Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132results about How to "Control is possible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

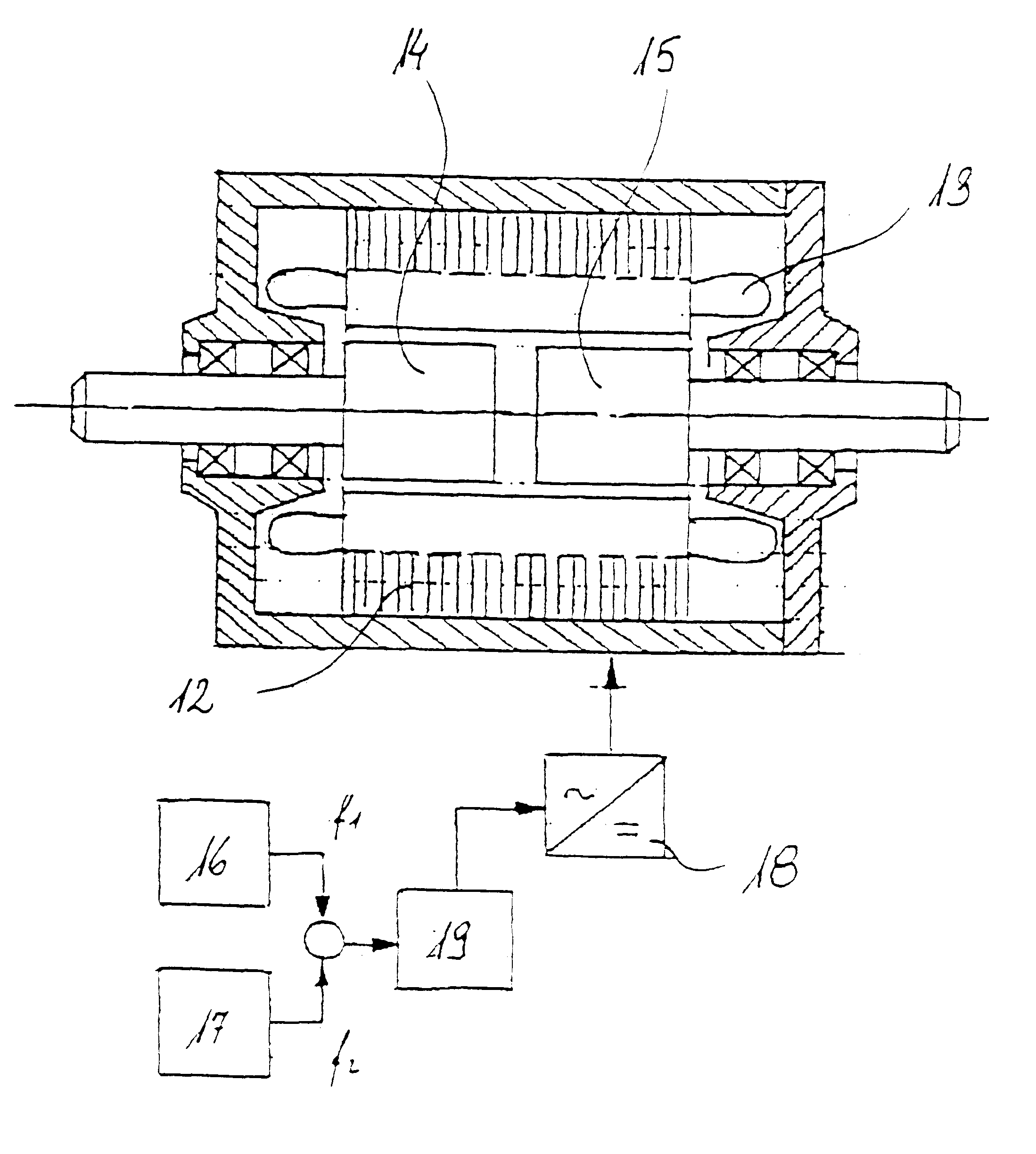

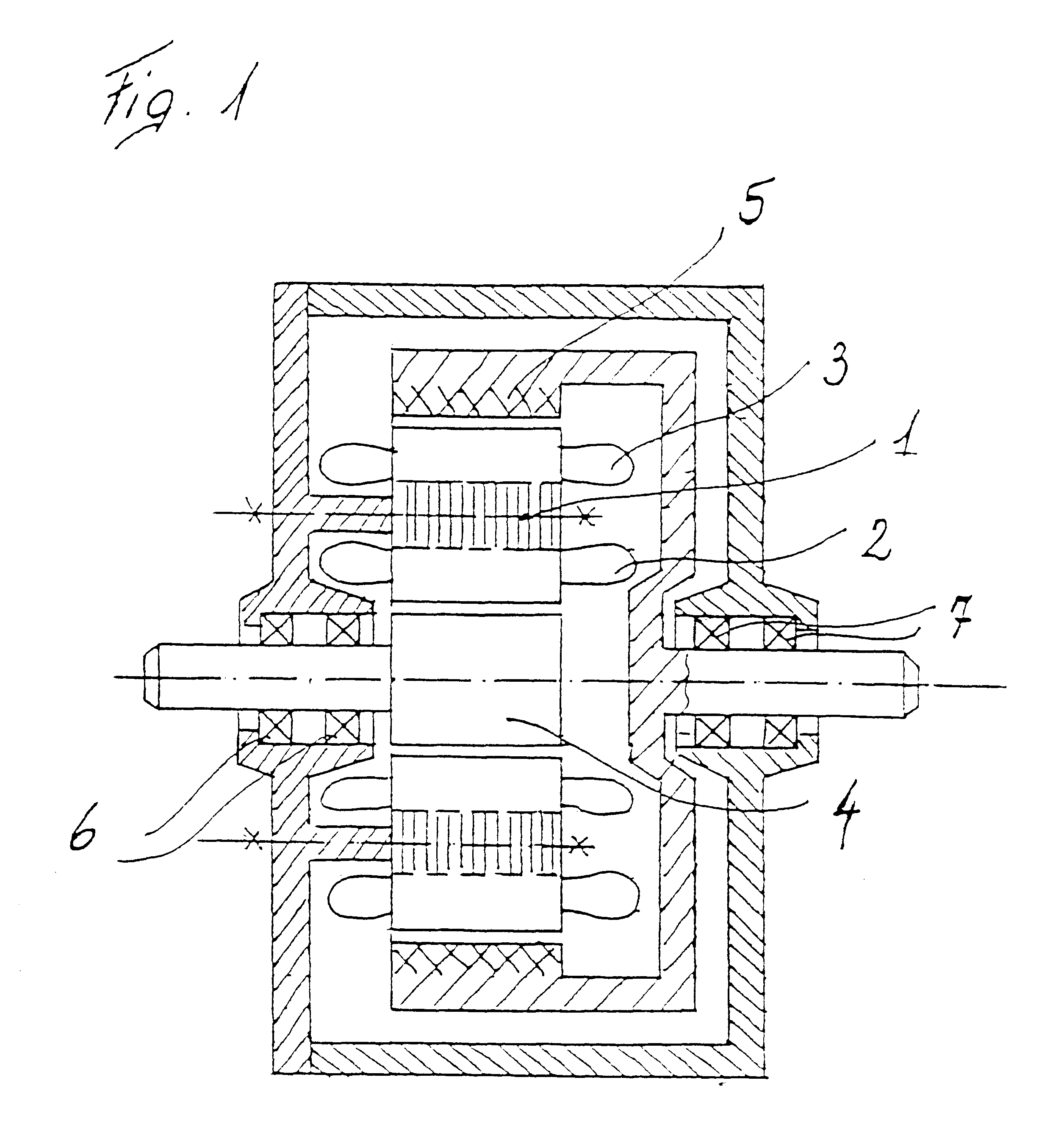

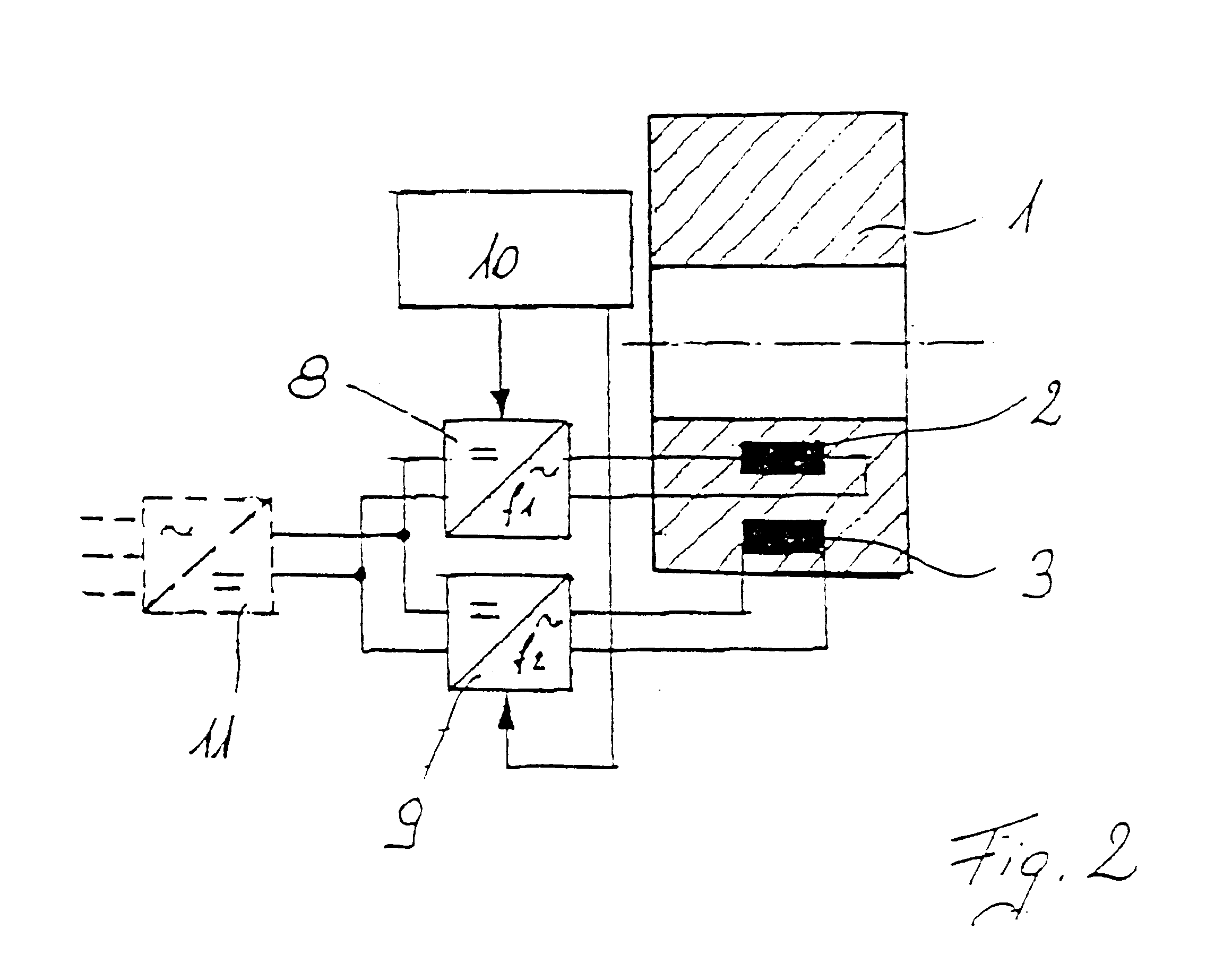

Electric machine

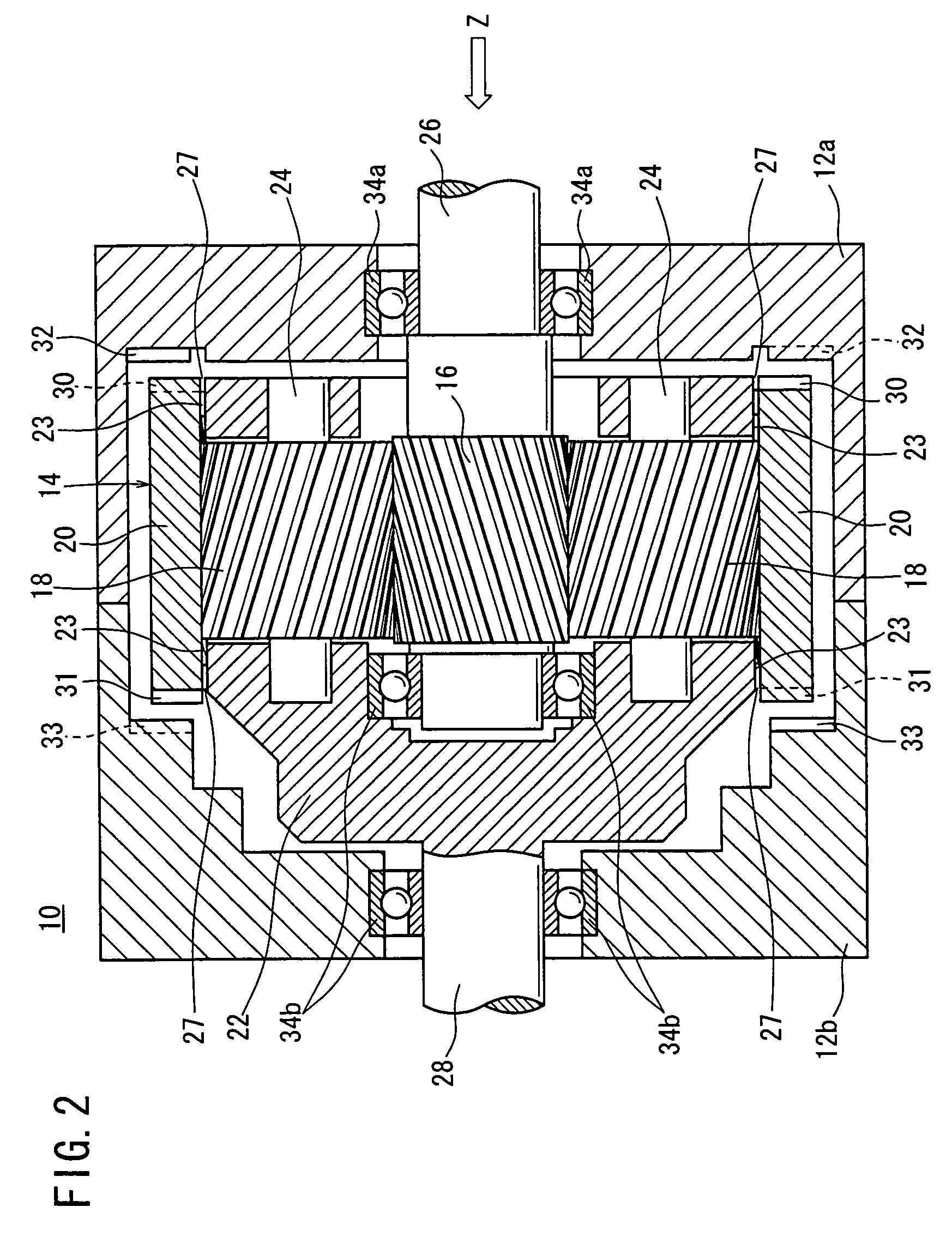

InactiveUS6373160B1Economically manufacturedEconomically usedSpeed controllerSynchronous machine detailsElectric machineEngineering

Electric rotary current machine that includes a casing and a stator fitted within the casing. The stator has at least one stator winding. At least two mechanically separate rotors are rotatably mountable within the casing and have a same axis of rotation. In this way, each rotor has electromagnetic interaction with the stator when the stator is electromagnetically active. The rotor speeds are the same or different. A motor control is arranged to control a supply to at least one of said at least one stator winding by superposition of at least two rotary field components, one for each rotor.

Owner:SCHRODL MANFRED

Self-boring and self-tapping screw for osteosynthesis and compression

ActiveUS20040068261A1Easy to installControl is possibleSuture equipmentsJoint implantsDistal portionBiomedical engineering

The invention provides an osteosynthesis and compression screw that is self-boring and self-tapping for the purpose of coaptation of small bone fragments. The screw comprises: a proximal portion formed by a screw head provided with an outside thread; an intermediate portion having no thread; and a distal portion provided with an outside thread. Wherein: each of the screw head and the distal portion includes at least one groove, firstly extending over the entire axial length of its thread, and secondly being formed through each thread in such a manner to form tapping means; and the terminal zone of the distal portion is provided with preparation means for preparing a housing in the bone fragments for receiving the intermediate and distal portions of the screw.

