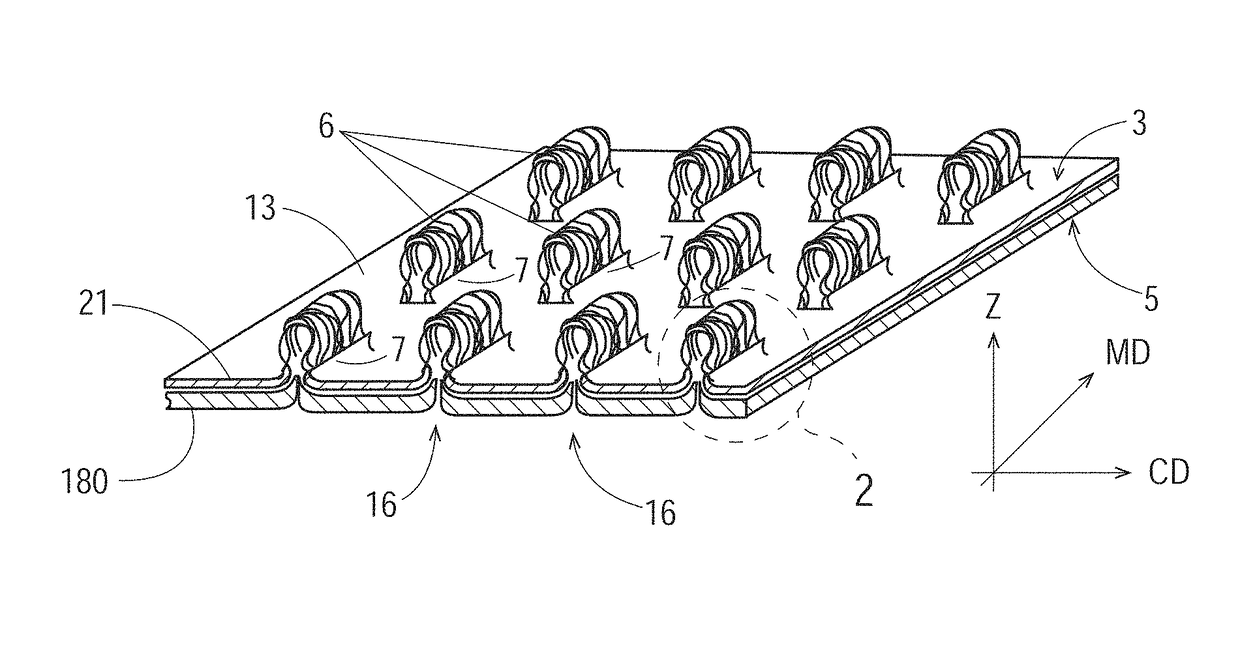

Topsheets integrated with heterogenous mass layer

An absorbent article and method of making the absorbent article are disclosed. The absorbent article having a topsheet, a backsheet, and an absorbent core structure having one or more layers wherein at least one layer is a heterogeneous mass layer, wherein the topsheet and the heterogeneous mass are integrated such that they reside in the same X-Y plane.

