Method for preparing layered lithium, nickel, cobalt and manganese oxide anode material for lithium ion battery

A lithium-ion battery, lithium-nickel-cobalt-manganese technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of uneven mixing of various raw materials, low tap density of products, etc., and achieve easy large-scale industrial production and low cost. , to avoid the effect of complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

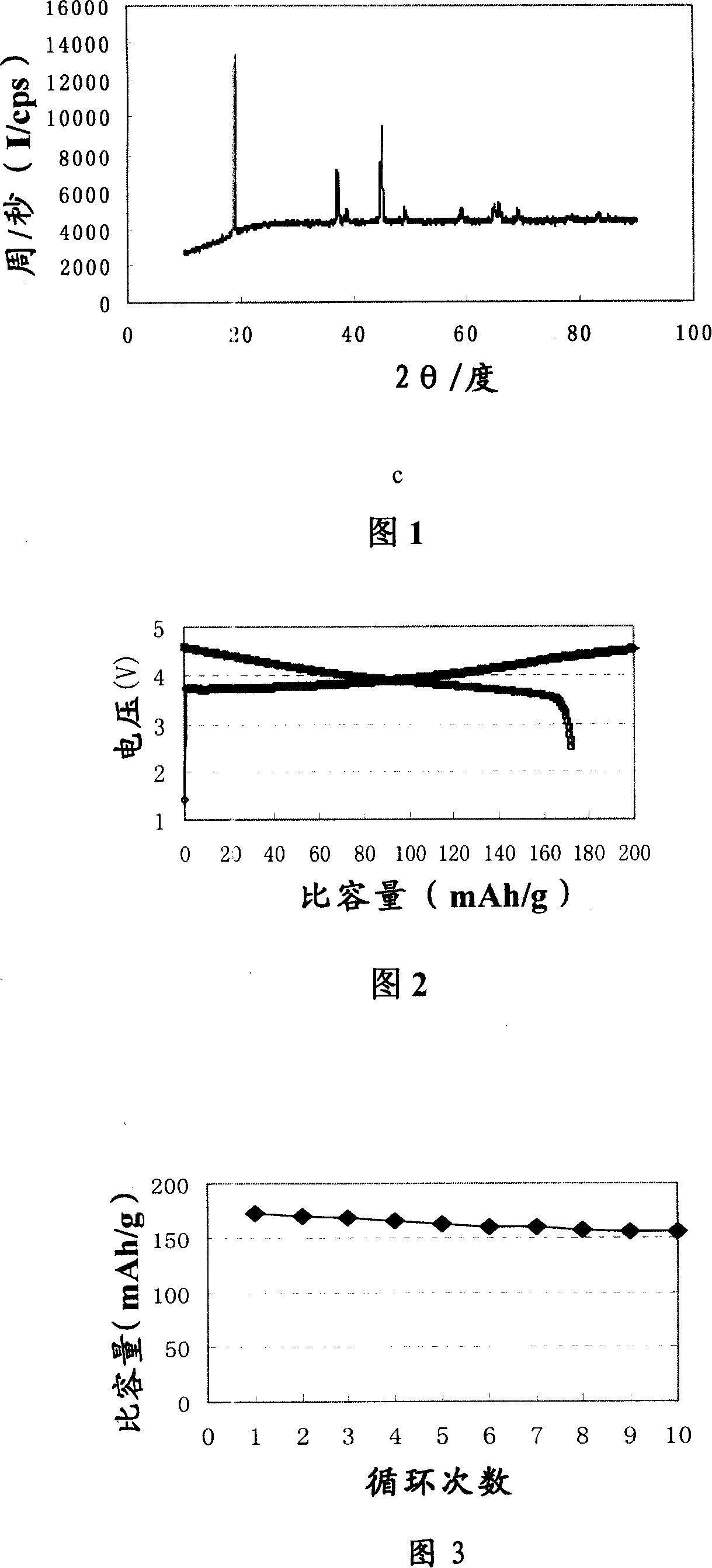

[0022] Weigh LiOH.H 2 O2 2.53 g, Co 3 o 4 Put 20.07 grams, 9.43 grams of NiO and 6.94 grams of metal manganese powder into a ball mill, add 100 ml of absolute ethanol to soak, add 50 grams of agate balls, wet grind for 2 hours, take it out, filter, dry and put it into a corundum crucible , put it into a high-temperature furnace for sintering, raise the temperature to 1000°C at a heating rate of 3°C / min, keep it warm for 15 hours, cool down at a rate of 0.6°C / min, take it out, grind it, and pass through a 300-mesh sieve to obtain the final product. The XRD pattern of lithium nickel cobalt manganese oxide prepared by the method of Example 1 is shown in Figure 1a. The first charge and discharge curve of the lithium nickel cobalt manganese oxide synthesized by the method of Example 1 is shown in Fig. 2. In the charge and discharge curve in Fig. 2, the abscissa is the specific capacity, and the ordinate is the voltage. The charge and discharge voltage range of lithium nickel cob...

Embodiment 2

[0024] Weigh LiOH.H 2 O2 2.53 grams, metal Co powder 14.8 grams, Ni 2 o 3 10.19 grams and 6.94 grams of metal manganese powder, put them into a ball mill, add 100 ml of absolute ethanol to soak, add 60 grams of agate balls, wet mill for 3 hours, take them out, filter, dry them, put them into a corundum crucible, and put them into a high-temperature furnace Carry out sintering in the medium, heat up to 1150°C at a heating rate of 10°C / min, keep it warm for 20 hours, cool down at a rate of 2°C / min, take it out, grind it, and pass through a 300-mesh sieve to obtain the final product. The XRD pattern of the lithium nickel cobalt manganese oxide prepared in Example 2 is shown in Figure 1b.

Embodiment 3

[0026] Weigh LiOH.H 2 O2 2.53 g, Co 3 o 4 20.07 g, Ni 2 o 3 10.19 grams and 6.94 grams of metal manganese powder, put them into a ball mill, add 100 milliliters of absolute ethanol and water mixture to soak, add 40 grams of agate balls, wet mill for 5 hours, take them out, filter, dry and put them in a corundum crucible. Put it into a sintering furnace, heat up to 950°C at a heating rate of 4°C / min, keep it warm for 25 hours, cool down at a rate of 0.6°C / min, take it out, grind it, and pass through a 300-mesh sieve to obtain the final product. The XRD pattern of the lithium nickel cobalt manganese oxide prepared in Example 3 is shown in Figure 1c. The cycle curve of the lithium nickel cobalt manganese oxide synthesized by embodiment 3 is shown in Fig. 3, and in the cycle curve of the lithium nickel cobalt manganese oxide of Fig. 3, the abscissa is the number of cycles, and the ordinate is the specific capacity (mAh / g) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com