Owner:SMITH & NEPHEW INC

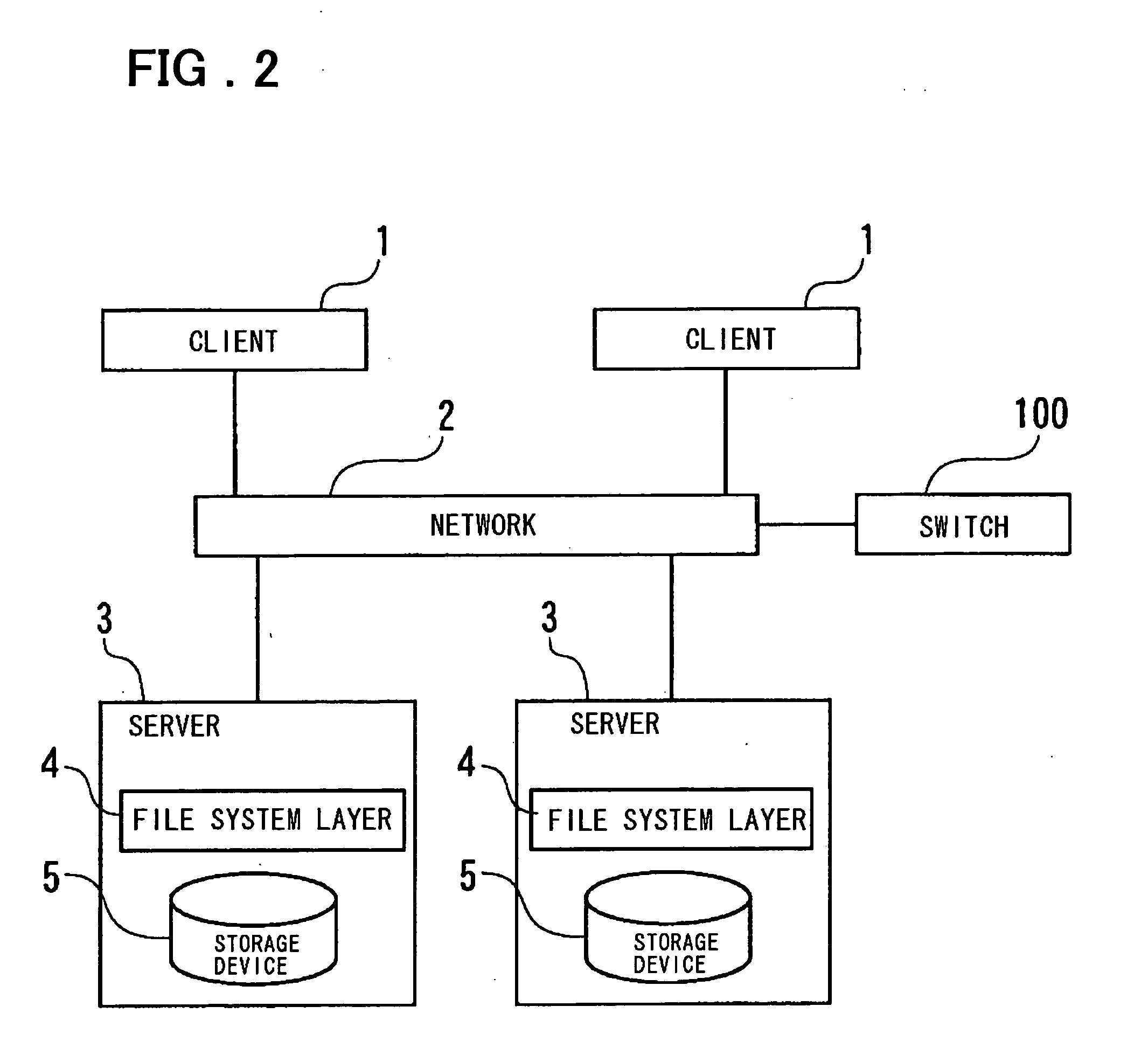

File access service system, switch apparatus, quota management method and program

InactiveUS20060069665A1Reduce usageControl is possibleTransmissionSpecial data processing applicationsClient-sideFile server

Disclosed is a file access service system including at least one client, a plurality of file servers each having a function for limiting amount of use of a respective storage resource, and a switch apparatus inserted between the client and the plurality of file servers. The switch apparatus, based upon a set value of amount of use of a storage resource that has been set in the switch apparatus, sets a set value that limits amount of use of each storage resource in a respective one of the file servers. The switch apparatus surveys amount of use of each storage resource periodically in each of the file servers and, based upon the result of the survey controls the set value of the amount of use of each storage resource in each of the file servers.

Owner:NEC CORP

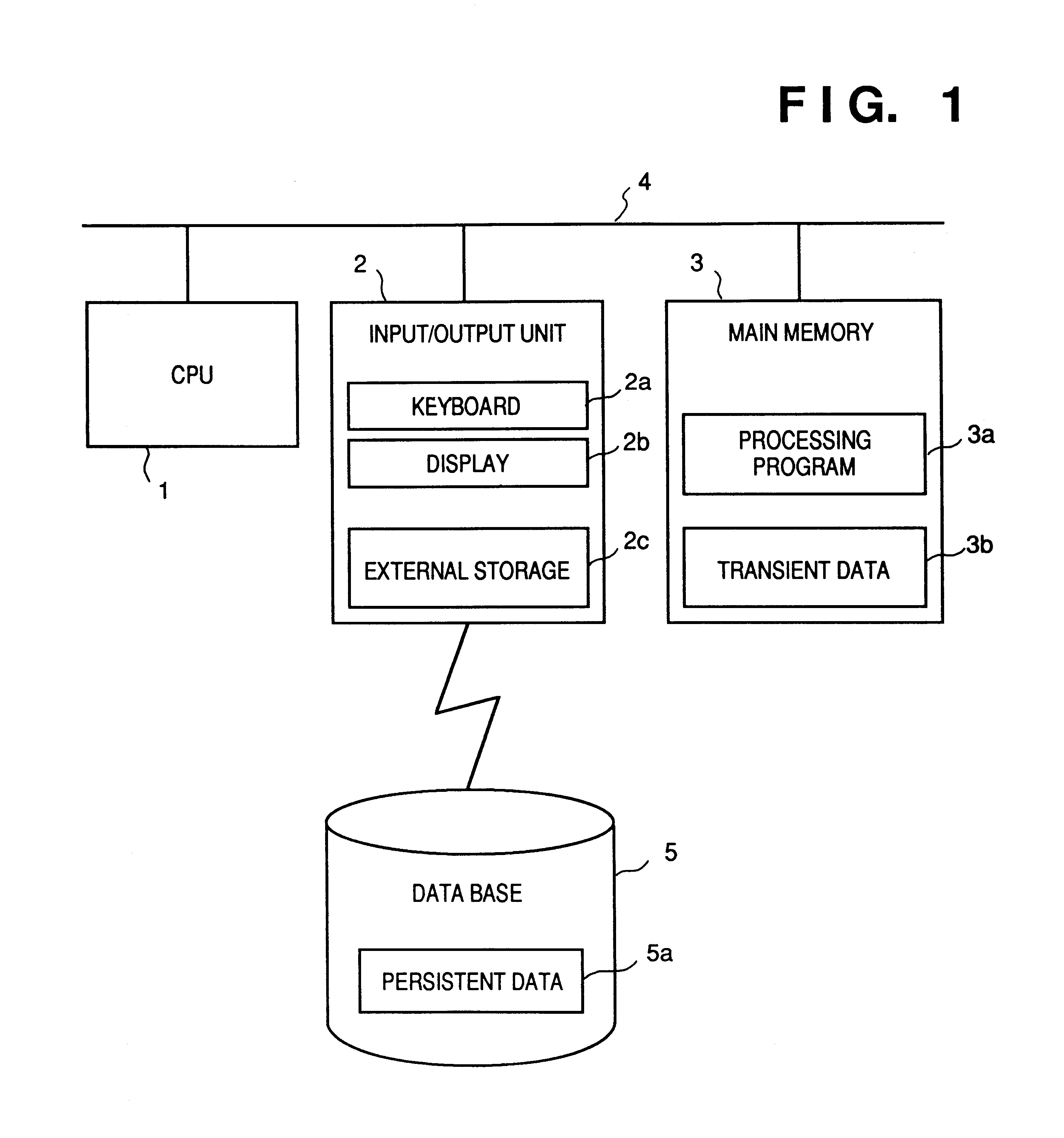

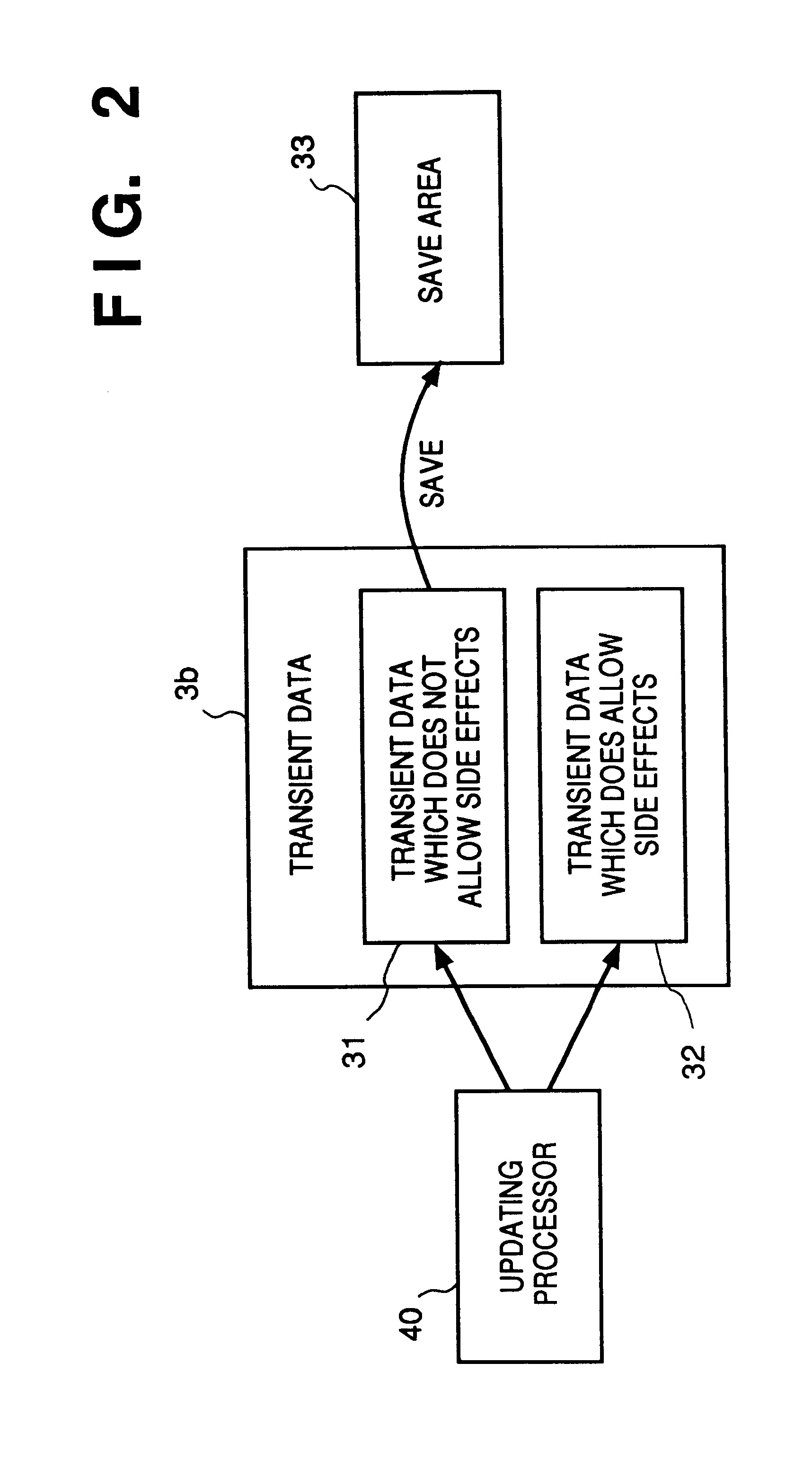

Avoiding unwanted side-effects in the updating of transient data

InactiveUS6920467B1Improve efficiencyControl is possibleData processing applicationsDigital data information retrievalInformation processingData set

An information processing apparatus includes memory for storing a plurality of data; updating means for updating data stored in the memory in a transaction; and setting means for setting, with regard to each of the plurality of data stored in the memory, whether updated data updated by the updating means is to be validated or invalidated at abortion of the transaction, respectively. The setting means performs its setting in advance of the transaction. Saving means saves data, for which updated data has been set to be invalidated at abortion of the transaction by the setting means, except for data for which updated data has been set to be validated at abortion of the transaction by the setting means, before execution of data update by the updating means in the transaction. Control means invalidates the updated data set to be invalidated by restoring the data saved the saving means and validates the updated data set to be validated by maintaining the updated data for which data before execution of updating has not been saved at an end of the transaction if the transaction has been aborted.

Owner:CANON KK

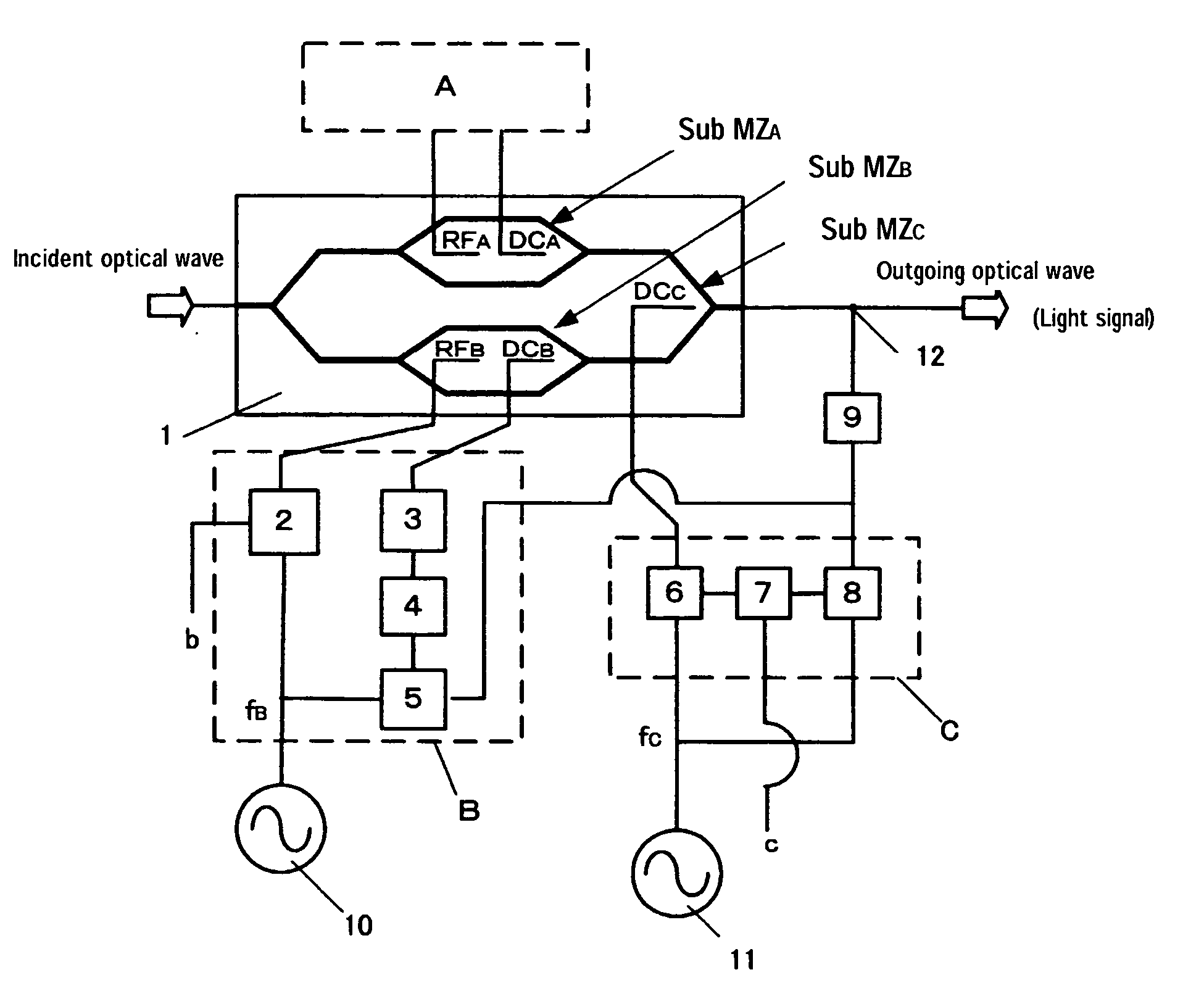

Method and device for controlling bias of optical modulator

InactiveUS20070019968A1Easy to understandControl is possibleElectromagnetic transmittersNon-linear opticsNormal modeEngineering

A method and device for adequately controlling the DC bias of each of the optical modulating sections of an optical modulator even while the optical modulator is operating in normal mode and even with a simple structure. An optical modulator bias controller (B) for controlling the DC bias of each optical modulating section of an optical modulator (1) is characterized by comprising DC bias application means (3) for applying a DC bias to each of the optical modulating sections, a low-frequency signal superimposing circuit (2) for superimposing a low-frequency signal fB with a specific frequency on a modulating signal b applied to each optical modulating section, optical sensing means (9) for sensing a change of the intensity of the light wave passing through the combining section, and bias control means (4) for extracting the change of the intensity of light corresponding to the low-frequency signal from the optical sensing means and controlling the DC bias application means according to the extracted change of the intensity of light.