Owner:THE PROCTER & GAMBLE COMPANY

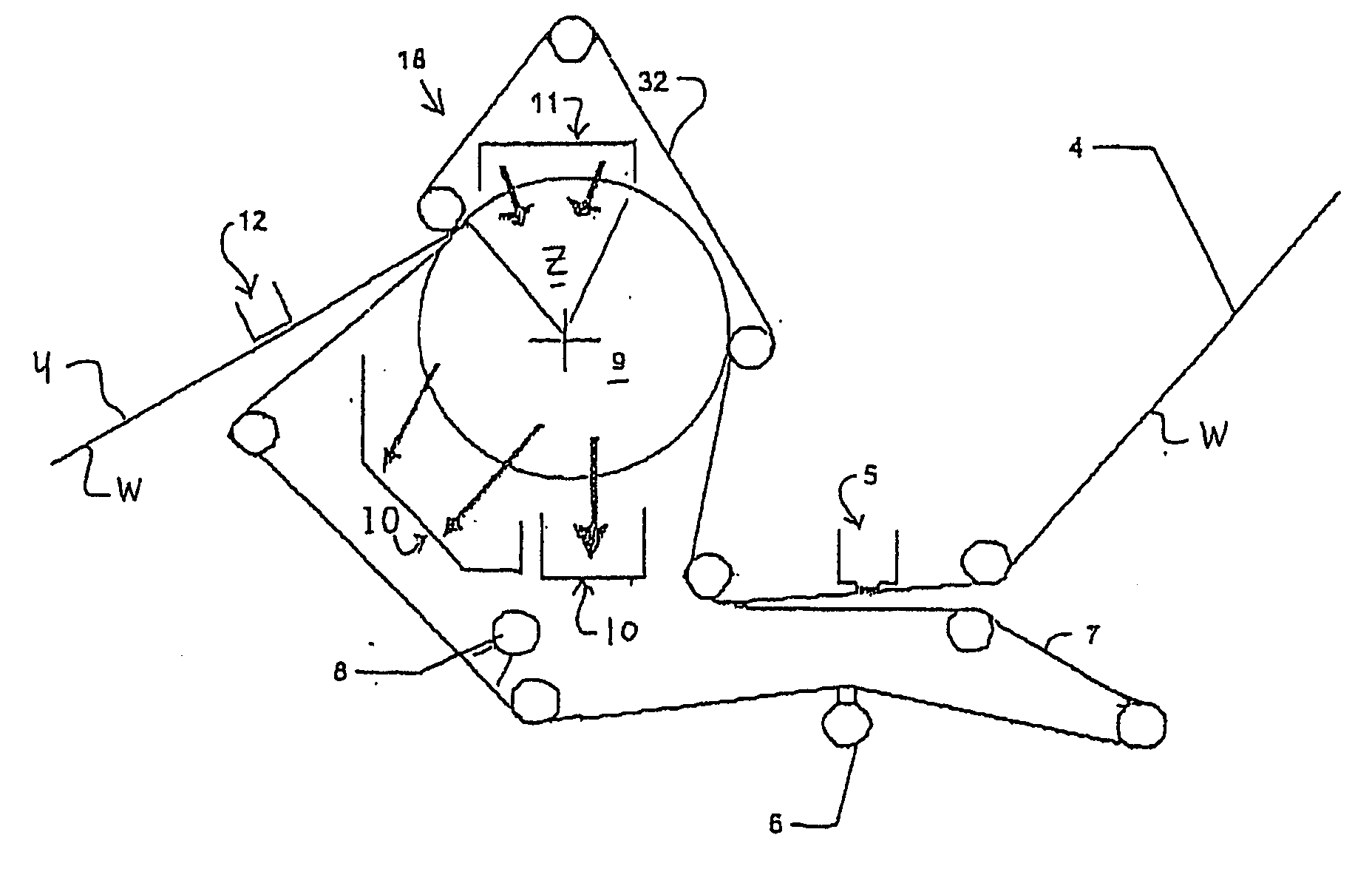

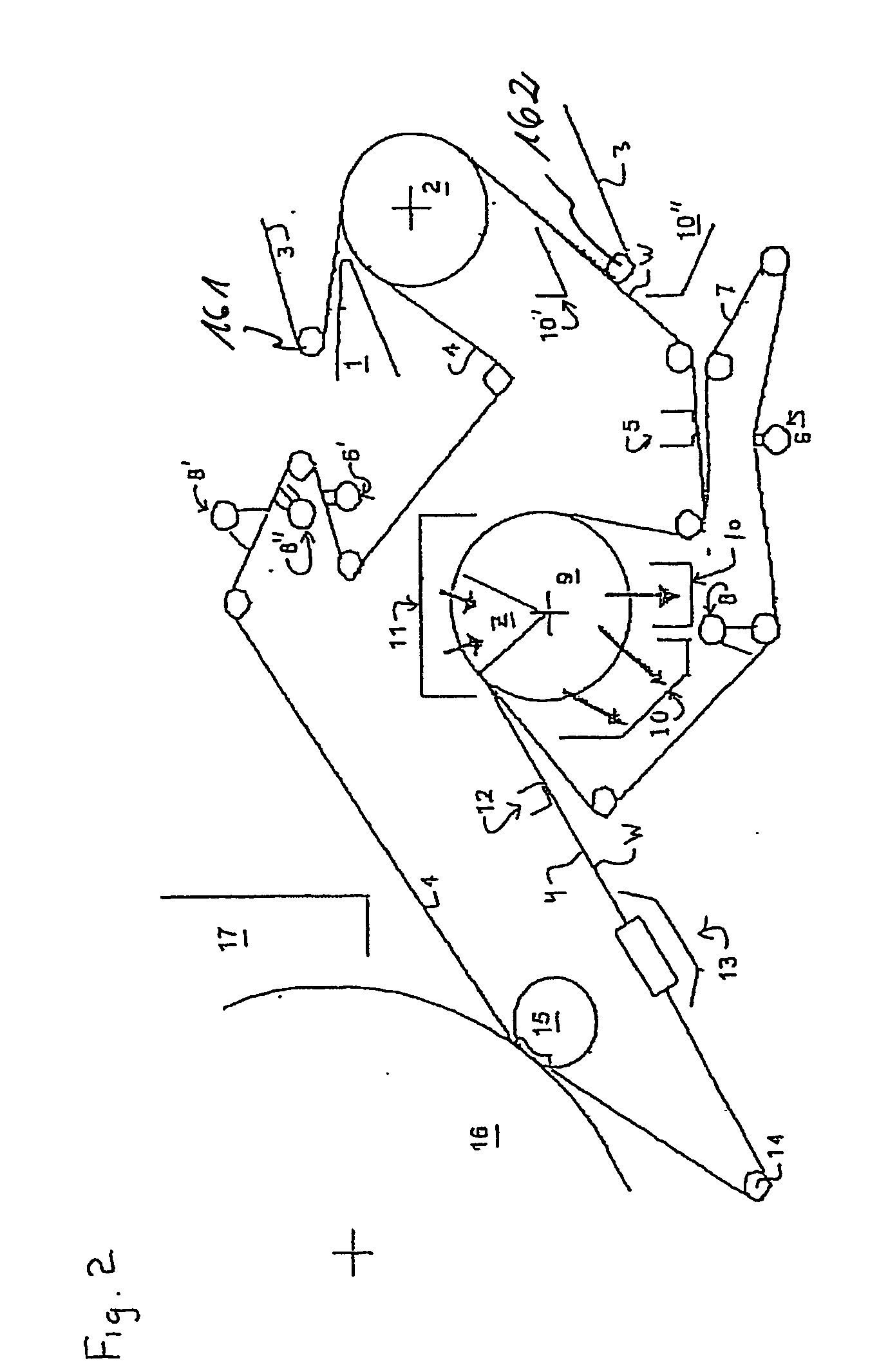

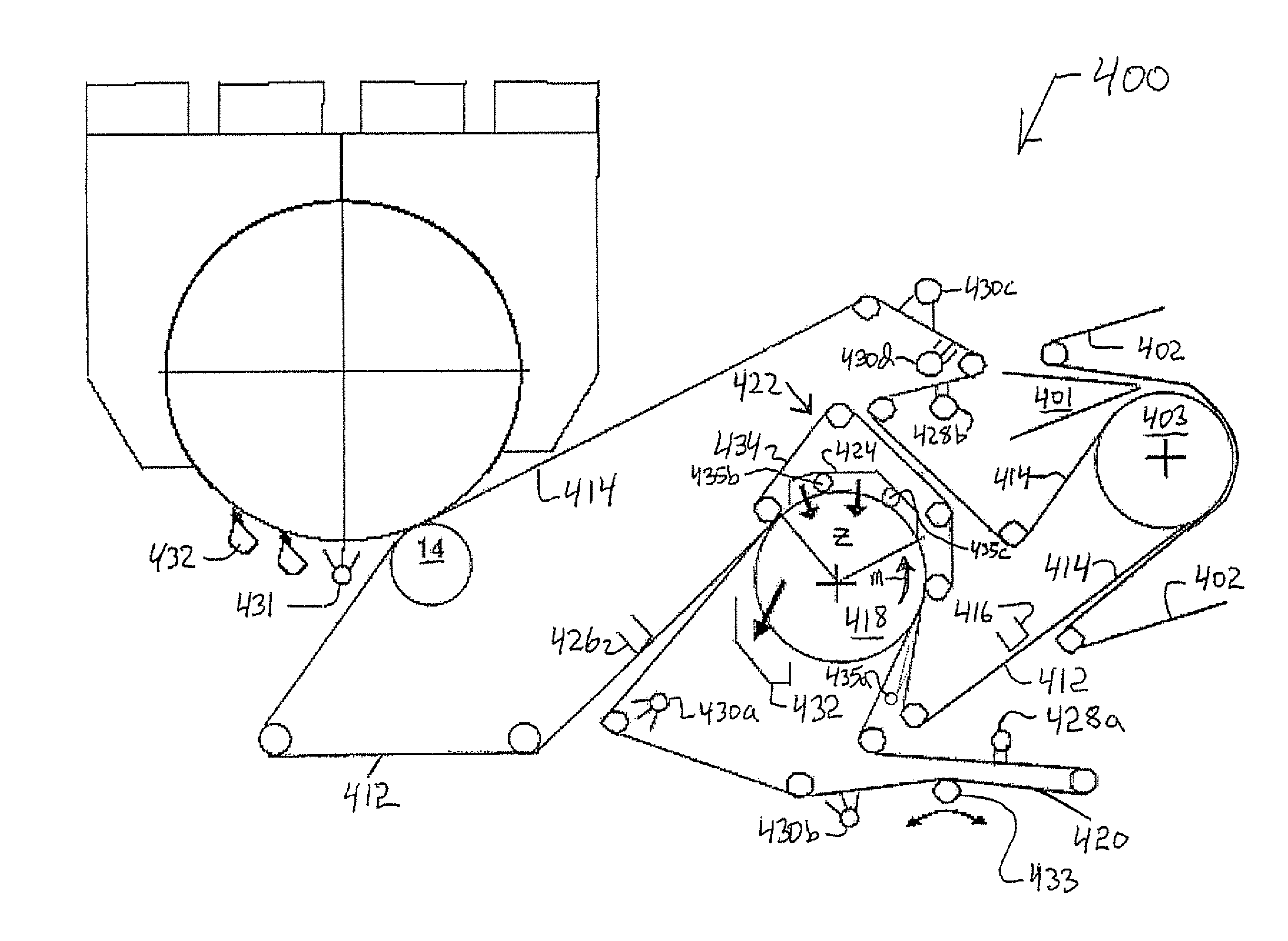

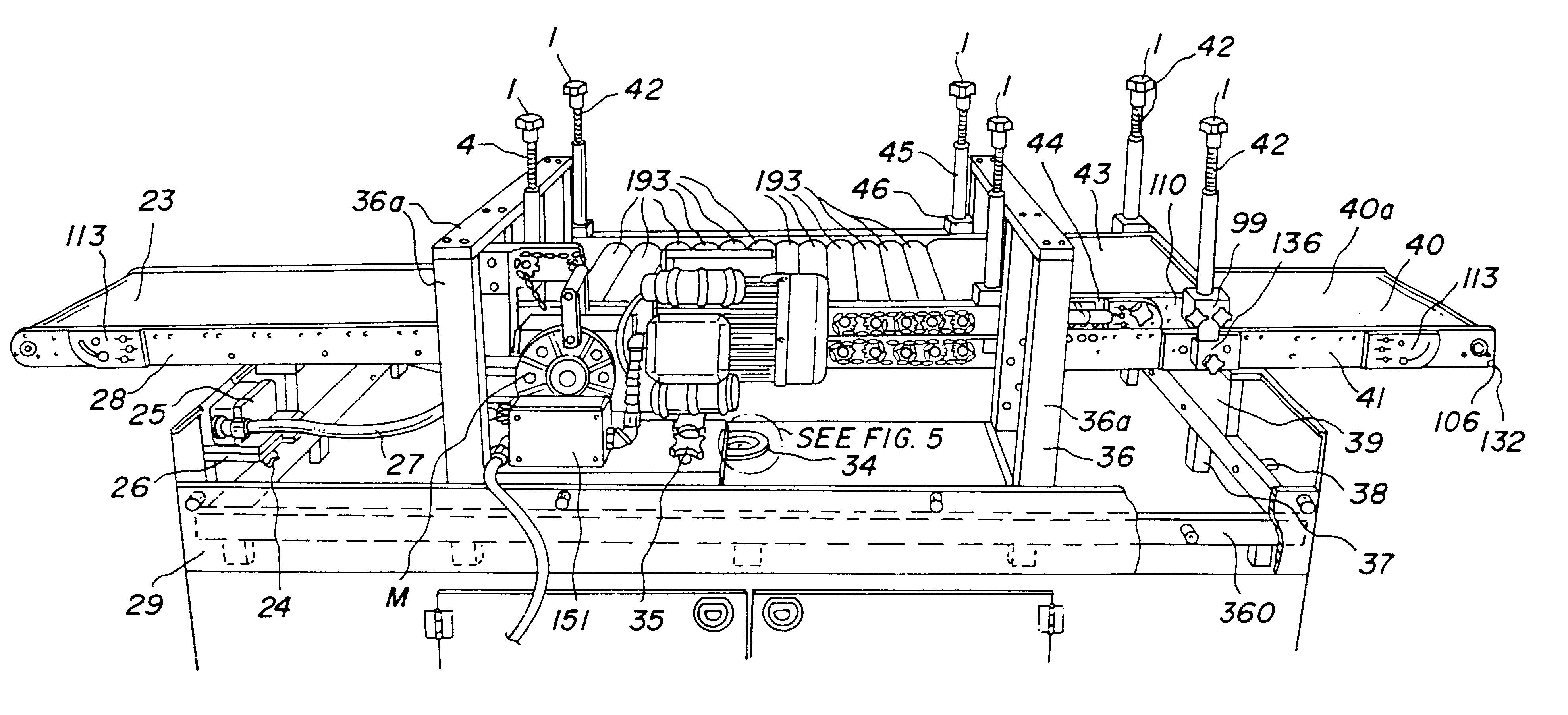

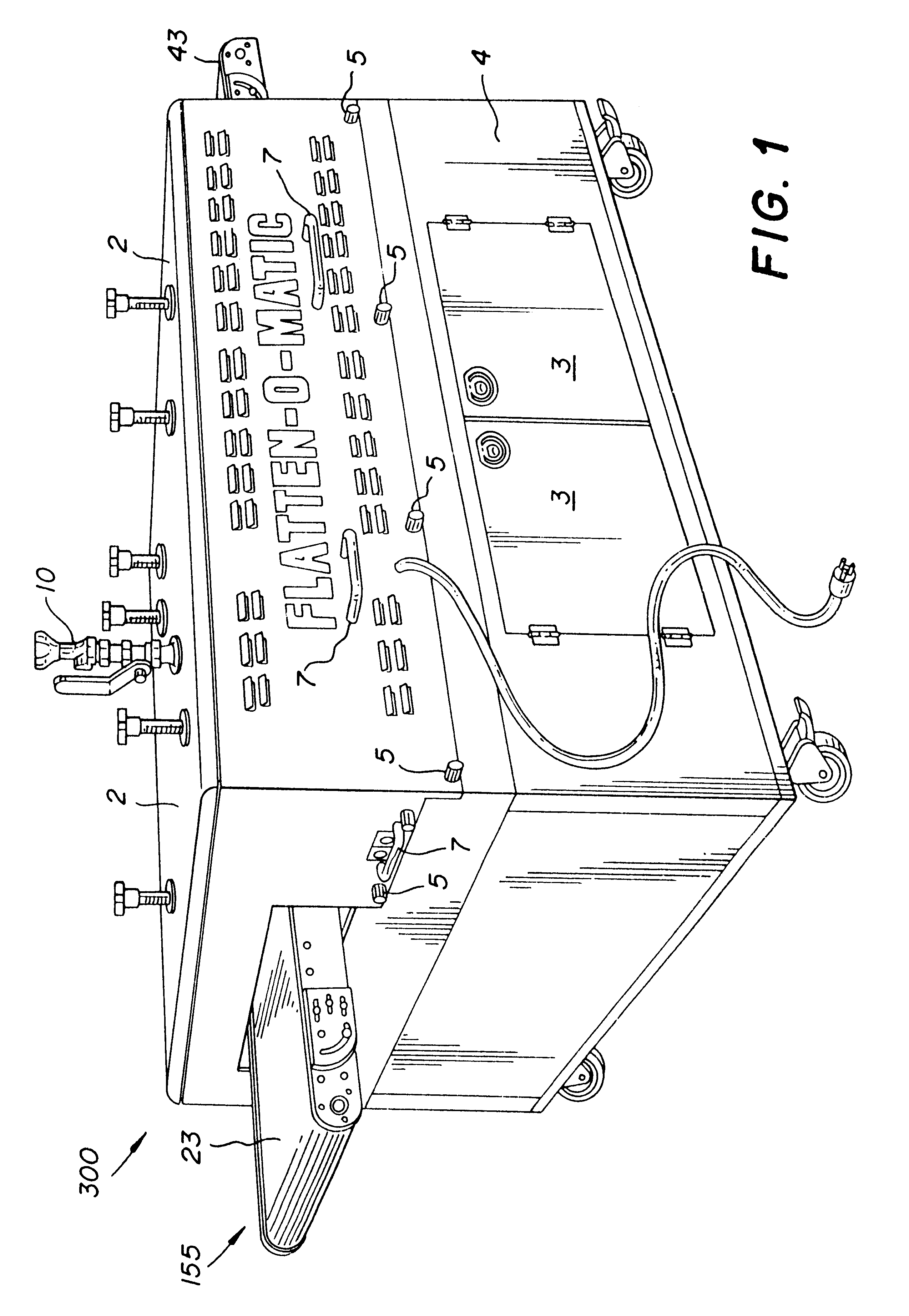

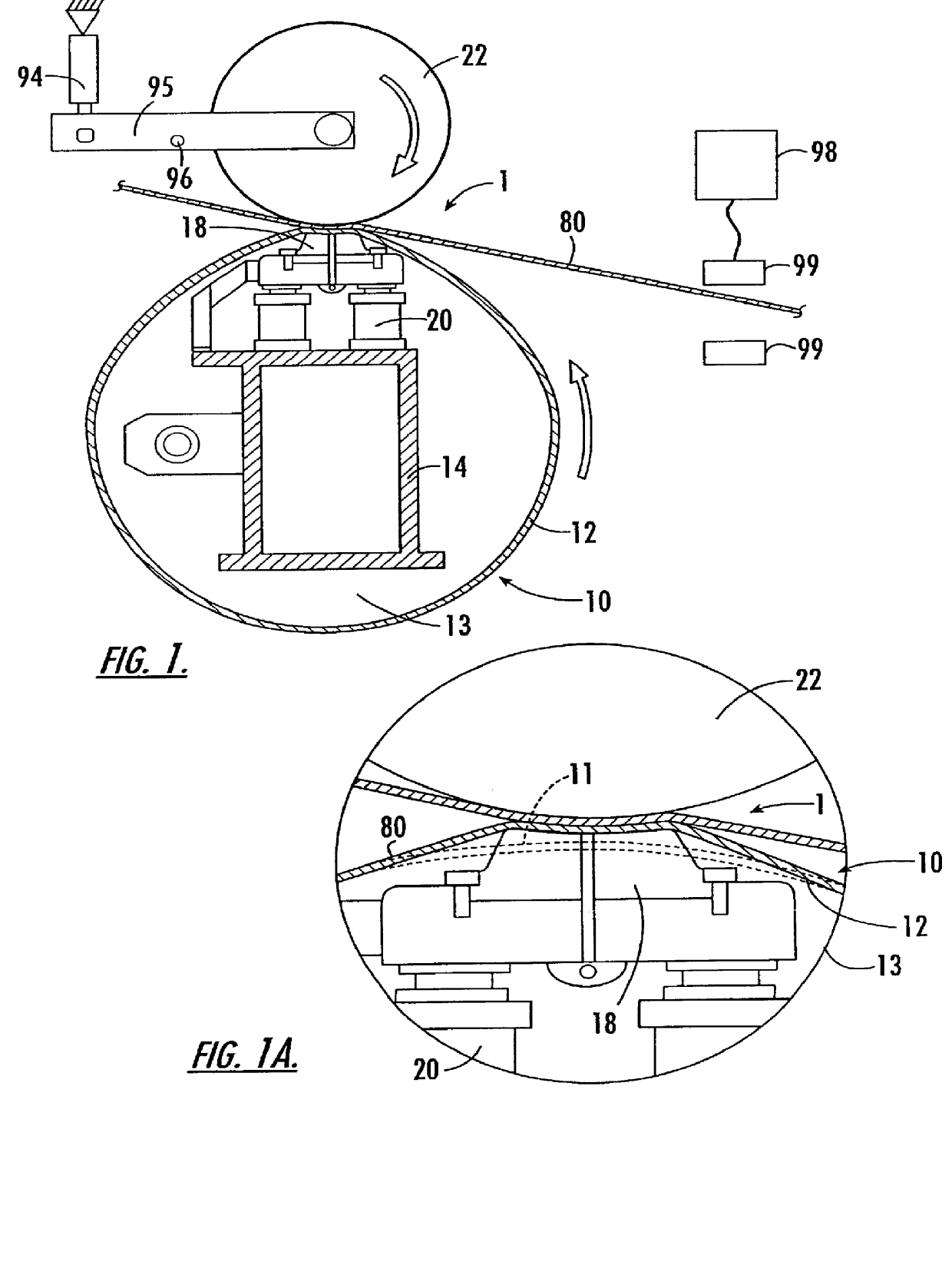

Automatic truss jig setting system

A automatic truss jig setting system is disclosed that includes a table including a plurality of segments with a side edge of adjacent segments defining a slot. At least one pin assembly, and optionally a pair of pin assemblies, is movable independently of each other along the slot. Movement apparatus is provided for independently moving the pin assemblies along the slot. Each of the side edges of the segments associated with the slot defines a substantially vertical plane with a zone being defined between the substantially vertical planes of the side edges, and the movement apparatus is located substantially outside of the zone of the slot. The invention may optionally include a system for handling the obstruction of pin assembly movement, and a system for keeping track of the position of the pin assembly when the pin assembly has encountered an obstruction.