Owner:SUMITOMO OSAKA CEMENT CO LTD

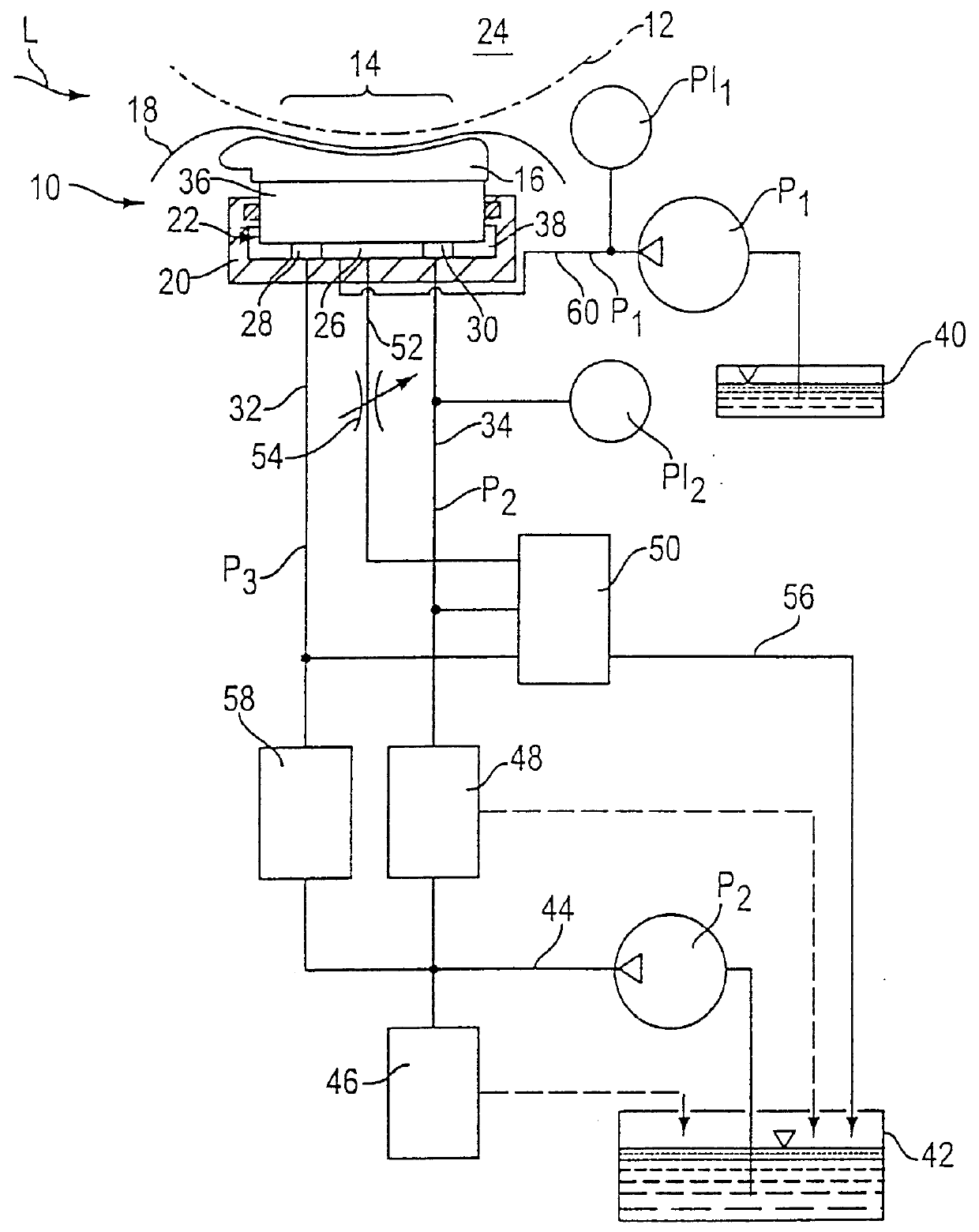

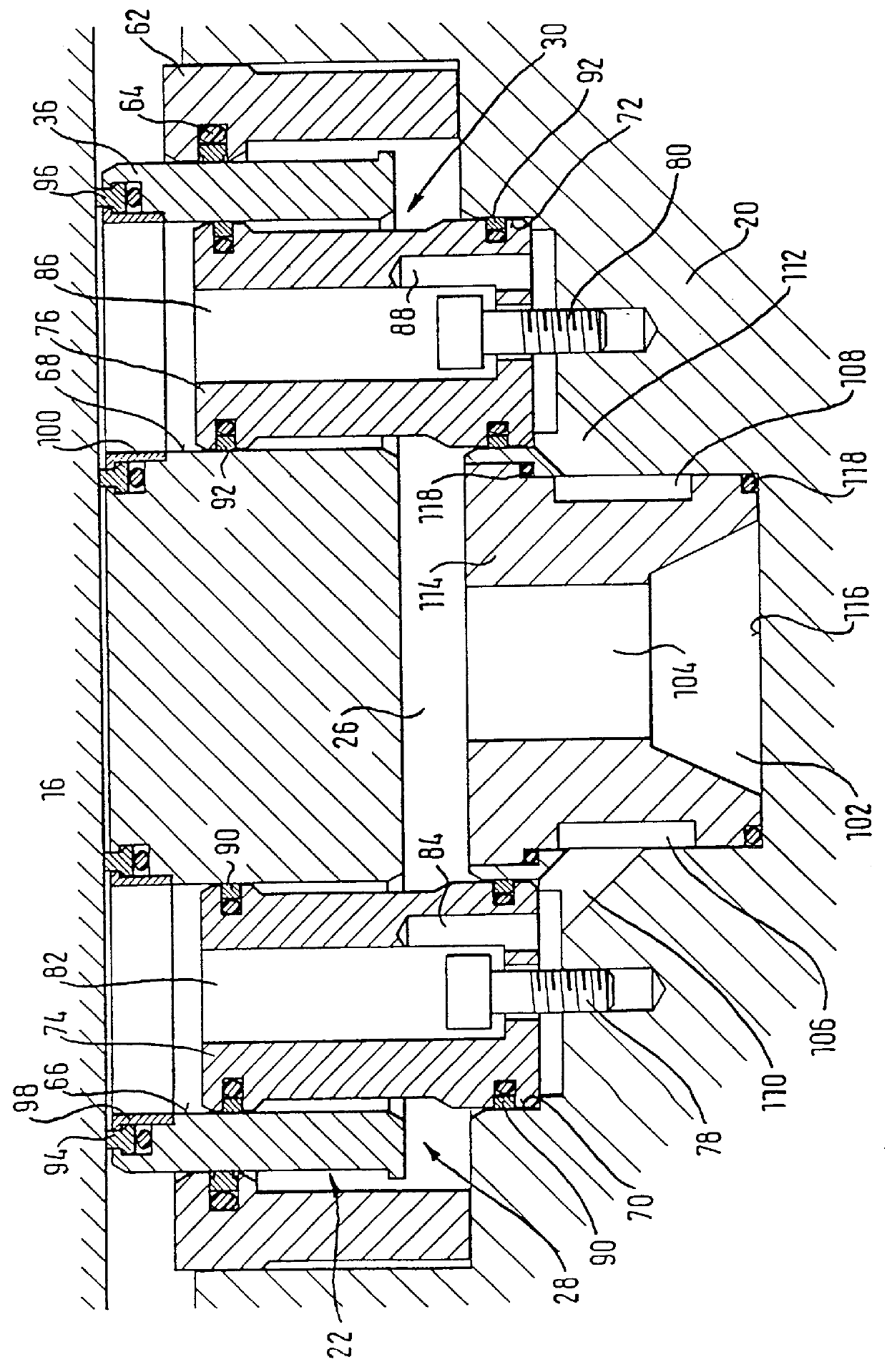

Shoe press unit

InactiveUS6036820ASimple wayControl is possibleNon-fibrous pulp additionNatural cellulose pulp/paperLine tubingEngineering

Shoe press unit and method for treatment of a fibrous pulp web. The shoe press unit includes at least one press shoe, an opposing surface, a flexible press belt guided over the press shoe, and at least one force element composed of a cylinder / piston unit supported on a carrier. The at least one force element presses the press belt against the opposing surface to form a press zone elongated in a web run direction, and the cylinder / piston unit include a pressure chamber having at least one pair of cylinder / piston subunits successively positioned in the web run direction. Pressure fluid lines are coupled to respective ones of the at least one pair of cylinder / piston subunits to separately supply pressure fluid to each cylinder / pressure subunit to impart a tilting moment long a tilt axis substantially perpendicular to the web run direction. The method includes supplying a pressure fluid to a first and second pressure fluid line from a common pressure fluid source at a source pressure, supplying pressure fluid through the first pressure fluid line at a first fluid pressure to a first subunit of the at least one pair of cylinder piston subunits, supplying pressure fluid through the second pressure fluid at a second fluid pressure to a second subunit of the at least one pair of cylinder piston subunits, and maintaining a sum of the first and second fluid pressures to be substantially equal to the source pressure.

Owner:VOITH SULZER PAPIERMASCHEN GMBH

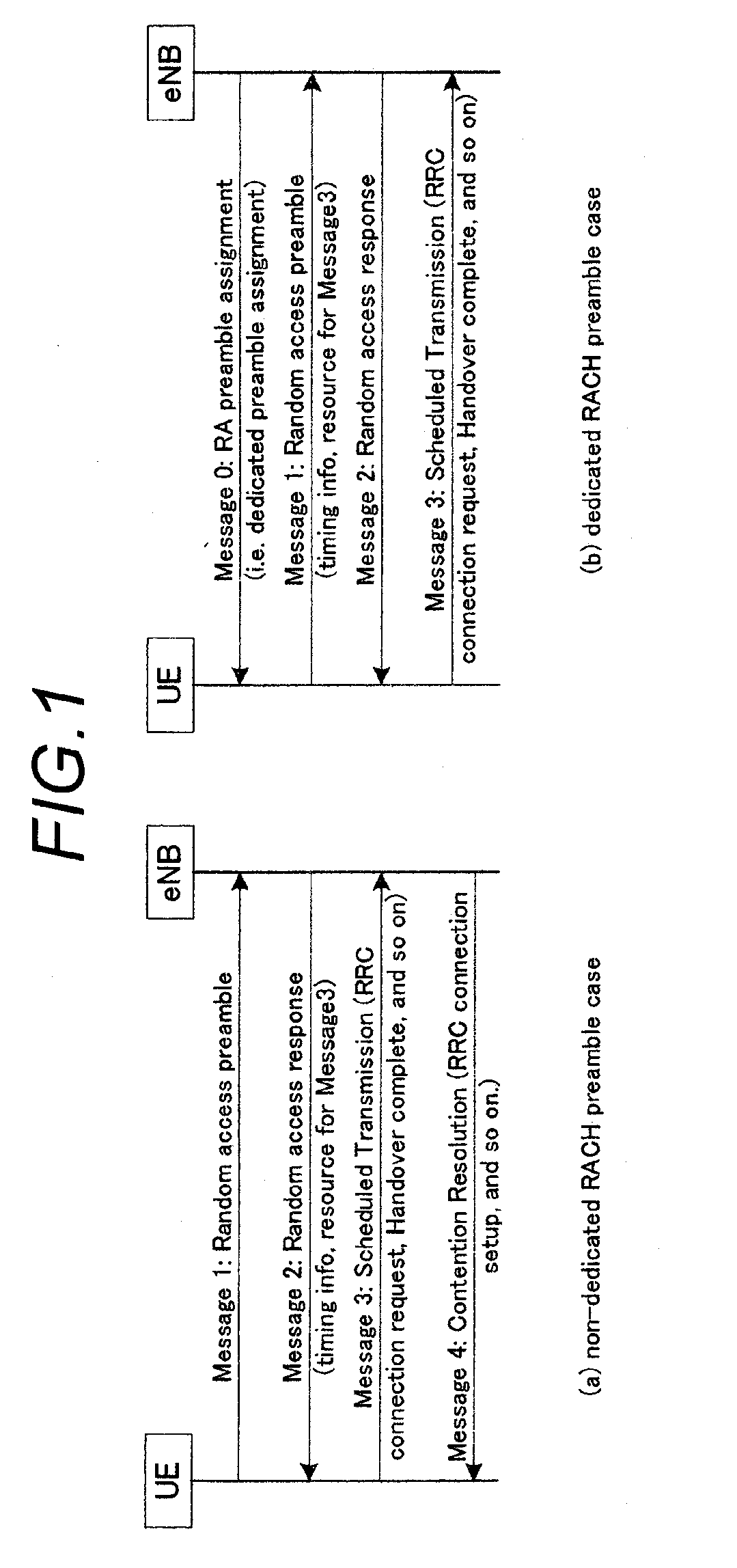

Communication terminal and base station

ActiveUS20100330995A1Control is possibleSynchronisation arrangementNetwork traffic/resource managementDelayed timeReal-time computing

A communication terminal adjusts the transmission timing of data transmitted to a base station so that the base station can receive the data within a predetermined delay time. The communication terminal includes a reception section 701 for receiving priority of MAC control information transmitted from the base station, a priority control section 703 for defining the relationship between the priority of the MAC control information and priority assigned to DRB and SRB, and a transmission message generation section 704 for controlling so as to transmit information having a high priority early in accordance with the relationship between the priorities defined by the priority control section 703. According to the communication terminal, a comparison is made between the priority of the MAC control information and the priority assigned to the DRB and the SRB, whereby it is made possible to control what information is to be transmitted as desired.

Owner:OPTIS WIRELESS TECH LLC

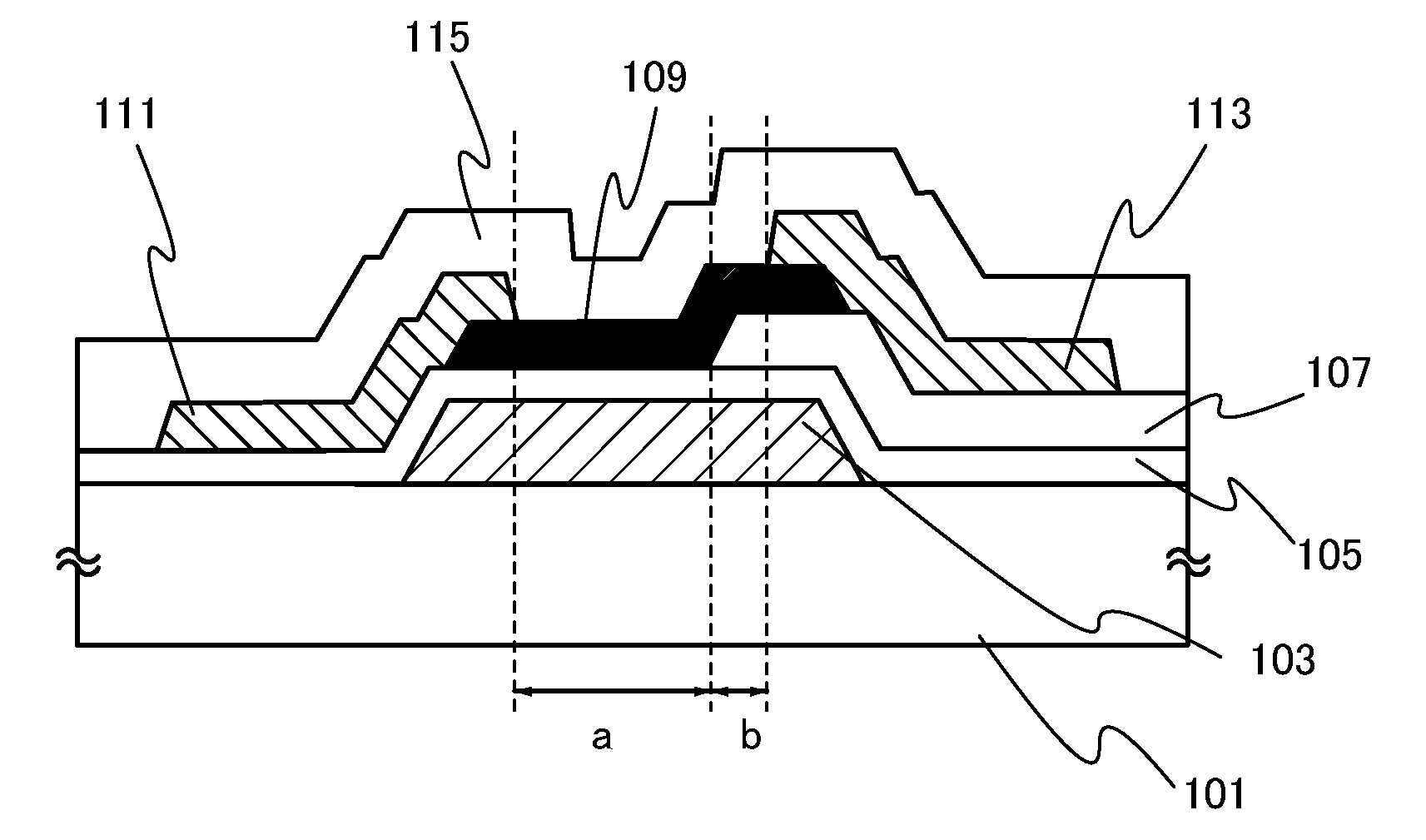

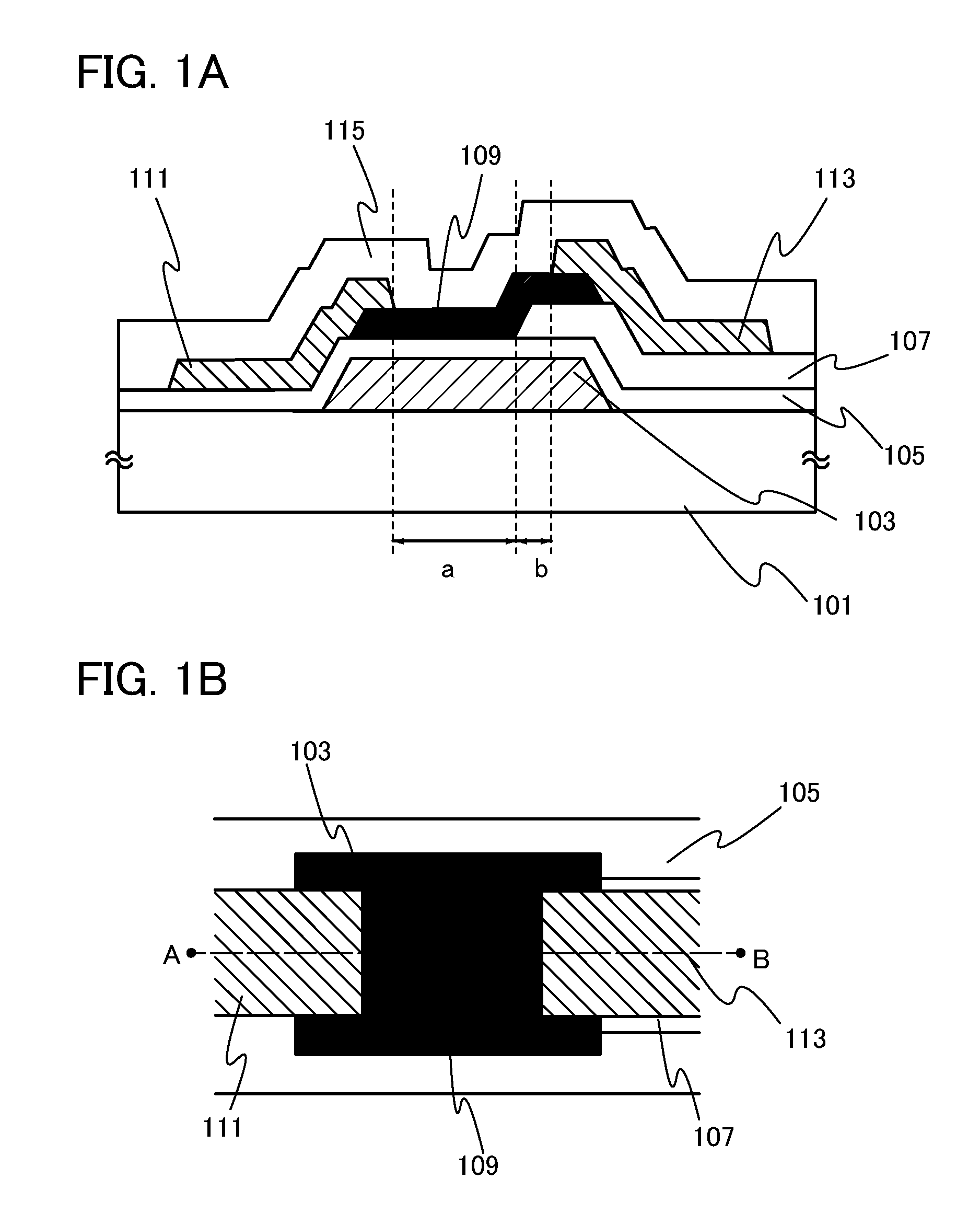

Transistor and semiconductor device

ActiveUS20120193620A1Increase in channel resistanceImprove the immunitySemiconductor devicesCapacitanceSemiconductor

A transistor which withstands a high voltage and controls large electric power can be provided. A transistor is provided which includes a gate electrode, a gate insulating layer over the gate electrode, an oxide semiconductor layer which is over the gate insulating layer and overlaps with the gate electrode, and a source electrode and a drain electrode which are in contact with the oxide semiconductor layer and whose end portions overlap with the gate electrode. The gate insulating layer includes a first region overlapping with the end portion of the drain electrode and a second region adjacent to the first region. The first region has smaller capacitance than the second region.

Owner:SEMICON ENERGY LAB CO LTD

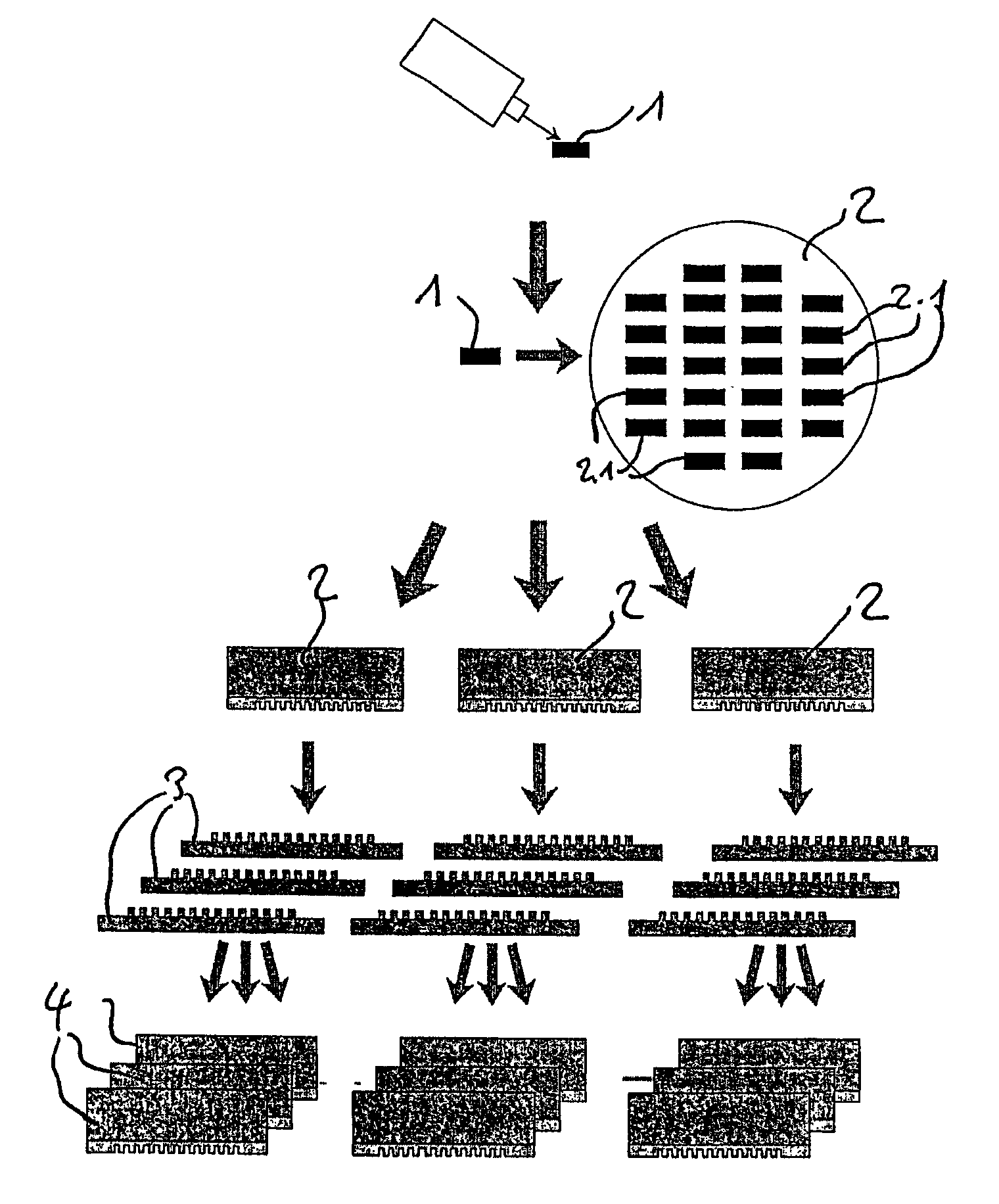

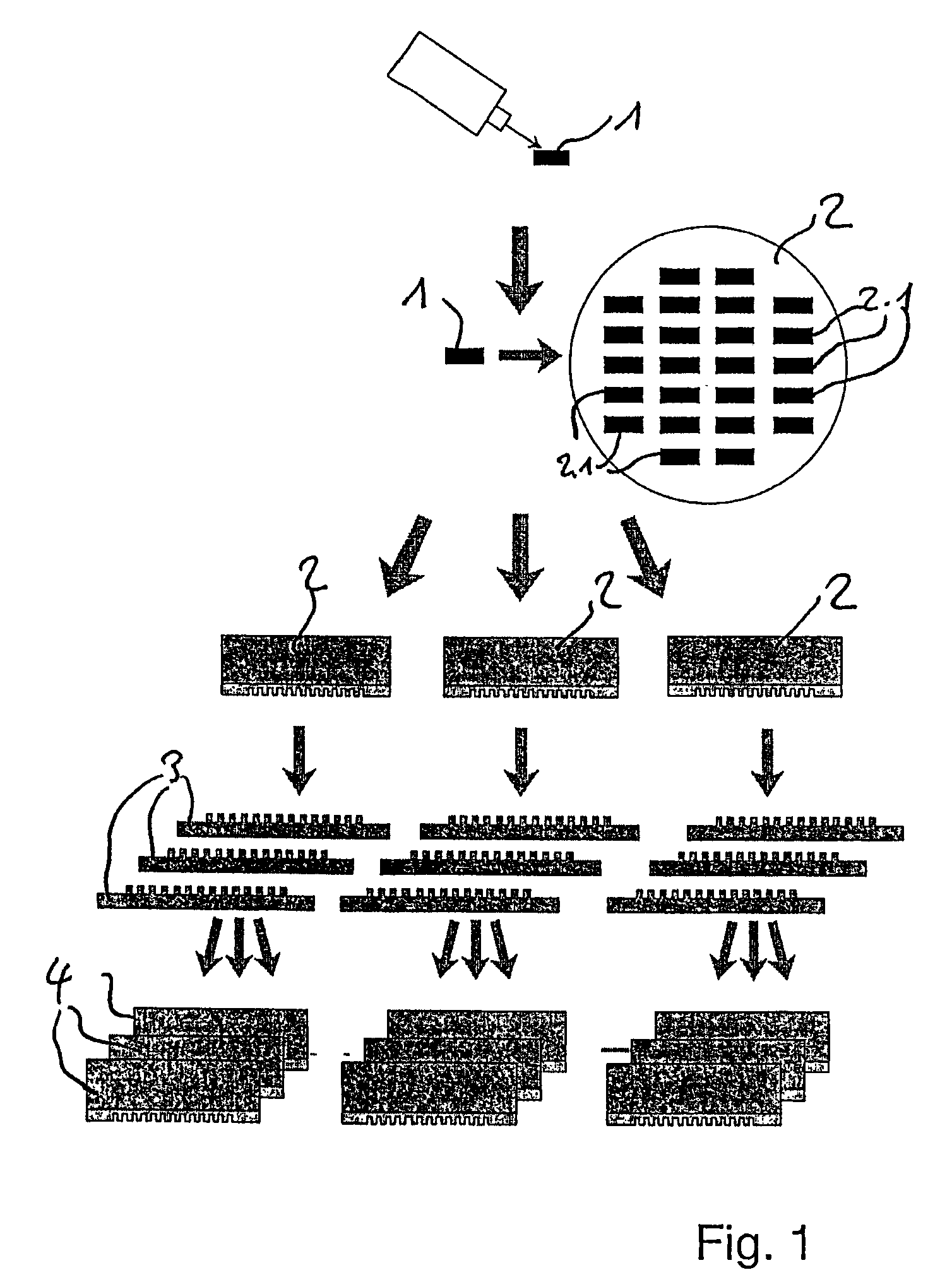

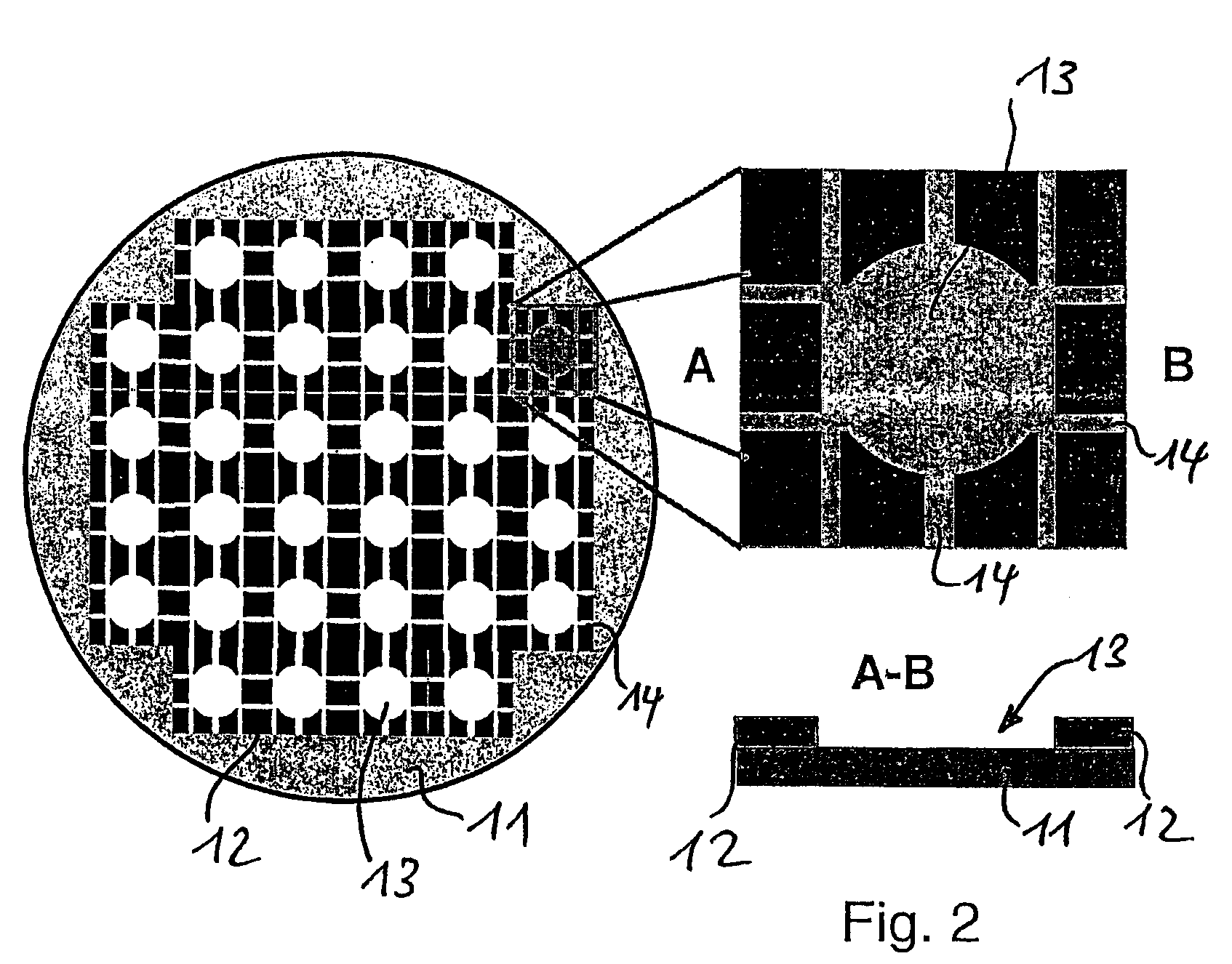

Manufacturing a replication tool, sub-master or replica

ActiveUS20060259546A1Easy to implementLarge scaleNanoinformaticsConfectioneryStructuring elementManufacturing engineering

Owner:AMS SENSORS SINGAPORE PTE LTD

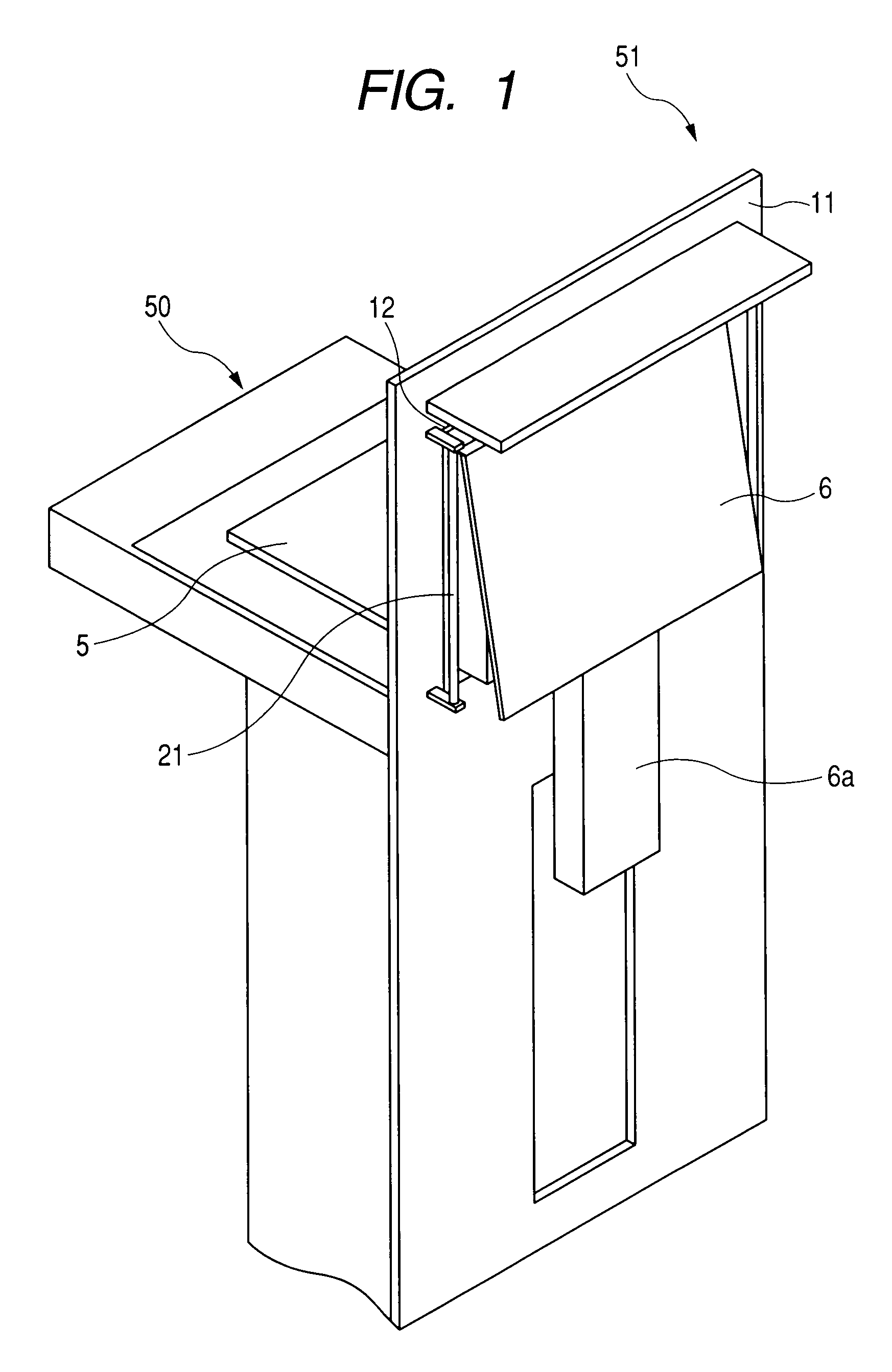

Hydraulic drive system

InactiveUS20140130487A1Control is possibleConvenient and accurateFluid couplingsServomotor componentsHydraulic cylinderHydraulic pump

A hydraulic driving system includes a hydraulic pump, a driving source, a hydraulic cylinder, a closed circuit hydraulic path between the pump and cylinder, a pump-flow-rate control unit controlling a discharge flow rate of the pump, a flow rate control valve between the pump and the cylinder in the fluid path, a directional control unit, a target flow rate setting unit and a control device. The directional control unit allows a flow of fluid from the pump to the cylinder and prohibits a flow of fluid from the cylinder to the pump when fluid is supplied from the pump to the cylinder via the flow rate control valve. The control device controls fluid flow to the cylinder with the flow rate control valve when the target flow rate is within a prescribed range, and with the pump-flow-rate control unit when the target flow rate is greater than the prescribed range.