Owner:MITEK USA

Finger pattern formation for thin film solar cells

InactiveUS20080173390A1Ornamental structuresSpecial ornamental structuresMetallic foilThin film solar cell

A method of forming metallic connector patterns for solar cells, whereby an embosser having raised features shaped in the form of a metallic connector pattern is used to attach a portion of a metallic foil to a transparent conductive layer formed on a top transparent surface of a solar cell structure. The raised surfaces of the embosser press the metallic foil portion against the transparent conductive layer. Heat and pressure directed to the metallic foil portion attach the metallic foil portion to the underlying transparent conductive layer, and then the rest of the metallic foil, which is not attached to the transparent conductive layer, is removed.

Owner:SOLOPOWER

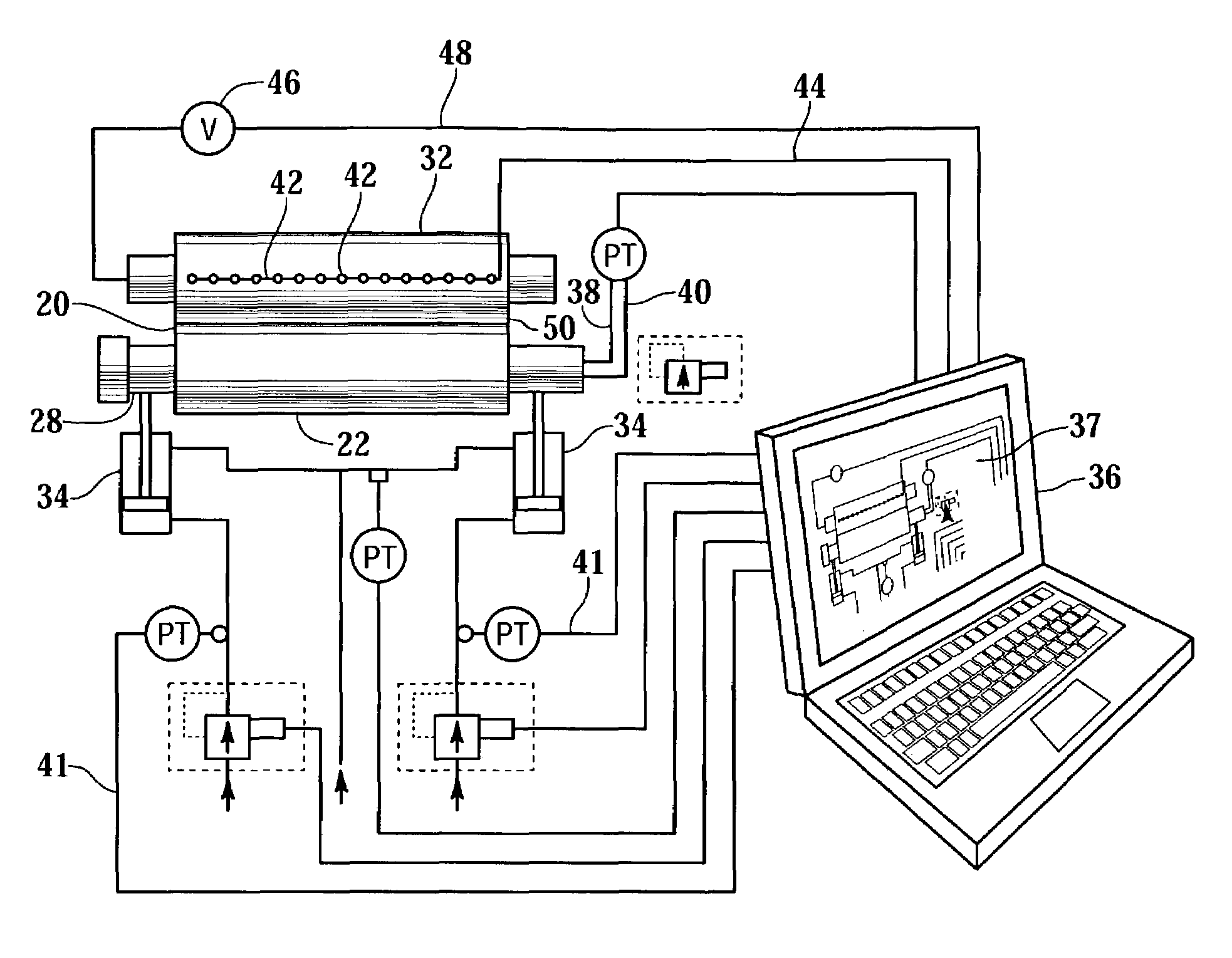

Nip and loading analysis system

InactiveUS7185537B2Improve assessmentBetter assessmentCalendersPress sectionEngineeringMechanical engineering

A nip characterization system which has as inputs the pressure applied to the nip by the hydraulic loading devices, and loads applied at the end bearings and / or the loads applied to the roll support beam, and in addition directly measures nip load, has more than sufficient information to completely characterize the nip.