Owner:KOMATSU LTD

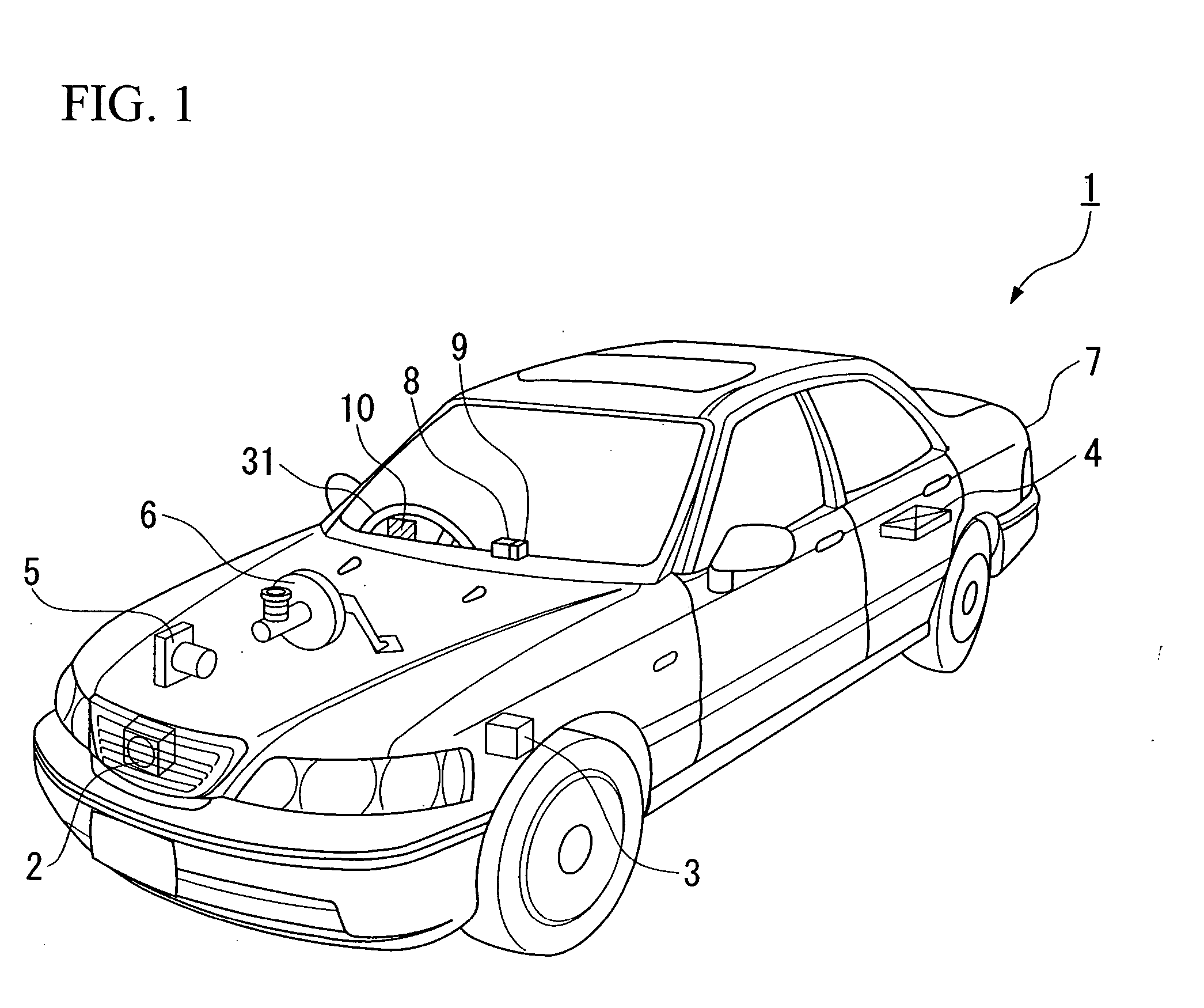

Car-mounted device control system

InactiveUS20040195031A1Avoid changeControl is possibleDigital data processing detailsInstrument arrangements/adaptationsSteering angleSteering wheel

A car-mounted device control system is obtained which can prevent or lessen erroneous operation of operating portions, switches, and the like during rotation of a steering wheel. When a CPU 16 starts up a function switching program from a storage medium 24 on the basis of an inputted touch signal, a present center control unit 10 compares a comparative rotational position R0 read from the storage medium 24 and a rotational position detection signal R from a steering angle sensor 32. As a result, when the rotational position detection signal R exceeds the comparative rotational position R0, a touch signal and a click signal are cancelled. Thus, inadvertent switching of functions due to a body touching a controller 70 while a steering wheel 22 is rotated can be prevented.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

Substrate processing apparatus

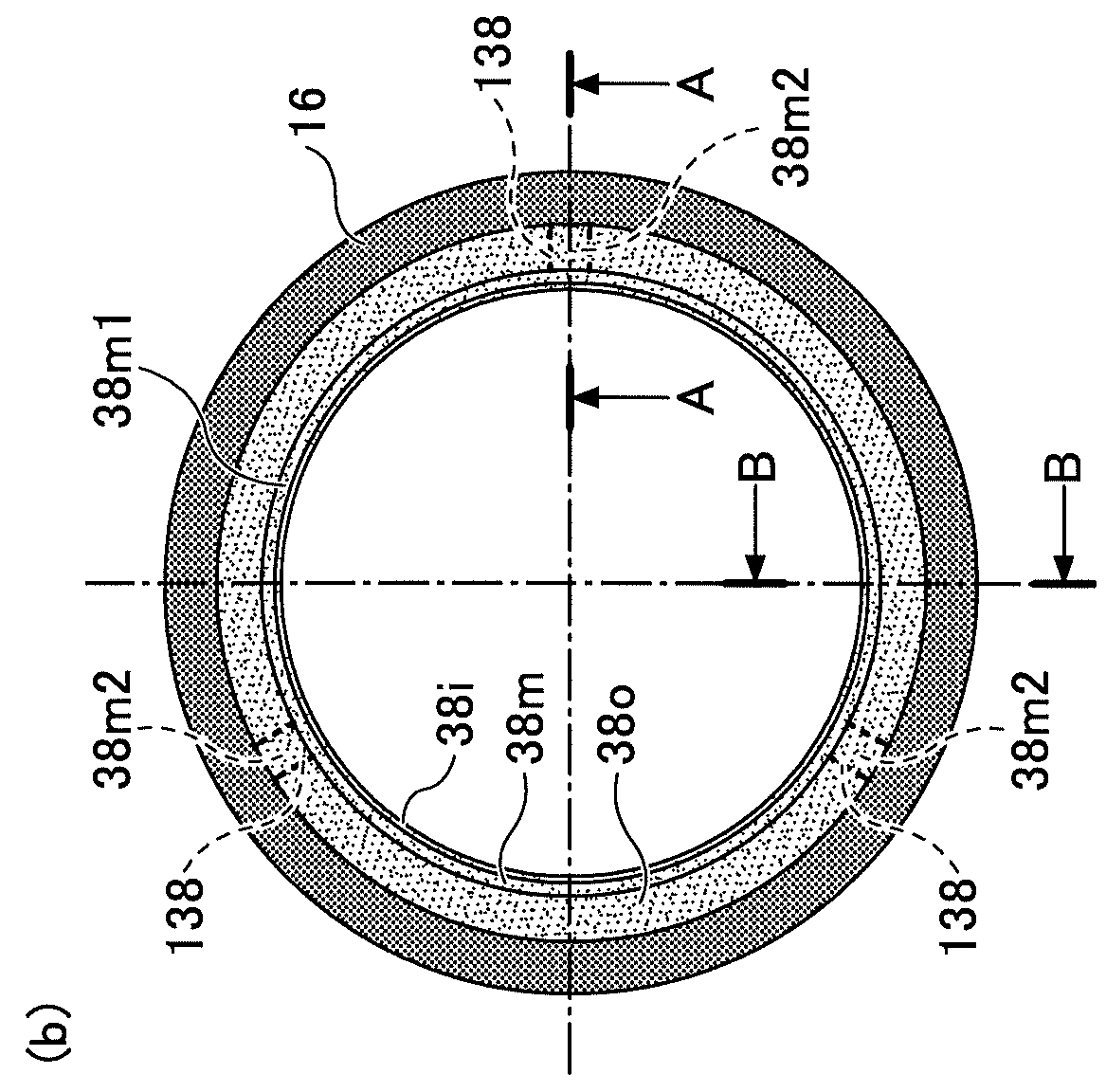

ActiveUS20180277416A1Control is possibleElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A substrate processing apparatus includes a process chamber, a stage that is disposed in the process chamber and on which a substrate is placeable, a moving mechanism, and a focus ring. The focus ring is disposed on the stage and includes an inner focus ring disposed close to the substrate placed on the stage, a middle focus ring that is disposed outside of the inner focus ring and is movable in a vertical direction by the moving mechanism, and an outer focus ring that is disposed outside of the middle focus ring.

Owner:TOKYO ELECTRON LTD

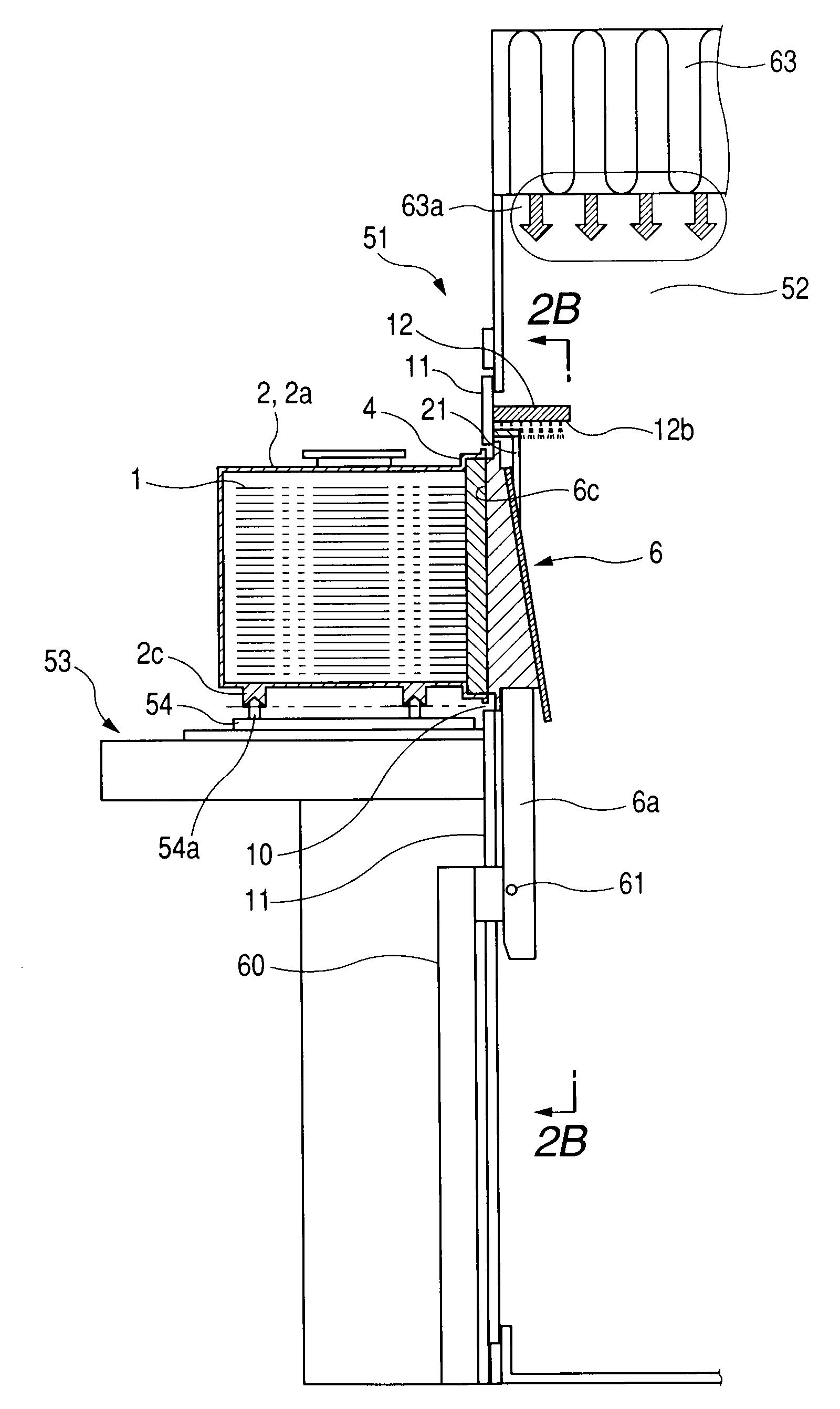

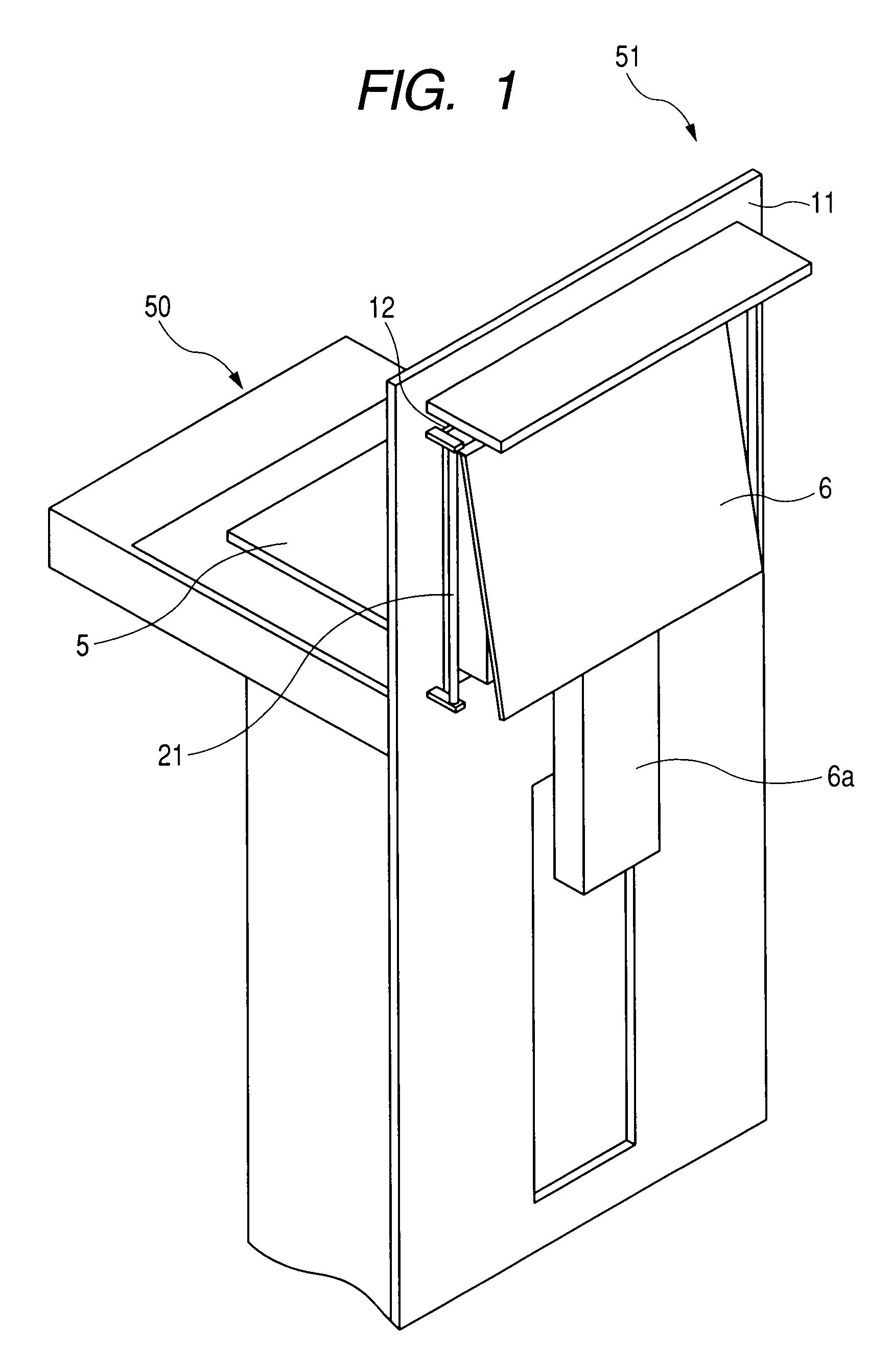

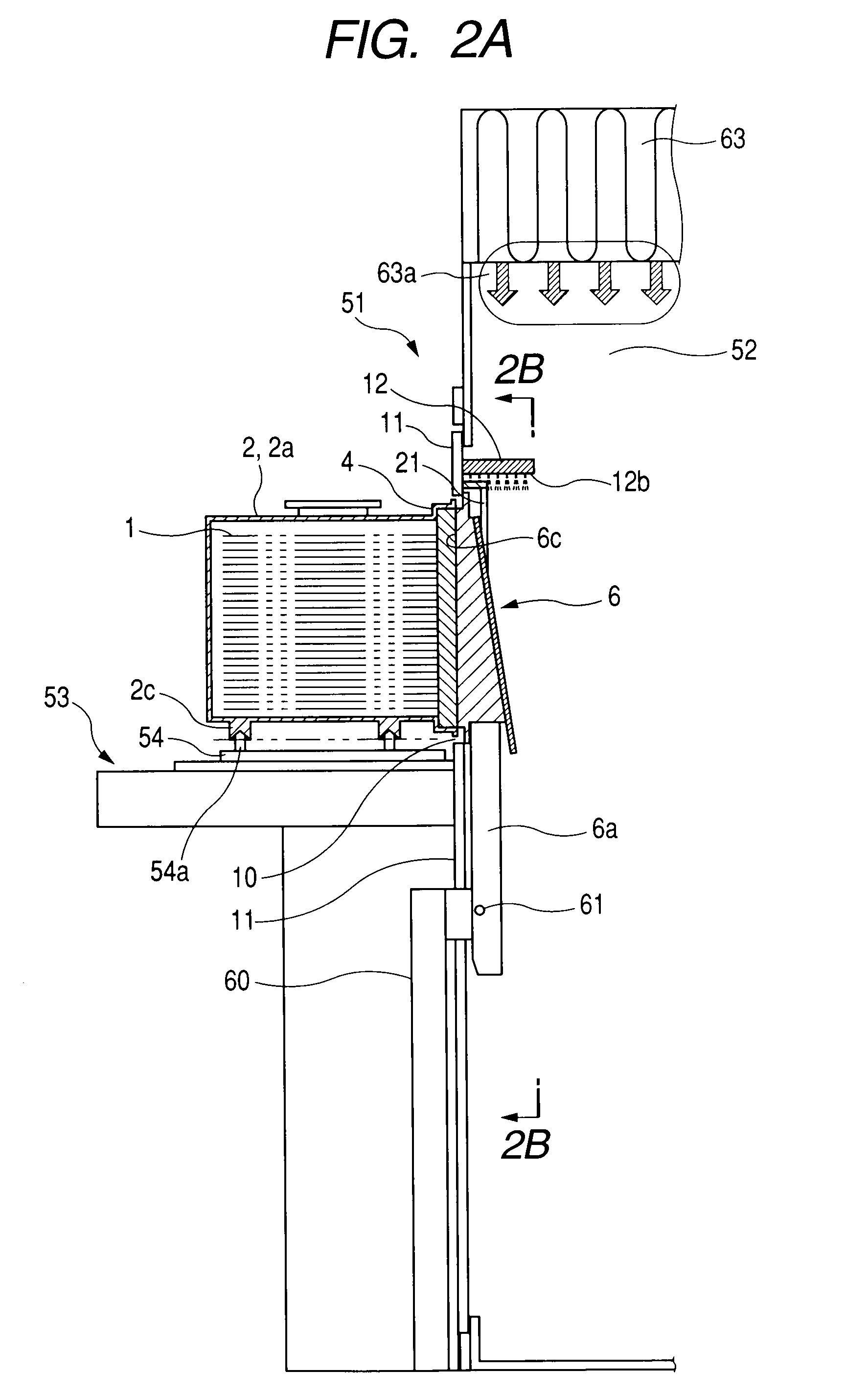

Method of processing an object in a container and lid opening/closing system used in the method

ActiveUS20090035100A1Control is possiblePurge operationLiquid fillingSemiconductor/solid-state device manufacturingGas supplyPartial pressure

A partial pressure of oxidizing gas in an opened state FOUP fixed in a FIMS system is reduced when the FOUP is closed. Purge gas supply nozzles are placed outside of two vertical sides of an opening portion (10) within the FIMS. A curtain nozzle is additionally installed which can form a gas curtain from purge gas above the top side of the opening portion (10). When a pod (2) is closed with a lid (4), a door opening / closing mechanism keeps the lid (4) at a given angle with respect to the flowing direction of curtain gas for a given period of time, and hence purge gas supplied to the gas curtain is additionally put into use for the purging of the interior of the pod by the lid 4.

Owner:TDK CORPARATION

Heat exchanger

InactiveUS20080149317A1Improve system efficiencyImprove efficiencyStationary tubular conduit assembliesHelical coilEngineering

A heat exchanger (10) has an outer housing (16) and a first helical fluid flow path or coil (12) located in the housing (16) defining a plurality of turns and having an inlet (24) and an outlet (22) for entry and exit of fluid into the flow path to be heated or cooled. A second helical coil (14) defining a second fluid flow path is located within the housing (16) adjacent to the first coil. The second coil also has an inlet (24) and outlet (22) for a passage for hot or cold service media. A conductive or non-conductive sheath (18) is disposed between the coils. A transfer medium is disposed in the housing for transfer of heat between the first and second flow paths. A plurality of baffles (20) are located between the outer housing and sheath and disposed between turns of the first coil. A plurality of baffles (21) are also disposed between turns of the second coil (14). By interposing a transfer medium between the two fluid flow paths rather than having one of the fluid flows as the medium itself, control over the cooling or heating of the fluid to be heated or cooled is possible. The fluid being cooled or heated and fluid transfer medium may be at different temperatures. The sheath (18) and baffles (20, 21) help control the transfer of heat and improve the efficiency of the heat exchanger.

Owner:BAKER BENJAMIN PAUL

Information processing method, collaboration server, collaboration system, and storage medium for storing an information processing program

InactiveUS6728756B1Reduced resourceControl is possibleMultiple digital computer combinationsOffice automationInformation processingDocument preparation

To display contents desired by a user in one information terminal onto another information terminal having no special software for collaboration when collaboration is performed through internets. If a customer clicks on a "call button" with a browser, an agent who performs collaboration is assigned. The browser on the customer side shows both a screen starting a default and an object giving instructions to display the next page. The screen on the agent side shows the number of a document to which the customer refers, and the agent can change this number. If the customer selects the object giving instructions to display the next page, a hypertext makeup language (HTML) including that object is generated based on the document number changed by the agent, the HTML being transmitted to the customer side.

Owner:SNAP INC

Enhanced emission from plasmonic coupled emitters for solid state lighting

ActiveUS20160190403A1Improve directionalityControl is possibleSemiconductor devicesPhoton emissionSolid-state lighting

There is provided an illumination device (100) comprising an energy source (102) for exciting a photon emitter; a first wavelength conversion layer (104) and a second wavelength conversion layer (106). At least one of the first and second wavelength conversion layer comprises a periodic plasmonic antenna array comprising a plurality of individual antenna elements (108). The wavelength converting medium in the wavelength conversion layer in which the antenna array is arranged comprises photon emitters arranged in close proximity of the plasmonic antenna array such that at least a portion of photons emitted from the wavelength conversion layer are emitted by a coupled system comprising the photon emitter and the plasmonic antenna array. The plasmonic antenna array is configured to support plasmonic-photonic lattice resonances at a frequency range corresponding to the wavelength range of the photon emitter in the layer in which the plasmonic antenna array is arranged, such that light emitted from the plasmonic antenna array has an anisotropic angle distribution.

Owner:LUMILEDS

Method of processing an object in a container and lid opening/closing system used in the method

ActiveUS8302637B2Control is possiblePurge operationLiquid fillingSemiconductor/solid-state device manufacturingEngineeringProduct gas

A partial pressure of oxidizing gas in an opened state FOUP fixed in a FIMS system is reduced when the FOUP is closed. Purge gas supply nozzles are placed outside of two vertical sides of an opening portion (10) within the FIMS. A curtain nozzle is additionally installed which can form a gas curtain from purge gas above the top side of the opening portion (10). When a pod (2) is closed with a lid (4), a door opening / closing mechanism keeps the lid (4) at a given angle with respect to the flowing direction of curtain gas for a given period of time, and hence purge gas supplied to the gas curtain is additionally put into use for the purging of the interior of the pod by the lid 4.

Owner:TDK CORPARATION

Method and apparatus for managing temperature of light emitting element, and lighting apparatus

InactiveUS20050057184A1Avoid problemsSimple circuit configurationElectroluminescent light sourcesSemiconductor devicesTemperature controlEffect light

The present invention aims at providing a lighting apparatus which is simple in configuration and which is capable of providing a stable light quantity from a light source constituted by an LED or the like. In the present invention, attention is paid to the fact that an applied voltage to an LED changes in correspondence to a temperature of the LED, and hence a temperature control device constituted by a Peltier element or the like is operated in correspondence to the quantity of change in applied voltage to the LED.