Owner:VALMET TECH INC

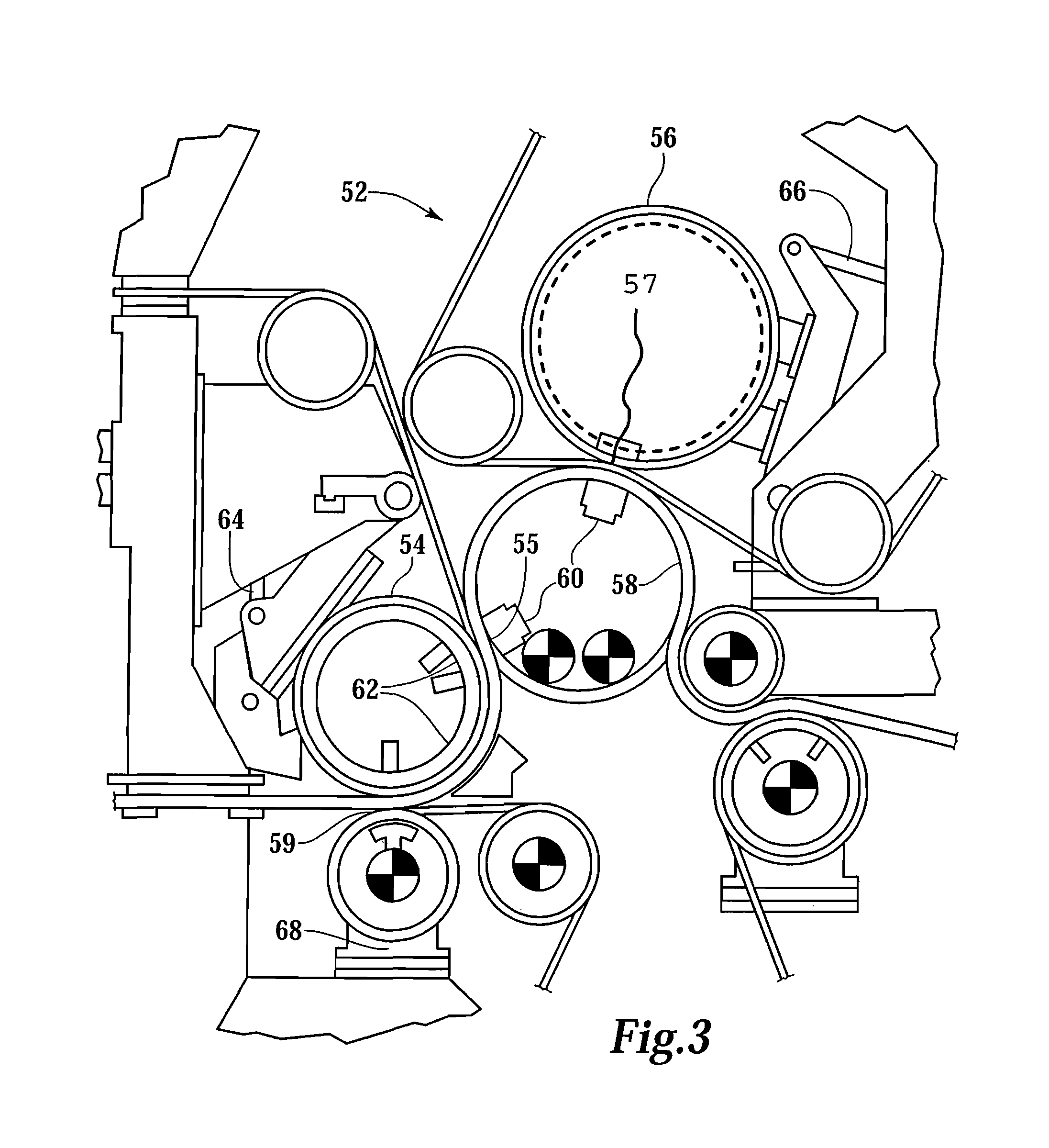

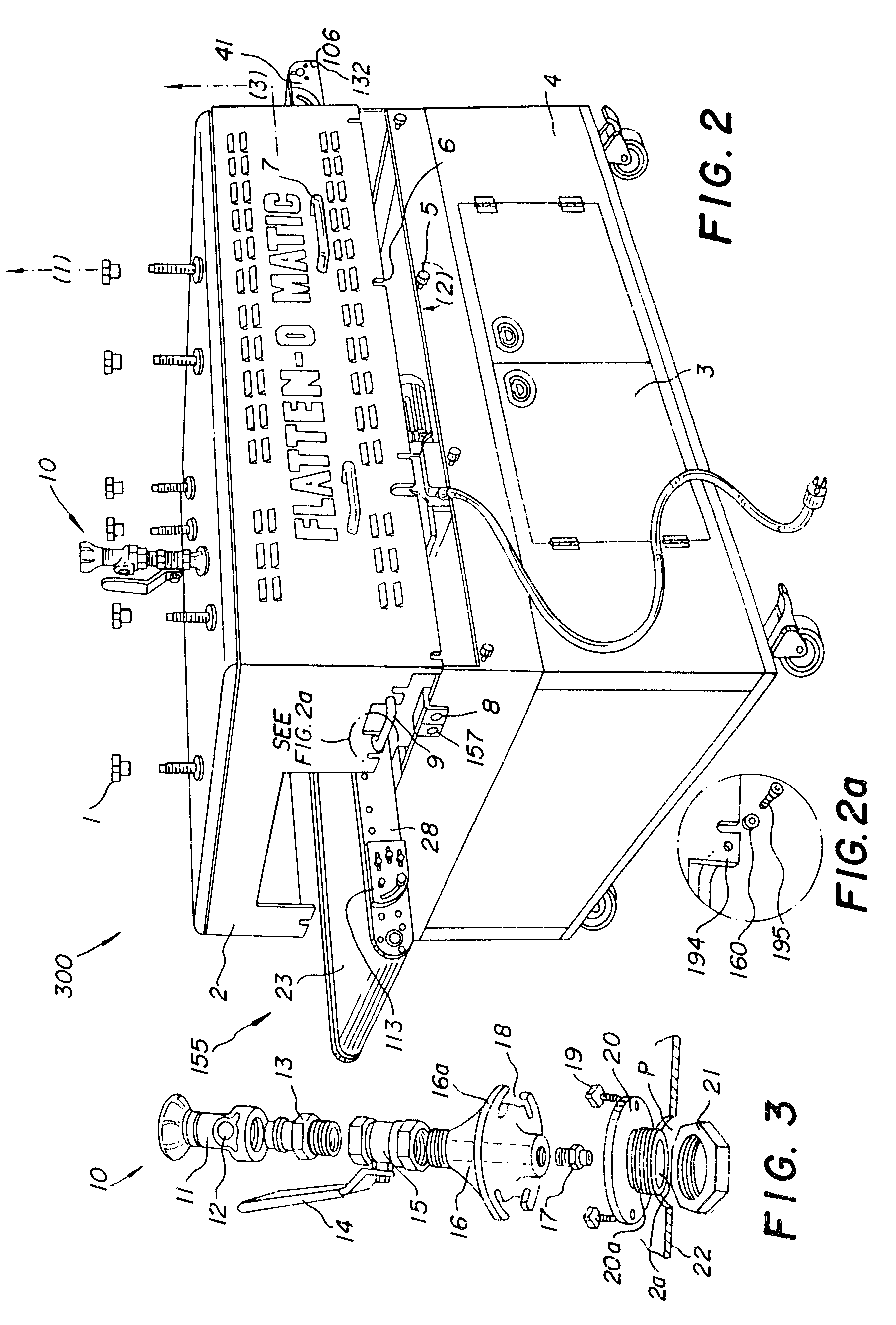

Apparatus for marinating, tenderizing, strip cutting cube cutting and progressively flattening meat

InactiveUS6601499B1Avoid stickingIncrease volumeGrain huskingGrain polishingEngineeringConveyor belt

An apparatus for flattening pieces of meat without piercing nor shredding the meat including a first roller set, each roller in the first roller set having non-sharpened outer edges; a second roller set, each roller in the second roller set having non-sharpened outer edges, the first roller set directly opposing and being spaced and fully separated from the second roller set, the first and second roller sets together having a product in-feed end into which meat pieces are drawn and having a product out-feed end at which flattened meat pieces are expelled from between the first and second roller sets; an adjustment mechanism for adjusting the spacing between the first roller set and the second roller set, where meat passing between the first and second roller sets is substantially flattened but not pierced nor shredded; and an in-feed conveyor belt assembly at the in-feed end including an in-feed conveyor belt and a rolling mechanism for rolling the in-feed conveyor belt in a direction to advance meat pieces placed on the in-feed conveyor belt to the in-feed end.

Owner:BIFULCO PHIL

Apparatus for calendering paper

The invention relates to a method for operating a calender, comprising a cylindrical heated roll and a flexible belt surrounding a stationary support beam which supports at least one actuator which may urge a concave load shoe against the heated roll by means of said flexible belt to form an extended and heated nip through which a fiber web passes to be calendered and a separating mechanism for having at least one of the rolls movable into and away from the nip characterized in that said flexible belt is a flexible tubular jacket which forms a part of an enclosed shoe roll such that the ends of said jacket have end walls mounted thereto, which end walls are rotatably mounted in relation to said support beam, and in that at least one of said end walls is driven by means of a drive arrangement which drive arrangement may be activated to drive the end walls and thereby also the jacket independently of its position in relation to the fiber web or the heated roll.

Owner:VALMET TECH INC

Device for extracting juice from plant

A device for extracting juice from one of various plants (e.g., grass, soybeans, or wheat) comprises a motor, a hollow container, a spindle in the container and is rotatably coupled to the motor, a strainer surrounded a portion of the spindle and fastened in the container, a cap secured to the other end of the container and including a drum tapered toward the other end, and an adjustment mechanism including a hollow, cylindrical member fixedly coupled to the cap, and a manipulation assembly. The manipulation assembly can either advance into a mouth of the spindle for decreasing a size of a residue outlet formed by the manipulation assembly and the drum or withdraw from the mouth for increasing the size of the residue outlet. Also, juice concentration is adjusted in the sliding movement of the manipulation assembly.

Owner:JAN TZUEN YU

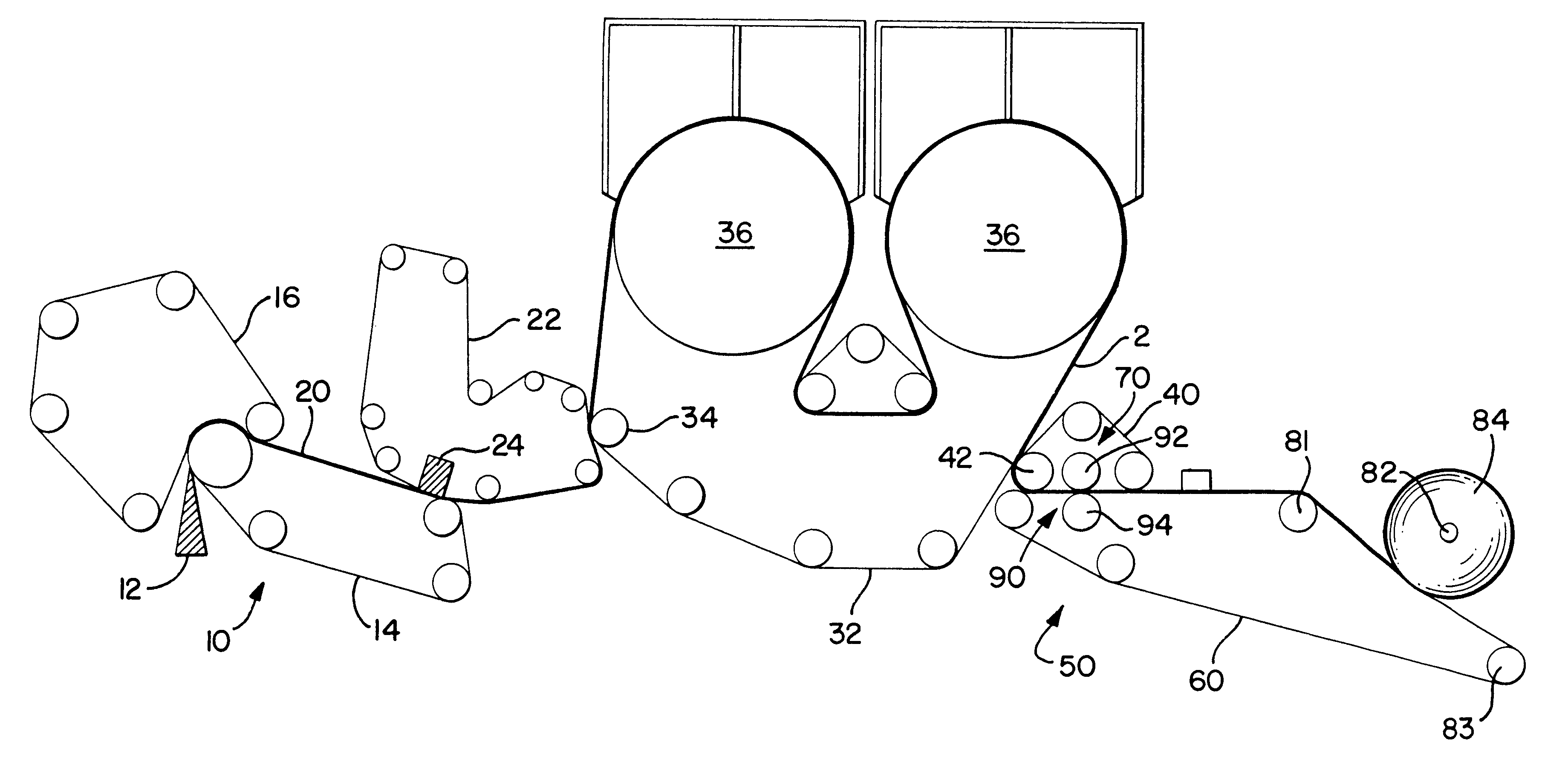

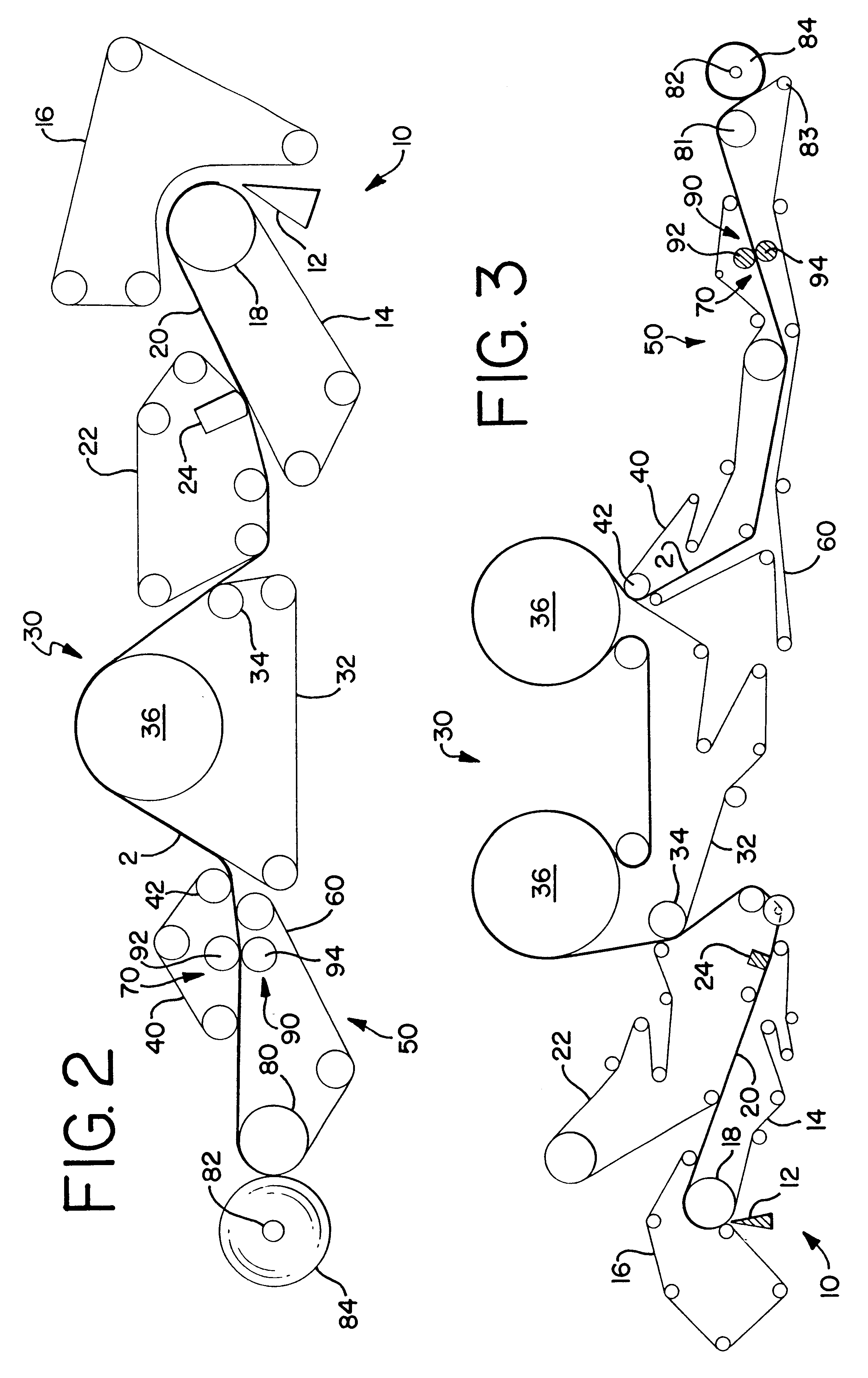

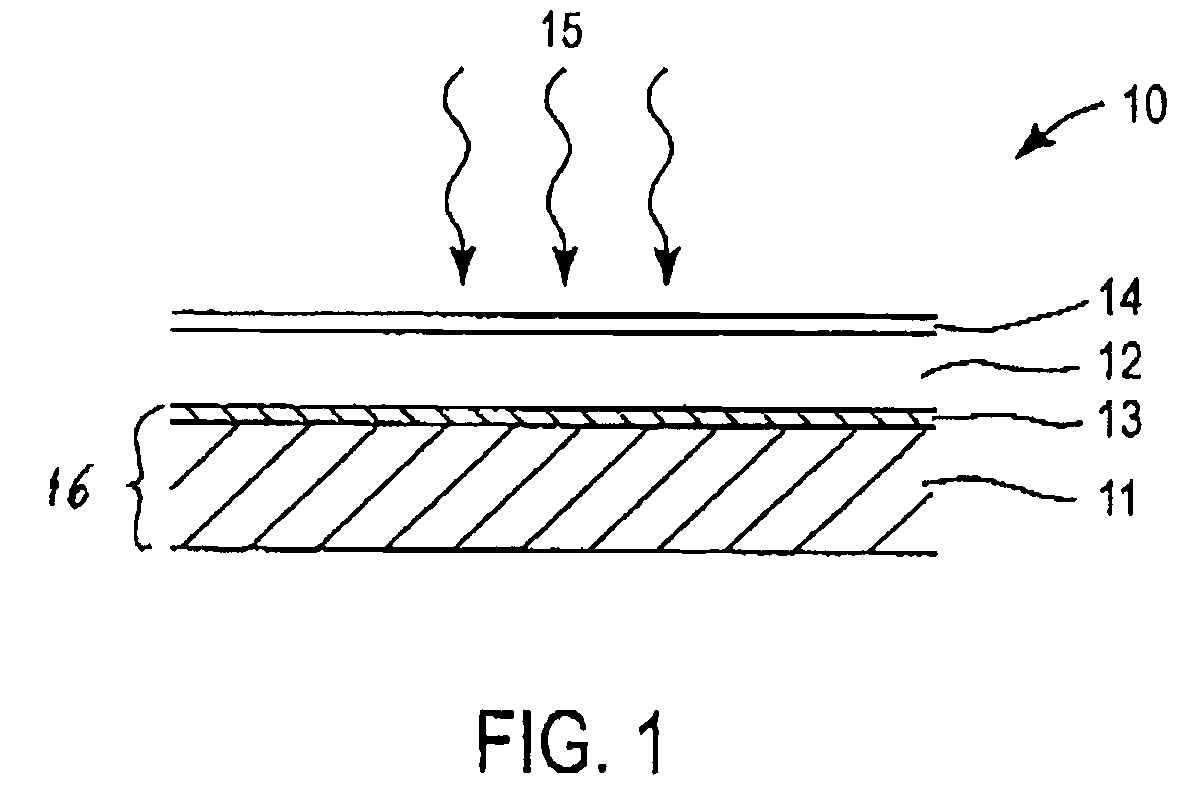

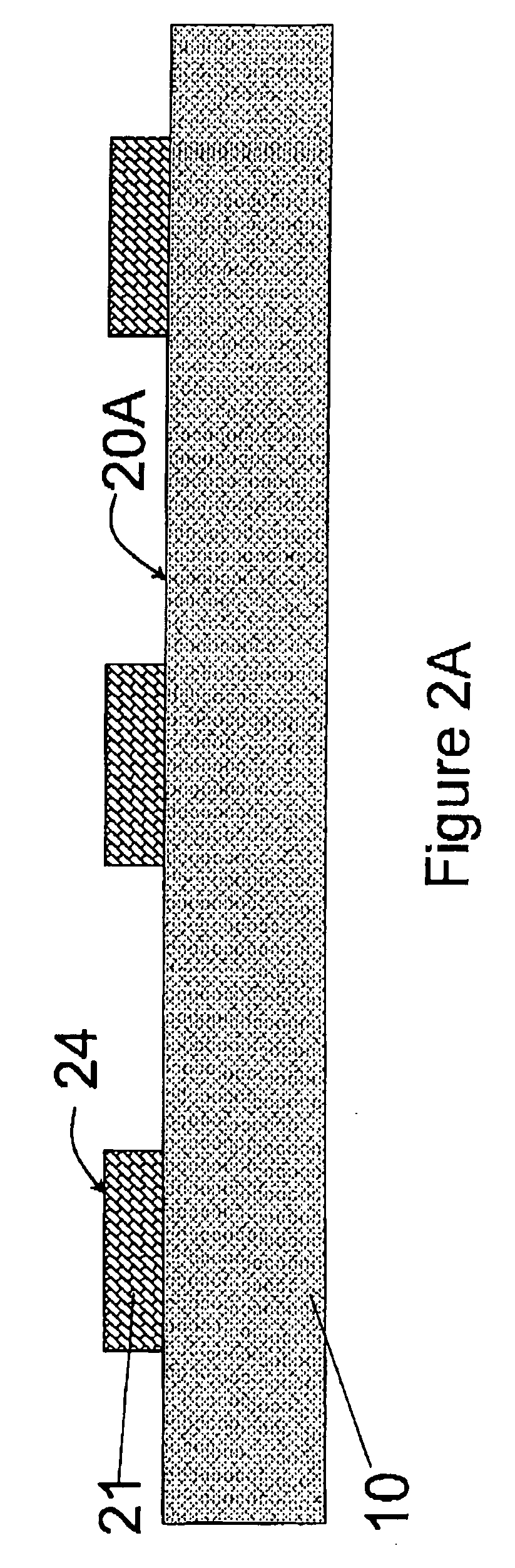

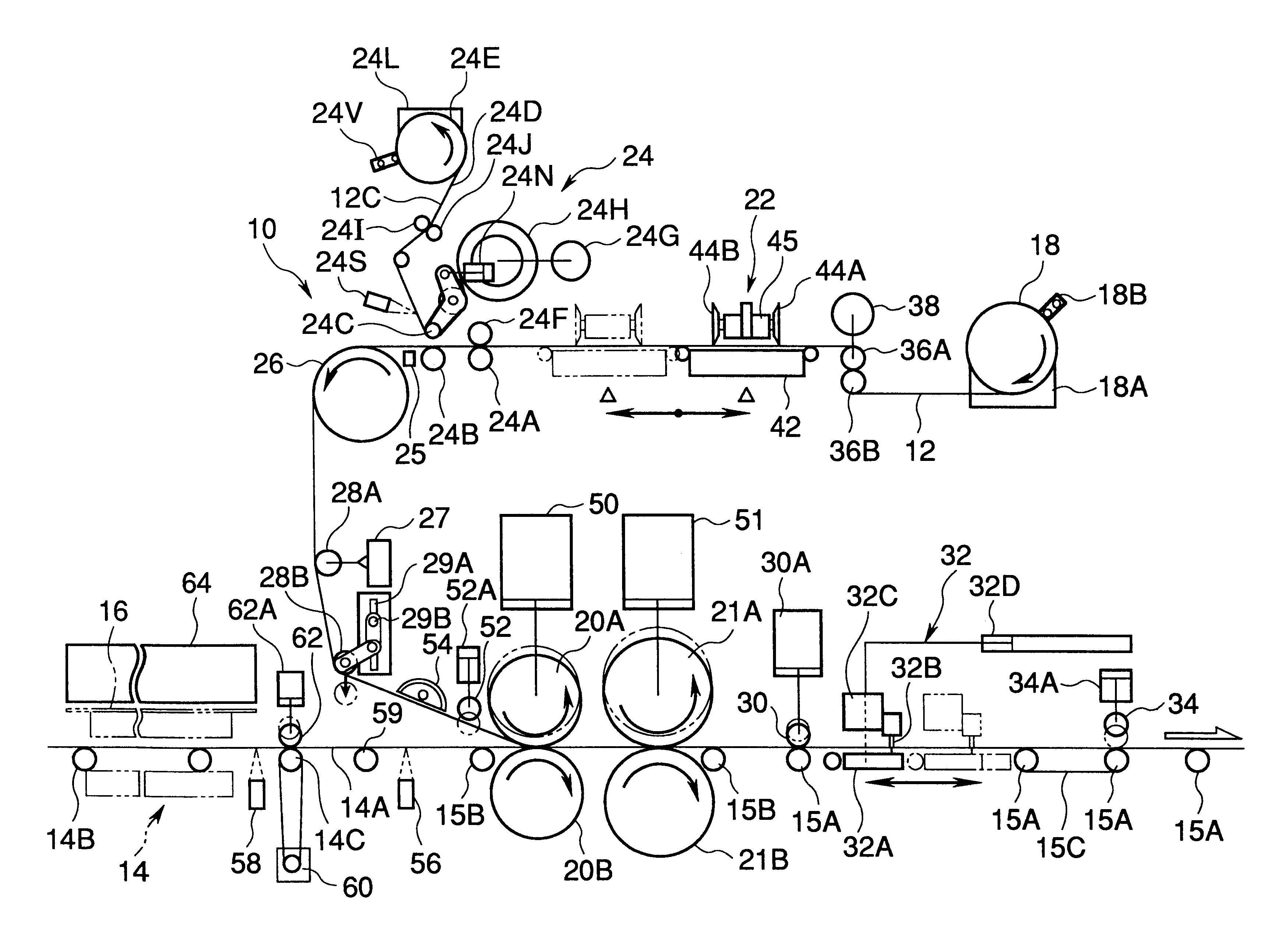

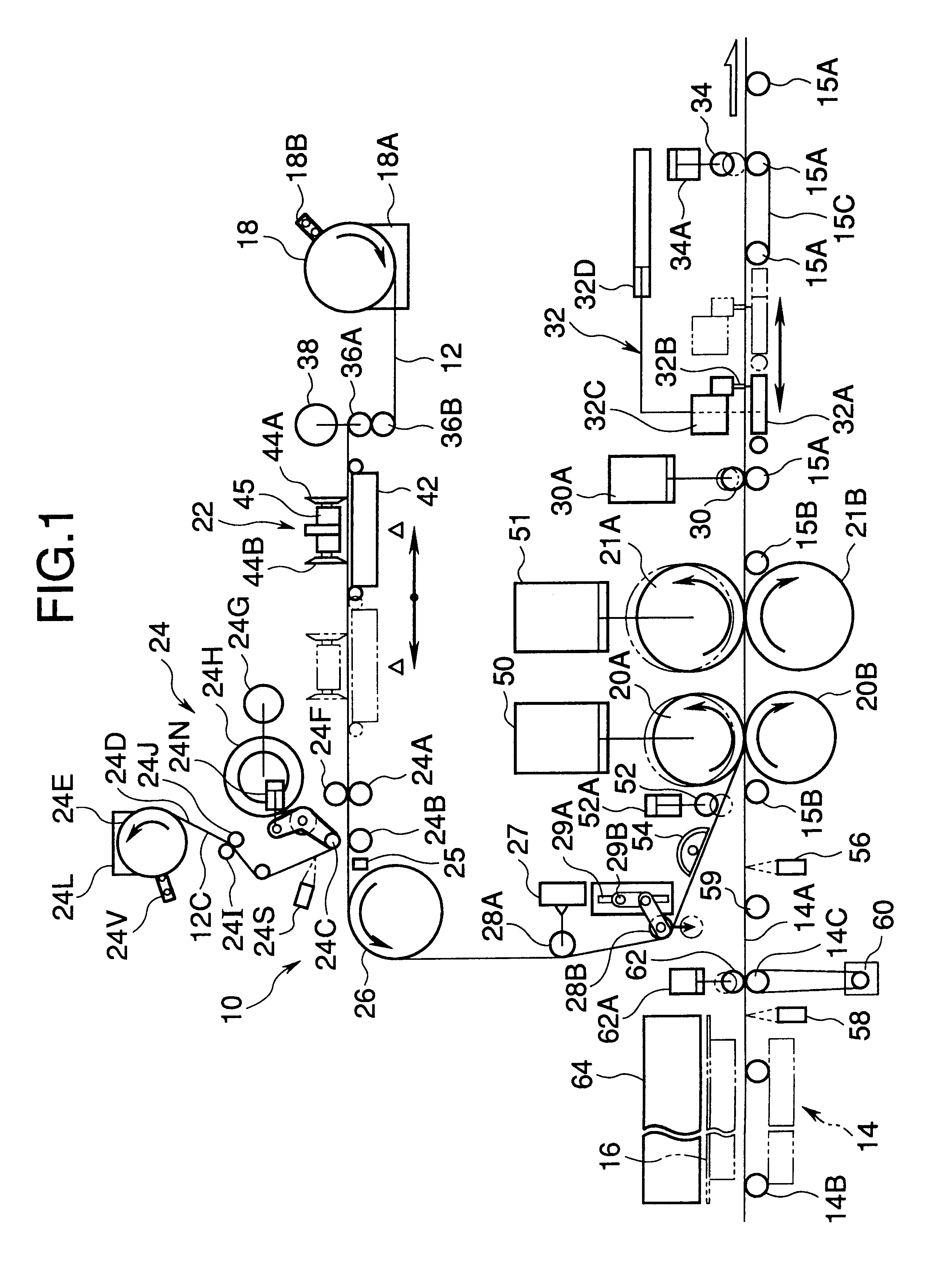

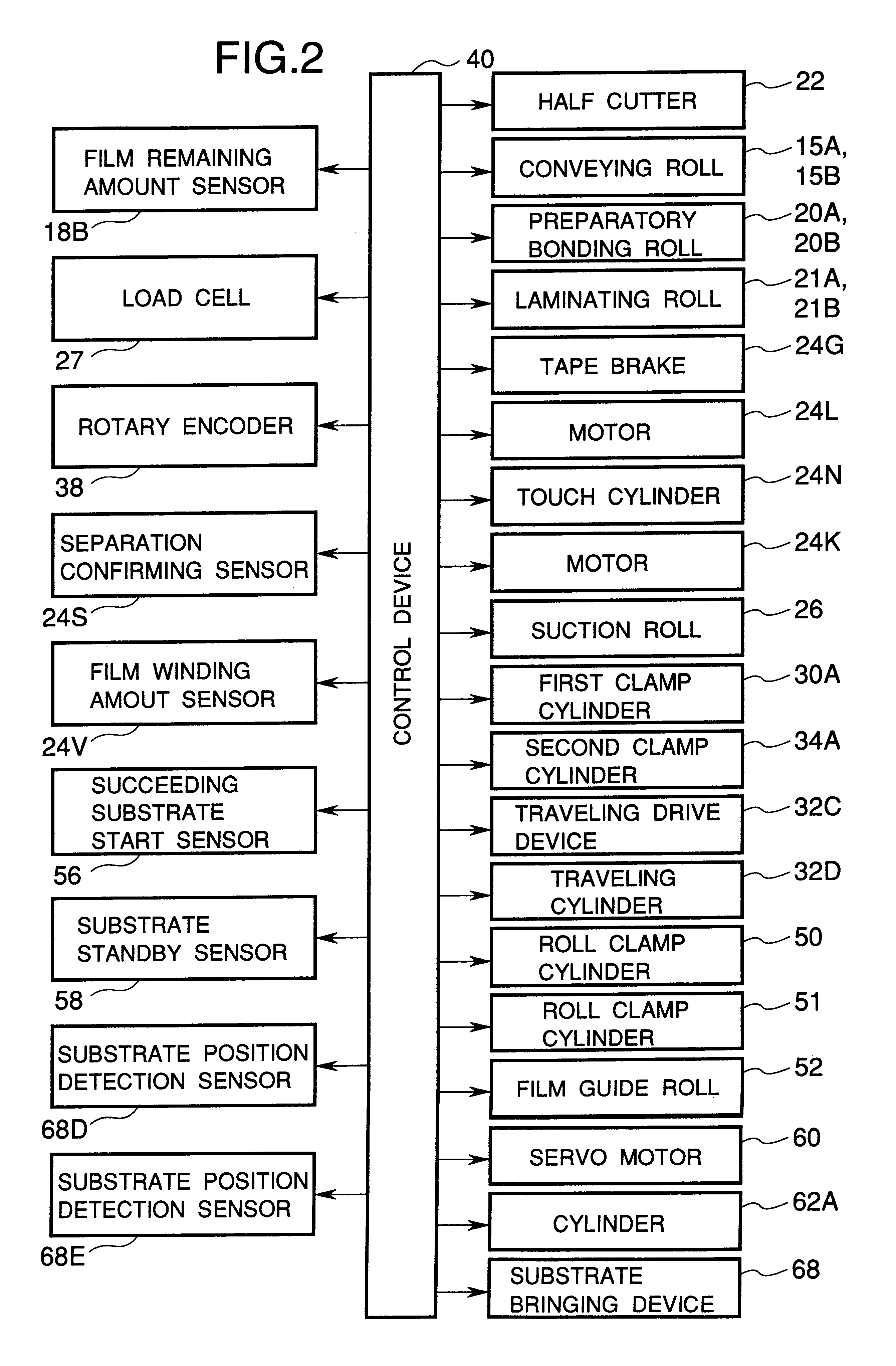

Film applying apparatus

InactiveUS6176286B1Small rangeSecure bondingMechanical working/deformationLamination ancillary operationsSheet filmEngineering

A film applying apparatus 10 is provided with preparatory bonding rolls 20A, 20B and laminating rolls 21A, 21B, and a laminated film 12 wound out from a film roll 18 and a substrate 16 conveyed by a substrate conveying device 14 pass between these rolls and pressure bonding is performed. Diameter of the preparatory bonding rolls 20A, 20B is made smaller than diameter of the laminating rolls 21A, 21B and range of elastic deformable area S1 at the roll surface at grasping starting of the substrate and the laminated film 12 by the preparatory bonding rolls 20A, 20B is made small thereby range of generating, air holding or the like is limited to small.

Owner:SOMAR CORP

Embossing process including discrete and linear embossing elements

An apparatus for producing an embossed product including a first embossing member having a plurality of discrete embossing elements disposed in a first non-random pattern having at least one first single pattern unit. The total area of the distal ends of the discrete embossing elements in the first single pattern unit is less than about 5.0 cm2. The apparatus also includes a second embossing member having a plurality of linear embossing elements disposed in a second non-random pattern having at least one second single pattern unit. The total area of the second distal ends in the second single pattern unit is less than about 10 cm2. The second non-random pattern is coordinated with the first non-random pattern such that when engaged with each other the first single pattern unit and the second single pattern unit make up an embossing pattern single pattern unit.

Owner:PROCTER & GAMBLE CO

Process for making an embossed web

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com