Owner:TDK CORPARATION

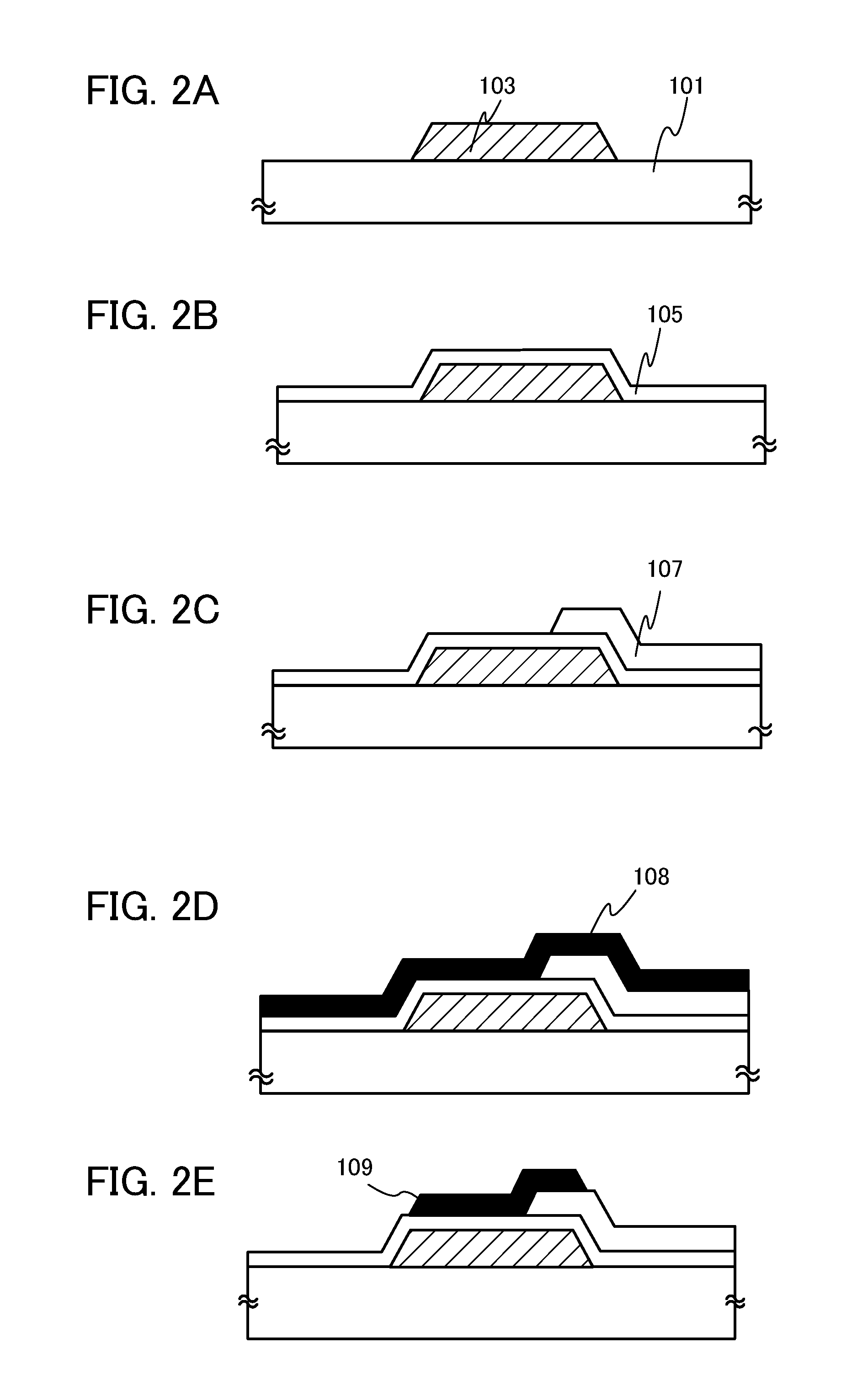

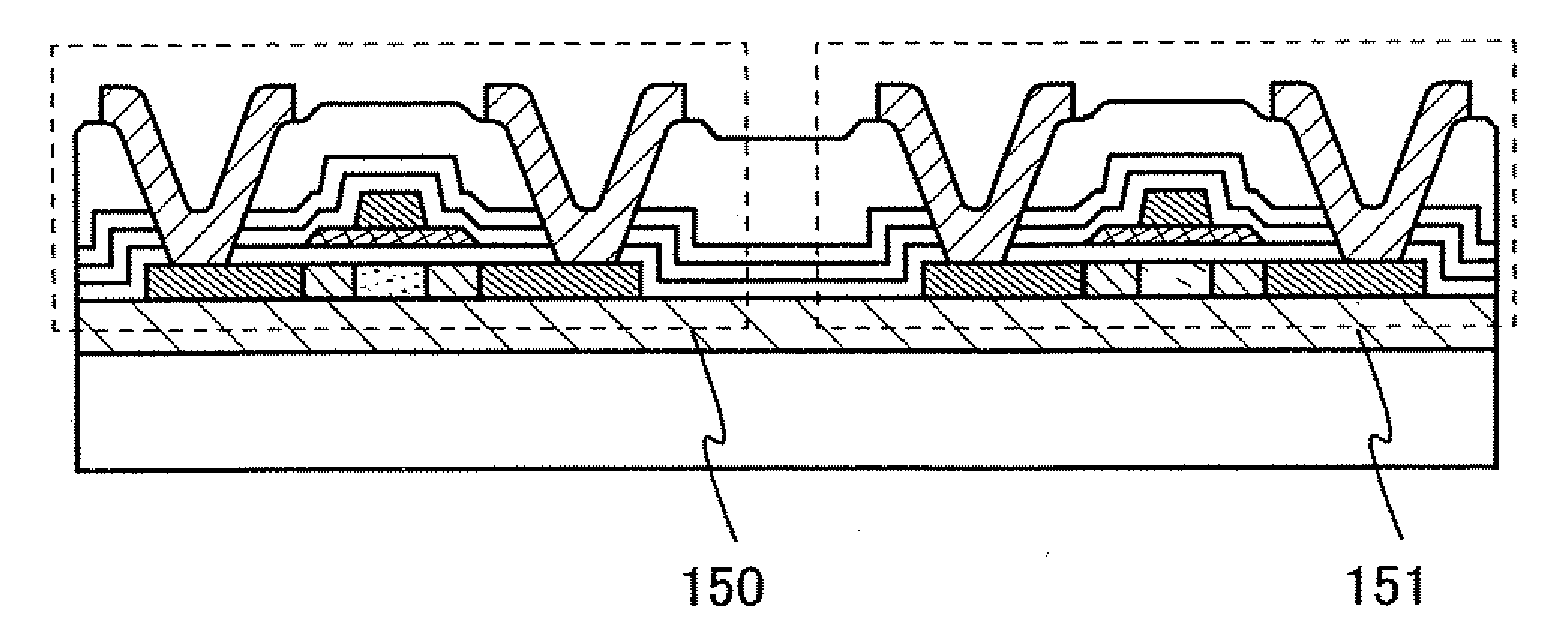

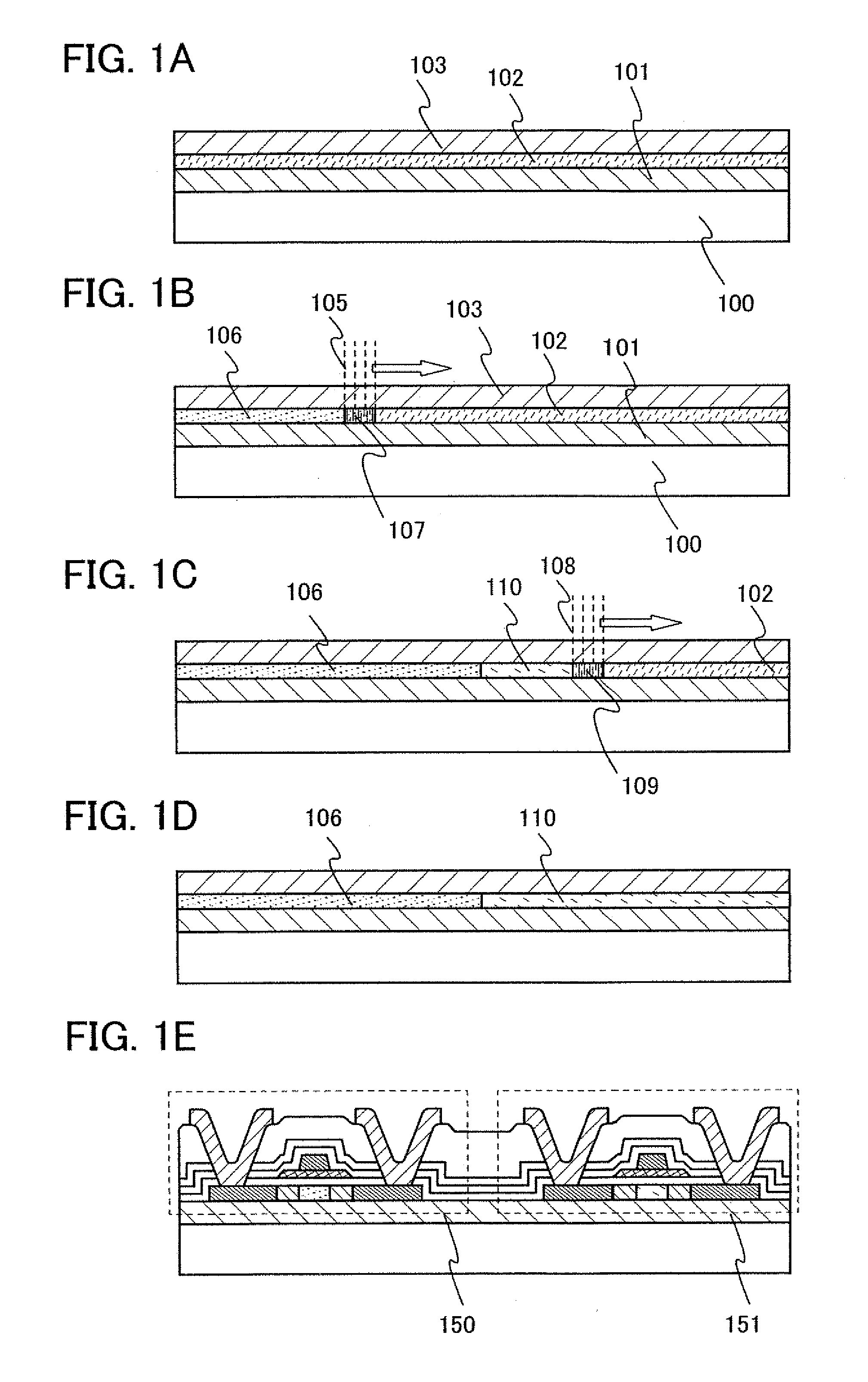

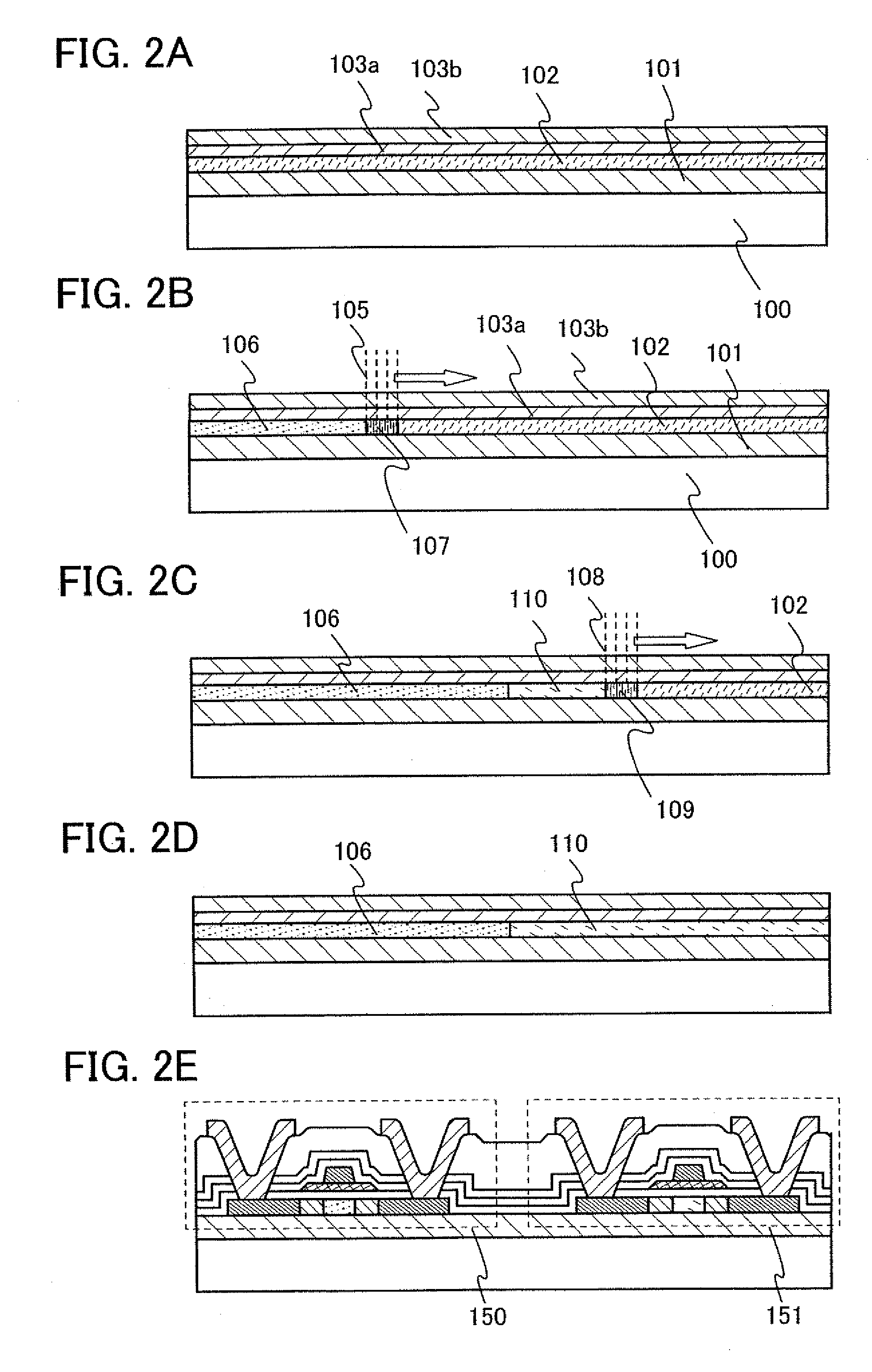

Manufacturing method of semiconductor device

InactiveUS20080213984A1Increase melt viscositySuppress turbulenceSolid-state devicesSemiconductor/solid-state device manufacturingCrystal planeP channel

A cap film is formed over semiconductor films formed over an insulating substrate; the semiconductor films are irradiated with a laser beam which is capable of completely melting the semiconductor film in a film-thickness direction to completely melt the semiconductor film. By controlling the laser beam, a crystalline semiconductor films are formed over the substrate, in each of which orientations of crystal planes are controlled. In addition, an n-channel thin film transistor is formed using a crystalline region in which crystal planes are oriented along {001} and a p-channel thin film transistor is formed using a crystalline region in which crystal planes are oriented along {211} or {101}.

Owner:SEMICON ENERGY LAB CO LTD

Mobile radio terminal and communication processing method

InactiveUS20100151863A1Control is possibleAssess restrictionRadio transmissionMobile radioMobile communication network

A mobile radio terminal stores transfer information indicating whether a base station to which the mobile radio terminal is connected is changed from a base station belonging to a second mobile communication network to a base station belonging to a first mobile communication network; and control the second communicating unit so as to search for a base station belonging to the second mobile communication network, when it is determined using the stored transfer information that the mobile radio terminal is on standby in a base station belonging to the first mobile communication network after the base station to which the mobile radio terminal is connected is changed from a base station belonging to the second mobile communication network to the base station belonging to the first mobile communication network.

Owner:FUJITSU TOSHIBA MOBILE COMM LTD

Needleless syringe comprising an injector with nested elements

InactiveUS6981961B1Easy to shapeEasy to produceJet injection syringesIntravenous devicesNeedle Free InjectionInjector

The invention concerns the field of needleless syringes for injecting an active principle for therapeutic purposes. More particularly, it concerns a needleless syringe for injecting an active principle (7) initially set between an injector (1, 10) comprising at least an injection nozzle, said injector being contacted with the skin, and a wall (8) mobile under the effect of a propelling system (9) pressurizing and expelling the active principle through the injector located at the syringe downstream end (2). In order to produce nozzles in a considerable injector thickness and to control the jet coherence distance, said injector (1, 10) comprises at least two elements (3, 4) whereof the contact surfaces (30, 40, 40′) are oriented towards the skin, at least a groove (31, 41, 41′) forming an injection nozzle in the assembly of said elements.

Owner:CROSSJECT

Dynamic Impedance Matching Network and Method for Matching an Impedance Between a Source and a Load

InactiveUS20110163935A1Control is possibleMultiple-port networksAntennas earthing switches associationDynamic impedanceImpedance matching

An impedance matching network includes an impedance matching circuit for dynamically matching an impedance between a source and a load. Matching is done by varying the real part and the imaginary part of the impedance of the impedance matching circuit independently.

Owner:QUALCOMM TECHNOLOGIES INC

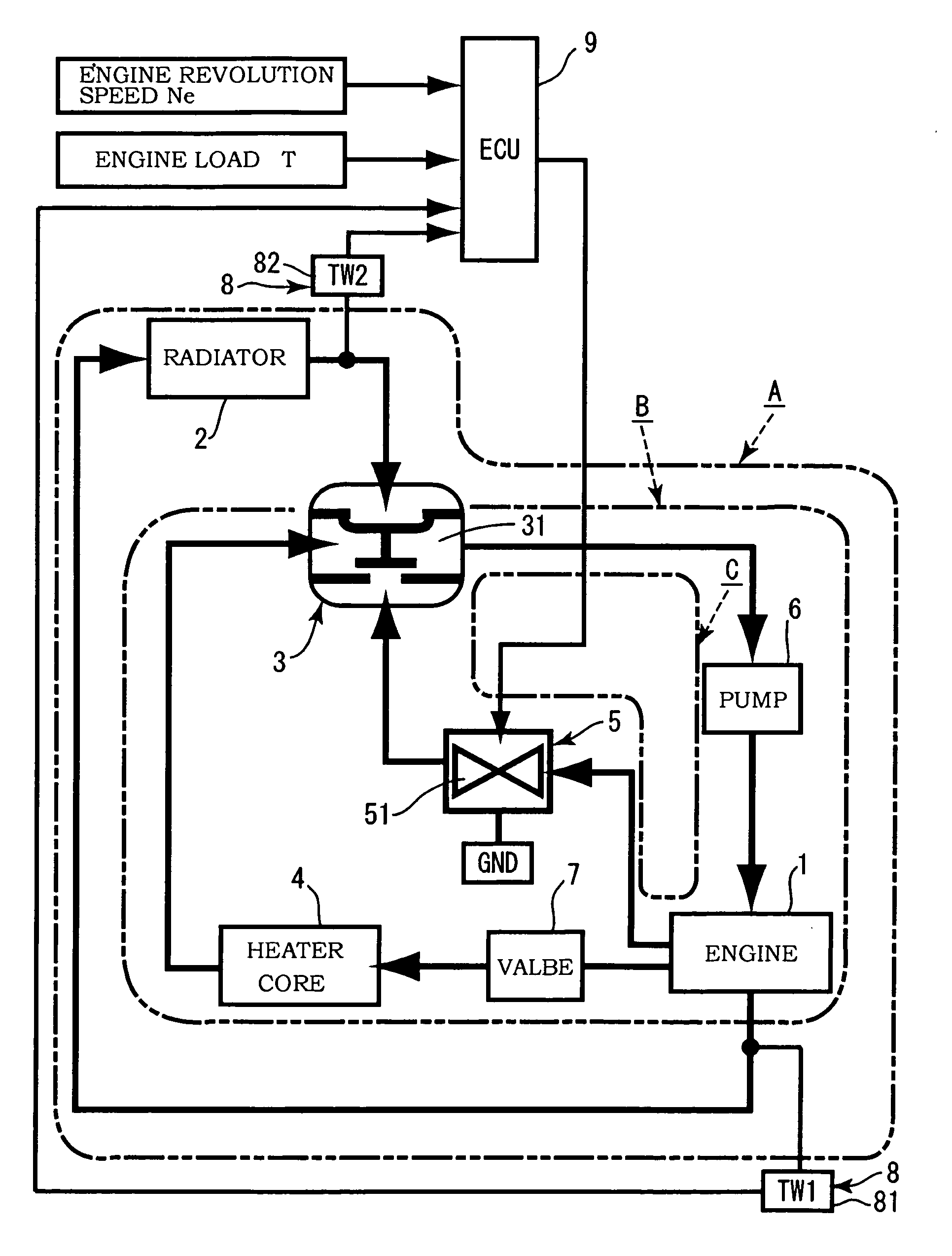

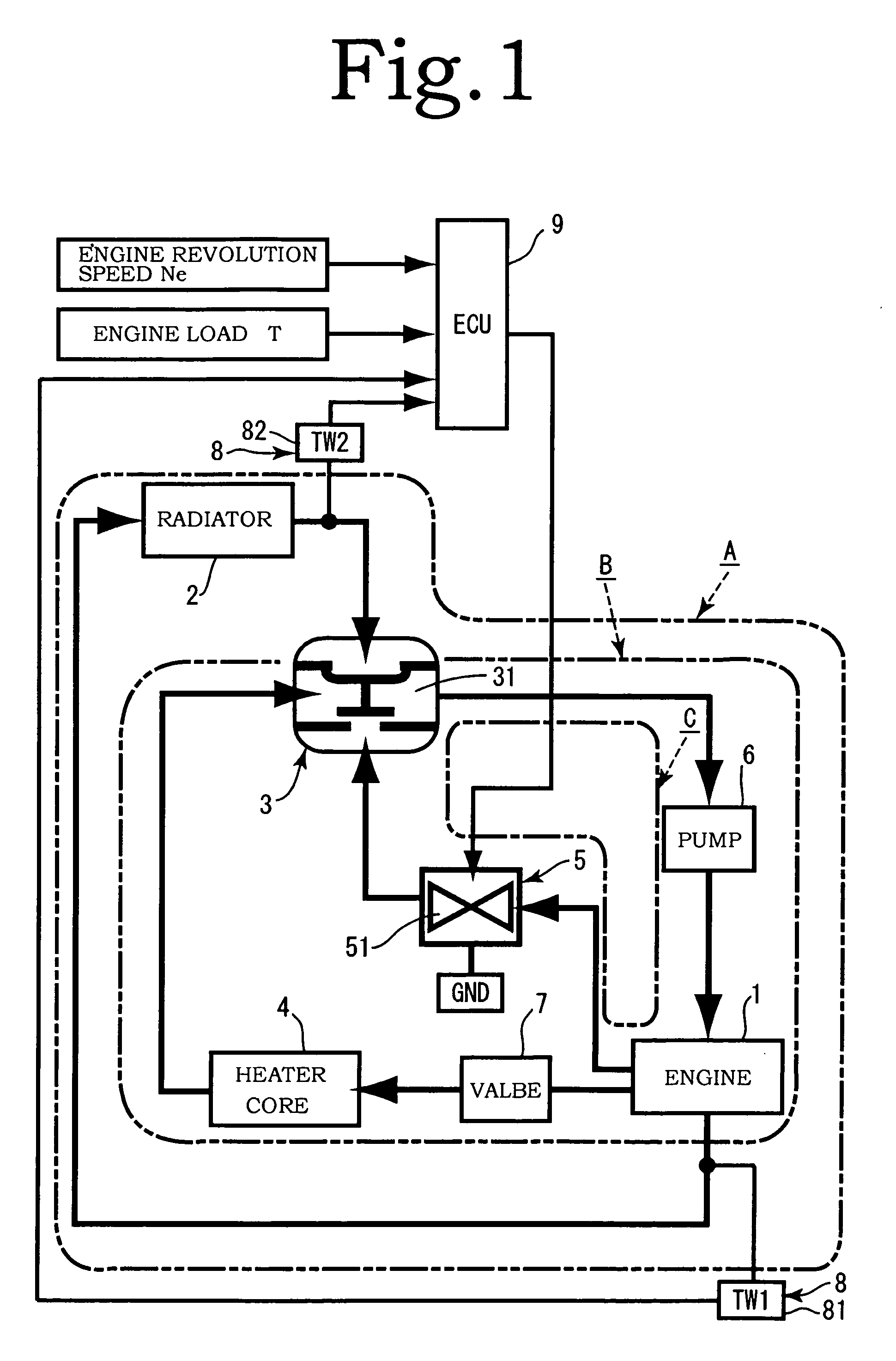

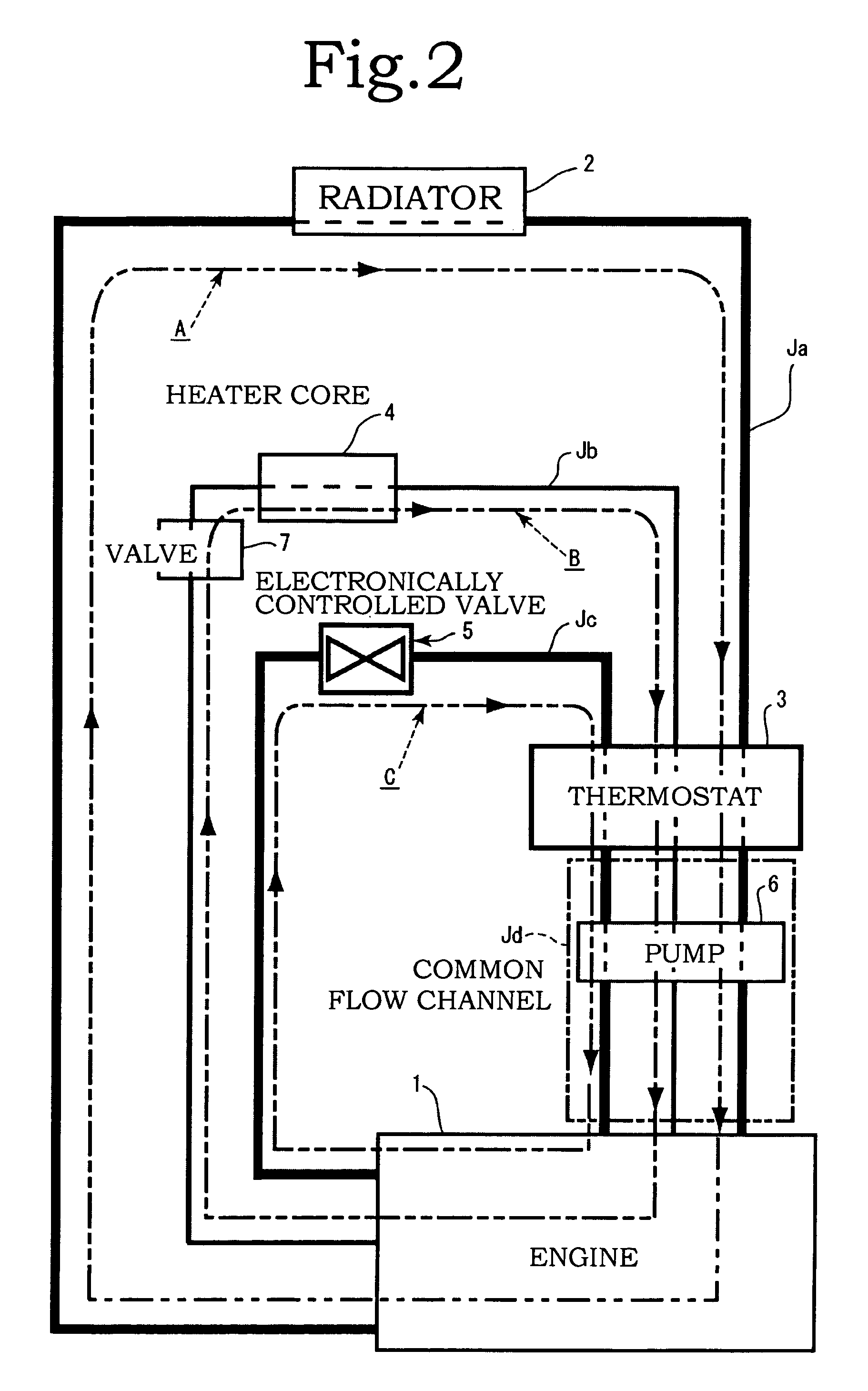

Cooling device for engine

InactiveUS20090255488A1Rapid temperature riseExtend service lifeCoolant flow controlCylinder headsWater circulationCooling water temperature

A cooling device for an engine that can raise the temperature of cooling water within a short period of time during the warm-up operation and allows a simple structure. The cooling device has a radiator circulation flow channel for circulation via an engine, a radiator, and a thermostat; a heater circulation flow channel for circulation via the engine, a heater core, and the thermostat; a bypass circulation flow channel for circulation via the engine and the thermostat; an electronically controlled valve; and a pump. The radiator circulation flow channel, heater circulation flow channel, and bypass circulation flow channel merge in the thermostat and form a common flow channel between the thermostat and the engine. The pump is provided in the common flow channel. At the start of the warm-up period and during the warm-up operation, the circulation in the radiator circulation flow channel is substantially stopped by the thermostat, cooling water circulation is actuated in the bypass circulation flow channel, and an opening degree of the electronically controlled valve is gradually increased from a minimum as the cooling water temperature rises. At the end of the warm-up period, circulation is actuated in the radiator circulation flow channel and substantially stopped in the bypass circulation flow channel.

Owner:YAMADA SEISAKUSHO KK

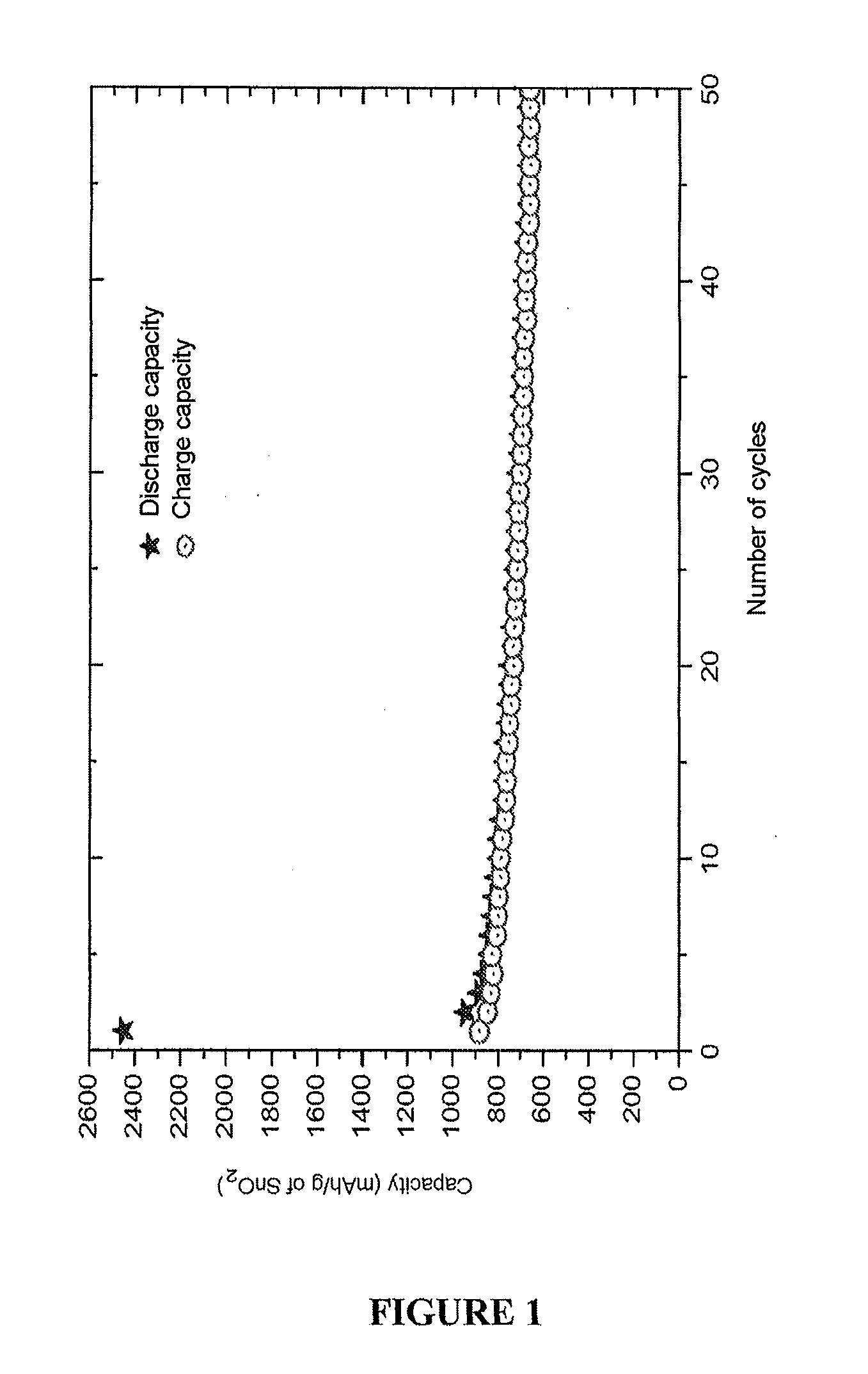

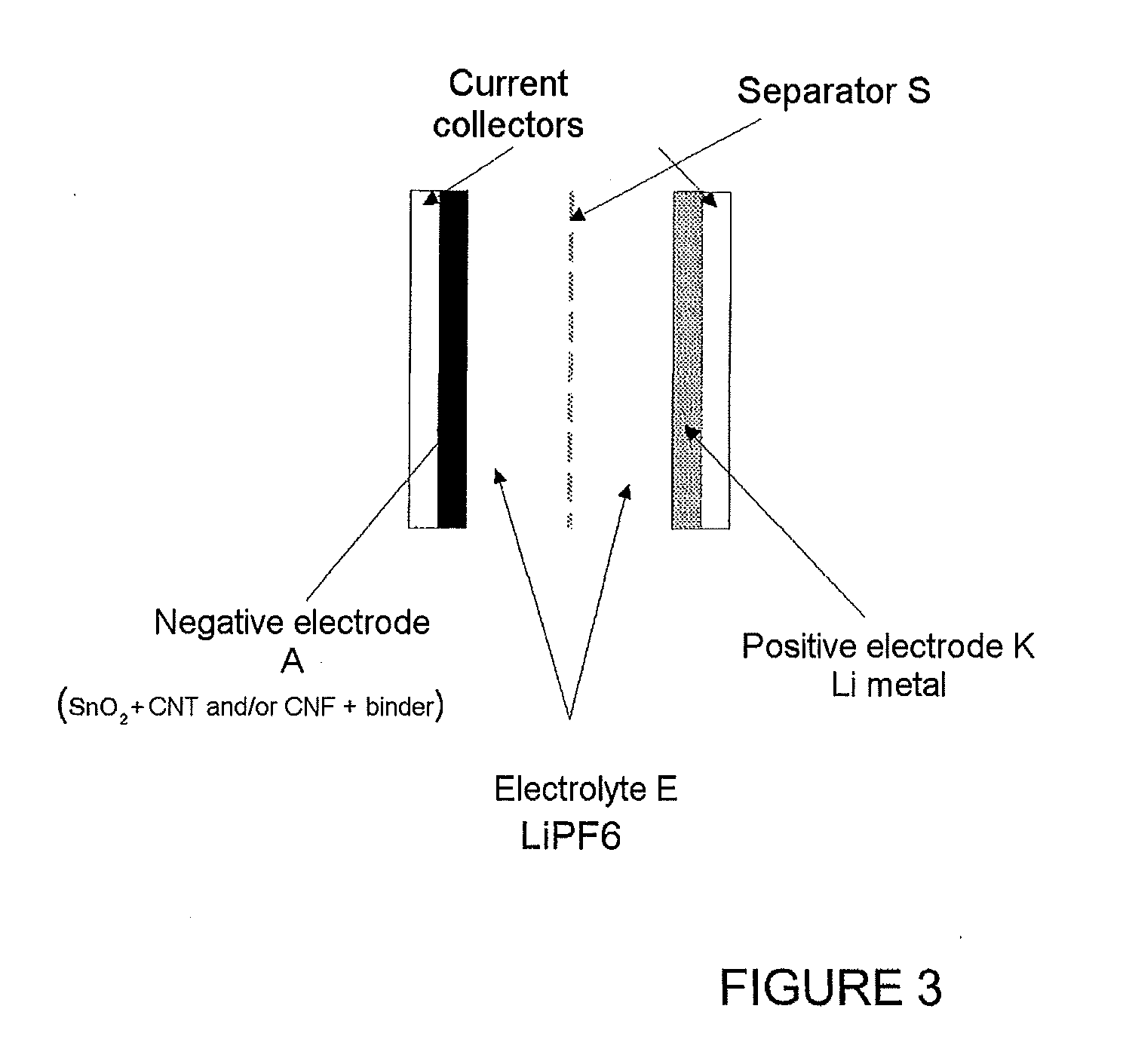

METHOD FOR MANUFACTURING A COMPOSITE MATERIAL OF SnO2 AND CARBON NANOTUBES AND/OR CARBON NANOFIBERS, MATERIAL OBTAINED BY THE METHOD, AND LITHIUM BATTERY ELECTRODE COMPRISING SAID MATERIAL

InactiveUS20110297889A1Improve electronic conductivityModerate expansionNon-metal conductorsMaterial nanotechnologyFiberAlcohol

A method for manufacturing a composite material including tin oxide particles and a fibrillar carbon material, including synthesising tin hydroxide particles obtained from a tin salt by precipitation / nucleation in a water-alcohol medium, in the presence of the fibrillar carbon material and an acid, the fibrillar carbon material being nanotubes, carbon nanofibres, or a mixture of the two. The method can be used for the production of negative electrodes for lithium-ion batteries.

Owner:ARKEMA FRANCE SA +1

Follow running control system

InactiveUS20050187697A1Stable controlControl is possibleVehicle fittingsDigital data processing detailsControl systemEngineering

A follow running control system includes a running control section for performing running control of the present vehicle based on data of the preceding vehicle and a signal from a device for detecting a driving operation performed by a driver of the present vehicle. If a driving operation by the driver for requesting starting of the present vehicle is detected while the present vehicle is stopped in a stop control state, the running control section changes a control state of the present vehicle, with respect to a follow running control device for controlling follow running of the present vehicle based on a target speed of the vehicle, from the stop control state to a follow control state for following the preceding vehicle, regardless of starting of preceding vehicle.

Owner:HONDA MOTOR CO LTD

Braking system with two pressure sources, and method for operating a braking system with two pressure sources

PendingUS20210053540A1Control is possibleShort maintenance periodBraking action transmissionVehicle sub-unit featuresInlet valveControl theory

A braking system including four hydraulically actuatable wheel brakes. A normally closed outlet valve is assigned to each wheel brake and a normally open inlet valve is assigned to each wheel brake. Two pressure supply devices are provided for active pressure build-up in the wheel brakes. A first and a second brake circuit are hydraulically configured with two wheel brakes respectively, wherein in each brake circuit a respective pressure supply device is hydraulically connected to two wheel brakes. A first and a second control and regulating unit are provided, wherein the first control and regulating unit electrically controls the pressure supply device of the first brake circuit, and wherein the second control and regulating unit hydraulically controls the pressure supply device of the second brake circuit, and the two control and regulating units are connected together via a data interface.

Owner:CONTINENTAL TEVES AG & CO OHG

Substrate holder

InactiveUS20100014208A1Easily contaminatedEasy to controlVacuum evaporation coatingSputtering coatingGas supplyElectrical and Electronics engineering

A substrate holder which has an electrostatic chuck on a substrate holding side of a holder main body and electrostatically adsorbs a substrate includes: a heating unit which is built in the electrostatic chuck and heats the substrate; a circulation medium distribution path which is formed inside the holder main body and connected to a circulation medium supplying unit which circulates and supplies a circulation medium; a heat transference varying unit which is formed by sealing a heat transfer gas in a gap between the holder main body and the electrostatic chuck and connected to a heat transfer gas supply system which can control a sealing pressure; and a gas sealing unit which is formed by sealing a heat transfer gas in a gap between the electrostatic chuck and the substrate and connected to the heating transfer gas supply system.

Owner:CANON ANELVA CORP

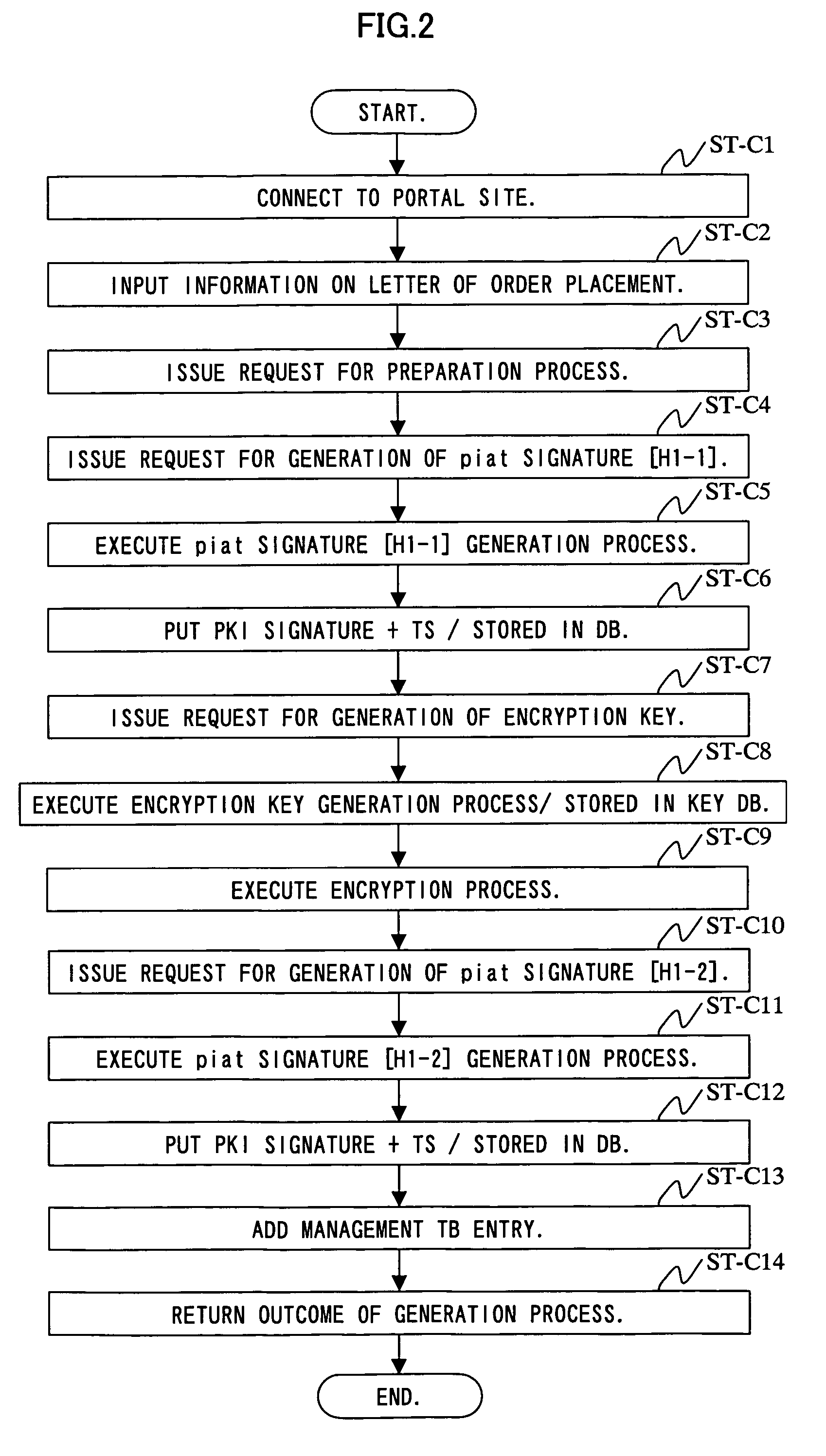

Electronic document management program, electronic document management system and electronic document management method

InactiveUS20070130627A1Originality is assuredControl is possibleKey distribution for secure communicationData processing applicationsThird partyElectronic document

It is possible to control electronic documents for partial disclosures and non-disclosures and prove to the third party that information other than non-disclosure part thereof has not been altered and the originality of decrypted information is assured. There is provided a section that controls electronic information for partial disclosures and non-disclosures according to conditions and situations such as viewers, systems and time and also a technological concept for proving to the third party that information other than non-disclosure part thereof has not been altered and the originality of decrypted information is assured, while controlling electronic information for partial disclosures and non-disclosures, by generating partial signature information (to be referred to as piat signature information in the embodiment of this invention which is described hereinafter) apart from the text of electronic information, dividing it for holding and separating the function and the role of electronic information and those of partial signature information (verifying information).

Owner:FUJITSU LTD

Automatic speed reducing ratio-switching apparatus

ActiveUS20050272548A1Control is possibleReduce in quantityToothed gearingsGearing controlEngineeringPlanet

Helical gears are used for a sun gear, planet gears, and an internal gear. Accordingly, when a load, which exceeds a preset torque, is applied to the internal gear, the internal gear is moved in a direction toward an input shaft or a direction toward an output shaft while making rotation in a direction different from that of the sun gear to automatically switch the speed reducing ratio.

Owner:SMC CORP

Automatic speed reducing ratio-switching apparatus

ActiveUS7220205B2Control is possibleReduce in quantityToothed gearingsGearing controlGear wheelEpicyclic gearing

Helical gears are used for a sun gear, planet gears, and an internal gear. Accordingly, when a load, which exceeds a preset torque, is applied to the internal gear, the internal gear is moved in a direction toward an input shaft or a direction toward an output shaft while making rotation in a direction different from that of the sun gear to automatically switch the speed reducing ratio.

Owner:SMC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com